Glasgow Resilience Programme (2025)

1500mm tunnel boring machine ‘Crookie Monster’ - Courtesy of CWA

The Ayrshire Resilience Scheme delivers a two-way connection between the drinking water networks in Greater Glasgow, Ayrshire and East Renfrewshire; significantly enhancing the security and resilience of the water supply. It is Scottish Water’s largest ever water infrastructure investment benefiting almost one million customers across the west of Scotland. The 12km Glasgow Resilience Programme (C1a) is the third phase of the Ayrshire Resilience Project, and involves the transfer of water from Milngavie WTW located north of Glasgow to the Ayrshire and East Renfrewshire regions to the south-west of the city. C1a is a duplication of the southern section of the existing C1 trunk main that currently runs through the centre of Glasgow, however, design optioneering identified routes to minimise impacts to the local community during the construction phase rather than following the existing C1 route.

Project background & scope

At the outset, the £95m Glasgow Resilience Programme was Scottish Water’s largest ongoing capital investment, which comprised the installation of 12km of ductile iron pipe through a predominantly urban environment with significant surface features impacting the route. The pipeline was installed through a mix of carriageway, public parks, urban and rural environments.

Pipe laying operations – Courtesy of CWA

They were four tunnelled crossings incorporating deep shafts and microtunnelling. These trenchless crossings included tunnelling below railways, motorways and watercourses.

To achieve the resilience driver for the project, a new 78 MLD pumping station with MCC was required, powered by two new HV transformers and solar PV panels.

Planning for the project started in 2016, with construction starting on site in May 2020 and completing in August 2025. It required highly complex interactions with the existing water network and multiple modes of control at the new pumping station.

Glasgow Resilience Programme: Supply chain – key participants

- Project delivery: Caledonia Water Alliance (CWA)

- AECOM

- M-Group Water

- Engineering support: DST SurvConsult Ltd

- Civils contractor: Cleantech Civils

- Civils contractor: Luddon Construction

- Excavations & earthworks: RJT Excavations

- Foundations: LB Civils Ltd

- Mechanical & electrical contractors: IDS

- Mechanical contractor: Dustacco Engineering Ltd

- Temporary works/shoring: Mabey Hire Ltd

- Tunnelling subcontractor: HB Tunnelling

TBM in place prior to tunnel excavation – Courtesy of CWA

- Pipe manufacturer: Saint Gobain PAM UK

- Surge vessels: Quantum Engineering Developments Ltd

- Valves: AVK UK Ltd

- Pumps: Celeros Flow Technology

- Steel pipework & fittings: Freeflow Pipesystems

- Systems & process software: Lintott Control Systems

- Temporary access solutions: TPA (Vp Group)

- Fencing & TrakMats: Safe Fence Ltd

- Solar PV system: RI Cruden

- Overhead cranes: Konecranes Demag

- Underpressure drilling: Swan Pipelines

- Steel fabricators: WM Services Scotland Ltd

- Steel fabricators: MacGregor Technical Services Ltd

- Plant hire:

- Gap Group

- Blackwood Plant

- Bedrock Plant

- Barrmill Plant

- Traffic management: Sunbelt Rentals

- Re-surfacing:

- Hamilton Tarmac

- DGM Surfacing Ltd

- Arbuckle Mclean

- Landscaping & Fencing: Alter Supplies & Contracting

- Vegetation management: Ayrshire Tree Surgeons

- Security: Proficient Security Ltd

Pipe laying operations – Courtesy of CWA

Excavations

Bedrock was encountered throughout the pipe laying route, predominately for the final 500mm before achieving formation level. Whilst this had an impact pipelaying productivity, the depth of the pipe installation did mean that the vast majority of existing utilities did not clash with the new pipeline and no diversions were required. However, due to the close proximity of residential properties, offices, shops, etc, precondition surveys were completed and vibration monitoring in-stalled to record and monitor any issues whilst the rock breaking was being completed.

The new pipeline route called for installation through several public spaces being Bellahouston Park, Lochar Park, Househill Park and Dams to Darnley Country Park. These parks have high amenity value whether it be major music events, local organisation events, sporting events or general walkers, dog walkers and runners.

Health & Safety was the primary concern through these areas and involved careful planning around upcoming events and robust security arrangements.

In addition, a number of the deep shafts were required for the trenchless works within these areas, again calling for alternative security arrangements which included semi-permanent security fencing to secure these works areas.

Tunnelling under the Levern Water – Courtesy of CWA

Pipe laying through urban environments

Approximately 60% of the pipeline was laid within public highways, through residential streets. The 900mm diameter ductile iron pipes were 7m in length and weighed approximately 2.4 tonnes. The project had to consider the most efficient and safest methodology of working in such areas and it became clear that this would involve significant road closures, traffic management and likely disruption through the centre of Glasgow.

A close relationship was developed with the local roads authorities with plans put in place to allow such major road closures. In conjunction with the project’s Customer Communications Team, information on the closures, diversions and timelines were issued to nearby residents whilst the wider public were informed through VMS and radio adverts. Post completion of the works, it was apparent that the road closures actually minimised disruption in comparison to traffic lights as motorists were likely to find alternative routes.

As expected in laying pipe through urban environments, the project encountered multiple utilities; both charted and uncharted. The pipeline design considered this aspect, with the crown level of the new pipe being such that it would be below the standard installation levels of other assets. This proved to be a success with no utility diversions needed, however, it did slow production as the teams had to carefully identify all utilities in the area and feed the new pipeline both between and under these exposed utilities.

The incredible utility avoidance record achieved throughout the course of the pipelaying activities should be highlighted; with 720 utilities encountered along the pipeline route, 33% of which were uncharted. All utilities were successfully located and crossed. This outstanding record of zero damage was achieved through industry leading utility location and safe excavation practices across the project.

In addition to the management of traffic movements, the project also had to consider the logistics of moving such large pipes and materials around the pipeline route. This involved the procurement of bespoke pipe cradles for transportation as well as procuring additional storage areas throughout the route.

Shaft construction for TBM tunnel excavation underneath a railway line and Water Cart Water – Courtesy of CWA

Trenchless construction

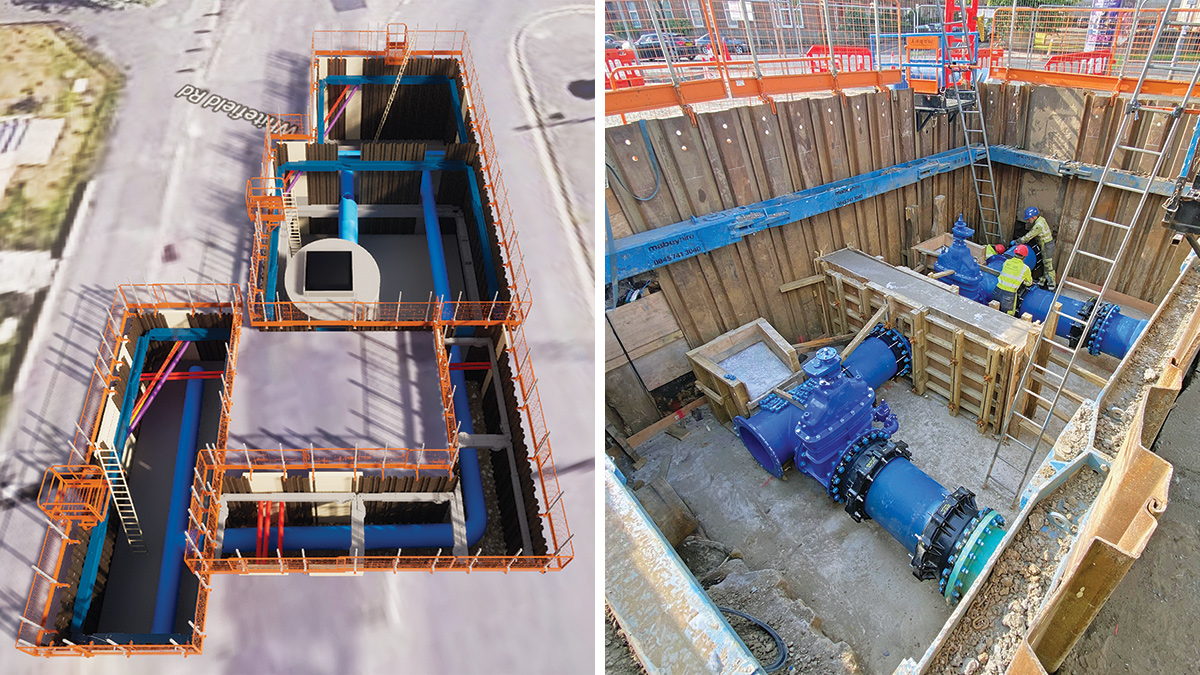

The pipe route included four sections where trenchless methods were required to install the pipe. The drive lengths ranged from 54m up to 264m. Shaft depths ranged from 9m to 24m incorporating shaft diameters of 6m and 8.2m to allow a 1500mm tunnel boring machine (TBM).

Within these drives, assets that were crossed included one of the busiest motorway sections in Scotland (M8 motorway) leading into Glasgow, three separate Network Rail under-track crossings (UTXs) and two watercourses. Engagement with the asset owners (Network Rail & Transport Scotland) were sought at an early stage to understand any constraints that there may be and continued, regular dialogue ensured that all relevant permissions were obtained in a timely manner.

On completion of the tunnels, the project team then had to install the permanent 900mm diameter DI pipe. This involved a complex operation by lowering the pipe into the shafts, connecting and winching the pipes through the concrete jacking pipe. Bespoke spiders were procured and installed ensuring a smooth transition where on completion, the pipe was pressure tested before subsequently being grouted into place.

Ibrox Pumping Station construction

Through the design process, it became apparent that the flows from Milngavie WTW to the next downstream pumping station could be managed hydraulically via gravity only. This is a route of approximately 30km. However, to achieve the resilience driver, it was identified that a new pumping station would be required.

Pumping station construction – Courtesy of CWA

The pumping station is required to manage 78 MLD which saw the design incorporate three 250kW pumps on a duty/duty/standby basis. To power these pumps, and again to support the resilience element, two independent HV power supplies were installed via two HV transformers which allows a backup supply should there be a power outage on the primary supply.

To support the power requirements of the pumping station, the footprint of the pumping station roof allowed the installation of 50kW SolarEdge solar PV system comprising of 135 Trina Vertex-S panels. In addition to the PV panels to helping work towards Scottish Water’s Net Zero targets, electrical vehicle charging points have been installed with the facility to upgrade to 75Kw chargers in the future.

The pumping station is linked to additional Scottish Water assets (including Thornliebank and Gorbals PS) via a SoGEA inter-site communications system. This allows the full network to be controlled remotely, ensuring a calm network response to any issue. The software enables monitoring of tank levels and control of the overall network, primarily fed back via a flow control valves, flow meters, needle valves and a comprehensive array of level sensor instrumentation. This allows the main to be predominantly controlled in gravity flow mode, reducing pump use, power usage and ultimately, lowering operating costs and CO2 emissions.

Inside the new pumping station – Courtesy of CWA

Connections to existing networks/commissioning

The new asset discharge into two existing distribution service reservoirs (DSR) within the Gorbals PS footprint. Both discharges required access to the reservoirs to complete civils elements of works which required close engagement with the Scottish Water CSD Team, Networks and Public Health.

One of the DSR’s was constructed relatively recently which allowed a clearer understanding of previous construction techniques so the project teams methodology to break into the tank was therefore well understood, however, the second DSR was constructed around 150 years ago. There was a degree of the unknown whilst breaking through into this tank, however, a careful and methodical approach was implemented to minimise risk to the structure.

The new pipeline was subjected to several pressure tests, to an average of 11 bar as well as completing a thorough cleaning and chlorination regime. This involved early dialogue with Scottish Water Networks as well as the reservoir engineers for the raw water reservoir where the flows would be discharged.

On completion of the chlorination activities and subsequent approval from Scottish Water Public Health, the water was able to be put into supply to allow the future commissioning activities to commence which required large volumes of water. This was an important project milestone.

(left) Render of temporary works installation by Mabey Hire on Edmiston and (right) east tie-in to existing main on Edmiston Drive – Courtesy of CWA

The project then had to perform various pump trials to support the resilience element of the project. Approximately 7.6 ML per trial had to be both received and discharged into the existing network which required detailed discussions and approvals with Scottish Water. Risk and constraints to the network had to be considered, however an open, honest and collaborative relationship between all parties allowed this highly complex operation to be completed successfully.

Carbon reduction techniques/sustainable approach

Wooden bog mats in conjunction with reusable plastic track mats have been used extensively instead of the traditional temporary stone access roads throughout the parks. This has saved the requirement of 12,000 tonnes of stone being brought in and out and saved approximately 1,200 HGV movements in the local community. This has proved an exceptional sustainable approach as the wooden bog mats and reusable plastic track mats can be reused and helps reduce the carbon impact in many ways while making the community streets greener and safer.

Restrained joints have been used on the project pipeline to allow CWA and Scottish Water to remove concrete thrust blocks, therefore further reducing embodied carbon associated with the capital aspects of the project. This totals an estimated 5,500m3 of concrete which has reduced carbon by approximately 16,000 tonnes; 15,000 from concrete and 1000 from transporting the concrete.

Solar panels will also offset the power demands at the new pumping station, with the new trunk mains also utilising increased gravity capacity to further reduce operational power consumption by 60%. The project site welfare and accommodation also utilised solar power and hybrid options. They also have a number of energy saving features which improve U-values such as high levels of insulation and passive infrared sensors to operate LED lighting.

The team also hosted a virtual consultation platform to share project information with customers and stakeholders to avoid the need to travel to community events.

Engagement with stakeholders throughout planning & delivery

Scottish Water and Caledonia Water Alliance have supported impacted customers and communities. The project team recognised that working closely with local schools would be important. The team arranged to supply pupils with school branded high-vis vests to make sure they are safe when they leave the school for outdoor learning.

They also spent time facilitating talks to teach children how to stay safe around construction sites; pupils were able to visit the site to learn more about the project and took part in a site safety poster competition. The school’s Head Teacher said that there was no doubt that the team had put the needs of the school community at the heart of their work.

The extent of the pipe route gave the opportunity to engage with a number of local schools. For the tunnelling operations, CWA set up competitions to name the tunnel boring machine. Fantastic winning names were chosen and got the community talking about the project. One name was ‘Cruella di Drill’ and another winner was named by the local primary school Crookston Castle as the ‘Crookie Monster’.

Other activities which CWA undertook with stakeholders included:

- Planting over 9,000 daffodil bulbs along the pipe route at Mosspark Boulevard with the local primary school at the end of the project.

- Returning to schools after the project to attend their careers fairs to promote engineering and STEM subjects.

- Volunteering with local groups such as installing a new woodland park with the Dams to Darnley Group and planting trees with Friends of Bellahouston Park.

(left) Daffodil bulb planting and (right) TBM “Cruella di Drill” and name competition winner – Courtesy of CWA

Conclusion/summary

Linking supply systems ensured that the high quality drinking water continues to be supplied to current customers and for generations to come. The investment in new pipelines and associated infrastructure below ground will also support the continued development above ground in communities across these areas and will enable them to continue to grow and thrive. CWA tapped into the skills from their diverse, integrated team to ensure they delivered an innovative, sustainable and cost effective project whilst supporting a flourishing Scotland.

CWA employed self delivery teams locally, trained a number of apprentices, and engaged local suppliers throughout the project.