Cowleigh Distribution Service Reservoir & Lower Wyche Pipeline (2018)

Mott MacDonald Bentley - MMB

Cowleigh Distribution Service Reservoir (DSR) and Lower Wyche DSR are located to the north and south of Great Malvern, Worcestershire and are overlooked by the Malvern Hills. Cowleigh DSR receives water from Powick Pumping Station and the Southern Strategic Main, whilst Lower Wyche DSR receives water from Bromsberrow WTW which is borehole site. Severn Trent Water was given a Drinking Water Inspectorate (DWI) obligation to clean and inspect both reservoirs. Due to their single cell construction, neither reservoirs can be taken offline for cleaning and inspection without compromising supply to customers. Site constraints at Lower Wyche Reservoir mean that there is no room for additional construction works, so building additional capacity at each reservoir site to allow the existing reservoirs to be taken out of service were ruled out early on.

Solution

The solution is to build two new reservoir cells at the Cowleigh DSR site and provide a pumping station and pipeline to Lower Wyche to allow Cowleigh DSR to serve both its own gravity supply area, and to pump to the Lower Wyche DSR network. This new DSR capacity allows the existing Cowleigh DSR cell and Lower Wyche DSR to be taken out of service whilst the DWI obligation is met. It also accommodates a 10% growth in population expected over the next 20 years.

The solution gives Severn Trent Water the opportunity to maximise the amount of water taken from the Bromsberrow source, to comply with the abstraction licence. It also provides additional resilience to the network by providing greater storage and providing a backup supply should either source fail.

A new control system will act to mimic the pressures in the system observed when Lower Wyche DSR is in service, thus allowing the reservoir to be valved-out without change to the network. The Bromsberrow source will be fully utilised by pumping at the maximum allowable flow into the network.

View of existing Cowleigh DSR site with Malvern Hills behind – Courtesy of MMB

At periods of low flow, the Bromsberrow water will feed the low demand and any excess water will be received at Cowleigh DSR, allowing the reservoir to fill, typically overnight. As demand increases, Bromsberrow water will continue to supply demand.

Once demand exceeds the pumped flow from Bromsberrow, and pressure in the system starts to drop, the Cowleigh pumps will turn on and pump into the network, allowing the pressure set point to be maintained. If Bromsberrow fails for a significant amount of time, Cowleigh will meet demand by relying upon Powick to maintain levels at Cowleigh reservoir. The technical challenges were in feeding a pressurised system from the fixed speed pumps of Bromsberrow, whilst using Cowleigh pumps to manage high demands.

Innovation in design and construction

The Cowleigh and Lower Wyche DSR project embraced the use of innovative materials and services throughout. The use of precast concrete wall units to construct the reservoir challenged the traditional in situ concrete construction and was only the second of its kind within STW’s operating region.

The team drew on MMB’s significant experience building reservoirs of this type in other areas of the UK, to realise many benefits including; speed of construction, reduced exposure to working at heights, reduced steel fixing on site, better quality joints (factory formed), high quality finish, and reduced thermal stress which reduces the overall steel reinforcement requirements.

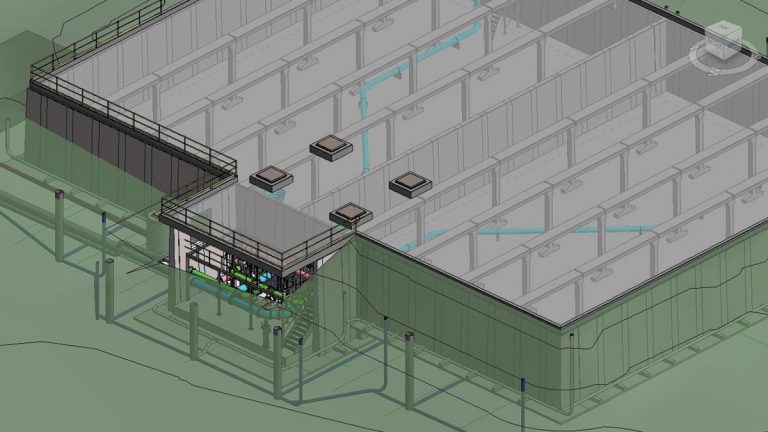

Building information modelling (BIM) was fundamental to the project and was used to drive a ‘right first time’ mentality within the team. In the design phase, the model was used to ensure design was coordinated and exported to create the structural finite element analysis model. A digital rehearsal was undertaken to plan the installation and challenge the proposed construction methodology. A construction sequence video was then generated to communicate with operatives and the wider team on site.

BIM model of the new Cowleigh DSR cells – Courtesy of MMB

During detailed design, Carlow Precast (now FLI Precast Solutions) and the MMB design team, worked collaboratively within the virtual environment to ensure the design of the precast units was fully integrated and compatible with all other elements. This highlighted several issues early on and allowed simple design changes to be made which reduced time on site, and reduced risks associated with installing the new pipework.

In an ongoing drive to improve health and safety during construction, the team creatively utilised drone footage of the reservoir site at frequent stages to review general health and safety and plan logistics. The bird’s-eye view brought a different perspective and allowed the team to identify issues potentially overlooked at ground level.

The Lower Wyche pipeline part of the project was the first within STW’s capital programme to use MoPVC pipework. The project team worked extensively with the chief engineer’s team to gain confidence in the product by investigating the body of evidence from elsewhere in Europe, and utilising recommendations from the STW front line repair team.

The MoPVC pipe is substantially lighter than traditional ductile iron or PE for the same pressure ratings, and that brings many benefits including; speed of installation, reduced manual handling risk, safer cutting and it can be transported and installed by smaller, less intrusive plant. The low elastic modulus of the material also reduced the size of the surge vessel required to control surge. The use of MoPVC saved cost, time and embodied carbon.

Cowleigh DSR and Lower Wyche Pipeline: Supply chain – key participants

- Principal designer & contractor: Mott MacDonald Bentley

- Precast reservoir designer: Carlow Precast (now FLI Precast Solutions)

- Molecor MoPVC pipes: R2M Limited

- Pumping station: Sultzer Pumps

- Surge vessel: Quantum Engineering Developments

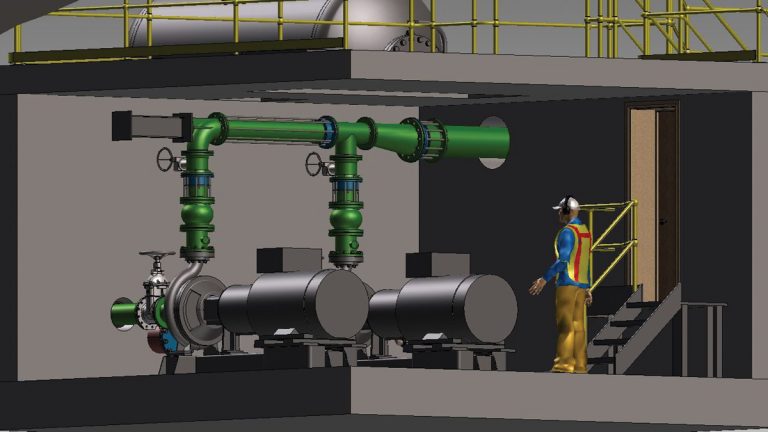

Surge vessel to protect against surge in the network – Courtesy of MMB

Challenges

Customer impact: One of the largest challenges of the project was determining the least disruptive and viable route for the pipeline. The route was constrained by the Malvern Hills to the west, which forced the pipeline through the centre of Malvern. Early optioneering steered the route through the least congested part of town, however, it was impossible to avoid the town centre entirely.

Through good design and the innovative reuse of the existing network, the team managed to reduce the overall length of the new pipeline by 1.2km and avoid construction through the ancient woodland. This reduced disruption to locals and saved approximately 230 tonnes of embodied CO2.

To ensure good communication, the team developed a customer and stakeholder engagement plan. As part of this, the team proactively sought buy-in from local stakeholders including the Malvern Conservators, Worcestershire Council, and Malvern College, who’s cricket pitch was part of the chosen route. Good planning and early consultation ensured the timing of the works fell within the school holidays to minimise disruption.

The team strived to engage residents to ensure that the benefits of the scheme were understood and appreciated. Announcements on local Radio and in newspapers were made and a public exhibition was held which aimed to both educate, inform and create open dialogue so that any concerns could be addressed.

BIM Model of inside the refurbished pumping station – Courtesy of MMB

Despite the potential impact to businesses and residents on the pipe route, the team received great feedback. This was largely due to the diligence and positive attitude of the gangs on site who went out of their way to minimise impact. They ensured access to frontages of shops was maintained, put bins out and helped out where possible. A local business owner praised the team by writing to say that ‘she had been concerned about the potential disruption before the team started but the reality was so much better than she had feared’. She was so pleased with the gang’s attitude and performance she baked them cakes on a regular basis.

Buried services: As part of the efforts to minimise disruption and to continue with the ongoing drive to aspire to zero incidents, the team went to great lengths to avoid damaging buried services. The team proactively planned each stretch scrutinising as-built records, using ground penetrating radar as well as CAT scanners and trial pits to pin point known services. Overall the team encountered, and safely managed working around, 489 services – 109 of which were uncharted.

Inside the newly constructed Cowleigh DSR – Courtesy of MMB

Ecology and landscaping: The Cowleigh DSR site is in an Area of Outstanding Natural Beauty and adjacent to a Site of Specific Scientific Interest and Ancient Woodland. The site is overlooked by the Malvern Hills and is popular for its beautiful walks. The ‘Worcestershire Way’ long distance footpath shares the access track to the site and is frequently used by ramblers wishing to enjoy the beauty of the area.

The team proactively engaged stakeholders to ensure practical measures were taken to avoid significant visual or noise impact during construction and to leave a lasting environmental legacy. With the permission of the council’s ecology team, dormouse boxes were installed in the adjacent woodlands to encourage the dormouse population and improve biodiversity.

The team specified locally sourced aggregate to top the reservoir which blended into the surrounding area, thus reducing the visual impact of the reservoir.

Inside the refurbished pumping station – Courtesy of MMB

Conclusion

The construction of the new cells, pumping station, associated assets and pipeline was completed in December 2017, 18 months from the start of construction and less than 2 years from the start of the outline design phase. Cowleigh DSR went into gravity supply in November 2017 and the commissioning of the control system is due to be completed in April 2018.