Walton S101a – First Time Sewerage Connection (2021)

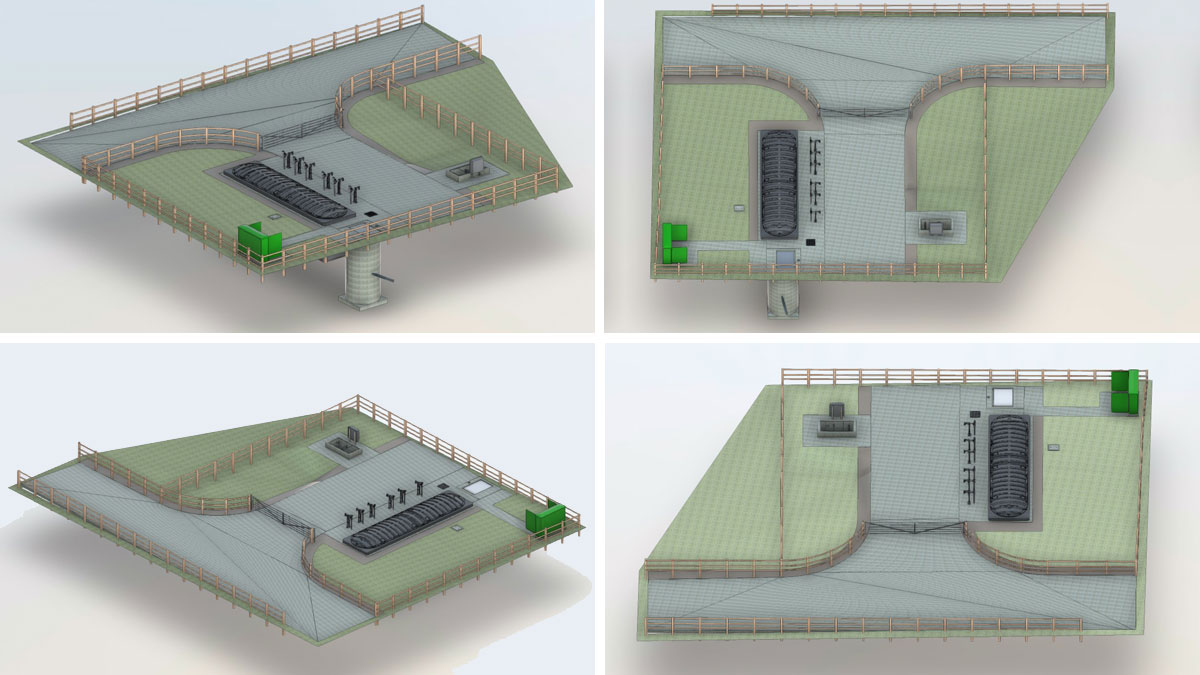

CADsite Services aerial overview of RBC installation - Courtesy of nmcn PLC (now Galliford Try)

The picturesque village of Walton is located within the heart of Warwickshire adjacent to the River Dene. The existing privately owned sewage treatment facility located on the bank of the River Dene was life expired and would often flood, resulting in pollution to the river. An application was made to Severn Trent under Section 101a of the Water Industry Act to provide a first-time sewage connection for all 20 properties in Walton village with a population of approximately 70 people. Due to the remote location of the village, a connection onto the existing Severn Trent sewer network, either gravity sewer or a pumped solution, was not deemed feasible. Therefore, the proposal was for the installation of a new rotating biological contactor (RBC) to replace the existing treatment facility.

Background

Severn Trent engaged with design and built contractor, nmcn PLC (now Galliford Try), to undertake the project as part of the AMP6 Framework. A review between Severn Trent and nmcn PLC identified that the new facility needed to deliver efficient, safe treatment without an adverse impact on the beauty of the area. Installation of a new RBC unit would improve the effluent quality discharged to the watercourse and increase biodiversity in the River Dene. The existing drainage system from private properties to the new facility would also be improved as part of the project.

Existing private treatment facility – Courtesy of nmcn PLC

Process

As part of the feasibility stage an optioneering exercise was undertaken to confirm the best solution for the S101a application. With the closest sewer network approximately 2km away a direct connection was ruled out from a cost and delivery perspective. With a new package treatment plant being the most viable option investigations were undertaken into the types available.

An RBC unit proved the most advantageous as it was able to achieve the required discharge consent without the need for additional tertiary treatment. The sealed until also minimised noise and odour in a sensitive location whilst the final design enabled part of the RBC to be buried reducing visual impact. A KEE Process 1800 RBC unit was finally selected. The advantages it offered in terms of its ability to treat the incoming flows within a small footprint with limited visual impact made it the best option both technically and aesthetically.

The KEE Unit installed at Walton was a self-contained single piece package treatment plant designed to deal with low flows. The RBC supports a bio-film which has microorganism membranes attached to rotating disks. The disks rotate slowly submerging them in the effluent. The rotation of the disks prevents excessive solids building up on the disks and provides aeration, exposing the media to the air. The unit was able to meet the necessary River Dene discharge consent of 40/60/20 (BOD/SS/NH3 mg/l) as stipulated by the Environment Agency.

The new RBC until was located in a new compound site outside of the surrounding flood zone. This required approximately 150m of new gravity sewer to connect the existing drainage network to the new site. The topography of the area was such that an inlet pump station would be required to lift incoming flows into the RBC.

KEE Process RBC 1800 unit delivery to site – Courtsey of nmcn PLC

A separate flow meter chamber was also installed on the outlet of the RBC together with approximately 100m of gravity sewer and a new outfall structure to enable discharge to the River Dene.

Design of the RBC and associated pipework proved a challenge in mitigating visual impact whilst ensuring effective hydraulic performance. River flooding levels were taken into account for effective outfall discharge in conjunction the necessary pipe gradients and fixed RBC inlet/outlet levels. The final outcome provided a partially buried RBC unit to maximise the use of gravity pipework where possible.

The RBC unit required a new access and vehicular tuning head to enable future maintenance operations. Consideration was given to the access being from a very narrow road with restricted visibility. As a result, a new splay was created to following consultation with the local Highways Authority. This included verge clearance and installation of specific road signage and a visibility mirror. The compound turning head was designed to utilise fibre reinforced concrete as a means of reducing construction duration whilst maintaining loading capacity for maintenance vehicles.

The technical aspect of project delivery required interface between civil, structural and mechanical and electrical engineers. This was delivered by nmcn’s in house team with a strong focus on collaboration to ensure all individual requirements were communicated as part of the larger project.

BIM models – Courtesy of nmcn PLC

Walton S101a: Supply chain – key participants

- Principal designer & contractor: nmcn PLC

- RBC unit: KEE Process Ltd

- Sewer lining subcontractor: Danaher & Walsh

- Civils engineering: LCS Groundworks Ltd

- Land agent: Dalcour Maclaren

- Ecology/environmental consultants: RammSanderson Ecology

- Archaeological consultant: Wessex Archaeology

- Control panel & kiosk: CEMA

- Pumps: Xylem Water Solutions

Challenges

Several challenges were faced by the team in ensuring technical excellence whilst satisfying surrounding planning, environment, archaeological and land owner requirements due to the remote location and beauty of the local area. Obtaining planning approval in a picturesque rural location proved particularly challenging. Extensive communications were required with several stakeholders including Archaeological consultants, land agents, utility providers including BT and Western Power, Warwickshire County Council and Environmental consultants.

Significant ecological surveys including a biodiversity assessment were undertaken, including mitigation of impact by planting new flora around the site. Ecological watching briefs were required including fingertip searches and surveys of the River Dene to allow for the headwall and outfall consent with Warwickshire County Council. A detailed planting schedule with whips and hedgerow was implemented post RBC installation to ensure the site blended in with the beauty of the surrounding area.

Archaeological screenings and excavations were undertaken to further understand any archaeological constraints. An initial LiDAR image of the site was reviewed by the county archaeologist which showed potential for medieval settlements.

Archaeological trial holes were undertaken in the site investigation phase with further archaeological watching briefs required for the main phase with medieval pottery and Mesolithic artefacts identified. All recovered artefacts have been distributed to local Warwickshire museums.

Location of the site also provided a challenge for the delivery of the RBC unit and associated plant due to the site’s rural nature. Pre-delivery haulage reviews were undertaken to plan the route and coordinated with local authorities.

The completed Walton site – Courtesy of nmcn PLC

Rehabilitation and first time connections

A majority of the existing private drainage in Walton was constructed from a mixture of vitrified clay pipes (VC) and pitch fibre (PF) which is a fibrous material reinforced with asbestos fibres. Pitch fibre pipes were widely installed between the 60s/70s and are understood to have a lifespan of approximately 40 years. Due to the fibrous nature these pipes tend to delaminate and deform resulting in blockages and poor flow.

As the scheme was an S101a, Severn Trent would be adopting the existing system. To ensure the pipes were to an adoptable standard all private drainage in the village was subject to internal camera survey (CCTV) to determine the condition. Several sections of pipe were identified for repairs which comprised a combination of sewer liner/patch repairs and traditional excavations.

Location of the existing private treatment facility – Courtesy of nmcn PLC

Managing stakeholders

A separate communication strategy was developed for the tight-knit community. Assessment identified a predominantly retired community for whom a lower tech communication strategy was the most effective. This initially comprised letters from Severn Trent informing the residents of the works and their opportunity to connect onto the public sewer network. This was followed by more detailed letters regarding construction activities and impact.

A public exhibition was held using Severn Trent’s mobile customer exhibition vehicle. This was parked in the centre of Walton to form a ‘drop in’ centre where the community could discuss the project and to voice any concerns. The mobile centre displayed various boards, drawings and plans to explain the project. An on-board monitor was utilised to display a BIM model which was considered a great success by our visitors who were able to visualise the proposal through 360°. The exhibition was attended by the project team including the nmcn PLC’s site manager who was specifically selected for being local to the area and able to develop a rapport with the residents.

Customer drop in forum with delivery team and Severn Trent’s ‘Dolly’ van – Courtesy of nmcn PLC

During construction update letters were issued together with local level discussions instigated by the site team. The site was even made safe for local residents to undertake a visit to see progress. As a result, the community supported the construction team displaying real sympathy as they battled through adverse weather in winter 2019.

As the construction drew to a close the delivery team was invited to produce an article for the Parish Council magazine providing an excellent opportunity to share the success across the wider community. A delivery team member attended a Parish Council meeting to appease concerns around vegetation clearance for the new access. At all stages of this project a direct presence was made available for the community to engage with on a more personal level. This resulted in a real support the site team and a genuine interest in our project.

Summary

This project provides an excellent example of the importance of delivering civil engineering projects whilst giving thoughtful consideration to the surrounding community, environment and land. Consultation with all necessary stakeholders enabled the implantation of a as a successful technical solution whilst mitigating impact on the area.