Whitlingham Water Recycling Centre (2021)

New FST and full scraper bridge prior to going into service - Courtesy of @one Alliance

Investment in Whitlingham WRC was identified by Anglian Water to ensure that the site remains resilient for Norwich’s growing population and support the environment of the River Yare; part of the Norfolk Broads. A full review of the existing assets and support to carry out on-site testing to understand the process limitations, identified potential opportunities to optimise specific existing assets through refurbishment or replacement with new, additional process plant in key areas to reduce risk due to the variations in flows and loads, and a need for a further final settlement tank for security of the final treatment phase.

Scope of works

The Whitlingham Water Recycling Centre (WRC) Extension and Resilience Scheme was a £30m investment ultimately delivered for £13m, which will ensure that Anglian Water’s sewerage network continues to remain resilient for the growing catchment of Norwich. The scope of works includes:

- Construction a new 45m diameter final settlement tank with associated returned activated sludge pumps (RAS).

- Replacement inlet screens and compactor systems.

- Modifications to the activated sludge plant (ASP).

Installation of the new FST scraper bridge – Courtesy of @one Alliance

Challenge to be an all-digital site

In February 2019, the entire project team was challenged to be the first in the @one Alliance to deliver Whitlingham as an all-digital scheme; a completely paperless project from design through construction to handover, against the backdrop of a challenge to deliver for 50% reduction in expenditure, and time on site, along with 70% reduction in carbon and 30% on operational budget, against the figures set within the business investment plan.

The team were already using the BIM system for 3D modelling for design and then received this additional challenge and opportunity to develop the model to be used to build the site from – of which they all quickly rose to the challenge.

Despite some initial concerns, such as what and how to get all the build information into and out of the model, how to get WiFi across site, what hardware to use and how to develop, encourage and support a change in behaviour, and ways of working on site; the team recognised the opportunity to work together and learn with one another, in order to build a new system and way of working for AMP7.

Together, the team trialled and implemented new systems, processes, hardware and training throughout the scheme and designed a model that site could use and incorporated the supply chain partners requirements. There was a continual loop of trialling, feedback and changes made to adapt to the varying needs of all and throughout all of this, the scheme was still moving forward and progressing well.

New FST into service – Courtesy of @one Alliance

Assembly/undertaking

Fully integrated team

Before commencing on site, a significant amount of work was carried out up-front to review and understand the site. The project team held a collaboration meeting in July 2018, pre-DM2 stage (as soon as the scope of the work was clear) with all the subcontractors and key suppliers. From this point, these key stakeholders were brought into the project and understood what was required. They became part of the project team with a ‘best for project’ mentality and were involved in completing the detailed design by attending design review meetings and determining and reviewing the programmes every 6-8 weeks. Anglian Water operational colleagues were also engaged and brought into the project early on as key members of the project team and were engaged in design reviews as well as programme updates.

Bringing all the key stakeholders on board through the early design stages enabled everyone to have input into the project. The range of experience and knowledge from within the integrated team supported changes in the design from re-use of existing assets and materials, to using different construction techniques and identifying opportunities to reduce risks on health and safety, as well as driving cost and programme savings.

Design

The @one Alliance team commenced the scheme using the 3D modelling functionality on BIM as a basis for a model, rather than using CAD. Working with the key suppliers and key contractors, this model was developed to enable the design to be completed and used to review with the end user for operability.

Use of standard products, solutions to minimise time on site and reduce carbon, were focused on in developing the solution. Extensive sampling was carried out to establish how the site was currently operating, looking at optimisation and re-use where possible. This drove the solution forward, providing additional air on the existing ASP plant rather than extending with new assets. Redundant filter beds were removed with the aggregate stockpiled and graded for re-use as backfill and hardcore for the new final settlement tank, which was designed in such a way as to enable effluent to travel to and from it under gravity; removing the need for a large pumping station system with its associated energy and carbon costs.

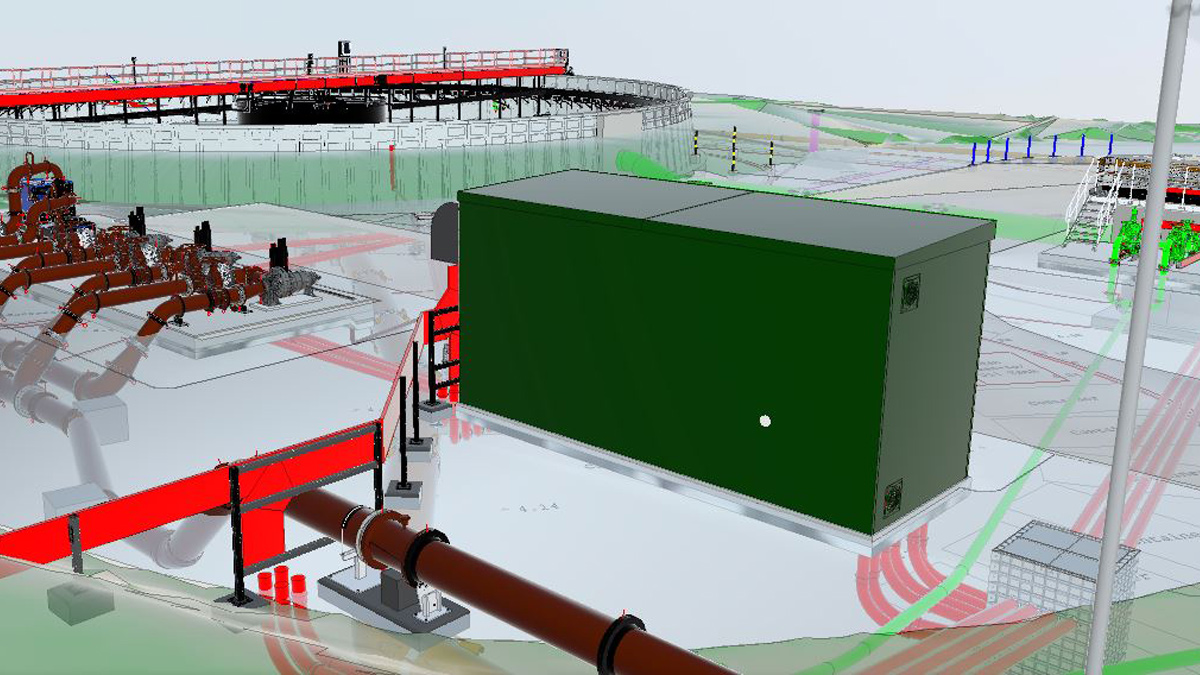

3D BIM model of the MCC kiosk, FST scraper bridge and new wash water pumping station – Courtesy of @one Alliance

Developing the model for construction however required further learning and development of the model. Information normally indicated on a drawing, needed to be included within the attributes of the model, in a way which can be easily located and interpreted by the team on site, whether that be the site manager or a steel fixer for example. Working alongside the team on site, this was developed and continually revised based on learning from their experience and knowledge.

Collaborative workshops, regular programme planning and an openness across the whole supply chain to listen and learn during development and use of the model for use on site including developing training and support methods and materials, fostered a proactive and positive attitude on this project.

Extension

The team started on site in August 2019, quickly changing their plans and having to adapt following the significant impact of the COVID-19 pandemic. The team had planned to have about 40 people on site at the end of March, but this was then reduced to 15 to comply with the strict social distancing guidelines.

At this point, the focus of the programme had to change. The supply chain were fully involved in discussions, and resources were altered to keep the project moving in the face of changing guidelines and material shortages, whilst putting in place a COVID-19 secure environment and maintaining the team’s wellbeing. The focus was firmly on getting the project delivered safely and looking after one another in what was a difficult period.

Whitlingham WRC: Supply chain – key participants

- Project delivery: @one Alliance

- Principal contractor: MMB

- Civil works & trial holes: Bell Formwork & Civil Engineering

- Removal of redundant filter beds: Armac Group

- Piling installation: Ivor King The Piling People

- FST precast wall units: Naylor Concrete

- Mechanical contractor: Waveney Pumps

- Electrical contractor: Glasswell & Last

- Compactors: Huber Technology

- Inlet screens: Jacopa

- Scraper bridge: EPS Water

- MCCs: TES

Construction of the MCC kiosk, FST scraper bridge and new wash water pumping station – Courtesy of @one Alliance

BIM system for 3D modelling

The use of 3D BIM modelling for design development has been used to within @one Alliance on previous schemes. The Whitlingham scheme took this early learning, and explored and challenged the system’s potential for use in construction, beyond a design tool. The ability to develop the full solution in 3D enables all parties to visualise and input into the solution, including the end user, to understand and challenge operability and maintainability aspects.

The system enables all parties to see, comment on and make changes in real time; reduces time frames for decision making and moving the project forward promptly. This was a clear benefit went to site as it significantly reduced communication time and also enabled the model to reflect what was actually being found and built as it progressed.

Developing the tool to use it to build from pushed the system and team’s capability, confidence and culture on site. The supply chain worked alongside the @one Alliance to trial what and how the model developed to provide the build information including dedicated personnel on site to support and train as well as develop processes and systems. This was key to support the cultural change of working from a model rather than traditional 2D drawings. No issue or concern was too small. Learning and development was recorded to support the strategy for using this tool in AMP7 and beyond.

Over the period of construction, the benefits became clear as a communication tool and a system for capturing real time issues and solutions for both sites based on office-based staff to contribute to. The model itself is reflective of the as-built situation, and is available for Anglian Water and the operations team to use for future schemes.

New inlet cofferdam and compactors – Courtesy of @one Alliance

Conclusion

The line of communication between all teams involved was key, and together they created an open and honest culture. Regular production and ‘look ahead’ meetings were held, which involved all relevant stakeholders and were extremely useful; enabling people to contribute at the most appropriate time, understand the detail of what was happening on site and deal with any technical and behavioural issues as they came up.

There has been a massive behavioural shift required to deliver this project, from the beginning through to the end, digitally and changing the digital operating manual (DOM).

Despite of the size of this project, the vast number of stakeholders and the significant challenges faced with the digital trial and the impact of the COVID-19 pandemic, the scheme has been successfully handed over. It provided circa 1.5 miles of trenching at various depths and widths, 63 identified services using existing surveys with 146 encountered and safely negotiated with no strikes.