Ashbourne STW (2021)

Dusk over the new FSTs at Ashbourne STW - Courtesy of MWHT

Ashbourne Sewage Treatment Works (STW) in Derbyshire serves a population equivalent of 48,259 from both domestic customers and a high trade load, primarily from poultry processing. There has been a works in this location since the 1930s, with existing processes including inlet pumping, 2mm fine screening, grit removal, primary settlement, secondary treatment through an oxidation ditch and final settlement. The drivers for enhancement at the works are a predicted 8% growth in domestic population of over the next 10 years, and quality improvements to meet both the Water Framework Directive (WFD) and Fisheries Directive respectively requiring an increase in treated flow to full treatment from 80 l/s to 175 l/s, and discharge permit changes including ammonia limit reduction to 5 mg/l and a total phosphorus limit of 0.5 mg/l. The existing conventional treatment process would be unable to meet the new permit conditions due in December 2021.

Design solution

The key enhancement is the addition of a new process stream, developed as the lowest TOTEX (capital and whole life operational cost) comprising of:

- Two new primary settlement tanks (PSTs) with a new secondary distribution to split flows between the new (60%) and existing (40%) process streams.

- New 5376m3 activated sludge plant (ASP) operating in enhanced biological phosphorus removal (EBPR) mode with two new final settlement tanks (FST).

- Refurbishment of two existing oxidation ditches to operate in an EBPR double ditch configuration.

- Tertiary treatment to the full flow including a 30m3 ferric sulphate dosing rig and tertiary solids removal plant.

- A new outfall pipeline with a new headwall.

Digital focus

MWH Treatment (MWHT) are committed to using digital processes to drive value throughout project delivery. The project commenced with visual project initiation, an approach which included a full digital survey of the site and utilised drone images to reduce the number of site visits required during design development. The added value continued through the life of the project e.g. digital information was included as part of the online induction process which gives all visitors an overview of the works and ongoing construction activities before arriving on site in addition to establishing standards and checking competencies.

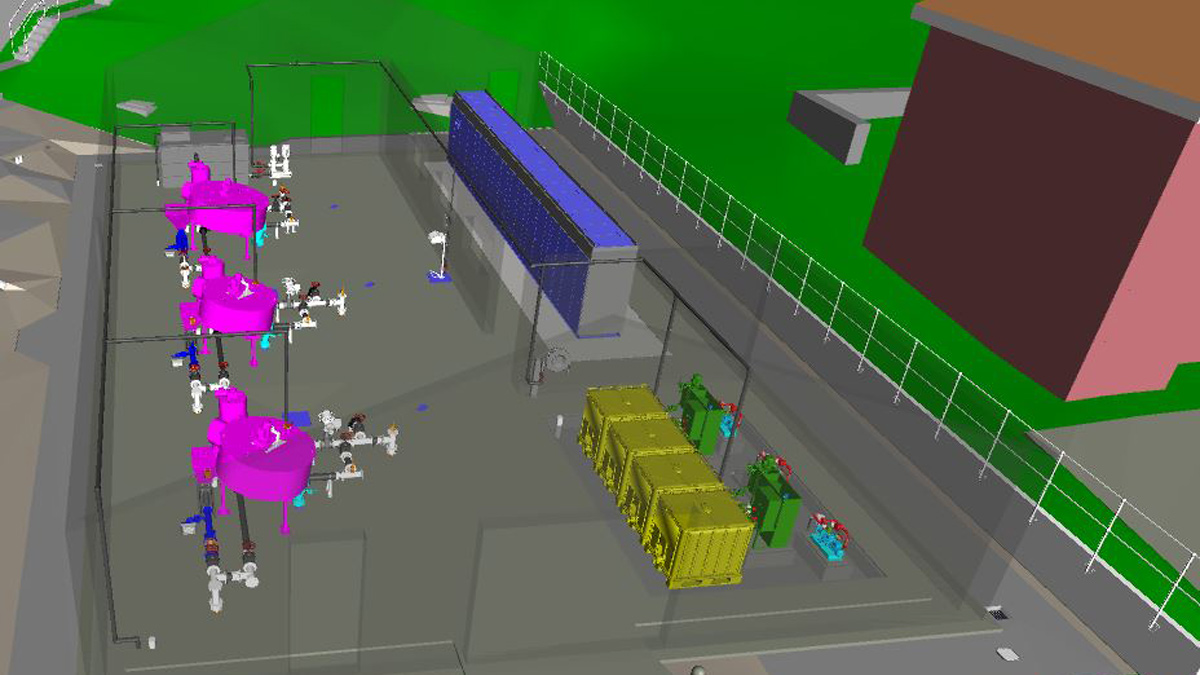

BIM model of Ashbourne STW – Courtesy of MWHT

At the heart of the project is the collaborative working and digital delivery techniques which have utilised tools such as collaboration software (Autodesk BIM360), digital planning tools including virtual reality, augmented reality and 4D planning (Synchro).

Autodesk BIM360 was used for building combined federated models of MWHT internal designed assets with supplier’s model details enabling true collaboration. With Severn Trent, MWHT and supply chain members accessing the model, real time collaborative reviews of the 3D model enabled optimising layouts, removing clashes and constraints. Additionally, the team progressed 4D Synchro digital scenario development and activity rehearsals, delivering programme efficiency.

The models were further used for access lifting maintenance and operability reviews with Client’s operational staff, the virtual reality giving an immersive interactive review that helped resolve ergonomic constraints for issue free handover to Operations.

MWHT completed all major procurement of subcontract packages four months into the project cycle, enabling early engagement and liaison with the varying partners throughout the design phase to incorporate innovative ideas, such as assessing all structures for off-site build potential or modularisation, wherever possible.

Process commissioning (February 2021) – Courtesy of MWHT

Collaborative design

Process design sizing of the new ASP was undertaken by Severn Trent Treatment Process Engineering (TPE) working closely with MWHT’s inhouse design team. Process flexibility to optimise biological treatment was collaboratively developed; plant flexibility provided by using a ‘swing zone’ within the ASP for nitrification and de-nitrification, and further allowing anoxic capacity reduction by turning the front-end mixers off.

This level of control will allow Severn Trent to optimise for efficient operation, saving power across the year and giving rise to major OPEX savings. The use of this technology needed everyone to be bought into the benefits and was peer reviewed by Severn Trent’s Community of Practice.

Ground engineering

Preliminary ground investigation enabled early identification that the ground conditions where the new ASP and FST’s would be sited contained soft alluvium material in parts, unsuitable to carry the 80kPa load from the ASP. This varied ground, had the potential to result in differential settlement of up to 30mm across the 45m long ASP structure. MWHT’s design team opted for a partially piled solution, utilising an existing sandstone shelf under 45% of the base of the structure to minimise the number of piles required for the construction.

ASP and FST construction area – Courtesy of MWHT

Ashbourne STW : Supply chain – key participants

- Client: Severn Trent

- Full design & main contractor: MWH Treatment Ltd

- Civil works – general: Hollywood Civil Engineering

- Civil works – general: Naylors Construction

- FRC: Smithform Ltd

- Piling: Aarsleff Ground Engineering

- Electrical installation: Elsym Installations

- Mechanical installation: Hollywood Mechanical Engineering

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

- MCC and ICA controls: Total Automation & Power

- Kiosk access stairs & platforms: Step on Safety Ltd

- Precast wall units: A-Consult Ltd

- Portal frame building: Saredon Steel Buildings

- Aeration system: Suprafilt

- Sludge thickening: Huber Technology

- Polymer dosing: Richard Alan Engineering

- Pumps: Xylem Water Solutions

- PST/FST bridges & chemical dosing rig: EPS Water

- TSR plant: Eliquo Hydrok Ltd

- RAM pumps: EMS Industries Ltd

Modern methods of construction

The use of off-site construction significantly benefits construction across a number of themes including reduced programme times as off-site manufacture runs in parallel with on-site activity and safer construction with activity in controlled factory environments away from weather impacts. Two design for manufacture and assembly value added solutions from Ashbourne are described below:

Precast PSTs and FSTs: The site required two 12.5m PSTs and two 18.8m diameter FSTs. Utilising the lessons learned on the recent successful adoption of precast post stressed wall units on MWHT’s Earl Shilton ASP project, an early decision was made to proceed with this construction method for Ashbourne’s circular tanks, with proven key supply chain partner A-Consult Ltd chosen.

The precast wall panels were built off-site in a controlled factory environment and simply erected on the base using a mobile crane. Each panel was lifted and placed sequentially until the tank was complete following which tank walls were then threaded with steel tendons circumferentially and post tensioned around the structure. Preformed GRP launders from the scraper bridge manufacturer, EPS provided were simply attached to the units. The precast solution saved 4 weeks per tank over a traditional in situ approach, minimising construction time and on-site risk.

Precast FSTs – Courtesy of MWHT

Pop-up sludge building: The increased sludge production generated by SAS in addition to primary sludges required enhancement of on-site thickening to reduce tankering and minimize OPEX. A new building was required and the team identified an efficiency to additionally include the new polymer dosing skids and the main MCC, negating the need for additional kiosks.

Traditionally this would have required a 22m x 13m conventional clad portal frame construction, requiring on-site assembly with significant durations of working at height to fix steel and the cladding. MWHT share innovations nationally across their business through Process Improvement Teams (PIT) and the Ashbourne team identified a novel DfMA portal frame building solution from supplier Saredon which had been used in the Thames region.

The DfMA portal frame building was delivered in sections with wall and roof structure and cladding units arriving in one piece and ‘unfolding’, before being lifted into position. The process of erecting the building and finishing works to make watertight and secure took less than two weeks, saving at least two weeks over conventional construction and minimizing assembly risks associated with erecting buildings of this type.

Saredon Steel Buildings ‘pop up’ building during installation – Courtesy of MWHT

Efficient project delivery

The team has delivered the first phase of the project by commissioning the ASP within 19 months from site start. Achieving this programme required drive from all parties and a collaborative team from project inception. Commencing with an initial whole team meeting to define objectives, critical success factors and setting the tone, communication was effective through the life of the project. A number of specific actions have helped drive programme out-performance that is contributing to over 10% reduction in project on costs over similar activity delivered in AMP6:

- Programme intensity: Operating multiple work faces across the site, completing many areas in parallel, shortening the critical path and removing the risk of areas of work becoming critical later in the programme.

- Multiple suppliers: Traditionally the civils groundworks would have been subcontracted to a single supplier however the volume and intensity of activity made this a significant programme risk. The package was split into independent work packages which ensured each subcontractors’ resources were not overstretched enabling efficient and safe delivery.

- DfMA opportunities for precast tanks and pop-up buildings were progressed delivering saving on critical and parallel activities.

- Collaborative working: All team members, including the clients commissioning team bought into one overall programme with regular collaborative working review to generate a ‘pull’, earliest finish, programme.

Sludge equipment model – Courtesy of MWHT

Safety innovation – augmented intelligence

Learning lessons from previous best practice helps inform safer and more effective Risk Assessments and Method Statements (RAMS). Augmented Intelligence can be used to review any RAMS produced against a database of similar RAMS, scanning for omissions and similarities to provide a report of correlation, contradiction and omissions. Ashbourne provided the base site for the trial of the first known AI system for RAMS assessment in the Water Industry with delivery partner Intuety. Many of Ashbourne RAMS were used to feed this system, machine learning used to continuously improve the system which has now been deployed, providing additional RAMS production support across MWHT projects in the Severn Trent region.

Community engagement

Leaving a community legacy of a job well done is a core objective, contributing to the communities in which we work. These initiatives align with both Severn Trent and MWHT’s corporate responsibility and staff wellbeing programmes. At Ashbourne, the MWHT site manager reviewed community engagement opportunities during the Covid-19 pandemic and identified an opportunity to support the local Scout group, providing essential first aid equipment that will be used once scouting activity restarts.

Precast PSTs – Courtesy of Hollywood Civil Engineering

March 2021 saw the new ASP (Phase 1) commissioned and it will be a significant success for Severn Trent and MWH Treatment, achieving AMP7 regulatory obligations early and leaving a legacy of high quality, low cost sewage treatment for customers for many years to come.