Morecambe WwTW Catchment Strategy: Part 2 (2019)

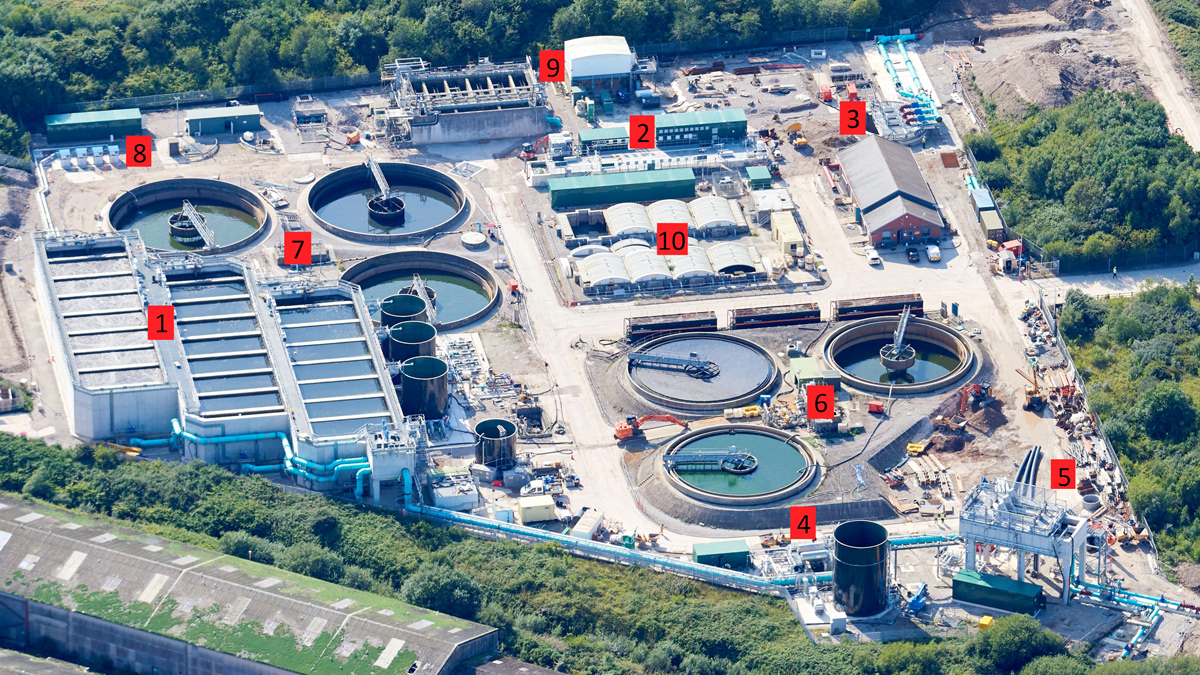

Morecambe WwTW overview (August 2019) - Courtesy of United Utilities

United Utilities’ Morecambe sewerage system collects at Schola Green Wastewater Pumping Station (WwPS) located in the west end of the town. From there, flows for treatment are pumped via a 6km long pipeline to Morecambe Wastewater Treatment Works (WwTW), which is situated to the south, near to the village of Middleton. Both sites have sea outfall pipelines which discharge effluent into Morecambe Bay. The Schola Green outfall is a storm overflow (which operates intermittently when the system is overloaded) and the Middleton outfall discharges treated effluent from the WwTW.

Project needs

The storm overflow at Schola Green WwPS had been identified by the Environment Agency (EA) in NEP4 as needing to comply by 31st July 2019 with the requirements of both the Shellfish Waters and Bathing Waters Directives, which will limit spills to no more than two per bathing season (15 May-30 September) and ten per annum.

Furthermore, at low tide the four diffusers at the end of the Morecambe WwTW outfall pipeline are not submerged and therefore the EA has also required a solution to ensure effective dilution of the final effluent by March 2020. This will require the introduction of a tidal pumping system at the treatment works: final effluent tidal storage and tidal pumping station to discharge treated effluent at sea, only when the outfall diffusers are fully submerged at high tide.

Additionally, as a secondary objective, the existing wastewater treatment process at Morecambe WwTW is obsolete and needs to be replaced. The population is predicted to grow and Morecambe WwTW needs to be capable of meeting its regulatory discharge requirements for the increased flows and loads up to a 2036 design horizon.

Elevated inlet works (August 2019) – Courtesy of United Utilities

Integrated solution

The integrated solution involves five main elements, as follows:

- The construction of 2 (No.) new storm water detention tanks at Schola Green WwPS, in order to increase storage capacity (from 22,000m3 to 46,000m3) and reduce the number of spills to the outfall.

- The installation of a second pumped transfer pipeline between Schola Green and Morecambe (Middleton) WwTW, in order to increase the pass forward flow to treatment at Morecambe WwTW.

- Replacement of the obsolete treatment process at Morecambe (Middleton) WwTW, in order to provide a full upgrade to the latest technology (including a Nereda® plant) and also to cater for the increased flow transfer from Schola Green.

- Provision of approximately 10,000m3 of tidal storage at Morecambe WwTW, achieved partially through conversion of the existing civils assets once the existing treatment process has been decommissioned.

- Upsizing of the land-section of the existing outfall pipeline from Morecambe (Middleton) WwTW, to cater for the increased treated effluent flows. The 2.5km long marine section of the outfall pipeline does not need to be upsized, but some improvement works are required at the discharge ports to address problems that have occurred as a result of beach/sea bed movement.

The main construction contract was awarded to United Utilities’ Construction Delivery Partner C2V+, a joint venture between VolkerStevin and CH2M (now Jacobs), in February 2017.

Morecambe WwTW Catchment Strategy: Supply chain – key participants

- Main construction contractor: C2V+

- Geotechnical investigation: Geotechnics Ltd

- Nereda process design and consultancy: Royal Haskoning DHV

- General MEICA Installation: Eric Wright Water

- Access steelwork: VolkerBrooks

- Inlet screens and compactors: Huber Technology

- Penstocks and stoplogs: Glenfield Invicta

- Tideflex valves: MeasurIT Technologies

- Rotary drum thickeners: Andritz

- Polyelectrolyte storage and dosing: NPS

- Nereda internals: Suprafilt

- Aeration blowers: Aerzen Machines

- Pneumatic compressors: Cooper Freer

- Pneumatic Valve: Islands Metalwork

- Inter-process above-ground pipework: Powerrun

- UV disinfection system: Xylem Water Solutions – Wedeco

- Washwater booster system: Grundfos Pumps

- Outfall and transfer pumps: Sulzer Pumps

- Electromagnetic flowmeters: Siemens

- Transfer main non-return valves: MGA Controls

- Centrifugal and submersible pumps: Xylem Water Solutions – Flygt

- SAS thickened sludge, thickener feed and tanker loading progressive cavity pumps (Morecambe): SEEPEX UK Ltd

- Glass-coated steel tanks: Goodwin Tanks

- RDT buffer tank air mixing: Utile Engineering

- Thickened sludge tank mixing: Hidrostal

- Systems integration: Tata Consultancy Services

- MCCs: Lloyd Morris Electrical Ltd

- Transformers: ESE

- RMUs and HV switchgear: Schneider Electric

- Pedestrian cranes: Mantis

Transfer main easement (pre-final reinstatement) March 2019 – Courtesy of United Utilities

Commissioning

Schola Green overpumping: Increasing the FTFT from Schola Green WwPS from 350 l/s to 580 l/s required the replacement of the 3 (No.) 96 kW transfer pumps with 4 (No.) 200kW pumps using the existing dry well connections. In order to facilitate this, an equivalent overpumping solution was required to replicate the operation of the existing pumps while the dry well was stripped out and the new 2500kg pumps installed.

Due to the critical nature of the transfer pump operation, the C2V project team worked closely with site operations to devise an optimal solution utilising 3 (No.) submersible pumps, 150kW VSDs and pipework with a tee connection into the existing rising main and a switchover panel that allowed all the existing control and telemetry to be seamlessly transferred onto the overpumping panels without any operational changes to the existing pump control or storm pumping regime.

Aeration blowers from Aerzen Machines – Courtesy of United Utilities

HV upgrades: The Schola Green site is equipped with dual 1650kVA power supplies from discreet network connections for resilience. Due to existing discrimination issues, condition and the addition of a new transfer MCC, the existing HV infrastructure at Schola Green required replacement of both the DNO and site 6.6kV ring main units as well as replacement of existing cabling. Following discussions with the DNO, it was agreed that the existing DNO switchgear could not be safely changed over in a phased manner and that the site mains would need to be fully shut down for 4 days to allow both supplies to be upgraded together.

Utilising 2 (No.) 2 MVA generators to support existing site operations during the shutdown, the project team successfully completed the replacement of both DNO and site ring main units as well as the installation of new inter-tripping panels and upgraded protection equipment.

Rotary drum thickeners and elevated inlet works (August 2019) – Courtesy of United Utilities

Seeding: The Nereda® granulated aerobic sludge process design at Morecambe is unique in that it is provided without a buffer tank to manage the feed flows and batching process – instead, the predictive algorithm constantly assesses the feed flows from Schola Green WwPS and adjusts the treatment ‘recipe’ to suit. In line with the startup protocol for the Nereda® process, a certain volume of granulated sludge was required from donor sites in Holland to allow the process to establish and indigenous granules to develop.

Maintaining the performance of the existing SBC process to achieve site consent during startup was a key consideration and following detailed discussions, it was agreed with Site Operations and Royal HaskoningDHV (RHDHV) that instead of feeding the reactors a gradually increasing proportion of the flow, all incoming flows would be passed through the Nereda® plant and 150m of 600mm diameter recirculation pipework provided across site to return the Nereda® effluent to the existing PSTs and hence through the existing process for full treatment. Following the completion of the Nereda® reactor pattern testing, a total of 375,000 litres of imported seed sludge was pumped into the reactors with the aeration blowers used daily to agitate and aerate the sludge prior to turn of flows.

A further 300,000 litres of sludge was imported during the seeding process under RHDHV direction to help assist the treatment and accelerate the granulation process.

Nereda® Cell 2 in full aeration cycle (August 2019) – Courtesy of United Utilities

MCERTs: The new 600mm diameter pipework arrangement at the elevated inlet works necessitated the certification of the new installation to MCERTs standard prior to turn of flows. In order to achieve this and maintain flow to the existing works, a return loop was installed using a combination of permanent and temporary pipework to allow the new flow meter to be commissioned and certified.

An added complication was the necessity to ensure that pumping to the elevation of the new inlet works (an additional 10m) did not increase the maximum operating pressure in the existing transfer main – to achieve this in the permanent state, the maximum flow would be reduced from 350 l/s to 300 l/s. In the interim, a temporary overpumping solution was installed to draw up to 70 l/s out of the transfer main to ensure the pressure did not increase as flows exceeded 300 l/s.

Inlet screens (August 2019) – Courtesy of United Utilities

Nereda® startup and RDT: Following an intensive period of electrical and mechanical installation, the first flows passed through the Inlet Works and filled the first Nereda® reactor on the 18th April 2019. Utilising the data acquired from the online instruments and on-site sampling, the initial batches and treatment performance were assessed by the commissioning team and the parameters agreed for discharge to the existing works under the Agreement to Operate (ATO) process on the 2nd May 2019.

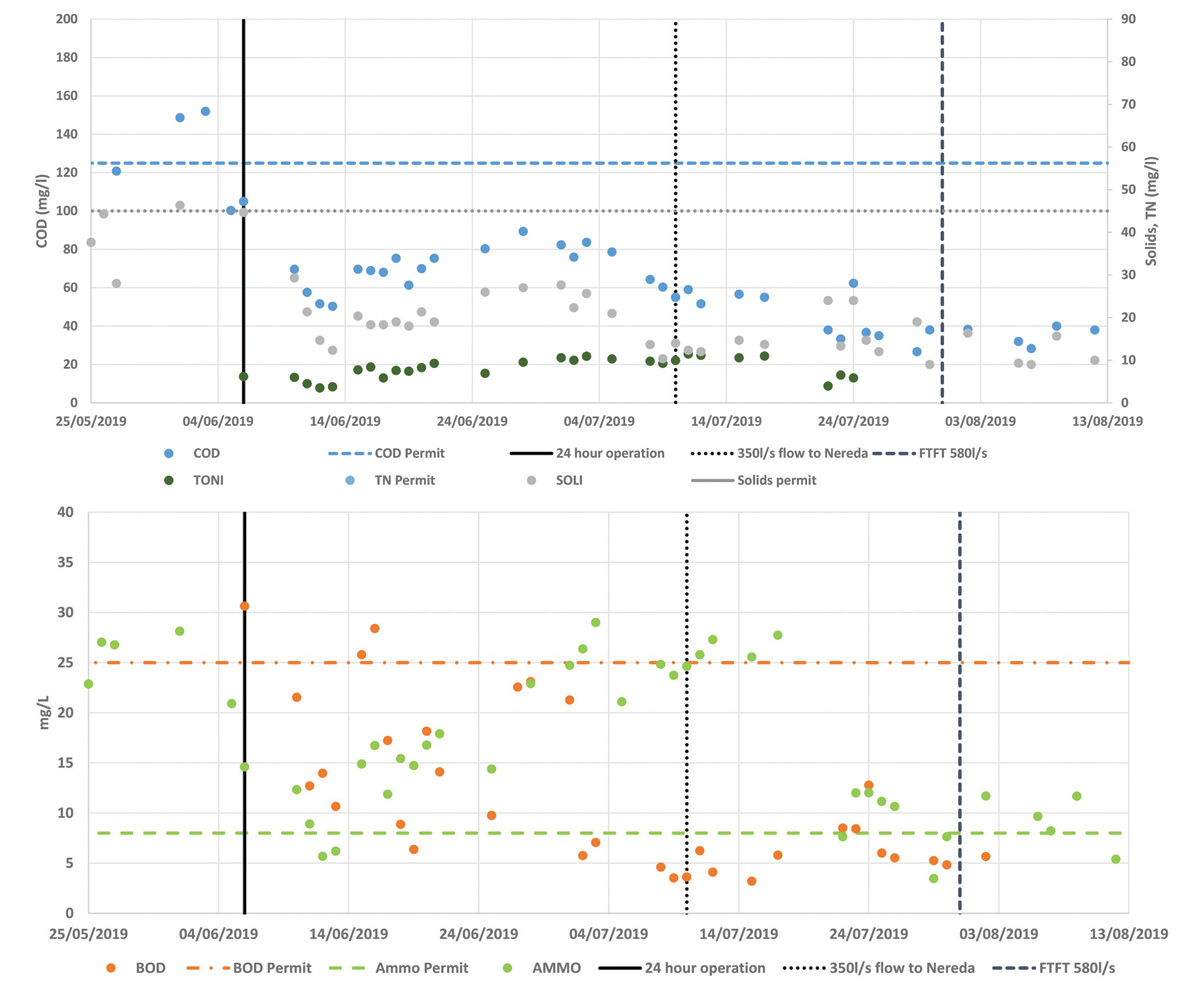

As the process matured over the next few weeks, the existing works saw a substantial improvement in performance due to the reduction in load and once the process data indicated that the site would reliably be within the existing consent parameters (30mg/l BOD, 45mg/l solids) through Nereda® treatment only, the decision was made to divert all flows around the existing plant on 8 July 2019 and the performance has continued to improve with evidence in the sampling that nitrification is now occurring in the reactors, building toward the new total nitrogen consent for March 2020.

The Nereda® sludge is also being drawn off to promote the granulation process. This sludge is thickened in a new rotary drum thickener system and stored in sludge holding tank with pump mixer. The target thickness is 5-6% DS for tankering with 95% filtrate capture.

Nereda® Cell 1 (August 2019) – Courtesy of United Utilities

Storm tanks, UV plant and outfall: The new transfer pumps were commissioned with the supplier using temporary pipework connected to the existing transfer main to prove performance before the new transfer main was commissioned and MCERTs flow meter certified. Once the capacity to deliver 580 l/s had been demonstrated and following completion of SAT testing of the new UV system and commissioning of the Outfall PS, flows were diverted from the existing RGF using the 2 (No.) 300mm diameter actuated eccentric plug control valves in the new RGF bypass chamber directly to the new UV channel, allowing the new FTFT of 580 l/s to be achieved from Schola Green.

Despite the fact that commissioning was being undertaken at the end of July, normally a period of dry weather, there was significant rainfall at the time of increase in flows and both the new FTFT and storm storage capacity were in use immediately, providing immediate environmental benefit to the Morecambe and Heysham receiving waters.

Optimisation and aftercare: The commissioning process now moves onto continued maturation of the process to achieve the new consent in advance of the performance and reliability testing with a soft landing to handing over key elements of site once the integrated operational staff have been fully trained on the new process and equipment and all 2500 telemetry signals have been tested and operational for monitoring by the integrated control centre.

Key performance parameters to be optimised include blower and UV power consumption, RDT polymer consumption sludge thickness etc. Depending on process performance, it may also be possible to bypass the RGF for significant periods of time without impacting on UV performance and with a significant reduction in OPEX.

New UV plant (August 2019) – Courtesy of United Utilities

Progress to date

Schola Green WwPS: Works on site commenced April 2017. As of July 2019 the new South Storage Tank, North Storage Tank and 4 (No.) new transfer pumps have been installed, tested and commissioned and were put into operation on the 31 July 2019 to meet the regulatory compliance date. This coincided with a period prolonged heavy rainfall which meant that the new 24,000m3 of storage and new FTFT capacity of 580 l/s were immediately put into use.

Transfer main: The new 4.5km long 500mm diameter transfer main between Schola Green WwPS and Morecambe WwTW which passes under a railway line, through a caravan park, around Morecambe FC, along highways and agricultural land, crosses the Heysham Link Road as well as numerous existing utilities including wind farm transmission cables was completed and tested and was put into operation on the 31 July 2019.

Railway crossing TBM breakthrough – Courtesy of United Utilities

Morecambe WwTW: Works on site commenced July 2017. Section 1 of the project involved the off-line construction of the new WwTW ready to receive and treat the increased FTFT from Schola Green WwPS. The new inlet works, Nereda® and sludge handling plant were completed to permit flows to pass through the new works to commence process commissioning of the Nereda® on the 18 April 2019, with effluent from the Nereda® returned to the head of the existing works.

(1) Nereda® cells (2) New UV plant and associated MCC kiosk (3) New 1000 l/s final effluent outfall pumping station (4) New rotary drum thickeners and associated storage tank (5) New elevated inlet works (6) Redundant primary settling tanks (7) Redundant final settling tanks (8) Blowers and associated MCC kiosk (part of the Nereda® plant) (9) Existing rapid gravity filters and redundant UV plant (10) Redundant SBCs (secondary biological treatment stage)

Process commissioning of the Nereda® continued to the 4 July when performance met the parameters set to enable effluent to be discharged to the existing RGF and UV Plants bypassing the existing PST/SBC/FST which were turned off. Completion and testing of the new UV and outfall pumping stations in July enabled flows to be turned from Nereda® to the new UV and outfall pumping station on 31 July 2019.

Decommissioning works have now commenced to enable works to Section 2 of the project to commence which involves converting the existing SBC and FST structures into gravity tidal tanks and the demolition of the PSTs to make space for the construction of a pumped tidal storage tank.

Outfall pipe diffusers (August 2018) – Courtesy of United Utilities

Outfall diffusers: Works on site commenced at the end of April 2018 and were completed by the end of August 2018. During this period additional site investigations were undertaken to confirm the extent of the flat spot along the existing marine outfall pipeline identified in the as built documentation. This showed that the first 250m of the pipeline undulated resulting in high spots where air could not be evacuated and would effectively reduce the pipe diameter posing a risk to the required new tidal discharge flow rate of 1000 l/s. To mitigate this risk additional works were planned to install air relief pipework which began in July 2019 and are planned for completion mid-September 2019.

Outfall pipeworks (August 2019) – Courtesy of United Utilities

Outfall pipeline: The existing 600mm diameter land section of the outfall pipeline has been replaced with a new 700m long 800mm diameter pipeline which runs above ground from the new outfall pumping station and then below ground through a biological heritage site and caravan park to the connection point on the existing 800mm diameter marine pipeline located within the caravan park, crossing multiple utilities including two crossings of windfarm transmission cables.

Success in sight

Since the new process stream at Morecambe WwTW was fully commissioned on 31 July 2019, the Nereda® plant has been performing above the project team’s expectations which enabled the start of the second phase of the project: the conversion of the existing PSTs, FSTs and SBCs into tidal storage tanks. It is expected that the conversion will be complete by February 2020.

Morecambe WwTW Nereda® effluent – Daily average spot samples

With one regulatory commitment already achieved (Schola Green Bathing Water driver), the second one (tidal storage system) is on target be achieved ahead of its regulatory date and a capital spend forecast currently under budget, the Morecambe Integrated Strategy Project is on track to be a great success.