Avonmouth Acid Phase Digestion Remedials (2017)

(left) Phase 2 - Reactors replacement at Bristol STW and (right) Tank 4 offline whilst remaining tanks still in operation - Courtesy of Trant Engineering

Wessex Water’s Bristol STW is the largest sewage treatment works within south west region, serving approximately a catchment of 1.1 million people. The works also accounts for more than 50% of region’s sludge treatment. It treats around 100 tonnes dry solid (TDS) per day of indigenous sludge as well as imported sludge to a compliant standard through digestion and lime treatment. Previously a major scheme was implemented at the works to increase electrical self-generation and to reduce land application rates of compliant treated sewage sludge. An acid phase digestion (APD) process was commissioned upstream of the existing mesophilic anaerobic digesters (MAD). The biogas output from the combined processes was used for generating electricity through the combined heat and power (CHP) engines.

(left) Stainless steel top rings and (right) new stainless steel tank erection in process – Courtesy of Trant Engineering

Background

Thickened sludge is heated to 36-37°C before being processed through the APD plant comprising 6 (No.) reactor vessels made in glass coated steel. Each reactor provides approximately 600m3 storage capacity with a combined 2 days retention. Biogas is compressed and recirculated through the tanks to mix the sludge. Each of the reactor is 8.5m in diameter and 13m in height.

In the autumn of 2012, the following issues were identified during the routine inspections:

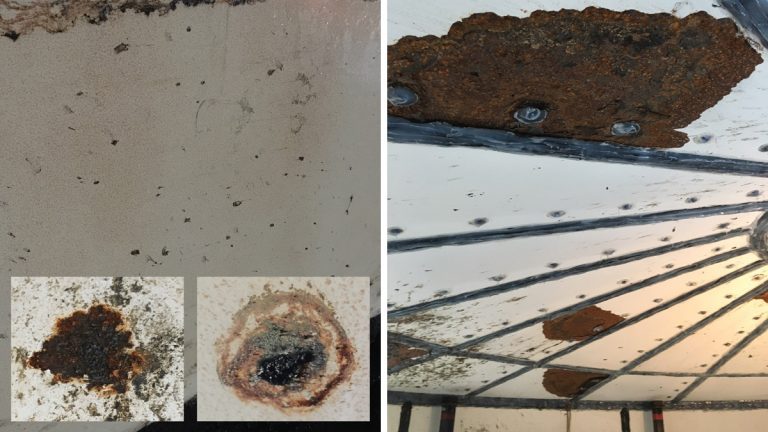

- APD tank roofs were showing significant signs of glass debonding and corrosion. The debonding was extending radially from penetrations (gas lifting and mixing pipework in particular) into the roof and the bolted stiffeners between roof segments.

- Cold storage tanks (i.e. APD buffer tank and thickened sludge feed tank) showed visible corrosion on the side panels at the sludge/air interface level. The top two rings of the sludge buffer tank and the thickened sludge storage tank were corroding from the inside. The sludge operating level was reduced below the top two rings in both tanks.

Surveys and inspections

Wessex Engineering and Construction Services (WECS) arranged a number of surveys and inspections to determine the condition of reactors and cold tanks. Glass coated steel tank panel thickness is nominally 2.5mm when it is new. Deterioration in the individual panels was measured and showed a 10-20% reduction in thickness, with the worst result being 28%, confirmed by ultrasonic thickness and coating thickness testing.

(left) Photos show a view of defects on tank panels. On continued swab testing, the Elcometer alarmed constantly with no visible evidence of damage or defects, this would indicate that the coating is either porous or defective to some degree. The third photo clearly shows pitting or pinholes throughout the surface of the coating and (right) internal panel of corroded roof where the patch repairs carried out externally – Courtesy of Hayes GFS Ltd

The conclusion was that short-term repairs should be made to stop the corrosion spreading and potentially extend the time until the full repair/replacement works in AMP6. However concerns remained that the reduction in roof thickness could lead to the tanks failing under pressure.

To provide full buffering capacity during the APD remedial works, replacement to the top rings of the sludge buffer tank and the sludge storage tank were carried out first prior to any APD outage. Temporary pipelines were required to bypass the cold tanks.

Existing APD process

The Avonmouth APD process is a 6-reactor process by Monsal. In the original design, the reactors cannot be bypassed individually. In assessing the methodology for the long-term remedial works to the tanks, it was identified that all 6 (No.) tanks needed to be taken off line in order to fit an individual bypass system so that one tank could be taken offline at a time for the repair. This required a contingency plan in place to ensure sludge compliance and treatment capacity were not compromised during the work.

Maintaining sludge treatment capacity

To maintain the sludge treatment capacity on site, the existing bypass to the APD process was tested and operated, whilst ensuring no cross contamination with hydrolysed raw sludge in the MADs.

The following issues were identified and formed part of the overall solution:

- The requirement for, and time scales associated with, the MADS to be conditioned/reconditioned to accepting raw/ hydrolysed sludge.

- The requirement for other treatment methods to ensure sludge compliance i.e. liming.

A new approach

It was considered that conditioning the MADs from hydrolysed sludge to raw sludge and back could take up to 6 months.

Operations and Workstream partners including Trant Engineering Ltd and the University of Bath developed a new approach with a much shorter shutdown period.

In this approach, the acid phase digestion plant would be shut down for a short period with the mesophilic anaerobic digesters essentially isolated. The APD/MAD digestion plant would be gradually brought back into operation by introducing sludge back into the APD/MADS in the following controlled manner:

- Feed to APD stopped, MADS isolated, sludge processed by dewatering followed by liming to ensure sludge compliance.

- APD reactors drained and purged with nitrogen.

- Individual tank isolation and bypasses installed. Shift work was utilised to ensure completion on schedule.

- Individual reactor pressure and vacuum relief valves installed.

- APD filled with raw sludge and arranged to operate in full 6-reactor mode.

- Recondition MADs to hydrolysed sludge by gradually ramping up sludge feed through the APD into the MADS (sludge was initially essentially raw but quickly became hydrolysed as the APD sludge reached its required retention time).

- Full sludge compliance throughput achieved.

- Liming and additional dewatering stopped.

The enabling works, comprising the installation of additional valves and pipework, allow each APD reactor to be isolated and taken out of service individually for inspection/repair without affecting sludge throughput.

Tank 4 out of service on human-machine interface – Courtesy of WECS

Bypassing an isolated APD reactor

Bypassing an isolated APD reactor whilst continuing to operate the APD Plant on the remaining 5 (No.) reactors requires additional sludge transfer pumps and bypass pipework for the tanks. The bypass pumps operate in such a way as to mimic the existing gas lifting transfer system between the tanks. The gas lift system will continue to operate for the non-isolated tanks as per normal operation.

When bypassing Tanks 1 or 6, no sludge transfer pumps are required. When Tank 1 is taken out of service, temporary pipework will enable Tank 2 to be fed using the existing APD feed pumps and allow the contents of Tank 2 to be recirculated through the existing heat exchanger. For Tank 6, the existing digester feed pumps can be utilised to move sludge from Tank 5 via the temporary bypass pipework for Tank 6 during its replacement.

Avonmouth site works within its existing hazard analysis and critical control points (HACCP) plan (i.e. critical control points of 33.5°C minimum and sludge feed of 1,863m3/d maximum) while operating on the 6 (No.) tanks.

Historic data of sampling directly from Reactor 5 of the APD plant suggest that the operation of five reactors is likely to be successful, albeit there may be a marginal increased risk of HACCP failure.

If there is a failed HACCP bacteria sample (or failure of the critical control plan), then the existing exceedance strategy would have to be enacted including re-sampling from farm stockpile (more than once if necessary) and liming to avoid non-compliant sludge being actually spread to land.

Proving period

Additional funding was agreed for a one month proving period operating the APD on five rather than six reactors. This trial was carried out prior to commencement of any tank repairs to confirm continued sludge compliance.

Preparation of concrete tank base rebate – Courtesy of WECS

The proving trial required liming of all digested sludge cake and started in April 2016. Tank 6 was selected as the tank out-of-service because no bypass pumps were required and it was the simplest way to convert the plant to five-tank operation.

The outcome of the trial has validated five-tank operation and confirmed liming was not necessary during APD repairs. Gas production during the trial with five tank operation varied but has not shown any significant reduction compared to that produced by six tanks, albeit that this is based on a limited dataset.

During the proving trial, APD Tank 6 was inspected from low level. Apart from large areas of corrosion observed on the roof, tank panels have developed glass coating defects at random locations.

The coating defects development was unknown although previously it was thought to be stress fracturing of the coating caused by over-torquing of the fixings. No effective methods for repairing damaged panels would guarantee a long-term solution.

An enhanced enzymic hydrolysis (EEH) feasibility study was also undertaken with the objective to determine whether an EEH plant provides more certainty to meet Biosolids Assurance Scheme (BAS)standards. The conclusion was conversion to an EEH plant would not guarantee a BAS compliant product.

Duty/duty sludge transfer pumps for Tank 4 bypass in operation – Courtesy of WECS

Due to high temperatures and varying levels of chloride a conversion to EEH would necessitate the use of stainless steel for Tanks 4, 5 and 6. High capital and operation cost without any other significant benefits to the process established there is not a strong business case to upgrade the existing APD to EEH plant now. However, future regulatory drivers to have EEH process means that provision for EEH would be necessary providing an ‘advance treated’ standard in accordance with the safe sludge matrix.

The cost of full replacement in stainless steel has previously been observed to be only marginally higher than full replacement in glass coated steel. Since it is not possible to be certain that if replacing in glass coated steel the issues seen would not re-occur, the recommended solution was to replace all 6 (No.) APD reactors roof and panels with stainless steel 316L with provision of additional flanges for future EEH plant upgrade.

Repair programme

In 2016, operational issues were discovered with Tank 4. Local repairs were subsequently carried out to the roofs of all tanks.

In order to accelerate the overall repair programme WECS awarded Trant Engineering Ltd the NEC Engineering and Construction Contract Option C contract for Tank 4 and 5. Meanwhile a delivery and procurement strategy for the remaining tank repairs was also developed. It was envisaged that the APD remedial scheme would be a rolling programme with no gap in between tank repairs to minimise disruptions to site operation.

Remedial work

Trant started the major APD remedial work in August 2016. The repair work to date has seen successful whole tank replacement of Tanks 4 and 5 in stainless steel 316L and their integration into the existing APD plant on budget and on time. Sludge sampling data on the 5 (No.) APD tanks during the construction period have been positive and fully compliant with HACCP.

The new tanks have included the provisions of additional flanges for future EEH plant upgrade, which are isolated and blanked off. With proper planning it is possible to keep the plant live during any future upgrade. Improvements on gas lifting and mixing connections to the roofs have also been made to reduce the risk of future gas leaks.

Lifting the gas draw-off pipe off the roof – Courtesy of WECS

Future planned work

Over the next 12 months, WECS will continue working closely with the contractor and Operations. Using knowledge gained from the replacement of the first two tanks, far more accurate costs and risks will be assessed for the whole-tank replacement of the remaining four tanks. The anticipated completion for the scheme is summer 2018.