Flamborough Head Sewage Pumping Station (2017)

Concrete storage pipes being delivered to site - Courtesy of MMB

The Flamborough Head Sewage Pumping Station (SPS) is located close to a scheduled monument, a Site of Special Scientific Interest, within a local nature reserve, adjacent to a Special Area of Conservation and Special Protection Area and is home to guillemots, puffins, dolphins and porpoises. The area is also a major tourist attraction, enticing thousands of visitors every year to see its lighthouses and chalk cliffs. It lies within the short term erosion zone of the cliffs and is in danger of falling into the sea within the next twenty years. Yorkshire Water Services (YWS) decided to respond proactively to this risk, investing in the sewage pumping station’s’ relocation to outside of the 100-year erosion line. YWS engaged with design and build contractor Mott MacDonald Bentley (MMB) to undertake the works.

Background

The scheme to relocate the SPS is itself a sustainable proactive choice by YWS to ensure the long term protection of its asset, and prevent potential environmental incidents that could result from the discharge of raw sewage into such an essential area. The new location of the SPS is such that no further protection works will be necessary for at least the next 100 years.

The area surrounding the SPS is home to a variety of fauna including the only mainland breeding colony of northern gannets. This, and the proximity of several protected areas, also ensured that the works had to be sensitive to the local environment and with the guidance of a qualified ecologist and through the planning process, a safe working area was defined and all works kept within that boundary. Furthermore the SPS was moved from a position immediately adjacent to the tourist footpath, to a less visually intrusive area beside an existing public car park.

Surveys and planning

An archaeological written scheme of investigation and geophysical surveys was undertaken in the proposed area of the new SPS due to the location of the ‘Operation Diver Heavy Anti-aircraft Gun Sites’ scheduled monument. A suitable location, away from any possible site of archaeological interest, was chosen for the new facility.

The relocated SPS had to match the existing in terms of hydraulic performance but located in an alternative location. In order to match the existing emergency storage capacity of the SPS, several options were considered and discounted such as a change in material for the 33m long 1.8m diameter storage pipe from concrete to a GRP plastic, which was overthrown due to the depth of placement being greater than the materials strength capability.

At the design stage and throughout construction, MMB presented their designs and ideas to the board of directors in an initiative named ‘director challenge’, which allows a project’s design to be dissected and reviewed from all aspects such as buildability, cost, and suitability. This formal yet informal brainstorm often leads to many different options being explored, including previous designs from other projects and then brought back to the board, all in all helping the ‘right first time’ directive being implemented from the outset.

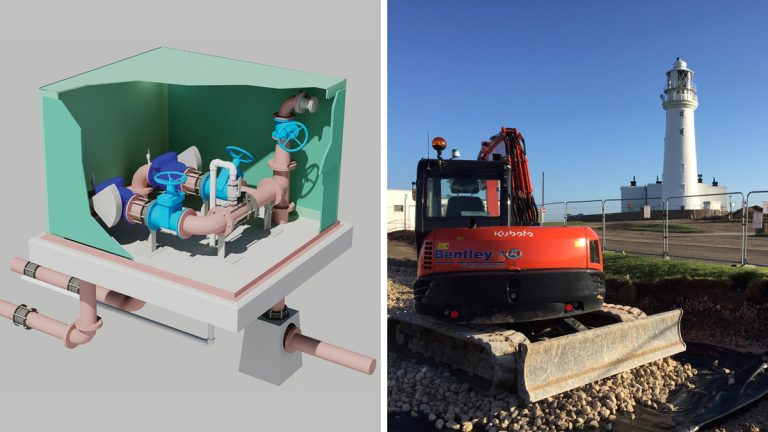

(first) Above ground valve kiosk and (right) works close to Flamborough Lighthouse – Courtesy of MMB

Design

Using MMB’s approach to standard products and designs, the MMB standard wet well design, created with Carlow Precast (now FLI Precast Solutions), was utilised to full effect on this scheme. Rather than using large diameter manhole rings a range of precast options (from 1.8m-2.4m diameter, and up to 6m deep) can be chosen and delivered in only two sections, as opposed to several segmental rings.

Furthermore, a precast sump (which is perfectly shaped to improve flow presentation to the pumps) was utilised. The sump is simply lowered into the bottom of the wet well and grouted into place, reducing the need for works to create benching within a confined space.

In order to help the site team deliver the design correctly, MMB produce guidance commissioning documents, which are item-specific to that project, usually in the form of a spreadsheet with requests for images at various stages of the build. Due to the new technology YorSurv being presented to the company, it was put into effect for the Flamborough Head SPS project for the commissioning team to produce their documents all on a tablet computer, with surveys specifically designed to review all sections outlined in the superseded commissioning spreadsheets, but in a new and more user-friendly manner and recognised as being more efficient.

Northern Powergrid

The electrical control panel of the SPS was located within a building jointly shared with the electrical distribution network operation Northern Powergrid (NPg). It was identified that potential efficiencies could be made by liaising with NPg regarding a joint relocation. Whilst NPg did not at the time have the available funds to invest in a relocation of their substation, YWS’ work has brought the erosion issue to NPg’s attention who have now added it to their risk register for future funding. Finally, YWS have made it clear that should NPg wish to relocate their substation in the future, the newly created YWS compound would be available to share with NPg.

Considerations

The access to the Flamborough Head fog signal, which is used as a navigational aid for passing ships during inclement weather, is over the line of the inlet sewer to the SPS. This access had to be maintained at all times and discussions with the fog signal owner were undertaken to ensure that there were no access issues.

As the area is visited by thousands of tourists every year and is close to several residences, MMB and YWS made a joint presentation to the local parish council to explain the likely disruption and take any concerns on board. As a result of this, and detailed discussions with local businesses, it was agreed that the works would only take place during winter months.

Due to the effectiveness of the team as a whole delivering and documenting the projects commissioning, this particular project has been nominated to be included on YWS’ shared internet service (YorDoc) as a key example of a good pumping station.

Flamborough Lighthouse with finished SPS compound and access track – Courtesy of MMB

Summary

In essence, the relocation of this YWS asset, which serves the adjacent properties along with thousands of visitors yearly, was a necessity due to the ever approaching corrosion of the headland which could potentially cause the discharge of raw sewage to a sensitive area of natural beauty.

When considering the potential for disruption to this community associated with the project, as well as constraints due to the listed buildings and historic remains surrounding the site, the delivery of this scheme is not only beneficial to the people living and visiting the area, but the methodology of construction and the proactive nature of the delivery team ensured that there was minimal impact on society as a whole, resulting in the popularity and beauty of the surroundings being maintained.