ReGenerator Technologies (2017)

3D image of Basingstoke STW DEMON® - Courtesy of Sweco

The concept of sewage treatment plants as energy factories originated in the Netherlands in the early 2000s, and Sweco (formally Grontmij) was a founder member of the Dutch-led ‘Energy Factory’ projects. Sweco then expanded the potential benefits, prompting a 2012 rebrand to ‘The ReGenerator® Concept’. The ReGenerator® methodology sees Sweco sourcing new pan-European sustainable technologies that can increase biogas production for energy generation, reduce energy consumption, increase water recovery, recover nutrients, reuse surplus waste heat, and in the future recover other bio-resources, thus supporting clients operating in a TOTEX environment.

Introduction

SHARON® and DEMON® liquor treatment technologies play an important part in the ReGenerator® Concept approach, as treating liquors prior to returning the flows to the mainstream unlocks capacity in the secondary treatment stage and provides an improved effluent quality.

The DEMON® process is a nitritation/deammonification process in which ammonia and nitrite are simultaneously converted to nitrogen gas, without the need for organic carbon, thereby delivering lower OPEX costs compared to other technologies. This paper builds on the fundamental principles of DEMON® (as previously described in the UK Water Projects 2016 paper) by focussing on two recently awarded UK DEMON® projects.

Knostrop WwTW for B&V / Yorkshire Water

Design of the DEMON® liquor treatment plant (LTP) for Knostrop WwTW commenced in November 2016. The site is located to the south east of Leeds in the Lower Aire Valley, just five miles from the heart of the city centre. Knostrop WwTW receives domestic and industrial sewage waste from the surrounding catchment, and comprises a sewage treatment stream and a separate Sludge Treatment Facility (STF), which processes indigenous sludge and imports.

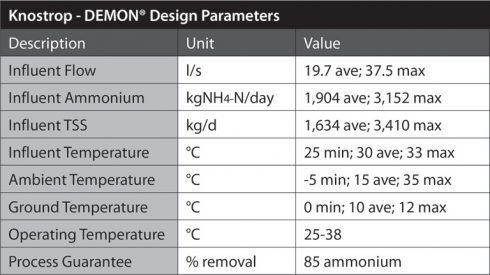

Table 1

The STF is currently undergoing a £72m upgrade to provide the site with capacity to process 131tDS/day. The project, which is being delivered by Black & Veatch (B&V), is the largest single project in Yorkshire Water’s AMP6 programme and includes new digestion and dewatering plants (but excludes thermal hydrolysis plant, THP).

Sweco is operating as sub-consultant to B&V to undertake the complete process/mechanical design, outline electrical design and full process commissioning of the circa £4m LTP.

Site configuration

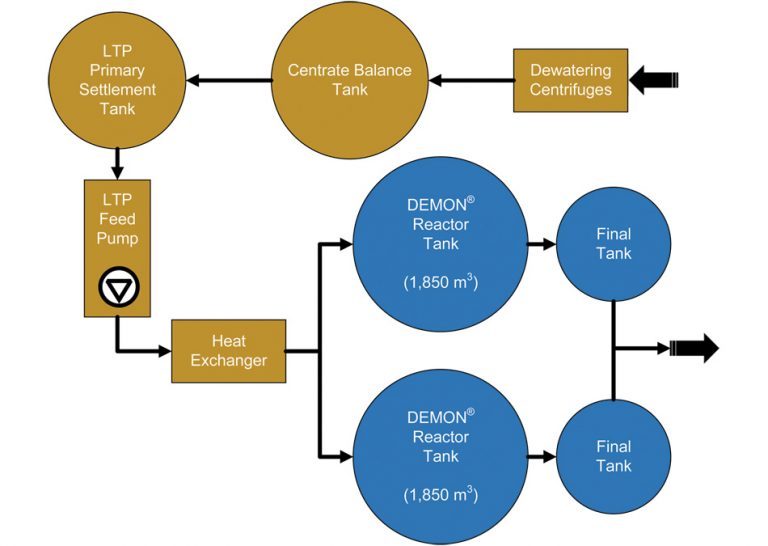

Under the new site configuration, centrate generated by three new post-digestion dewatering centrifuges is pumped to a centrate balance tank, where flow is buffered and mixed prior to controlled gravitational transfer to a dedicated primary settlement tank (PST) upstream of the LTP.

Ordinarily, inclusion of a settlement stage upstream of DEMON® is not necessary, as the process can tolerate influent solids in the range of 750-1000mg/l, usually achievable with dewatering plant that has a 95% separation efficiency. However, on this site it was considered there may be occasional periods of inefficient dewatering, and therefore it was considered advantageous to include an upstream settlement stage to facilitate the removal of heavier solids (and scum) from the process flow prior to treatment. Yorkshire Water agreed with B&V to provide a PST, the design of which also includes provision for polymer dosing connections to enhance solids removal. This ensures that the influent quality will always be within the DEMON® process limits, either during commissioning or once the LTP is in service.

As with most biological systems, the size of the DEMON® reactors is a function of the incoming load. At Knostrop, the maximum instantaneous feed flow to the LTP is 37.5l/s and the load is capped to 3,152kgNH4-N/day, enabling Sweco to guarantee an 85% ammonia removal efficiency. In practice, the DEMON® process should achieve 90% ammonia removal due to the high alkalinity ratio expected as a result of the centrate being lime dosed for pathogen kill post-digestion.

Knostrop LTP schematic – Courtesy of Sweco

Twin stream arrangement

The Knostrop DEMON® liquor treatment plant is a twin stream arrangement, in that flow is split between two reactor tanks each with their own dedicated settlement tank downstream. One benefit of this approach is that only 50% of the seed sludge is required for commissioning, since the second reactor can be seeded from the first. Furthermore, in the unlikely event of a reactor losing its deammonifying bacteria (DABs), the second reactor should be available as a source, thereby saving on potential down time. Twin reactor configurations provide the end user with additional security following any unexpected events, through added treatment options and greater critical plant availability; all for a small increase in CAPEX cost.

Sweco’s typical battery limit for the LTP influent pipework is just above slab level, adjacent to the DEMON® reactor tank(s). At Knostrop, B&V was already committed to presenting the flow to the LTP via duty/standby submersible feed pumps discharging into a single rising main with a single heat exchanger. Sweco therefore enabled flow balancing between the twin stream reactors by the inclusion of actuated eccentric plug valves within the inlet pipework. The logic was designed such that the valves would not conflict with each other when the biological treatment capacity in each reactor differed.

Sweco’s standard approach is to provide a dedicated variable speed feed pump for each reactor without flow control valves, thereby enabling the flow into each reactor to be adjusted to take account of differing treatment capacities in the reactors; this approach would have required additional pumps and heat exchangers in the Knostrop design.

A bypass facility of each DEMON® reactor has also been provided; this is often catered for by using simple open/close actuated gate valves. At Knostrop, however, it was necessary to incorporate further actuated eccentric plug valves in order to preserve the pressure head required to continue to feed the adjacent reactor.

Reactor tanks

Each of the two open-topped DEMON® reactor tanks is 18.7m internal diameter by 7.2m high (6.7m water depth), constructed by Balmoral Tanks from epoxy-coated mild steel. Within each reactor is a pair of duty/duty 5.8kW Xylem banana blade mixers for solids suspension, and a single duty-only 5.9kW submersible centrifugal SAS pump (also Xylem) that delivers waste sludge to a patented DEMON® hydrocyclone mounted at walkway level.

The hydrocyclone separates the heavier deammonifying bacteria from lighter waste sludge. The deammonifying bacteria is dropped back into the reactor tank to maintain the sludge age and promote the growth of deammonifying bacteria over the competing nitrite oxidizing bacteria.

Air is provided to the Xylem FBDA grids by five 75kW variable speed positive displacement Aerzen blowers, configured to provide dedicated duty/assist operation for each reactor, with a common shared standby unit automatically brought into operation when required using actuated valves.

Instrumentation

As explained in the 2016 paper, the DEMON® process restricts the nitrite and nitrate levels within the reactor by monitoring the change in pH levels that controls oxygen levels within the reactor(s). As Knostrop is a twin stream plant, each DEMON® reactor tank has its own bank of dedicated instruments.

The nitrate and nitrite levels are specified to be measured using submersible online s::can UV Spectro::lyserTM instruments, which also measure the TSS level. The pH level is specified to be monitored by a submersible online s::can Ammo::lyserTM Pro monitor, which also provides ammonium and temperature measurement.

Both the s::can Spectro::lyserTM and Ammo::lyserTM are connected to a local Con::cube controller, which interfaces the measuring instruments with a PLC control system using a combination of Ethernet and hardwired signals.

The oxygen level within each DEMON® reactor is monitored with a submersible online ATI Model Q46D dissolved oxygen monitor with its own cleaning system, which is used to control the operation of the air blowers and mixers.

The instruments used have been selected to meet various criteria; in priority order these are: accuracy, online functionality, reliability, facility for automatic cleaning.

WwTP Nieuwegein DEMON®, NL has been operational since 2011 (450 kgNH4-N/day, 4.9 l/s) – Courtesy of Sweco

Heat demand

As Sweco is providing the process and mechanical design, guaranteed figures have also been offered for total energy consumption and heat demand. The DEMON® operating temperature is expected to vary between 25°C and 33°C under normal conditions, with no external heat input being required. However, the reactor temperature will drop significantly in the event of a prolonged operational shutdown, at a rate of around 8°C per day assuming worst case ambient and ground temperatures conditions (note the mass of deammonifying bacteria remains unaffected).

Sweco considered the heat transfer offered by a 1.6MW heat exchanger on the feed line and found it to be sufficient to allow the DEMON® reactors to recover under typical local temperatures.

In order, however, to mitigate against the risk of lower reactor temperatures when faced with the extreme conditions of low ambient temperature and high wind speed, additional connections and laydown areas have been included in the design to allow for the recirculation of flows, as well as provision for temporary mobile heat exchangers.

Settlement tanks

The downstream settlement tanks are bespoke and broadly of a Dortmund style design. Manufactured by Balmoral Tanks in epoxy-coated mild steel at 6.2m diameter by 7.3m high overall, they are dominated by their 60° hopper cone.

RAS is drawn from the base of the cones with two dedicated 11kW progressive cavity Mono pumps. A third common shared standby pump is again automatically brought into operation when required via actuated valving on the suction and discharge lines.

The DEMON® effluent discharges over a partial peripheral weir (6.8m long), the full length of which can be accessed for cleaning from the above working platform.

The platform layout has been intelligently designed such that the access stairway is positioned centrally, and all plant and instrumentation positioned peripherally, to allow operational personnel to attend to equipment well away from access pathways and associated changes in floor elevation. All submerged equipment can be easily removed from the tank using dedicated lifting plant, and moved by trolley to a davit for transfer to ground level without needing to pass near either of the two instrumentation banks, thus minimising the risk of instrumentation damage.

The high level hose reels near to the settlement tanks are ideally positioned for washing down the settlement tank weirs as well as any removed submerged equipment. As their location coincides with the ground level hose reel, the local service water pipework routing is kept simple and efficient.

Pipework considerations

Each DEMON® reactor’s inlet and outlet pipework is virtually diametrically opposite to mitigate against the risk of flow short-circuiting. Whilst the RAS return pipework penetration is within the vicinity of the reactor tank outlet pipework, the former is above water level (to provide a hydraulic safe-guard against RAS pump non-return valve failure) and the latter is over 2m below water level.

With this design, the risk of short-circuiting is low, but has been minimised further by directing RAS flow away from the area with a 45° bend fitting. Larger equipment such as the blowers and RAS pumps are positioned within easy reach of adjacent roads to accommodate removal using mobile lifting plant. The aforementioned reactor tank temporary recirculation connections are also positioned adjacent to nearby roads, for easy connection to temporary mobile heat exchangers.

At the time of going to press, B&V have placed orders for all key mechanical and electrical equipment, and are currently overseeing the construction of the DEMON® reactor tanks. Once commissioned in late 2018/early 2019, the Knostrop LTP will be the largest twin stream DEMON® in Europe.

Basingstoke STW for eight2O/Thames Water

This project is at a much earlier stage of design compared to Knostrop and equipment orders have yet to be placed; however some key decisions have already been made regarding the delivery strategy, resulting in quite a different DEMON® configuration being proposed at Basingstoke.

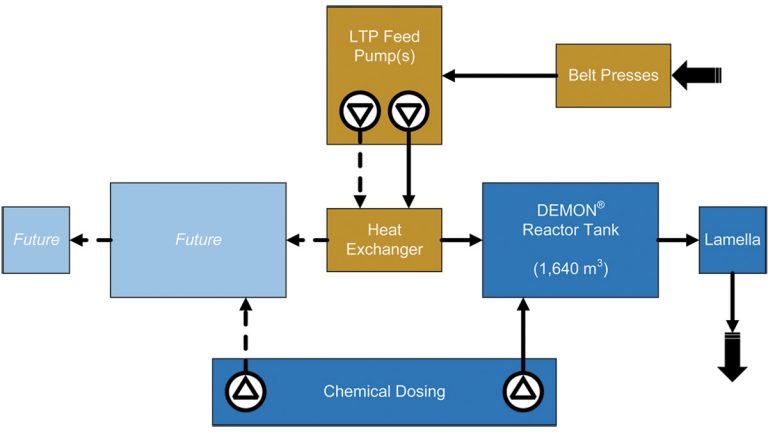

Basingstoke LTP schematic – Courtesy of Sweco

Although the ammonia load present in the (post-THP) dewatering liquors is predicted to be consistent across AMP6 and AMP7, it has been proven – through analysis of the performance of the existing ASP – that only one ‘half’ of the final DEMON® LTP is required to be constructed in AMP6. This provides a neat commercial solution in two respects:

- Investment can be staged, by capitalising on an existing assets’ outperformance.

- The future AMP7 DEMON® LTP can be a complete mirror image of the established AMP6 design.

The site itself presents its own challenges in that the only feasible area for the LTP is long and narrow. To overcome the space constraints a rectangular, in situ concrete reactor tank has been selected, with a slightly deeper water depth than Knostrop.

Whilst the tank geometry does not affect the DEMON® biological process, mixing energy will need to be carefully considered to ensure sludge settlement is avoided and that there are no dead zones, for example in the tank corners. Lamella separation technology has also been chosen, for the smaller footprint it offers when compared to typical Dortmund style settlement tank(s).

Overall, the Basingstoke DEMON® is a smaller LTP than Knostrop in terms of flow and load, but Sweco has been able to provide a higher guaranteed ammonia removal efficiency for this project, through the inclusion of a caustic dosing system (25% sodium hydroxide).

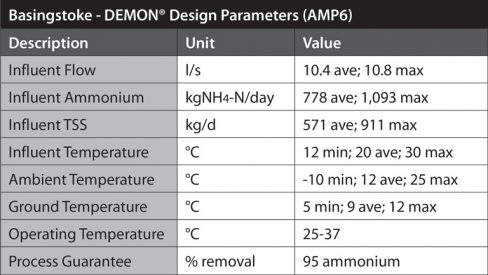

Table 2

The Basingstoke DEMON® reactor(s) will be covered, and at the time of going to press a floating cover has been recommended. This solution will ensure the temperature of the DEMON® reactor(s) is less affected during the THP’s annual regulatory shutdown, whilst still being capable of being removed to minimise the risk of overheating in summer. The design for this project will be complete by late autumn 2017, and commissioning of the AMP6 reactor is programmed for spring 2018 onwards.

Closing remarks

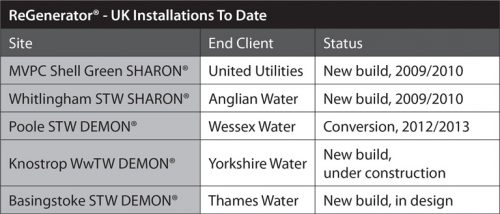

With around 70 DEMON® and SHARON® installations across the world, the use of these technologies for liquor treatment (municipal and industrial) is now established. In the UK, the use of specialist LTP processes is now common practice, and the current two DEMON® schemes together with the three other constructed sites has established Sweco as a leading provider of these technologies.

Table 3

Looking forward, Sweco will be offering DEMON® solutions with improved features for simplifying the plant controls and increasing the DAB/waste sludge separation efficiency. With these advances, Sweco will seek to continue to offer its clients unique TOTEX-driven ReGenerator® solutions.