Seagahan WTW (2025)

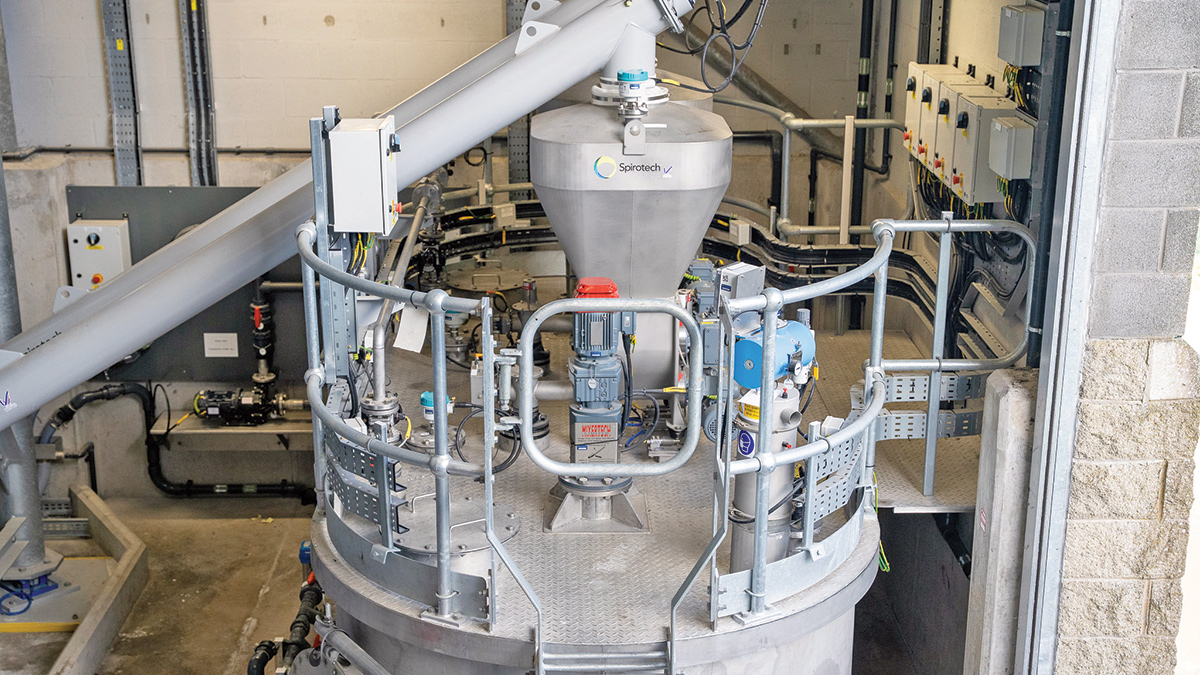

Mix tank B mixer & hopper feeder - Courtesy of NI Water

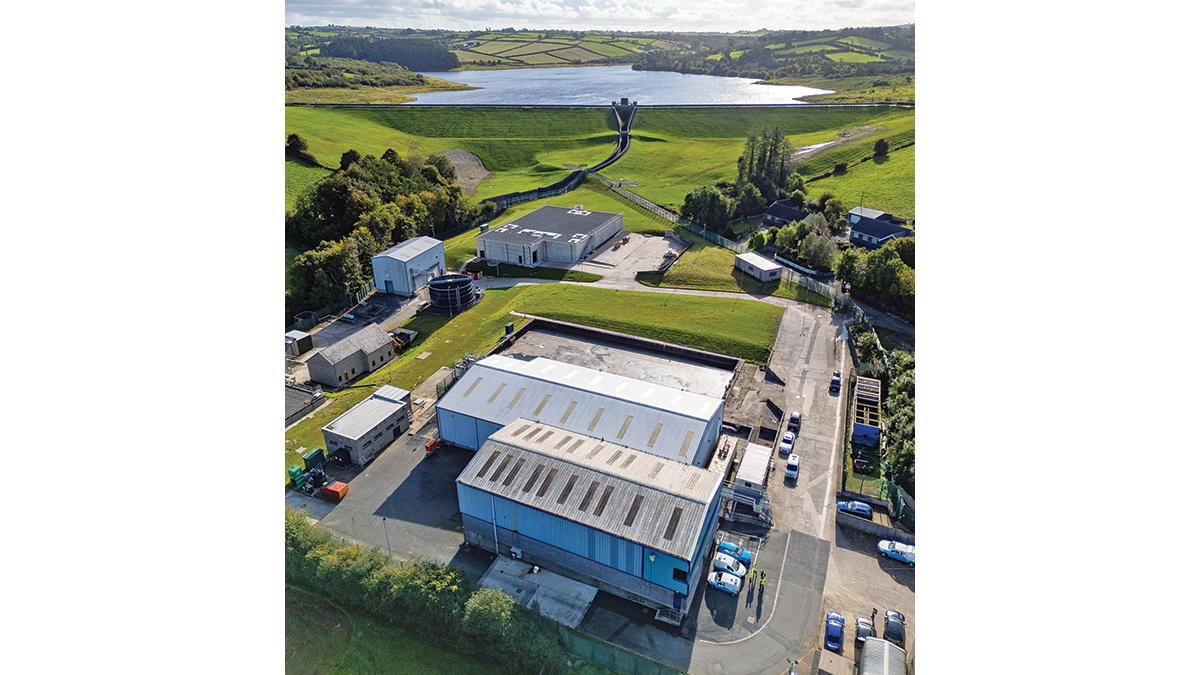

The Seagahan Water Treatment Works (WTW) is located approximately six miles south of Armagh in Northern Ireland and serves communities in Edanveys, Corran, and Roughfort via a single gravity-fed main from the Seagahan impounding reservoir. The Seagahan Treatability Improvements Project is a strategic initiative within the Water Non-Infrastructure work stream, designed to address persistent operational and compliance challenges at NI Water’s 23 water treatment works. Seagahan WTW currently treats an average of 10 million litres per day (MLD), with a design capacity of 16.3 MLD and plays a critical role in regional water supply.

Project need

In recent times Seagahan WTW has faced ongoing issues including:

- Elevated trihalomethanes (THMs) and turbidity in final water.

- Inadequate contact time for disinfection.

- A failing soda ash system.

- Chlorinated backwash water and backwash capacity issues.

Unaddressed, these deficiencies could pose risks to regulatory compliance, limit future growth capacity, and increase the potential for Cryptosporidium contamination.

Seagahan WTW & Seagahan Reservoir – Courtesy of NI Water

Project scope

The Seagahan WTW Treatability Improvements Project has implemented a series of targeted upgrades to enhance water quality, improve operational resilience and maintain compliance. Key interventions included:

- Replacement of the soda ash plant.

- Installation of automatic coagulation dosing system to analyse trends.

- New orthophosphoric dosing system.

- Replacement of valves and actuators.

- Upgrade of one rapid gravity filter with glass media.

These upgrades are informed by a treatability appraisal conducted by Arup, which identified critical shortfalls and recommended improvements to ensure the facility could meet current and future regulatory standards.

Project team

NI Water engaged Arup and Murphy DAWSON-WAM (MDWAM) early in the project through an Early Contractor Involvement (ECI) approach, fostering a collaborative environment that allowed the project to evolve efficiently. As Principal Contractor, Murphy DAWSON-WAM, supported by strong coordination across all parties, successfully delivered the project on time and within budget. Arup played a dual role, providing NEC Project Management and Supervision throughout the construction phase, while also leading design reviews and approvals. Their involvement extended to managing stakeholder engagement within NI Water and liaising with external bodies such as the Department for Infrastructure.

A key success factor was the strong working relationship developed with NI Water’s Operations, which enabled a clear understanding of practical operability challenges. This collaborative approach informed strategic decisions around infrastructure layout, including pump and panel positioning, freeing up space for storage and maximising the use of existing buildings. These efforts not only streamlined project delivery but also ensured the long-term resilience of water treatment at Seagahan WTW.

BIM model of existing GAC building – Courtesy of Murphy DAWSON-WAM

Seagahan WTW: Supply chain – key participants

- Client: NI Water

- Project manager: Arup

- Main contractor: Murphy DAWSON-WAM (MDWAM)

- Process & MEICA designer & contractor: Murphy Process Engineering

- Civils designer & contractor: DAWSON-WAM Ltd

- Civils design: RPS

- Formwork: Raptic Ltd

- Chemical storage & batch tanks: Spirotech

- Chemical dosing pumps: ProMinent Fluid Controls (UK)

- MCC works: Pronto Automation Systems Ltd

- Static mixer: TPS Filtration

- Chemical storage tank: Forbes Technologies Limited

- Air scour blower: AERZEN Machines

Design & planning

ECI with MDWAM and Arup enabled a collaborative and informed approach from the outset of the project. Arup provided up-front technical input through treatability studies, which were instrumental in shaping Business Case submissions and developing focused Basis of Design reports. This proactive engagement supported scope progression and ensured a robust design strategy. Throughout the process, NI Water stakeholders were actively involved in decision-making, fostering transparency and alignment across all phases of delivery.

As designs evolved, a number of design review workshops were held which involved the use of walkthrough models to highlight pinch points and process walk-throughs.

Preference was for the new soda ash storage silo to be located indoors, restricted space for which was determined in the existing GAC building. MDWAM introduced innovative methods, including a 3D scan of the existing GAC building, to validate the feasibility of initial design proposals and facilitate the reuse of existing storage space. The volume and design of the storage silo were influenced by these constraints. The 3D scanning of the existing GAC building was instigated in the absence of record drawings, with new equipment designed to fit head height constraints and roller door access for installation.

A key design decision identified during a design review meeting was the introduction of a structural steel mezzanine platform level to locate the new MCC as floor space was limited.

During the initial investigations, the team identified gaps in the existing information relating to original structures, highlighting the need for further exploration. In several instances, monitoring data was unavailable, so dosing pump and process design had to be guided by SCADA trend analysis where possible. Temporary instruments were also set up during ECI to capture critical analytical data that was otherwise missing. These proactive measures ensured that design decisions were grounded in accurate, site-specific information, ultimately enhancing the reliability and efficiency of the final solution.

(left) Mezzanine platform: MCC & holding tank and (right) soda ash bulk storage silo – Courtesy of NI Water

Construction & implementation

The project was delivered within a live operational environment, requiring meticulous planning and coordination to ensure continuity of service and safety. Construction on site began in December 2023 and completion was at the beginning of July 2025. The works were sequenced to minimise disruption to ongoing treatment operations, with close collaboration between the design, construction, and operations teams throughout. A key inherent risk exists when interfacing with existing operational works, live instruments and electrical assets, and this collaboration and careful planning helped to ensure no negative effect on network assets or output during the upgrade.

Early challenges included the failure of legacy equipment originally earmarked for reuse, such as manganese blowers and seized valving arrangements. These issues were addressed through rapid redesign and procurement, ensuring the programme remained on track. Spatial constraints within the site presented further complexity, particularly during the construction of the new dosing chamber and associated pipework diversions. Temporary works and phased excavation strategies were implemented to maintain access and operational integrity.

Modifications to the clean water tanks (CWT1 and CWT2) were carried out under confined space protocols. The installation of actuated valves and bell mouth fittings required innovative approaches due to restricted access openings. Sequencing was critical, with CWT2 brought back into service prior to converting CWT1 into a dedicated un-chlorinated backwash tank.

Static mixer chamber roof & CWT1 inlet pipe – Courtesy of NI Water

All works were delivered on a live site, with embargo periods and planned maintenance activities carefully managed. Temporary dosing systems were installed to facilitate safe changeovers, and effective stakeholder engagement with NI Water operations teams ensured that risks were mitigated and service continuity maintained. The new soda ash plant was commissioned in April 2025 and has since been used as the pH controlling process, taking over from the old system.

The project also included the installation of a new potable water supply to the site, with future-proofing measures incorporated to support additional connections. Engagement with DfI Roads and NI Water Distribution Teams ensured compliance and coordination with wider infrastructure planning.

Process enhancements

As part of the project, several process-driven improvements were implemented to enhance operational reliability, chemical dosing accuracy, and overall treatment efficiency.

Soda ash system upgrade: The existing soda ash silo was experiencing structural issues and material bridging, leading to inconsistent dosing. A new soda ash system was installed, comprising a silo with integrated shakers, blowers, and a batch tank. A third mixing/maturation tank was introduced to stabilise pH levels and eliminate dosing spikes. Strategically positioned at the opposite end of the building, it also shortens suction lines and improves soda ash solubility. This upgrade ensures consistent material flow and improved pH control, particularly important given the variable pH levels observed due to temperature fluctuations in Seagahan Reservoir.

Soda ash mix tank A & B – Courtesy of NI Water

Potable water protection measures: To prevent back siphonage and protect potable water quality, the supply to the backwash tank was removed following its conversion to an un-chlorinated backwash tank. A new supply line was established from the main distribution network, ensuring compliance with water safety standards.

Centralised control via MCC panels: Motor Control Centre (MCC) panels were installed to provide centralised control of all newly commissioned equipment. This integration enhances operational oversight and simplifies maintenance procedures.

Efficiency gains in backwashing: The transition to unchlorinated water for backwashing has led to reduced chemical wastage and improved backwash efficiency, especially during periods of poor water quality. This required careful reconfiguration of valving arrangements and blanking off interconnections between tanks to prevent contamination of clean water leaving the site.

Flow monitoring & chemical dosing control: A dedicated flow meter chamber was constructed to monitor flow rates of orthophosphate and chlorine dosing. The flowmeter also interfaces with an actuated valve to regulate the filling of CWT1, now designated as the backwash tank. This setup allows for precise control of chemical dosing and tank filling operations.

To protect operatives, the chlorine and orthophosphate are installed in separate chambers to reduce the risk during leaks. This item was identified during a hazard identification meeting.

Orthophosphoric dosing plant – Courtesy of NI Water

Hydraulic improvements: The upstand level of CWT2 was increased to enhance hydraulic head, supporting improved flow dynamics across the system. An actuated valve was installed to prioritise flow between the backwash line and CWT2, ensuring that neither system is starved during simultaneous operations.

Water recovery gains: The backwash system was previously a bottleneck to reliable output, following review a hydraulic restriction in the lamellas was identified and addressed which allowed a greater flow to pass through them to reach their design capacity. This improved the overall efficiency and removed the bottleneck, providing headroom in the dirty wash water system and ultimately providing the works with more frequent backwashing facilities.

Innovations, cost savings & carbon reduction

The Seagahan WTW Treatability Improvements Project incorporated a range of innovative and sustainable measures that enhanced delivery and long-term operational performance. By maximising existing assets and deploying efficient technologies, substantial carbon and financial savings were achieved, both in construction and ongoing operation.

A 3D scan of the GAC building was undertaken to address the absence of reliable as-built records. This enabled accurate coordination with the BIM model and informed the design of new equipment, including a bespoke mezzanine platform for the MCC panels, optimising use of available space.

Sustainability was embedded throughout the project. Excavated material was reused on-site for landscaping and reprofiling, eliminating disposal costs and reducing carbon emissions. Modular blocks were re-purposed for use on other sites, supporting circular economy principles.

The introduction of a third process tank and the use of un-chlorinated water for backwashing improved chemical efficiency and reduced waste, particularly during periods of algal blooms. Additional measures included the installation of a spill tank with integrated safety features and the design of dosing skids with enhanced access and flushing capabilities.

These innovations supported efficient delivery, reduced environmental impact, and aligned with NI Water’s long-term sustainability goals.

Soda ash transfer pumps – Courtesy of NI Water

The project exemplifies sustainable infrastructure delivery, with substantial environmental and financial benefits realised through three key initiatives:

- Embodied carbon avoidance: By re-purposing existing infrastructure rather than constructing a new 100m2 facility, the project avoided significant carbon emissions and capital expenditure – This approach resulted in an estimated carbon saving of 60 to 90 tonnes of Co2e and a cost saving of £350,000 to £500,000.

- Energy-efficient equipment: The installation of high-efficiency motors helped reduce operational energy consumption – This measure contributes an annual carbon saving of 2 to 5 tonnes of Co2e and an annual cost saving of £216 to £432.

- Process optimisation: Enhancements in chemical dosing reduced both chemical usage and sludge production – These improvements yield an annual carbon saving of 2 to 10 tonnes of Co2e and a cost saving of £1,000 to £2,000.

Overall, the combined impact of these measures in the first year is estimated to deliver a total carbon saving of 64 to 105 tonnes of Co2e and a cost saving of between £351,216 to £502,432.

Project outcomes

The Seagahan WTW Treatability Improvements Project was successfully delivered on time and within budget driven by early contractor involvement, innovative design solutions, and a shared commitment to operational excellence and sustainability. With this project NI Water has been able to enhance operational efficiency, enable real-time monitoring via advanced SCADA telemetry, and has future-proofed the system for further instrumentation upgrades. Collaboration between the client, project manager, contractor and other key stakeholders was central to the execution of the project and its overall success.

Seagahan WTW project team - Courtesy of NI Water