Blackburn and Darwen WwTWs (2021)

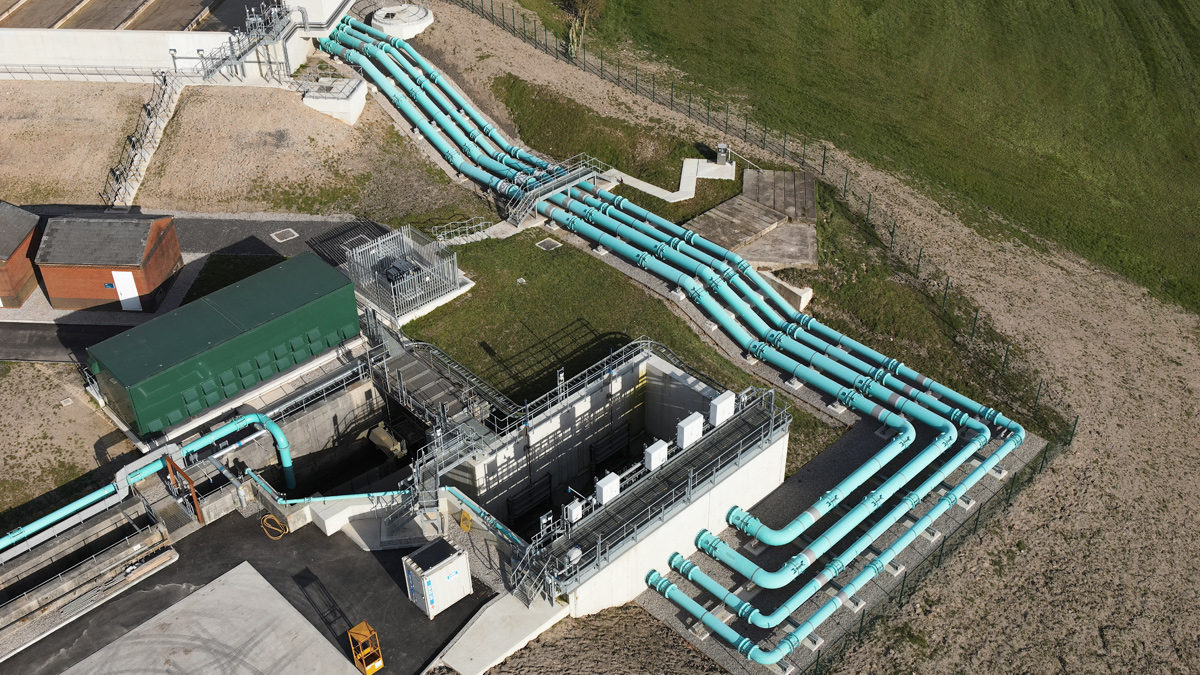

Nabs Head Pumping Station and storm tank - Courtesy of United Utilities

Blackburn WwTW was constructed in the 1960s and principally treats domestic crude sewage from the Blackburn catchment, with two major additional contributions; a high strength trade effluent from the InBev brewery and an ammonia rich return liquor flow from the sludge treatment plant. The key river water quality/water framework directive parameters within the revised environmental permit are the need to achieve a BOD of 7 mg/l and ammonia of 1 mg/l both on a 95%ile basis. The £150m Blackburn batch of projects being undertaken by United Utilities in partnership with LiMA and Atkins, includes Blackburn WwTW, Darwen WwTW, Nabs Head Inlet Works and the Darwen Pipeline. This case study details the progress at each of these sites, which, when fully delivered in 2022, will result in much improved river and batching water quality in the River Darwen, the River Ribble and the Fylde Coast bathing waters of the Irish Sea.

Project scope

The solution is taking advantage of the natural topography of the site and avoiding the need for the ongoing costs of interstage pumping resulting in lower power consumption and operating costs linked in with our company targets for net zero carbon. Work undertaken by United Utilities and LiMA over the last 12 months are detailed below.

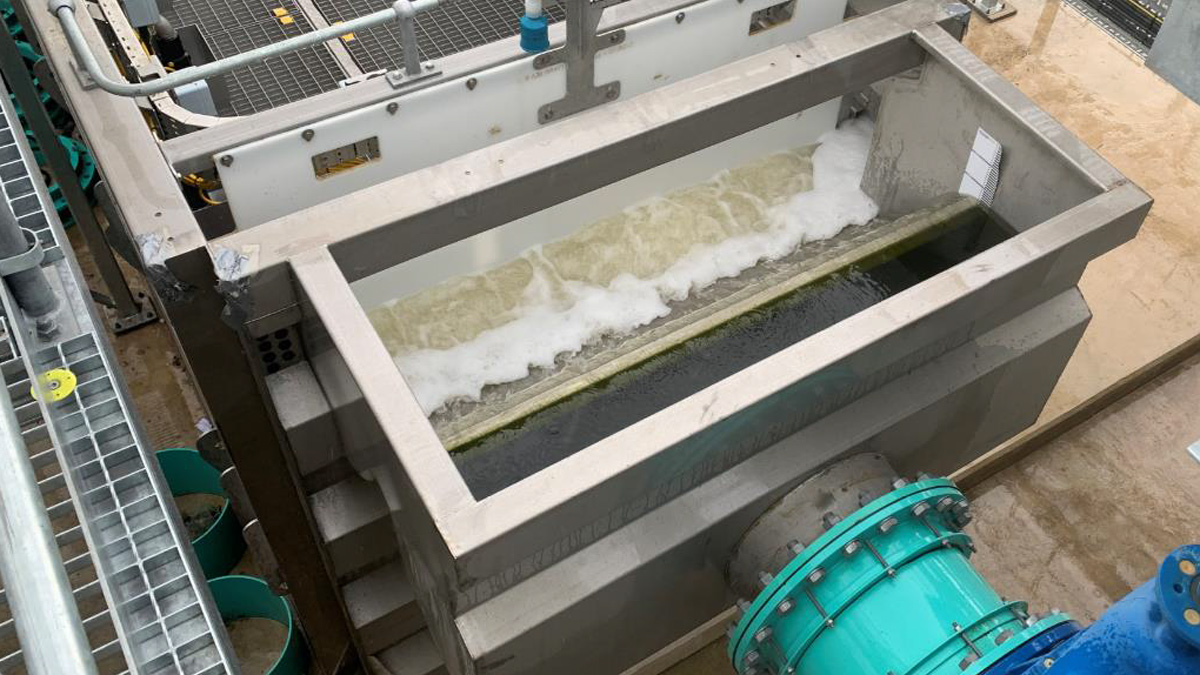

Nabs Head storm storage – Courtesy of United Utilities

Blackburn WwTW

Works has been impacted by the recent COVID-19 outbreak including third party, planning, production, deliveries and availability of resources. However joint working between United Utilities and LiMA has ensured that a safe working environment was maintained for site teams with many areas of good practice implemented along with the challenges brought to us via local and international supply chain restrictions and constraints.

The development of a federated model including the use of 3D visualisation tools was one innovation to speed up the build and construction process. These continue to be used to facilitate the design development with integration of hazard management, safety and access lifting & maintenance reviews with our operational teams to achieve the most efficient design prior to construction. This in turn is being integrated with the team’s philosophy to allow operational benefits to enhance the way the plant will be maintained and operated in the future from both the site and the integrated control centre.

Migration work has been extremely complex, however the use of a staged controlled interim Authority to Operate procedure has assisted with a controlled change over plan. This commissioning plan is still ongoing with great success to date. This process is also allowing great engagement and training of staff on the new process in parallel with the migration of treatment.

The Nereda® plant

The new inlet channel to feed a 72,000m3 in situ concrete structure is complete and the final stage of process transfer of full flows to the new process has now occurred. The Nereda® system is now treating the flows of Blackburn WwTW’s crude sewage and has been developed to treat peak load at the works; i.e. a complete replacement and expansion of the existing wastewater treatment plant with a future flow to full treatment (FTFT) of approximately 2,850 l/s, (once Darwen WwTW flows are transferred).

New inlet channel feeding Nereda® via splitter chamber and two underground siphon feeds July 2021 – Courtesy of United Utilities

The Nereda® process structure comprises 6 (No.) 12,000m3 treatment cells, 2 (No.) 800m3 sludge buffers, 1 (No.) 800m3 water level correction buffer and associated aeration and pumping equipment.

Landscaping works around the tank is due to start. The blower building is now full operational and contains five HSTTM 30 Turbocompressor Sulzer blowers with a pipework network to each cell.

The SAS plant, poly dosing, sludge holding tanks from Stortec Engineering Ltd, the drum thickeners from Huber Technology and the Jacopa lamella areas are also now operational.

Permanent ferric dosing

The permanent ferric dosing rig is now in build and is one of the last assets to be constructed on site, following demolition of one of the original second stage filters after transfer of flows.

Mecana tertiary filter in operation – Courtesy of United Utilities

Tertiary treatment – Mecana cloth filtration plant

The Mecana SF21 permanent filter bank is complete with eight filters installed and commissioned in the permanent location. There is phased commissioning plan to move the remaining two filters from their existing operational position to conclude the last element of filtration, now that flows have been diverted to the new process.

UV treatment

The new UV disinfection system has be provided by Xylem Water Solutions is designed to treat the final effluent prior to discharge, meeting the EA requirements for compliance with the Bathing Water and Shellfish Directives. At the time of writing (July 2021), dry and wet testing work is ongoing on the new validated dose system while the full flows currently pass through the legacy UV plant.

New inlet plant (imports) south of new inlet channel leading to Nereda® plant – Courtesy of United Utilities

Blackburn & Darwen WwTWs: Supply chain – key participants

- Client: United Utilities

- Project delivery contractor: LiMA JV

- LiMA JV contractor: Laing O’Rourke

- LiMA JV civil designers: Atkins

- Nereda® process: Royal HaskoningDHV

- Tertiary filtration: Eliquo Hydrok Ltd

- UV treatment: Xylem Water Solutions

- Package dosing unit: Galliford Try

- Physical model: Hydrotec Consultants

- Mechanical installation – pipework: FSE

- Process tank internal installation: Crown House Technologies

- Process tank internal installation: Suprafilt

- LV electrical installation, MCCs: Lloyd Morris Electrical Ltd

- Systems integration: Tata Consultancy Services

- Package inlet works: M and N Electrical and Mechanical Services

- Drum thickeners: Huber Technology

- Blowers: Sulzer Ltd

- Transfer pipeline & tunnel: VJ Donegan Civil Engineering Ltd

- Steelwork: Galloway Group

- Tanks: Stortec Engineering Ltd

- Flow controls: Auma Actuators Ltd

- Penstock, stoplogs, valves: Glenfield Invicta

- Lamella: Jacopa Ltd

Nabs Head Inlet Works

Nabs Head comprises screening and grit removal, with an additional 10,700m3 of storm storage constructed in AMP5. Bathing Water Directive requirements of no more than 3 spills per bathing season, and the Shellfish Waters Directive of no more than 10 spills per annum resulted in the solution increasing the pass forward flow (PFF) to circa 2,850 l/s from 1,800 l/s, as well as commissioning the new 23,100m3 of storm water storage tank.

Nabs Head inlet works – Courtesy of United Utilities

Storm storage

The new storm storage utilised the footprint of the original 1890s storm storage tanks. The two new storm storage tanks are both 102m long by 34m wide and are pumped filled (at up to 3,000 l/s) and empty by gravity, once there is sufficient capacity to pass the flows on to the main works. Each tank is now cleaned using a 6-lane Eliquo Hydrok Ltd flushing gate system, to reduce ongoing operating and maintenance costs. The system is now in full operation and working well.

Screenings

Works to refurbish the 4 (No.) existing Longwood escalator screens and 4 (No.) new Kuhn wash presses to wash and compact the extracted screenings is now complete. In addition the two existing cross flow detritors are now refurbished with new grit scrapers, grit pumps and classifiers. Thermal imaging cameras are being used to detect fill capacity on the screenings and grit skips, to provide a robust operating system without the need for a more complicated auto skip changeover arrangement. RAMP pumps are also commissioned.

Fibre optics

A new fibre optic link has been installed to enhance signalling between Blackburn WwTW and Nabs Head to allow swifter communication of flow changes and alarms connecting directly into our central management platforms.

Washwater

A new washwater main has been installed between Blackburn and Nabs Head to facilitate final effluent for the screens and compactors.

Darwen WwTW inlet channel modifications – Courtesy of United Utilities

Darwen Wastewater Treatment Works

The works were built in the 1960s and comprised an inlet works, primary settlement tanks, trickling filters and humus tanks. A new energy intensive treatment process would have been required to achieve the treatment element of the Water Framework Directive (WFD) driver and the lowest cost solution identified was to abandon the works and transfer flows under gravity into the adjacent Blackburn drainage catchment, ultimately receiving treatment at the new Blackburn WwTW.

At present the works at Darwen contain an operational ferric dosing system which was installed in November 2018 and doses upstream of the primary settlement tanks and achieve the new phosphorous permit of 2mg/l . This plant is running successfully and achieving consent.

The second WFD element at Darwen WwTW required the reduction of intermittent discharges by increasing the volume of storm water storage, to meet the required river water quality (FIS/RE 99%ile) standards. The best whole life cost design is the refurbishment and conversion of what would become redundant primary settlement and humus providing some 6,000m3 of storm storage facilities with a pass forward of 517 l/s via the transfer main.

TBM being lifted into position for M65 motorway crossing – Courtesy of United Utilities

Darwen Pipeline

The pipeline is effectively a tunnel beneath the M65 motorway before reverting back to a traditional gravity sewer construction as it passes alongside a residential and business developments, a river and along Branch Road. As at July 2021 83% of the pipeline has been installed by VJ Donegan Civil Engineering Ltd. The solution submitted at the tender stage for a 1.6km pipeline of 700mm diameter remains substantially unchanged, although some route realignment has had to be made due to significant service congestion on the route. Network modelling work has been undertaken to confirm the storm water storage requirements and ensure that flows diverted from Darwen into the Blackburn catchment cause no ‘level of service’ issues within the existing sewer network.

A Section 61 agreement was enabled with the support of Highways England for the pipeline to traverse under the M65 motorway, (16m underneath) to facilitate a key section of the pipeline route. The tunnel drive is now complete and the works to install and grout the traversing pipeline is ongoing.

M65 tunnel drive complete: TBM breakthrough – Courtesy of United Utilities

Progress/current status

At the time of writing (July 2021), The Nereda® structure mechanical installation is now complete, with commissioning performance optimisation underway. The tertiary and UV plant is being commissioned. The work at Nabs Head has been completed. The transfer main pipeline is ongoing and Darwen WwTW is in full build. The project is due to be handed over to United Utilities in 2022.