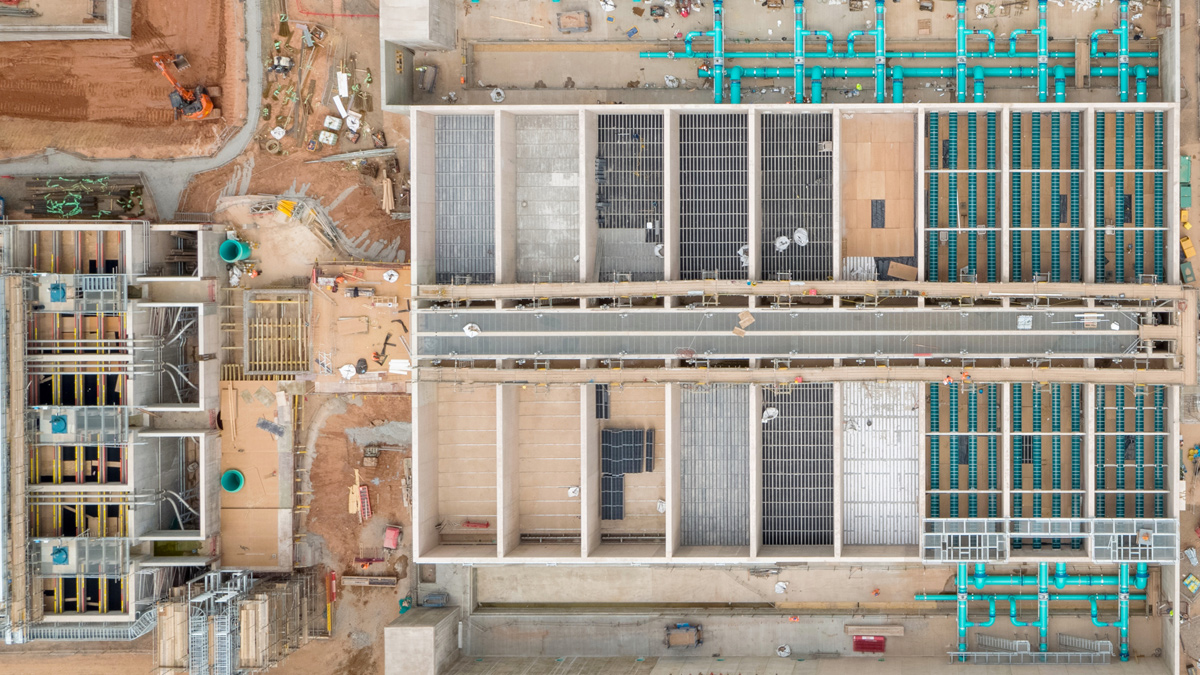

BRP – Treated Water Project – Birmingham Resilience Project (2019)

New treatment stream under construction - Courtesy of Severn Trent

Since the beginning of the 20th century, raw water has been conveyed 118km from the Elan Valley in Wales, under gravity by aqueduct, to the water treatment works (WTW) in Birmingham for treatment and supply to the population of the city. The aqueduct has been in continuous service for over 100 years and requires some important maintenance work to be undertaken, requiring it to be shut down and drained a number of times, and for a number of weeks each time, to complete elements of this work. To enable the work on the aqueduct to be undertaken, the WTW is being upgraded with a new treatment stream capable of treating raw River Severn water. The river water will be pumped to the WTW for treatment, whilst the Elan Valley supply is isolated to allow maintenance works to be undertaken on the aqueduct. The new treatment stream will also be capable of treating the Elan Valley water to provide enhanced treatment capability to the existing works in normal operation.

Background

The new WTW stream contract was awarded by Severn Trent to NMC Construction Ltd (now Galliford Try) in June 2017. NMC have formed a joint venture alliance with Korean giants Doosan Enpure Ltd to deliver the project as DNMA. The construction works is valued at around £120m with completion of commissioning of the new stream currently programmed for 13 March 2020, ahead of the OFWAT deadline set out in the Final Business Plan of 31 March 2020.

Existing WTW

The WTW today comprises two parallel process treatment streams fed from an off-site and an on-site reservoir, both supplied with water from the Elan Valley. The current treatment processes have evolved from the original sand filters and now comprise much more modern treatment processes including: dissolved air flotation (DAF), rapid gravity filters (RGFs), granular activated carbon (GAC) filtration and pH correction. Treated water is disinfected with chlorine, utilising 3 (No.) contact tanks to provide suitable contact time. The GAC plant is dedicated to one stream following the RGFs and enables blended river water treatment capability but not raw river water treatment capability.

New process stream

Severn Trent has promoted the Treated Water Project to provide a new process stream (Stream 3) at the WTW capable of treating the current raw water feed from the Elan Valley and also raw water from the River Severn. The treatment capacity of the new process stream will be approximately 25% less than the current works maximum throughput and will be supplemented by the water network, during an aqueduct outage, to meet demand.

The new treatment stream processes and their state of progress (as of June 2019) is described in the following section.

Powdered activated carbon plant

Lickhill PAC plant- Courtesy of Severn Trent

Two new powdered activated carbon (PAC) plants have been constructed to provide removal of pesticides from the River Severn water; one on each of the two raw water feed mains. Each plant doses PAC into its associated raw water main and contact time is provided whilst the water is in transit to the WTW. The delivery mains discharge into the on-site reservoir which provides settlement of excess PAC prior to entering on site water treatment processes at the WTW.

Both PAC plants are constructed and ready for commissioning. The PAC plant is a proprietary package system designed, produced and installed by Transvac Systems Ltd.

Each PAC plant comprises twin horizontal silos with twin horizontal conveyors delivering PAC to the packaged metering and dosing equipment contained in a converted shipping container. This equipment mixes the PAC with water and doses it into the main at the appropriate rate dependant on the delivery flow in the main and the raw water quality. The control equipment is separately housed in an adjacent kiosk.

Connection to the on-site reservoir to new treatment stream

Excavation works for south tower pipework connection – Courtesy of Severn Trent

Raw water from the aqueduct or from the river arrives at the inlet chamber to the existing on-site raw water reservoir. This reservoir has two draw off towers – north and south. Only the north tower is currently used for take-off and feeds the existing treatment streams. The south tower requires alteration to allow it to be utilised as a draw off tower for the new treatment stream.

The draw-off pipework is at the base of the 100 year old south tower, approximately 10m below ground level. To enable the new pipework connections to be made, and to allow the existing isolation valves to be replaced, the existing take off pipework has been temporarily sealed inside the reservoir with steel plates installed by divers. For the excavation adjacent to the tower and reservoir, secant piles have been installed to provide a structure allowing safe excavation to formation level.

As the excavation has progressed, props have been installed to prevent soil movement which may destabilise the tower or reservoir causing structural damage and potential inundation of stored water.

The excavation works and the monitoring requirements were agreed with the Reservoir Panel engineer prior to commencement of these works. These excavation works have now been successfully completed in readiness for connection to the new manifold and feed pipework to the new treatment stream.

Sectional view of south tower excavation works – Courtesy of Severn Trent

Whilst the south tower excavation works were progressed, the first section of withdrawal pipework, 200m of lined 2.1m diameter precast concrete tunnel segments, was driven from the downstream end towards the tower, using an open faced shield. This method was deemed more suitable than open cut given the depth of the pipes (6-9m) and proximity of the reservoir. The ground falls away beyond this point so the remaining 400m of pipework can be safely installed using open cut pipe laying methods.

Raw water inlet pumping station

Raw water inlet PS rear right, mixing chamber rear left, chemical building foreground – Courtesy of Severn Trent

With the reservoir full to its maximum top water level (MTWL) down to 2m below MTWL, water will be drawn for treatment under gravity. To ensure the majority of the stored water can be used, and to allow treatment in the rare instances when the level drops below the gravity feed cut off, a new raw water inlet pumping station (RWIPS) is being installed providing a static lift allowing the reservoir to be drawn down to 7m below MTWL of the 10m deep reservoir.

New treatment processes

The raw water is fed under gravity or by the pumped system from the reservoir into the new clarification process.

Clarification: STW have selected the sand ballasted lamella (SBL) process as the most suitable clarification process for treating both river and Elan Valley water, rather than the currently used DAF process, due to the amount and nature of the solids the river water carries.

This will be the first installation of SBLs in the Severn Trent Region and to ensure their suitability a pilot plant was set up at Trimpley and run on River Severn water for a year. The pilot plant was provided by Veolia; the installed SBLs are Veolia’s Actiflo® AC10 units, 3 (No.) in total.

SBL installation (foreground) RGF installation (background) – Courtesy of Severn Trent

The process units comprise bespoke reinforced concrete structures which have been cast in situ with inlet structures promoting mixing of dosed polymer and tanks containing mixers and lamella panels. The structures are substantial and elevated with process critical mechanical plant sitting on flooring spanning the units.

Control equipment is housed in a separate motor control centre (MCC) steel clad portal framed building.

Construction of the SBLs and installation of mechanical plant is complete, there is a small amount of cabling outstanding to complete the installation. The MCC building is also substantially complete in readiness for installation of the MCC panels. The SBL will then be ready for commencement of commissioning.

RGFs under construction – Courtesy of Severn Trent

Rapid Gravity Sand Filters (RGFs): An 18-cell rapid gravity filtration unit is under construction for the new process stream to provide effective river water filtration. The RGF unit comprises 18 (No.) treatment cells, inlet and outlet channels and a dirty backwash channel. It is an in situ reinforced concrete structure of overall dimensions of 38m wide x 66m long x 8.5m deep, connected to the SBL’s by a common channel inlet channel. At the time of writing (June 2019) The concrete construction works are complete and the process plant and pipework are currently being installed.

RGF clean and dirty backwash systems: The new RGF process requires clean and dirty backwash systems for running the RGF process. The existing facilities for the existing RGFs are under-capacity for the new works and asset expired. The new clean and dirty backwash systems will also therefore service the existing RGFs.

Clean backwash water tank under construction (February 2019) – Courtesy of Severn Trent

The new clean backwash water tank (CBWT) is a 40m x 40m x 5m deep in situ reinforced concrete structure with two compartments to allow future inspection and maintenance, and a backwash pumping station. The tank is built within existing sand filters with the benefit of limited buried services to contend with, but partial demolition of heavily engineered perimeter walls to manage. The tank is covered as the water is used in the treatment process.

The dirty backwash water tank (DBWT) receives dirty backwash water and returns settled water to the on-site reservoir. The tank comprises two compartments and a pumping station constructed from in situ reinforced concrete. The DBWT is a similar size to the CBWT and also built within a sand filter.

The pumping station has a dual function and has the capability to return flows from any treatment stream to the reservoir in the event of a water quality failure on a treatment stream, in this mode it is known as the emergency return pumping station (ERPS). The ERPS will also be used as a critical part of the commissioning strategy.

Dirty backwash tank and liquors/emergency return PS – Courtesy of Severn Trent

Ancillary systems and processes

Chemicals: The new treatment stream includes the construction of its own dedicated chemical treatment dosing plant, to support the new clarification, filtration and sludge processes. Substantial, buried in situ reinforced concrete chambers containing twin mixers up to 2.1m diameter and flow meters have been constructed to ensure chemicals are suitably dosed and mixed are provided.

Sludge treatment: Due to sewer capacity limitations and programme delivery risk a new sludge treatment plant is being constructed which will serve the whole site. The treatment is based on a wash water lamella plant (WWL) provided by Paques maximising water recovery for treatment and minimising sludge discharged to sewer. Centrifuges provide additional treatment when the plant is treating river water, to produce an inert sludge cake for removal off site.

Sludge plant area – Courtesy of Severn Trent

Infrastructure work

In addition to the treatment units the scheme includes 3000m of pipework from 80mm ID to 2100mm ID, ancillary pumping stations HV cabling, LV Cabling, HV substations, demolition of an existing building, new roads, new drainage systems, security systems and fencing.

BRP Treated Water Projects: Key participants

- Delivery contractor: DNMA – Doosan Enpure Ltd/nmcn PLC (now Galliford Try) joint venture alliance

- Civil/structural design: GHD

- FRC: STAM Construction Ltd

- Shoring/temporary works: National Trench Safety UK

- Precast concrete columns – CBWT: Marshalls CPM

- Precast concrete – Trench & covers: FP McCann

- Precast concrete – Wall panels: ACP Concrete

- Buildings: Structural Steelwork Ltd

- Mechanical installation (RGF, SBL and RWPS mechanical build and South Tower works): Franklyn Yates Engineering Ltd

- Pipes & fittings: Freeflow Pipesystems Ltd | Radius Systems | Pipesource UK

- Access covers & walkways: Technocover | Deritend | Steelway

- Filter media: Western Carbons Ltd

- Transformers & HV switchgear: Schneider Electric

- Actiflo® sand ballasted lamella: Veolia Water Technologies

- Powdered activated carbon plants: Transvac Systems

- Wash water lamella plant: Paques

- Centrifugal pumps: Bedford Pumps | Hidrostal Pumps | Sulzer

- Ventilation: Project 77 Environmental Ltd

- Valves & penstocks: Glenfield Invicta

- Valves & penstocks: Cotswold Valves Ltd

- Tanks: Balmoral Tanks | Forbes Technologies Ltd | SPEL Products

- Chemical dosing: IIES (Northern) Ltd

- Chemical dosing tanks: Richard Alan Engineering

- Lime dosing progressive cavity pumps (BRP): SEEPEX UK Ltd

- Lime dosing items: Sulzer | Siemens

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

- Kiosks: Morgan Marine

Progress/conclusion – June 2019

Construction of the new treatment stream at the WTW is a huge undertaking within a challenging timescale and within the confines of a critical asset. The client and contractor have adopted a highly collaborative and supportive framework for delivery to maximise the chances of success. Progress against the schedule has been maintained and commissioning is set to commence in October 2019 with completion within the final determination delivery period.

A monumental amount of work has been delivered in the last 12 months. There is still some way to go to deliver the project within the challenging timescale, however the spirit and desire to succeed remains unwavering and the team are focussed and determined to deliver this critical and complex project on time.