Don Regulators (2023)

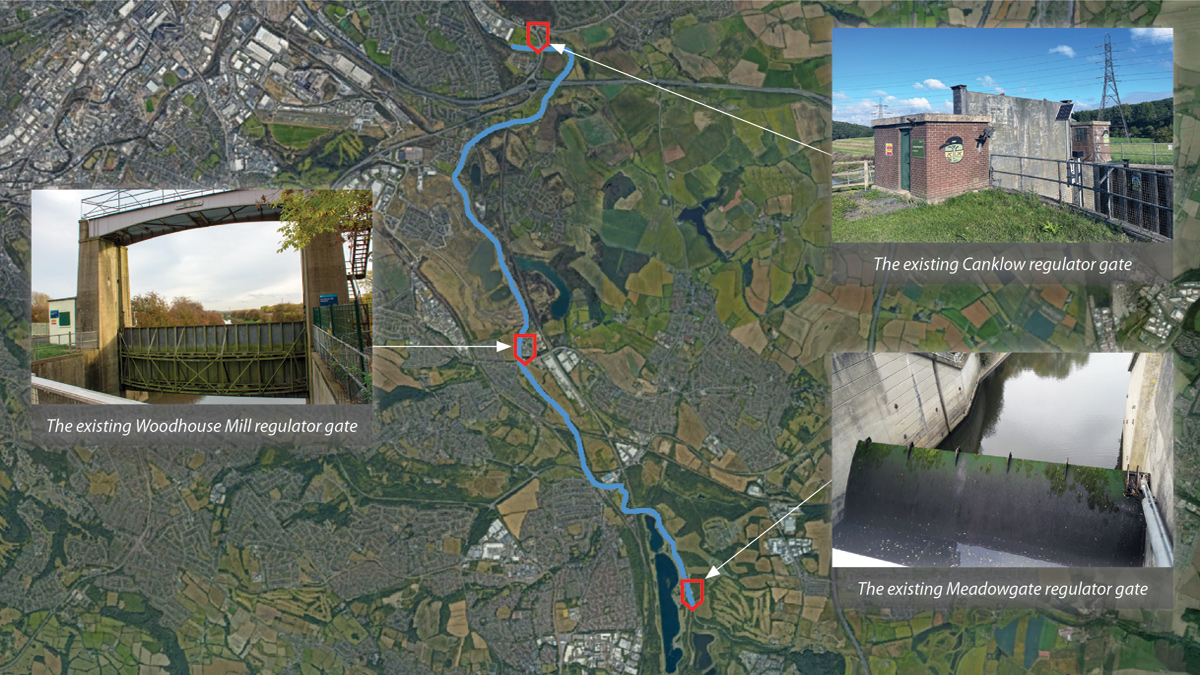

Figure 1: Google Maps - Location of sites - Courtesy of JBA-Bentley

The Don Regulators comprise three strategically important regulator gates on the River Rother that are owned, operated and maintained by the Environment Agency (EA). The purpose of the regulators is to reduce the risk of flooding to settlements within the Don catchment, by attenuating flows in the River Rother. JBA-Bentley, in a joint venture relationship, are working on the replacement of the three regulators, each being at a different stage of design or construction. Figure 1 illustrates the locations of the three sites.

Canklow

The Canklow Regulator is the furthest downstream of the three Regulators, approximately 3.5km upstream from the confluence of the River Rother and the River Don at Rotherham. It is located approximately 50m downstream of the A630 Rotherway near junction 33 of the M1. The existing structure, consists of a single electrically powered vertical lifting sluice gate operated by an electric wire rope hoist, comprising drive motor gearbox assembly and cross shaft with integral rope drums and support bearings. To improve resilience and the operation and maintenance of the asset, JBA-Bentley were required to provide a new guillotine gate and associated MEICA and civils infrastructure.

The Canklow Regulator is usually the first of the three gates to operate and is activated when trigger levels are reached elsewhere within the catchment. Operating the regulators on the Rother during a significant flood event allows the flood peak on the river to be delayed until the peak on the River Don has passed Rotherham and prevents flooding from the Don. Lowering the gate at Canklow can hold back over 1.5 Mm3 of flood water across seven washlands.

The existing Canklow regulator gate – Courtesy of JBA-Bentley

Canklow is currently in the detailed design phase of works. Alongside the gate design some additional civil engineering works are required. This includes some remedial works to the existing sheet piled channel walls including new anchors, a new crane pad to be utilised during construction and to facilitate future gate maintenance as well as the substructure for the new motor control centre (MCC). One of the key constraints of the site are high voltage overheads; therefore, the crane pad location and the siting of the EA’s compound with MCC had to carefully considered.

To assist in undertaking the design and developing the business case for the project, 3D survey was undertaken to create a 3D Matterport tour of the site. It allows the user to quickly navigate around the site and view all the infrastructure remotely. This proved particularly useful during the pandemic when restrictions were in place and site visits were limited.

Woodhouse Mill

The Woodhouse Mill Regulator is located on the Rother between Canklow and Meadowgate, upstream of the B6200 Retford Road. It retains water using a single electrically powered vertical lifting gate. It is operated by an electric wire rope hoist, comprising a central drive motor and gearbox assembly and half shafts, with spur and pinion driven, counterweight assisted, rope drums and support bearings. The proposal at this site is to decommission the current regulator and replace this with a passive solution, such as a baffle or orifice plate which spans the width of the channel, to further utilise some of the upstream storage in the washlands. JBA-Bentley are currently undertaking modelling of options for Woodhouse Mill regulator to inform the next phase of the project and the viability of the proposed solution.

The existing Woodhouse Mill regulator gate – Courtesy of JBA-Bentley

Meadowgate

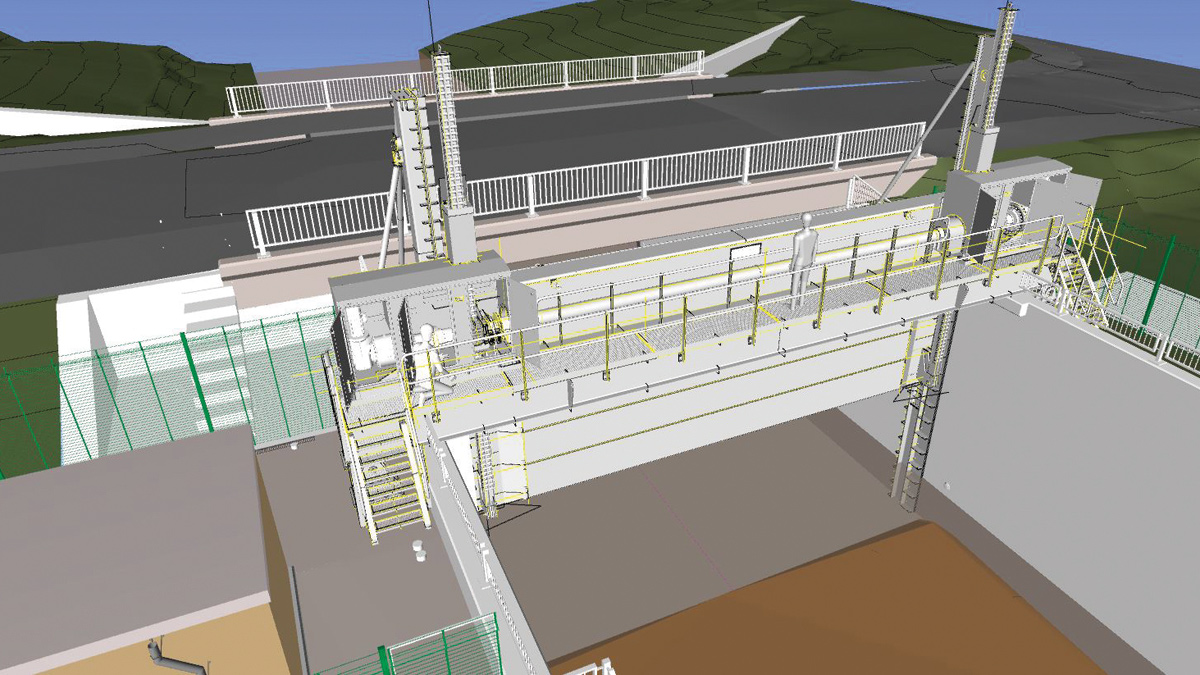

The Meadowgate Regulator is located within the Rother Valley Country Park. The existing regulator consisted of a single fish belly bottom hinged tilting gate, operated by a single electrically powered hydraulic ram. As per Canklow, the new gate will be a top-down vertical control gate improving resilience of the structure; as per the model above.

When the new gate is lowered, water levels in the Rother rise and begin to spill into the washlands that are located within the Rother Valley Country Park, which can retain approximately 1.5 Mm3.

Temporary set up

The civils elements of the scheme have included demolishing the existing buildings and installing new control building. To ensure the gate remained operational during this time a temporary control centre was established during the early part of the scheme; once the gate has been commissioned this will be removed from site.

River Don Regulators: Supply chain – key participants

- Project delivery: JBA-Bentley JV

- JBA Consulting

- JN Bentley

- Principal designer: Callsafe Services Ltd

- Gate design: Aquatic Control Engineering

- Electrical Installations: IMAC Ltd

- Building design: JP Chick & Partners

- Building design: Peter Wells Architects

- Supporting ECC Supervisor with new gate & associated equipment: KGAL Consulting Engineers Ltd

- Precast fish pass tiles: Craven Concrete Ltd

- In situ concrete works : Bells Construction Ltd

- Metalwork fabrications: Fabtek

- Green roof: ABG Geosynthetics Ltd

Model of the new Meadowgate regulator – Courtesy of JBA-Bentley

HAZOP

Working closely with the Environment Agency’s Operational and Maintenance teams the gate design and associated infrastructure has been developed to ensure it allows safe access and operation; a Hazard & Operational Study (HAZOP) was undertaken during the early design stages to ensure all requirements were included.

Full channel fish pass

By removing the bottom hinged tilting gate, there was an opportunity to improve fish passage on the River Rother. Currently, there is a stilling basin immediately downstream of the gate approximately 40m in length, 12m wide and up to 3m deep at the upstream end.

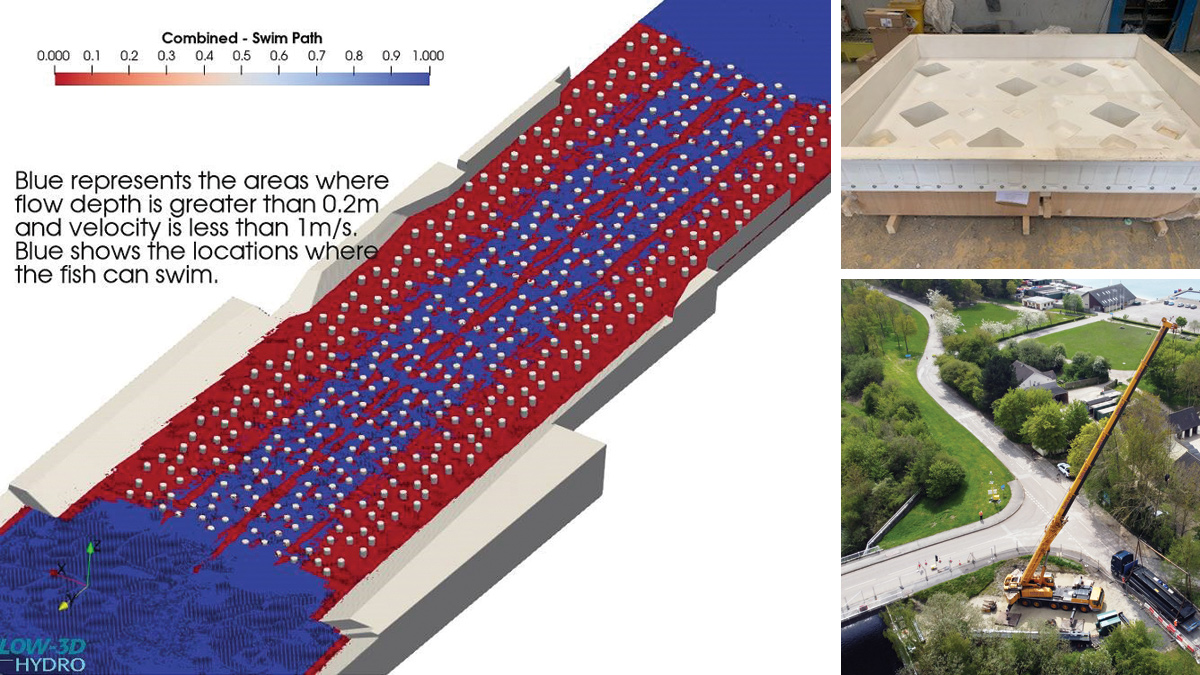

Through design development a unique full channel fish pass has been developed which removes the stilling basin by infilling to grade out the bed levels before installing reinforced concrete fish tiles with upstands of varying heights.

Computational fluid dynamics (CFD) modelling of fish pass

Due to the engineered nature of the channel in this location and the operation of the gate, the fish pass is required to withstand high velocity flows up to 8m/s during extreme events. This proved challenging to the more traditional fish pass construction leading to a heavily engineered solution.

(left) Screenshot of fish pass model – Courtesy of JBA-Bentley, (top right) fish tile mould – Courtesy of Craven Concrete Ltd, and (bottom right) the Meadowgate site – Courtesy of JBA-Bentley

To refine the design and prove passability for a range of species, the proposed arrangement was modelled using CFD. This allowed the upstand heights to be adjusted to provide the optimum depth and velocities through the range of design flows.

Fish pass tiles

Once the height and arrangement of the upstands was agreed with the Environment Agency’s National Fish Pass Panel, the structural design of the fish pass tiles began. Each tile measures 2.5m x 2.0m and weigh 4 tonnes; therefore, the design not only had to withstand hydrodynamic forces but also the lifting requirements for construction. In total, 80 fish pass tiles will be manufactured and placed into the channel, within a dry working area.

Precast fish pass tiles – Courtesy of Craven Concrete Ltd

Temporary works consideration

To allow the fish pass to be installed within a dry area of channel, the full river channel needs to be dewatered. This will be achieved by installing an upstream dam and fluming the flow through the working area. The decision to install precast units reduces the risks of in-channel pours and to reduce programme duration for the in-channel works.

Summary

The replacement Don Regulators will protect Rotherham and the surrounding area from flooding, improve resilience, and ensure the gates can be operated as required both now and as we see the effects of climate change.

Meadowgate site - Courtesy of JBA-Bentley