Boherbue Wastewater Treatment Plant (2024)

Boherbue WwTP completed - Courtesy of Glanua

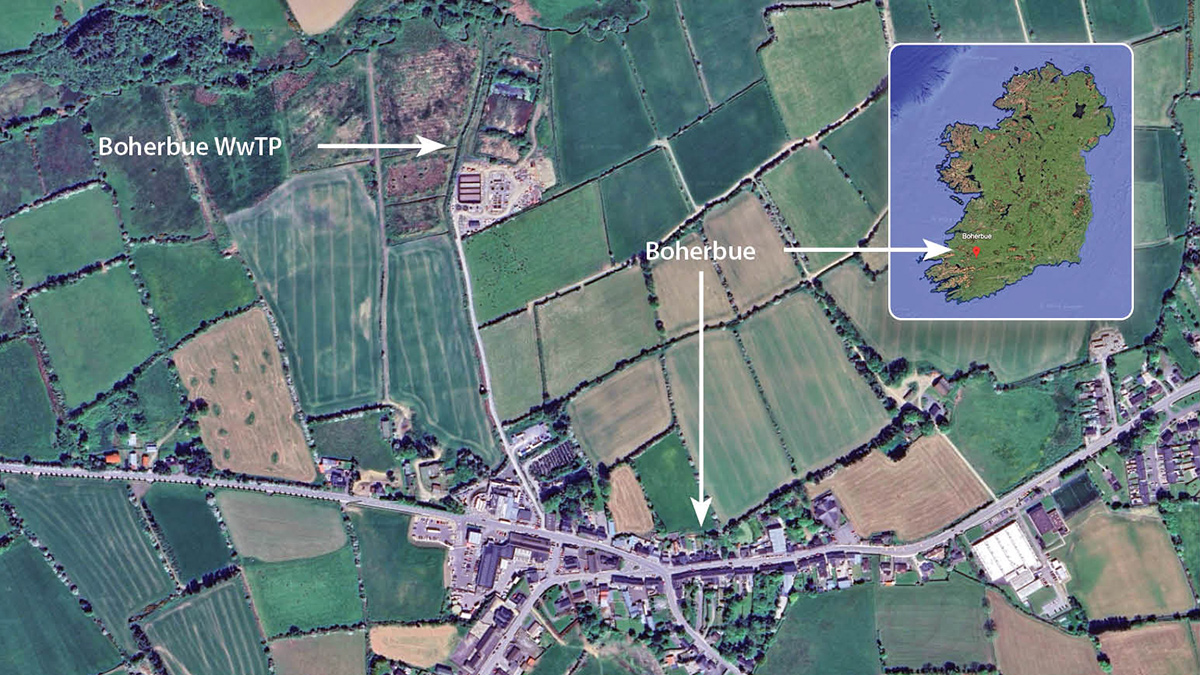

In recent years, the village of Boherbue in north-west Cork has undergone considerable expansion, resulting in increased demand for housing. This growth has presented challenges, particularly for the existing wastewater treatment facility, which has struggled to cope with the surge in population. Additionally, the plant has fallen short of the Environmental Protection Agency’s treatment standards, underscoring the pressing need for an upgrade. Of particular concern is the discharge of treated wastewater into the River Brogeen, a protected conservation area that serves as the habitat for the freshwater pearl mussel. In collaboration with Uisce Éireann (Irish Water) and Cork County Council, a comprehensive project has been undertaken to modernise and enhance the capacity of the treatment plant. This initiative not only addresses the immediate needs of Boherbue’s growing community but also ensures compliance with environmental regulations.

Early Contractor Involvement

The project, delivered under the innovative Early Contractor Involvement (ECI) framework, aimed to address the overloaded and outdated infrastructure while ensuring compliance with regulatory standards and meeting the evolving needs of the community. The innovation in this project lies in its multifaceted approach to efficiently treat wastewater, reduce carbon emissions, and protect natural ecosystems.

Leveraging the ECI framework allowed for the integration of innovative solutions such as solar energy, natural sludge drying reed beds, and the preservation of existing constructed wetlands for stormwater overflow. This innovative approach not only sets a new standard for sustainable wastewater treatment but also ensures long-term environmental benefits for Boherbue and its natural surroundings.

Google Earth image of Boherbue

The scope of works for the upgraded facility included:

- A new inlet works.

- A stormwater storage tank.

- Biological treatment processes.

- Tertiary solids removal cloth filtration system.

- Sludge drying reed beds.

A description of these key features follows.

New inlet works

An inlet works with fine screening to 6mm in 2D and a manual bypass screen to 19mm with a stone trap upstream of the screens were installed. The screens were designed to cater for the Phase 2 Formula A flows of 23.2 l/s screens are to be designed to cope with a minimum of 150% of the design capacity for works under 2,500 PE, i.e. a design capacity of 35 l/s based on the Design Formula A. The hydraulic design of the inlet works was also based on the fine screen(s) being blinded by a minimum factor of 70%. The screen selected by the ECI team was the Definitive Ecology SF/T3 in-tank screw screen, with SDACA (specially designed anti-clog auger) system to ensure compliance with the screening handling requirements.

Inlet works preliminary treatment – Courtesy of Glanua

Stormwater tank

Flows exceeding the plant’s peak design flow, overflow by gravity (weir discharging via overflow screen) to the stormwater holding tank, which has been designed to provide a retention time of two hours for the difference between the Design Formula A and FFT flows plus 40 l/PE for SWO compliance as only 1:7.1 dilutions will be available for the WwTP effluent in the Brogeen River (based on DWF and 95th percentile river flow).

The stormwater holding tank is provided with a Eliquo Hydrok CWF flushing bell in order to automatically clean the tank once the storm flows have abated and the tank has been emptied; which is an innovative approach to this, requiring no energy input.

The CWF Storm Flush system is a highly effective non-powered cleaning system for all stormwater retention tanks, utilising the sewage stormwater for the flushing process thus requiring no additional fresh water. Storm return pumps located in a sump within the storm tank, which will reduce retention of larger volumes of waste and reduce the risk of odour.

Biological treatment processes

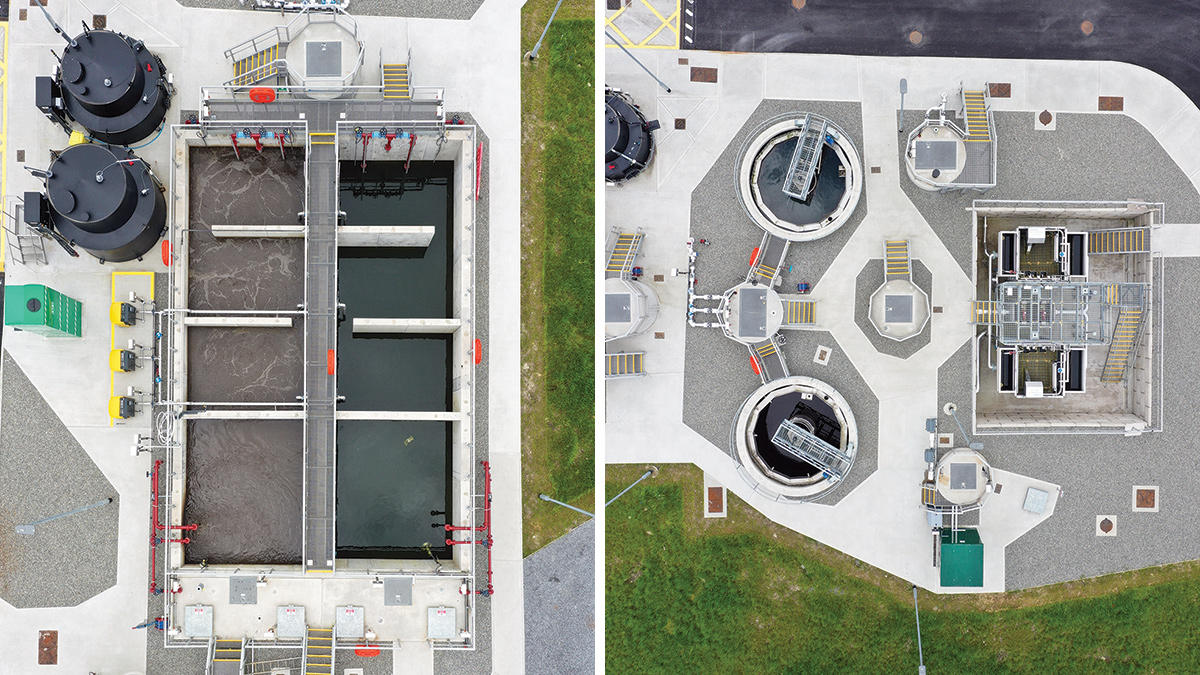

The secondary treatment stage for Boherbue includes the following:

- Two anaerobic selector tanks with three separate selector cell volumes.

- Two 624m3 aeration tanks with 109m3 of anoxic volume each for denitrification.

- Settlement provided by two 5m diameter/3.5m side wall depth secondary settlement tanks.

Secondary aeration treatment – Courtesy of Glanua

Each aeration tank is 15.6m length x 5m width x 4m working depth. Aeration is provided to the tanks using a fine bubble diffused aeration system designed to achieve an overall peak standard oxygen transfer rate of 66.15 kgO2/h (i.e. 33kg O2/h per cell).

The aeration system comprised three screw blowers from Kaeser Kompressoren operating on a duty/duty/standby basis, with automatic changeover of the standby blower on a time-basis; ensuring equal use of the equipment. Air from the blowers is forwarded to each aeration cell by an air header, which feeds individual branches into the aerobic cells. The diffusers are disc membrane units from Xylem Water Solutions.

Tertiary solids removal systems

Following settlement, secondary treated effluent is passed onto a tertiary solids removal treatment stage for final effluent polishing prior to discharge to the Brogeen River. The TSR process was required in order to ensure compliance with the WwDL ELVs, and in particular with the phosphorus ELV of 0.25mg/l, through coagulation/flocculation and filtration treatment.

Cloth filter tertiary treatment – Courtesy of Glanua

During the design stage and evaluation of the ECI team, the supplier Eliquo Hydrok was found to have the most reliable, energy and cost-efficient equipment that includes both flocculation and filtering stage. The package unit includes a flocculation stage comprised of one stream with two chambers that split into the cloth filters.

Sludge drying reed beds

The implementation of sludge drying reed beds (SDRB), which significantly increases sludge concentration to up to 40% dry solids (DS) after 10 years of operation is a key innovation. This revolutionary approach reduces sludge export volumes by more than tenfold compared to conventional methods, thereby minimising transportation and dewatering costs while substantially reducing the carbon footprint of the Boherbue WwTP. SDRB sludge can also be directly land spread without the need for additional chemical conditioning, further enhancing its environmental benefits.

There are numerous benefits in the inclusion of the sludge drying reed beds vs traditional sludge management practices. These include but are not limited to the following:

- Reduction of carbon footprint of the plant by approximately 45 T over a 10-year period.

- Carbon capture via natural plant growth.

- Up to 25% organic matter removal due to mineralisation.

- Dewatering process completed with zero energy consumption.

- At full design loads, the SDRBs will remove over 49 (No.) 20,000 litre tankers from the road per annum.

Sludge drying reed beds to process wastewater sludge naturally – Courtesy of Glanua

The construction of the sludge drying reed beds (SDRBs) commenced in early February 2023, incorporating earth embankments and precast concrete wall sections for formation. Each cell was meticulously lined to ensure water-tightness, with feed and drainage pipework installed for optimal functionality. Reeds were planted in late April to establish and grow during the summer months, aided by the importation of sludge to promote growth. This comprehensive approach ensures the effectiveness and sustainability of the SDRBs in treating wastewater and reducing the carbon footprint of the Boherbue WwTP.

Solar technology

The use of solar technology underscores the project’s commitment to renewable energy sources, contributing to further reductions in carbon emissions. By leveraging these innovative technologies and practices, the initiative sets a new standard for sustainable wastewater treatment, offering a replicable model for other treatment plants to follow. This holistic approach not only improves operational efficiency but also promotes environmental stewardship, paving the way for a cleaner and more sustainable future in the wastewater sector.

50Kw solar panels from The Low Carbon Energy Company Ltd have been installed which will produce 42,500Kwh of electricity per year. This alone will introduce a carbon saving of 13.7T/CO2 per year which shows significant savings versus a traditionally built wastewater treatment plant of this kind.

Solar panels for clean, renewable energy – Courtesy of Glanua

Reuse of constructed wetlands

The integration of the existing constructed wetlands into the wastewater treatment facility which was core to the design development brought a multitude of benefits, ranging from low operational costs, support for diverse ecosystems as well as sustainable water management. The wetlands improve water quality of streams and rivers in surrounding area creating conditions for aquatic life to thrive, and also create a scenic area in the village, promoting biodiversity and providing a habitat for small animals.

Boherbue WwTP: Supply chain – key participants

- Precast concrete: Glanua Group

- Designers: Jennings O’Donovan & Partners

- Designers: Construct Engineering

- Precast concrete: Shay Murtagh Precast

- Precast concrete: Carlow Tanks

- Precast concrete: FLI Precast Solutions

- Precast concrete: Tracey Concrete

- PLCs & automation: UMAC Systems

- Inlet screens: Definitive Ecology

- Tertiary solids removal cloth filters: Eliquo Hydrok Ltd

- Aeration blowers: Kaeser Kompressoren

- Aeration diffusers: Xylem Water Solutions

- Solar panels: The Low Carbon Energy Company Ltd

- CWF Storm Flush system: Eliquo Hydrok Ltd

- Steel modular buildings: Shanette

(left) Precast concrete aeration tanks reduced construction time and safety risks and (right) view of final clarifiers and cloth filters – Courtesy of Glanua

Innovative construction methods

Throughout the entire design process, Glanua Group and Uisce Éireann’s PMO team evaluated several project aspects such as energy efficiency (BEP), TOTEX costs, and environmental impact.

- Energy efficiency of all motors and equipment (BEP).

- Process and equipment selected on TOTEX costs (including CAPEX, OPEX and capital replacement at end of life).

- The impact to the local environment was carefully assessed for all design options considered during the planning phase.

Modular and off-site construction

Modular/off-site construction was used to reduce the carbon footprint and on-site safety risks, with precast panels and BCAR-compliant steel modular buildings used to promote efficient delivery and enhance safety.

Precast panels were instrumental in constructing the main aeration tank, reducing construction time and mitigating safety risks compared to traditional in situ methods. Precast wall sections were used to separate the sludge drying reed beds sections to reduce the footprint size and again to reduce construction time and safety risks. Throughout the project, precast process tanks were used extensively contributing to streamlined construction processes and improved safety measures.

A BCAR-compliant steel modular building from Shanette was used for the control room, laboratory, and caretaker’s office facilities. This has a significantly lower carbon footprint than that of a conventional block-built structure and in turn reduced health and safety risks significantly during construction due to fabrication being completed before assembly on site.

Off-site fabrication of steel building, fully assembled as works have been completed (April 2024) – Courtesy of Glanua

Sustainability

The construction of the Boherbue Wastewater Treatment Plant is an example of Uisce Éireann and Glanua Group’s commitment to sustainability across various dimensions, including environmental, social, and economic considerations.

The inclusion of sludge drying reed beds demonstrates dedication to environmental sustainability. These beds offer an innovative solution for sludge management, reducing the environmental impact of waste disposal while also providing opportunities for ecological conservation.

By using nature-based solutions to treat and manage sludge, the carbon footprint associated with traditional disposal methods is minimised; thereby mitigating environmental harm. The SDRBs also significantly reduces operational costs, providing a long-term cost-effective solution.

The integration of solar technology underscores the commitment to renewable energy and carbon reduction. By harnessing solar power to supplement the energy needs of the wastewater treatment plant, reliance on fossil fuels is reduced, contributing to the transition towards a more sustainable energy future. This not only reduces operational costs but also mitigates greenhouse gas emissions, thereby supporting climate action efforts and environmental preservation.

Socially, the decision to reuse the existing wetlands demonstrates dedication to maintaining and sustaining biodiversity in the Boherbue community. By incorporating natural elements into the design, not only is disruption to local ecosystems minimised, but also to the overall health and vitality of the local environment.

Darran O’Leary, Programme Manager at Uisce Éireann said:

“We are delighted to have delivered this important project for the community of Boherbue. The modernisation and improvement of the wastewater infrastructure will accommodate further growth in the area and ensure that cleaner and safer treated wastewater is being discharged into the Brogeen River.

“It also adds biodiversity value to the area and remains sensitive to the surrounding landscape. This, coupled with the use of solar energy, demonstrates our commitment to putting sustainability at the heart of everything we do”.

Boherbue WwTP upgrade works is a flagship project for sustainable and carbon saving treatment processes and will serve as a reference project for future similar projects within the industry.

By demonstrating the feasibility and benefits of integrating renewable energy, advanced treatment technologies, and ecological conservation practices, this project sets a precedent for industry-wide innovation and best practices.

It complies with stringent Environmental Protection Agency (EPA) discharge consent standards, while minimising impact on the existing landscape, demonstrates a commitment to environmental sustainability, operational efficiency, and community well-being, making it a catalyst for positive change within the wastewater treatment sector and beyond.

The new Boherbue WwTP - Courtesy of Glanua