Heybridge Sea Gate & Lock Gate Replacement (2017)

Timber mitre gates installed in February 2017 - Courtesy of Northumbrian Water Group

At the start of construction for the Hanningfield Raw Water Reservoir, an Act of Parliament The Hanningfield Water Order 1950 was passed with agreements put in place for the maintenance of the lock between the navigation company (Essex Waterways) and Northumbrian Water Group (NWG), parent company of Essex and Suffolk Water. NWG abstracts water from the Chelmer and Blackwater Navigation pumping it to Hanningfield Reservoir, where supplies of raw water are held before treatment and distribution to 1.8 million customers in Essex and parts of east London. This is a valuable additional source of raw water for the reservoir and NWG is keen to secure and protect this water resource from saline incursions from the river estuaries.

Introduction

The lock is located at the end of the Chelmer and Blackwater Navigation Canal, which runs approximately 14 miles from Chelmsford in Essex through to Heybridge Basin, where it meets the tidal estuary and the sea. The original lock and navigation was constructed in 1797 and was overseen by John Rennie F.R.S. who was the principal engineer for the project.

The lock measures approximately 8.2m wide by 5m deep by 60m long and is a grade II listed structure under the Town and Country Planning (Listed Buildings and Conservation Areas) Act 1990.

(left) View of seaward end of lock and (right) old timber mitre gates – Courtesy of Northumbrian Water Group

Under the Hanningfield Water Order 1950 a subsequent agreement was made in 1964, the Chelmer Navigation Agreement, whereby the Navigation Company had the responsibility of carrying out any major repairs to Heybridge Sea Gate, costs to be reimbursed and repairs to meet with the approval of NWG. The water company has a statutory obligation to keep the lock operational for Essex Waterways’ use (formerly known as The Chelmer and Blackwater Navigation Company) and so in 2014 it was agreed that due to the major investment and complexity, NWG would procure a new gate and manage the project directly.

NWG carried out a feasibility study in October 2014 and completed detailed design in December 2015 for the replacement of the sea gate. The scheme would eventually encompass the replacement of the timber lock gates as well as the sea gate to make additional use of the closure and isolation of the lock at Heybridge Basin.

The construction phase would need careful planning with residential and business properties within close proximity of the lock. The site is also designated as a SSSI, SPA and Ramsar, meaning further constraints would be placed on the replacement project. The site is also immediately adjacent to a Marine Conservation Zone.

Original sea gate removed in November 2015 by JMH Ltd – Courtesy of Northumbrian Water Group

Original gate construction and removal

In the mid 1960s, the original masonry lock structure was extended with a reinforced concrete structure to house a new steel caisson outer gate, designed by Sir William Halcrow & Partners. The steel caisson gate was moved across the lock by a chain-pulling mechanism, driven by an electric powered motor. The closed structure was buoyancy adjustable with ballast. The estimated weight of gate and ballast was around 58 tonnes.

The gate was pulled over pairs of cast iron rollers at the base of the lock and into a recess. With deterioration of the steel gate and addition of ballast, the assembly controlling the water flowing in and out to control the buoyancy to move the gate had become ineffective. This resulted in the heavier gate causing wear on the cast iron rollers, which became seized, preventing the gate to be pulled freely across the lock.

The feasibility report and condition appraisal concluded that the gate was beyond economical repair; therefore NWG commissioned the demolition and removal of the gate in November 2015. This provided the opportunity to carry out some further dimensional checks of the original construction.

(left) Demolition of old steel caisson sea gate and (right) Roller bearing removed from base of lock – Courtesy of Northumbrian Water Group

Heybridge gate internal inspection: Ballast within gate – Courtesy of Northumbrian Water Group

Detailed design

NWG procured the design of a new sea gate and associated systems using framework consultant MWH Global Ltd (now Stantec UK) with specialist design carried out by KGAL Consulting Engineers Ltd. Considering the constraint of the grade II listing of the structure, NWG decided to progress with an option for a like for like replacement, with improvements to be made learning lessons from the previous gate design.

The new design would make use of the existing lock structure, without the need for any major structural redevelopment of the lock.

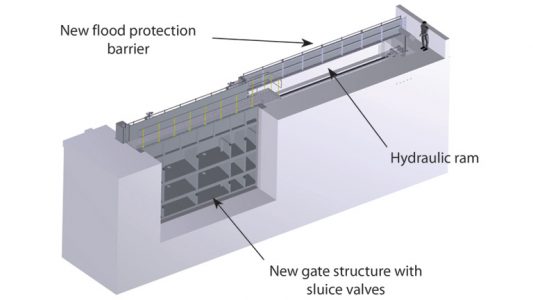

The new gate design features several improvements made on the previous design, with consideration given to the sustainability and maintenance features of the new lock installations. Some of the key features are summarised below:

- New moving mechanism: The new sea gate will feature a more modern hydraulic ram system, replacing the old chain pulling system. This is a key element of the new design and increasing the moving power, allowing for the new ‘buoyancy free’ open structure design.

- Open structure, net heavy: The open steel structure removes the reliance on buoyancy to move the gate. The resultant weight is less, approximately 26 tonnes as against the estimated weight of the old gate of 58 tonnes. It also removes the hazard of entering a confined space to adjust ballast.

- Removable gate seals: The gate seal is mounted on a sub-frame in sections which can be removed to facilitate replacement.

- Gate rails will replace rollers: New rail beams installed features a removable bearing plate in sections which can be replaced when necessary due to any excessive wear.

- Raised height with barrier: The new gate features an infilled handrailing barrier which will enhance the flood protection of the area, including tide impact protection of the statutory timber flood gates.

3D image of new gate design – Courtesy of KGAL Consulting Engineers Ltd

Construction Phase September 2016-March 2017

Temporary works – considering future maintenance: One of the significant considerations was the future isolation of the lock to carry out any major maintenance activities on the sea gate. It was decided to install a reusable stop-log dam facility, to firstly facilitate the isolation of the lock for the installation of the new sea gate and secondly, provide a means of isolating the lock in the future.

The installation of the permanent guide brackets for the stop-logs would need to be carried out working within the low tide times. The design for the anchor fixings to install the guide brackets required accurate drilling of the existing concrete structure, with several fixings requiring drilling depths of up to 600mm. This proved to be a very time consuming and challenging aspect of the project but it would enable future isolations to be carried out with relative ease.

Lifting of new timber mitre gates – Courtesy of Northumbrian Water Group

Replacement of upper timber mitre gates: To make use of the isolation of the lock, it was agreed that due to the poor condition of the upper timber mitre gates, these would be replaced as part of the project. The new gates would be very similar in appearance, considering the listed nature of the lock.

The new timber gates are constructed out of sustainably sourced timber, namely FSC oak for the main structural members and FSC Ekki for the cladding infill panels. The original jack heads to raise and lower the gate sluices have been refurbished and reused on the new gates. Each gate leaf has a dry weight of 5.5 tonnes and was successfully lifted into place just before Storm Doris passed through Essex during late February 2017.

Construction of gate rails and sills for new sea gate: The setting out and installation of the new gate rail beams and horizontal sill members was carried out in March 2017. With this element of the work completed, the remaining work to install the sea gate will take place from October 2017 with the lock re-opened for the summer period.

View of Heybridge lock looking upstream – Courtesy of Northumbrian Water Group

Conclusion

There has been a significant amount of planning for the new gate installation with consideration of the sensitive location. The lock is in close proximity to residential and business properties and attracts many visitors throughout the year as a tourist destination and a place for vessels to moor.

The installation of the new sea gate will not only benefit NWG in protecting a key water resource but will also benefit the Heybridge-area. The new gate will provide additional flood protection and will enable flexibility in the operation of the lock and supporting the continuing operation of this popular and widely used waterway.

The first phase of construction was finished for the re-opening of the lock on 31 March 2017, with the installation of the sea gate to be carried out in November 2017. NWG has spent £2.2m on the project so far and will continue to invest further with the second phase of the works for completion in the winter of 2017/2018.