Keadby Terminal Assisted Outfall Pumping Station (2022)

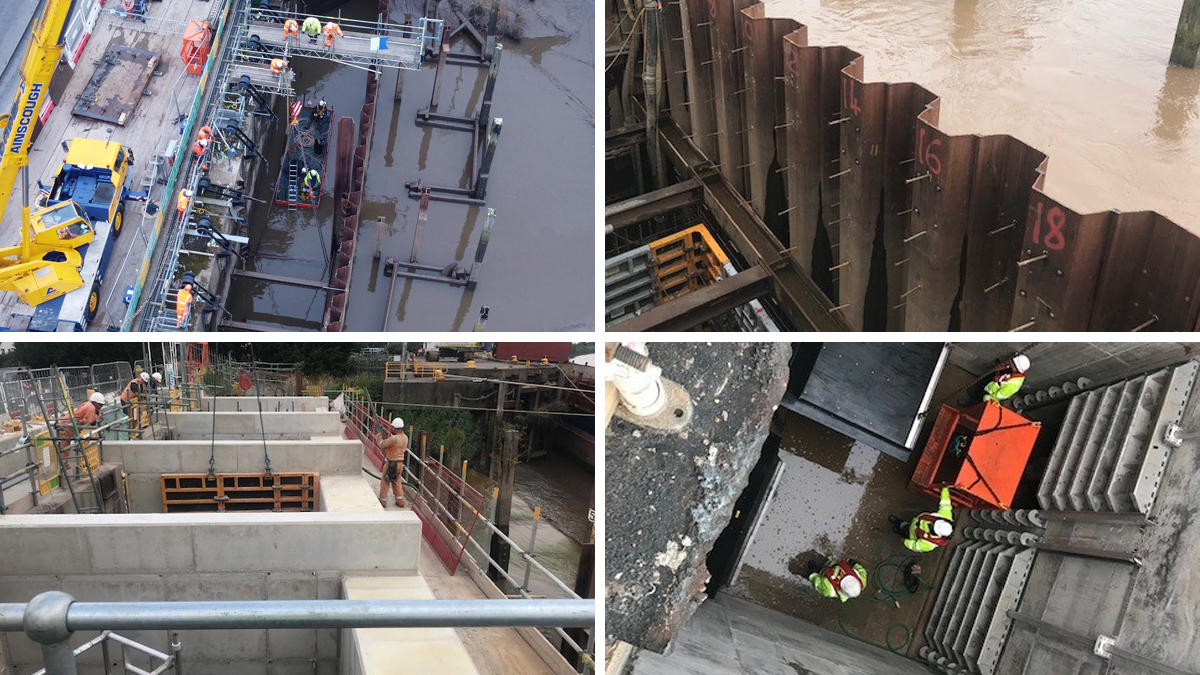

Keadby Pumping Station - Courtesy of Galliford Try

Keadby Terminal Assisted Outfall (TAO) Pumping Station is at the end of an intricate system of rivers and pumping stations within the low-lying Isle of Axholme catchment in Lincolnshire. It was originally built in the 1940s to discharge water from three parallel channels known as the Three Rivers, into the River Trent during high tides. The Three Rivers service a catchment of some 37,000 hectares. The station is over 80 years old and has reached the end of its working life. The old pumps and associated equipment were unreliable, inefficient, and costly to maintain. The Environment Agency worked in partnership with Local Authorities and Internal Drainage Boards to consider options for the renewal of Keadby Pumping Station and how water in the wider Isle of Axholme is managed.

Scope

The 3-year project will see the renewal of the Keadby Pumping Station to provide a resilient, modern flood defence asset delivering the following improvements:

- Replacement of existing diesel pumps with new fish-friendly electric pumps.

- Provision of a new high voltage grid connection and standby generator to bring a resilient electricity connection to the site.

- Replacement of all mechanical, electrical and control equipment.

- Construction of a new outfall structure to discharge to the River Trent.

- Refurbishment of the pumping station building and grounds incorporating improved operational and welfare facilities.

The pumping station remained operational during the works and could be operated as and when required during flood incidents and for water level management across the Isle of Axholme.

Pumping station under construction – Courtesy of Galliford Try

In addition to the requirement for improved resilience at the station, there were two further key drivers to the project’s development. The existing site had an exemption to the Eel Regulations 2009, but any changes to the station would require it to be made fully compliant. The project was also required to demonstrate a carbon saving and contribute towards the EA’s carbon reduction and net zero targets.

The key component of the project has always been the replacement of the old diesel engine pumps with new electric pumps. Six vertically mounted, fish-friendly, electric, axial flow pumps were designed for the site and supplied from the Netherlands by Aquatic Control Engineering (ACE).

The pumps have been specifically designed to operate in new, core-drilled pump chambers that have been cut into the existing pumping station following the removal of the old diesel engines.

Specially fabricated ‘formed suction intakes’ direct flows from the forebay to the pumps themselves to ensure that suitable flow is presented to the pumps without causing rapid changes in pressure or velocities that would injure fish and eels.

Pumping station under construction – Courtesy of Galliford Try

Key aspects

In April 2019, the EA and its delivery partners GBV JV, a joint venture comprising Galliford Try and Binnies, began the construction phase of a £35m project to renew the pumping station and ensure the ongoing reliable operation of the site for years to come.

Keadby Pumping Station falls within the Isle of Axholme (IoA) Flood and Coastal Risk Management (FCRM) Strategy Area. It is the final link in a complex network of managed drainage and pumping systems. The fundamental conclusion of the IoA FCRM Strategy was that the ongoing provision of a reliable pumping regime at Keadby was essential to protect over 15,000 homes from flooding.

In developing the solution, the project team undertook an intensive period of flow modelling and design development in order to establish the best and most cost-effective way of meeting this strategic requirement. The team worked with the EA’s delivery supply chain (Arcadis, Capita and GBV JV) along with specialist equipment suppliers to evaluate potential solutions ranging from a new pumping station to a ‘make-do and mend’ approach. A major asset renewal solution was developed as the preferred option. This retained the main existing structure, whilst constructing new outfall and inlet and replacing all the mechanical and electrical equipment at the site.

Keadby Pumping Station: Supply chain – key participants

- Design & build contractor: GBV JV (Galliford Try and Binnies)

- Client technical advisors: KGAL Consulting Engineers Ltd

- Commercial management: Arcadis

- NEC ECC site supervisor: Capita

- NEC ECC project manager: Turner & Townsend

- Design, supply & installation of pumps: Aquatic Control Engineering (ACE)

- Electric pumps/motors/drives: Pentair (supplied by ACE)

- Outfall construction: CPC Civils Ltd

- Mechanical installation: Alpha Plus Ltd

- Interlocking steel sheet piling: Keltbray Ltd

- Diving: Red 7 Inshore Diving

- MCC: Blackburn Starling Ltd

- Penstocks & flap valves: Glenfield Invicta

- Knife gate valves: EBRO Valves Ltd

- Generator: Yorpower Limited

- Transformers: Wilson Power Solutions Ltd

- HV switchgear: Midlands Power Networks Ltd

- Concrete: Ever Readymix Concrete Ltd

Pumping station under construction – Courtesy of Galliford Try

Construction progress

To replace diesel engines with electric motors has meant that a new high voltage (HV) grid connection was required. Within the relatively rural setting of North Lincolnshire, this in itself, was no simple matter. Throughout the design and construction phases the project team worked with the local district network operator to put in place 9km of new HV grid power supply. This meant drilling under three main rivers and a major passenger and freight railway line, along with cable laying through towns and highways to connect the station to the grid. Replacement of pumps 1-6 is now complete and these pumps are in active service providing the full station capacity. This major component of the project was completed in June 2020 with the energisation of the pumping station’s new HV switchgear, transformer, and motor control centre (MCC), all of which sat on a newly constructed platform on the banks of the Three Rivers.

On-site control and automation system commissioning is ongoing. Building refurbishment works are underway and a new inlet walkway bridge is in place. New roofing and windows have been installed and the new welfare facilities are substantially complete. External and internal concrete repairs and re-painting is ongoing. A new boundary wall and public footway has been constructed on Station Road alongside the pumping station.

The next steps

The final component to the project is the construction of a new outfall structure to discharge into the River Trent. The first phase of the work has been to complete new piling across the old outfall, whilst leaving a flow path for the continued operation of the pumping station during construction. Phase 2 works on the outfall commenced early 2021 to complete the outfall construction involving a new concrete headwall and outfall chambers and will continue to mid-2022.

New electric pump replacement (pump house) – Courtesy of Galliford Try

Works are ongoing to commission SCADA and automation systems. Building and site refurbishment works continue and all internal and external works will be complete by late 2022. Throughout the delivery, the team worked closely with the operational teams to dovetail the construction works with the ongoing operation of a live site, ensuring that flood risk and water levels are actively managed is a testament to all involved that despite record breaking rainfall, catchment flows, and water levels were kept in check.