Audley & Alsager WwTWs (2022)

Final commissioning of key assets - Courtesy of United Utilities

United Utilities, through two major capital projects, is investing over £25m at Audley and Alsager Wastewater Treatment Works (WwTWs), between 2020 and 2025. This is to meet new regulatory permits under the Environment Agency’s Water Industry National Environment Programme (WINEP). Audley and Alsager WwTWs are located in East Cheshire and serve a population of 9,000 and 12,000 respectively. Prior to the capital projects, Audley WwTW consisted of an inlet works, primary settlement tanks, trickling filters, humus tanks, storm tanks and sludge tanks. Alsager WwTW, although similarly equipped, also benefited from chemical dosing and tertiary treatment in the form of continuous operating upward sand filters (COUFs). Investment was required at both Audley and Alsager WwTWs to ensure each site could meet its new tighter permit conditions.

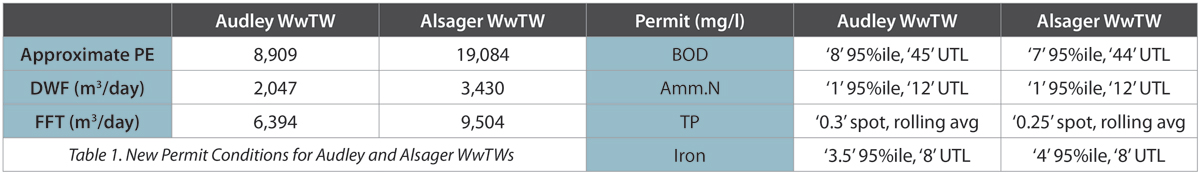

Revised permit limits

The new permit date for Audley WwTW new permit date was 31 December 2021 and for Alsager WwTW is 31 December 2022. Each site’s revised permit limits are summarised in the table below.

Courtesy of United Utilities

To achieve the tighter permit limits at Audley WwTW, chemical dosing was introduced along with the installation of an additional humus tank, new sludge storage, moving bed biofilm reactor (MBBR) and tertiary pile cloth filters (TPCFs).

To achieve the tighter permit limits at Alsager WwTW, upgrades have been made to the inlet works, additional storm and sludge storage capacity has been provided along with enhanced chemical dosing, an MBBR and tertiary cloth filters.

The scope of works also includes decommissioning the site’s existing COUFs, which will be considered for re-use elsewhere within the United Utilities.

Undertakings

Both capital projects were awarded to C2V+, one of United Utilities Construction Delivery Partners (CDPs) as part of the Asset Maintenance Programme 7 (AMP7) under a Design and Build ‘New Engineering Contract’ (NEC3) form of contract. Contract Completion at Audley is currently forecast in February 2023. All construction work is complete and the project is preparing for a series of completion tests between December 2022 and January 2023. Contract completion at Alsager WwTW will be April 2023, with a majority of the construction works nearing completion and commissioning of the new plant well underway. This site will also have to pass a series of completion tests between December 2022 and January 2023.

Audley & Alsager STWs: Supply chain – key participants

AUDLEY WwTW

- Main contractor: C2V+ (VolkerStevin Jacobs JV)

- MBBR: FLI Water

- Tertiary treatment: Evergreen Water Solutions Ltd

- Electrical installation: Eric Wright Water

- Sludge & MBBR tanks: Balmoral Tanks

- Washwater package: Grundfos Pumps

- MCCs & kiosks: Lloyd Morris Electrical Ltd

- Chemical dosing plant: Northern Pump Suppliers

- Half bridge scraper: Tuke & Bell

- System integrators: Tata Consultancy Services

ALSAGER WwTW

- Main contractor: C2V+ (VolkerStevin Jacobs JV)

- Civil engineering: LCS Civil Engineering Ltd

- MBBR: FLI Water

- Tertiary treatment: Evergreen Water Solutions Ltd

- MBBR tanks: Balmoral Tanks

- MCC & kiosks: Lloyd Morris Electrical Ltd

- Chemical dosing package: Northern Pump Suppliers

- System integrators: Tata Consultancy Services

Seeding the Alsager tanks – Courtesy of United Utilities

Optioneering the solution

The design teams produced an optioneering report and design solution recommendation for each capital project. To complete the report, the first stage involved an extensive review of all of the relevant data, drawings and available asset surveys was undertaken. The process design teams then used modelling software to identify a number of technical solutions, primarily focussed on meeting the project’s performance objectives and end-user requirements. Each solution was assigned a suitability rating, based on a series of determinants, including CAPEX, OPEX and whole life costs.

Opportunities were also taken into account. These looked at reductions in both site footprints and construction activities such as piling, along with material usage. Re-use of process units and offline construction were also considered and captured as programme efficiencies.

The case for MBBRs

MBBR technology had not previously been used within United Utilities and so its inclusion as part of the design solutions for Audley and Alsager WwTWs is regarded as a pioneering approach.

In order to thoroughly assess its risks and mitigations, the proposed MBBRs were assessed against a newly formed Technical Approval Matrix (TAM). This novel business process was developed by United Utilities in AMP7 to brainstorm, analyse, document and mitigate the risks associated with new technology, enabling approval of its use at Senior Management level. To support the use of MBBR technology, reference case study sites were identified. Data from the sites was collated and analysed and interviews with other UK operators were undertaken collaboratively with the CDP. This led to the development of a series of risk criteria which were used to populate the TAM, allowing for each risk to be ranked and mitigated, where possible. The risk criteria included micro-plastics degradation, cold weather issues, start-up risks and direct coagulant dosing onto the media. The final TAM, when fully developed, was taken to United Utilities’ Technical Approval Board (TAB) and approval for the first use of MBBR technology within the company, was granted.

The optioneering process concluded that the preferred option for both Audley and Alsager WwTW’s was to move forward with the MBBR process followed by tertiary solids removal in the form of tertiary pile cloth filters from Evergreen Water Solutions Ltd.

Final commissioning of key assets – Courtesy of United Utilities

MBBR basis of design

To achieve low effluent ammonia levels and cope with varying ammonia feed loads, two MBBR tanks in partial series were required. The original design intention was that the first tank would do the bulk of the nitrification and the second tank would polish the effluent. In practice, however, the reactors operate in partial series with 80% of the inlet flow fed to the first reactor and 20% of the inlet flow fed to the second reactor. This means that during variable load (first flush peaks or low loads), the biomass can adapt more effectively. The MBBR design was based on the following criteria:

- Maximum applied ammonia rate to the system will be 0.25 g N/m2 media/day.

- Two tanks in series, where the total media volume could fit in one tank. This would allow one tank to be out of service and the transfer of its media to the other tank.

- Maximum design fill for the in-service tank to be 50% with the option to increase this to 65% if needed for process contingency.

- Minimum air rate of 5 (Nm3/hr)/m2 of tank area for mixing.

Construction: Audley WwTW

The site construction took place through 2020 and 2021 with short shutdowns of the existing plant to allow process connections.

The new humus tank and de-sludge system along with the new MBBR feed pumping station were all constructed using concrete. The MBBR process is housed in glass coated steel tanks. The inlet to the MBBR consists of a glass reinforced plastic (GRP) splitter tank which also includes a unique design for secondary ferric dosing, mixing and flocculation.

The new tertiary pile cloth filters are gravity fed from the outlet of the MBBR and then flow under gravity to the existing outlet. The TPCF backwash and the new humus tank de-sludge is returned to the head of the works via a new pumping station.

Commissioning: Audley WwTW

Extensive commissioning was required ahead of the 31 December 2021 regulatory date to ensure the new plant and processes were fully embedded.

In order to safeguard meeting the regulatory deadline, an assessment was made of the elements of process commissioning that could be advanced using temporary measures. Critical to the success of the project was the use of temporary blowers and feed pumps to start the seeding of the MBBRs ahead of programme.

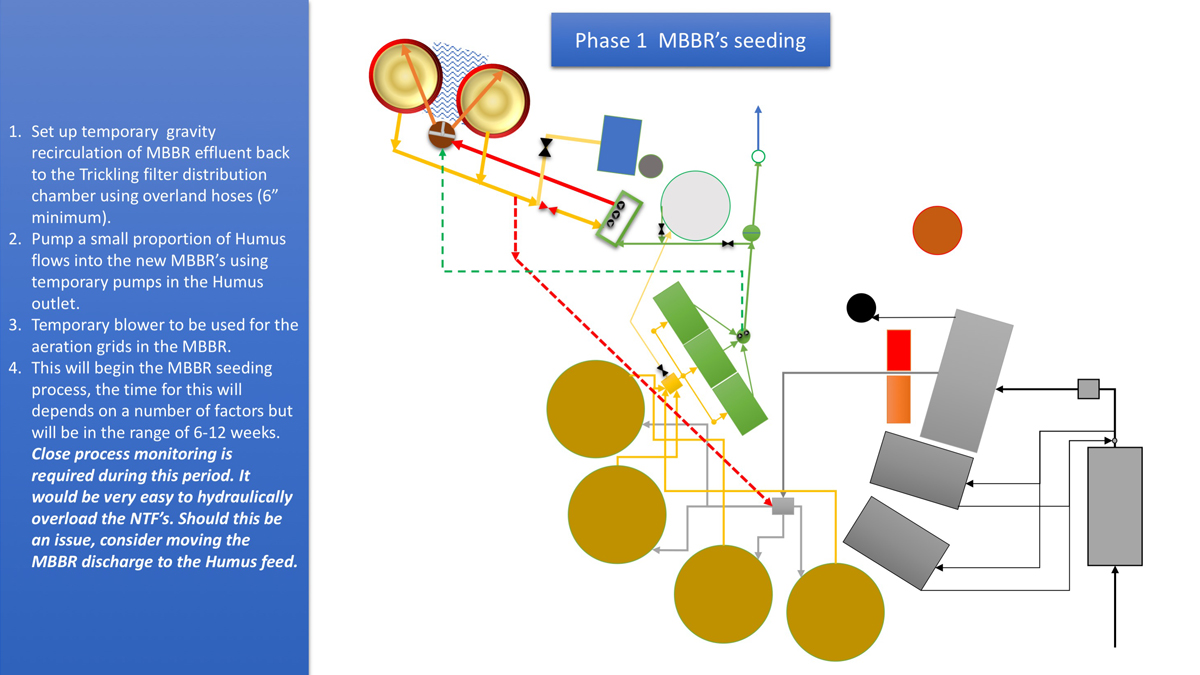

Prior to carrying out any on-site commissioning activities, a set of storyboards were generated to explain the various stages of the commissioning process.

Storyboard explaining the seeding strategy – Stage 1 – Courtesy of United Utilities

These were used to initiate discussions with United Utilities’ WwTW operational teams before the process risk assessments were developed. They were then issued to update any staff on call throughout the seeding period to explain the purpose of the temporary pipework and pumps located around the site. This helped with the ‘One Team’ approach to achieving the regulation date.

The MBBRs were brought online in the following phased approach:

- Temporary pumps were installed in the outlet of the existing humus tanks.

- Flows (of around 14 l/s) were returned from the outlet of the MBBR to the front end of the trickling filters in place of the existing site recycle flows. This also assisted with the seeding of a refurbished nitrifying trickling filter after its tank floor and media had been replaced as part of an operational maintenance activity.

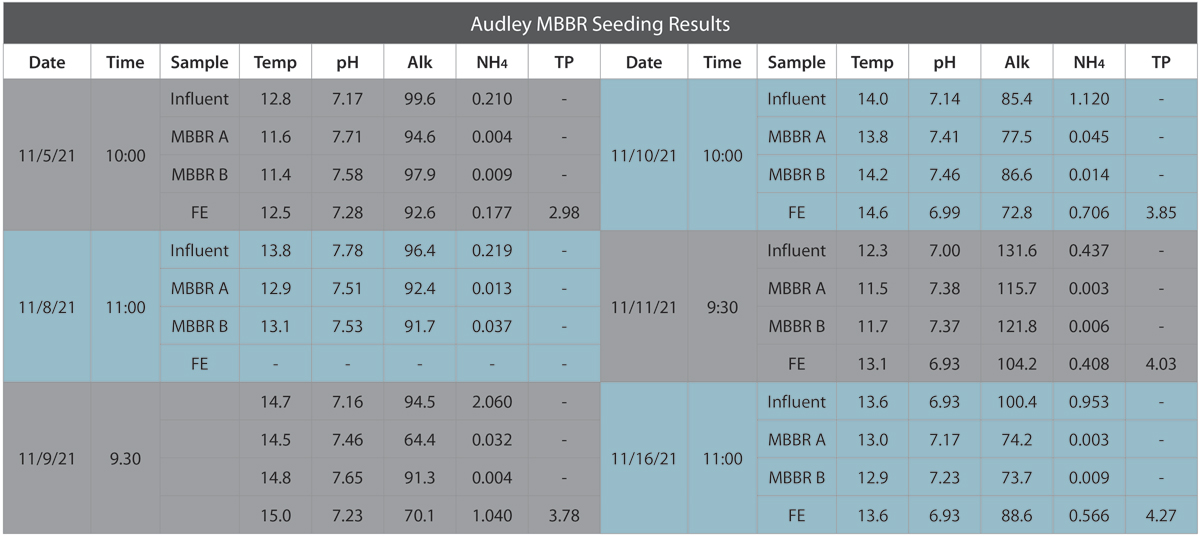

The new MBBRs were sampled regularly and media film growth examined. Within one month the MMBR filter media had clearly darkened in colour, signifying the effectiveness of the seeding process. The progression of this process is evident in the following table of MBBR sampling results:

Courtesy of United Utilities

Following the seeding of the new MBBR system, the ferric and caustic dosing units were commissioned. Dual point dosing was installed to ensure that the existing trickling filters were not starved of the required nutrients, and to provide reliability in controlling phosphorous levels below the 0.3 mg/l WwTW permit limit. The ferric dosing commissioning was started after the caustic commissioning. A novel air mixing and flocculation chamber was designed and installed in the 4m wide concrete chamber for the primary ferric dosing point to ensure efficient mixing given the tight permit limits.

Commissioning: Alsager WwTW

Following best practice identified when commissioning Audley WwTW, and given the later regulatory date of December 2022, seeding of the MBBRs at Alsager WwTW commenced early summer 2022, ahead of programme. The MBBR feed has been provided by a temporary pump ahead of modifications to re-purpose the site’s existing COUF pumping station. The project remains on schedule to be fully operational and have optimised all new key process plant ahead of the 31 December 2022 regulatory deadline.

Similar to Audley WwTW, before undertaking any on-site commissioning activities, story boards were developed and used to explain the various stages of the commissioning process to the key project and WwTW operational teams.

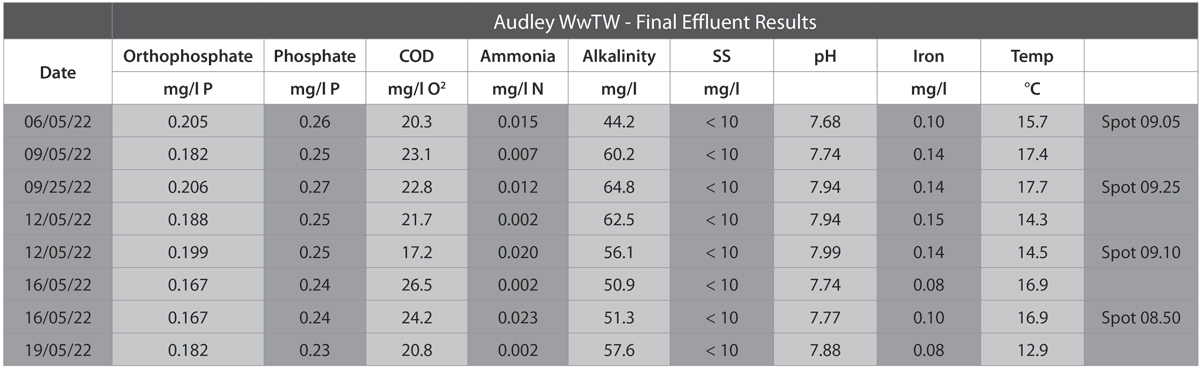

Performance of the design solutions

At Audley WwTW the revised, tighter permit conditions came into effect on the 1 January 2022. The site has benefitted from detailed performance monitoring and to date the final effluent results have been excellent. With an MBBR influent of around 1.5 mg/l, the average ammonia leaving the WwTW is around 0.05 mg/l, with a peak value of 0.23 mg/l against the new consent limit of 1 mg/l.

The MBBR blowers operate at fixed speed which acts to increase dissolved oxygen (DO) levels to around 4 mg/l and also keeps the media agitated to improve treatment. NB: Audley WwTW does not have any form of DO control, performance is monitored against alarm set points only.

The secondary ferric dosed at the front end of the MBBRs, within the air mixed splitter chamber, has had no effect on the measured ammonia removal rate following its introduction. The table below demonstrates the levels of performance achieved by the design solution operating at Audley WwTW.

Courtesy of United Utilities

Alsager WwTW is still progressing through its commissioning activities in preparation for the 31st December 2022 regulatory date. Seeding of the MBBR system is underway using reduced flows; again exceptionally high ammonia removal rates are evident with most of the ammonia being removed by the MBBRs.