BRP – Trimpley WTW Trials – Birmingham Resilience Project (2016)

Example of an Actiflo® plant - Courtesy of Veolia Water Technologies

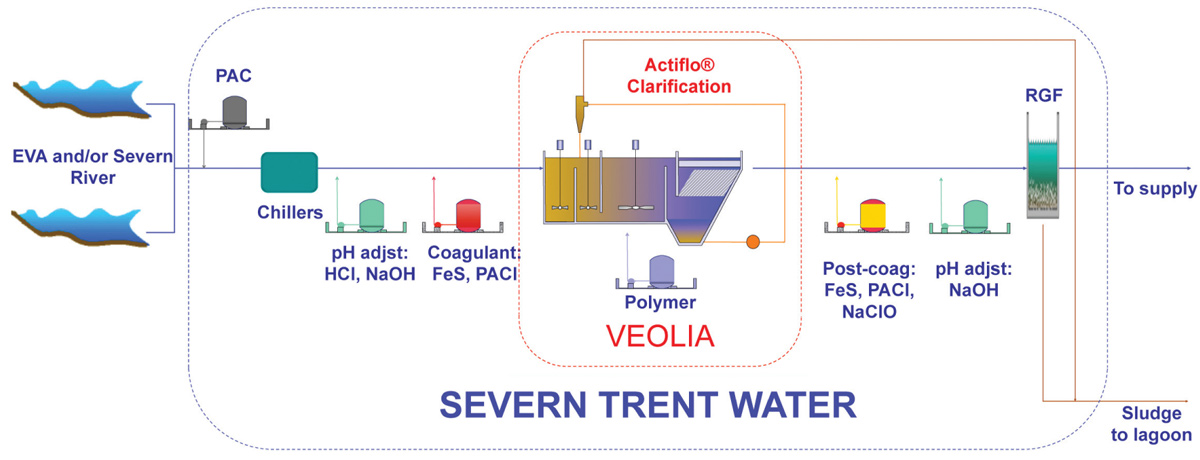

As part of the Birmingham Resilience Project, Severn Trent Water has been investigating process solutions to treat the River Severn water at the existing Frankley WTW. The current dissolved air flotation (DAF) and rapid gravity filter (RGF) plant was designed to treat the Elan Valley Aqueduct water (EVA), a relatively clean soft upland reservoir source. The EVA, a legacy of Victorian engineering achievement needs infrequent but regular maintenance, requiring it to be taken out of service for short periods. Whilst out of service, Frankley will be supplied with raw water from the River Severn, and while the DAF treats the EVA waters well, it is not capable of treating the River Severn water. As a result, Severn Trent Water has been investigating other clarification technologies to provide a new treatment solution building resilience to this strategic asset.

Third treatment stream at Frankley

The new treatment stage, comprising Actiflo® high rate clarification and new RGFs, forms a third stream at Frankley WTW, thereby providing Birmingham water supply with additional resilience as well as River Severn treatment capability. Capable of treating both River Severn water and/or EVA water, it is required to provide an average output of 237Ml/d and peak flows of up to 312Ml/d when treating the River Severn water. During normal operation, it treats EVA water, providing resilience to the existing two streams of DAF and RGFs .

In order to demonstrate the suitability of the most compact Actiflo® process to effectively clarify River Severn water, the EVA water and a blend of both sources, Veolia Water Technologies installed a mobile 2.5Ml/d Actiflo® high-rate, sand ballasted clarifier (SBL) in conjunction with Severn Trent Water and MWH (now Stantec UK) at the nearby site of Trimpley WTW. Treating a combination of River Severn and EVA water sources, the pilot plant operated between the 14 May 2015 and the 4 March 2016. The installation clearly demonstrated the effectiveness of the proposed process in clarifying a wide range of water combinations under varying operating conditions. The clarification plant was only one component of a comprehensive installation which included chemical conditioning, powder activated carbon dosing and rapid gravity filtration.

Actiflo® pilot plant at Trimpley WTW – Courtesy of Veolia Water Technologies

Pilot plant trial: 10 months of comprehensive operation

The pilot plant is an automatic system equipped with its own MCC and SCADA system. Fitted with extensive analytical in-line instrumentation, it provides the operator with the facility to monitor the operating conditions and the quality of the treatment in a similar way to a full scale plant including remote monitoring. It is equipped with two different automatic coagulation modes:

- A conventional Turbidity/UV254 control application.

- An innovative S::Can/Com::Pass monitor using solids compensated UV-Vis spectra and turbidity to characterise natural organic matter (NOM).

Initial treatment criteria were identified at the start of the trial in order to assess the ability of the Actiflo® process to meet the objectives of the new clarification plant. These evolved as the basis of design for the Frankley Water Treatment Works project developed in order to provide extensive data to support the Birmingham Resilience Project.

Example of an Actiflo® plant – Courtesy of Veolia Water Technologies

The plant treated a combination of sources which presented significant seasonal variations in natural organic matter, turbidity and temperature as low as 2ºC. The objectives of the trial were to validate the key operating conditions and provide design criteria for the main project, particularly in the following areas:

- Suitability of ferric sulphate as main coagulant as used currently at Frankley WTW.

- Suitability of pre-selected anionic polymer LT27.

- Requirement for pH correction.

- Ability to treat effectively a blend of River Severn and EVA water, particularly dealing with the transition periods.

- Coagulation contact time requirement especially at below 3ºC obtained under engineered chilled conditions.

- Mirror velocity, tested beyond the design target of circa 65m/h up to >80m/h.

- Impact of clarified water conditioning in relation to the clarified water filterability.

- Impact of powder activated carbon (PAC) dosed upstream the Actiflo® as well as performances on the organic, pesticides removal rates and THM formation potential.

- Filtration rates, headloss build-up, backwash frequency and metals removal across the downstream RGFs.

Actiflo® technology

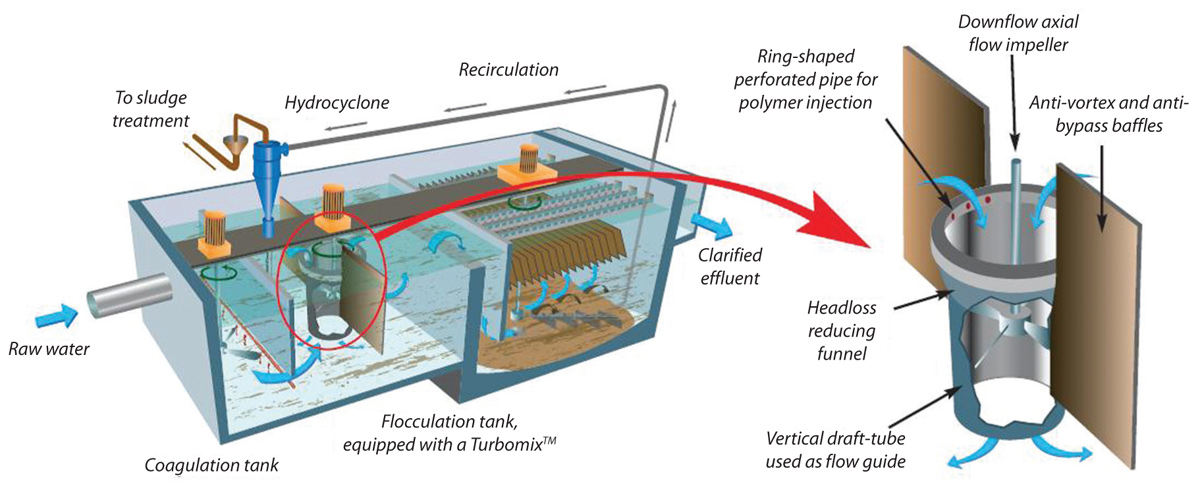

The Veolia Water Treatment technical solution centers upon the high-rate sand ballasted clarifier (SBL) Actiflo® process, which is ideally suited for difficult-to-treat sources with sudden variations of turbidity and colour.

Trimpley WTW Actiflo® schematic – Courtesy of Veolia Water Technologies

Actiflo® is a patented extremely versatile clarification system that effectively removes suspended solids and organic matter in surface water by coagulation/flocculation and lamella settling, achieving consistently low levels of outlet turbidity and true colour. Microsand (known as Actisand®) is utilised as a seed for floc formation, providing surface area that enhances flocculation and acts as a ballast or weight.

The resulting sand ballasted floc enables clarifier designs with high rise rates and short retention times, having a typical footprint between 5 and 20 times smaller than conventional clarification systems of a similar capacity.

The Actiflo® process is the most compact clarification process on the market with mirror velocity up to 80m/h in surface water clarification. It offers a high degree of operating flexibility, such as rapid and automatic start up/shut down combined with an outstanding capacity to cope with flows and loads variations.

The Actiflo® process – Courtesy of Veolia Water Technologies

Key results

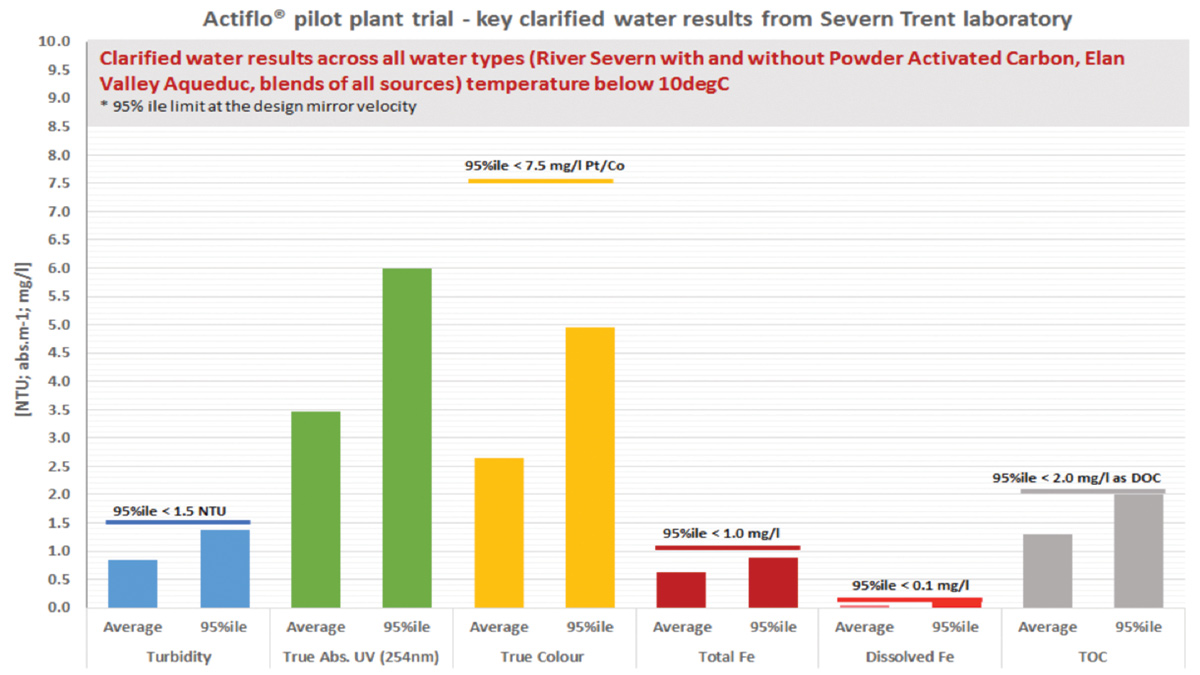

The table below summarises the key results across the majority of the trial, when treating the River Severn, the EVA and a blend of both sources under water temperature below 3oC and under mirror velocity enveloping the design value.

The pilot plant confirmed the suitability of the high-rate, sand ballasted lamella clarification Actiflo® process to effectively treat any combination of the River Severn and EVA waters specified for the Birmingham Resilience Project new third stream. It successfully met the initial objectives during the trial and fixed the design basis that is now part of the proposed works Information.

Ferric sulphate currently used as the main coagulant on the existing DAF at Frankley WTW has been retained whilst confirming the requirement for an extended coagulation time of ~9 minutes at peak flows to maintain the same treatment quality for temperatures as low as 3ºC. Operating under chilled conditions and throughout the winter has provided valuable data used to specify the contact duration needed by the ferric sulphate.

PAC was dosed upstream of the Actiflo® plant when treating the River Severn in order to treat pesticides and to maintain at all time a single pesticide concentration well below the regulatory limit of 0.1ug/l. The clarified water filterability remained in line with the operational target across all raw water combinations.

The proposed dual media RGFs, whilst also proving manganese removal via a 10% manganese dioxide seed within the filter bed, confirmed the backwash frequency of well in excess of the targeted 48 hours even at worst raw water quality.

Key clarified water quality results (Severn Trent laboratory data) – Courtesy of Veolia Water Technologies

By finalising the design basis and identifying the positive impact of clarified water conditioning using sodium hypochlorite solution, the Actiflo® sand ballasted lamella clarifier successfully demonstrated a stability of performances under high mirror velocities. Under MWH supervision, the pilot plant replicated at an unparalleled level, a permanent installation confirming the potential design basis of a full scale solution.