Cricket Inn Crescent CSO (2025)

Drone shot of site showing temporary works excavation and constrained working area - Courtesy of Galliford Try

Located next to Cricket Inn Crescent in Sheffield, the existing combined sewer overflow (CSO) is a brick-built, unscreened chamber with 375mm combined inlet, outlet, and overflow pipes discharging to a nearby surface water system flowing into the River Don. Flagged as a high-priority site under Yorkshire Water’s Sewage Spill Reduction Programme, it faced frequent and high-volume spills. The goal was to cut annual discharges from 41 to just nine, improving downstream water quality and meeting environmental targets. While the initial plan called for a storm tank with rising main return, detailed investigations and collaboration with specialist partners led to a more sustainable, cost-effective, and safer alternative, delivering the same results with added long-term operational and environmental benefits.

Engineering a smarter solution for network efficiency

Site investigations uncovered critical flaws in the existing CSO system’s design and performance. Poor pipe alignment and high-velocity incoming flows caused hydraulic inefficiencies, leading to premature overflows across the benched weir wall, triggering spills before the downstream network could be fully utilised.

These findings enabled the development of an improved, gravity-based solution that eliminated the need for a pumped return shaft and its associated infrastructure. This strategic shift brought multiple benefits: simplified construction, lower operational costs, and significantly improved sustainability.

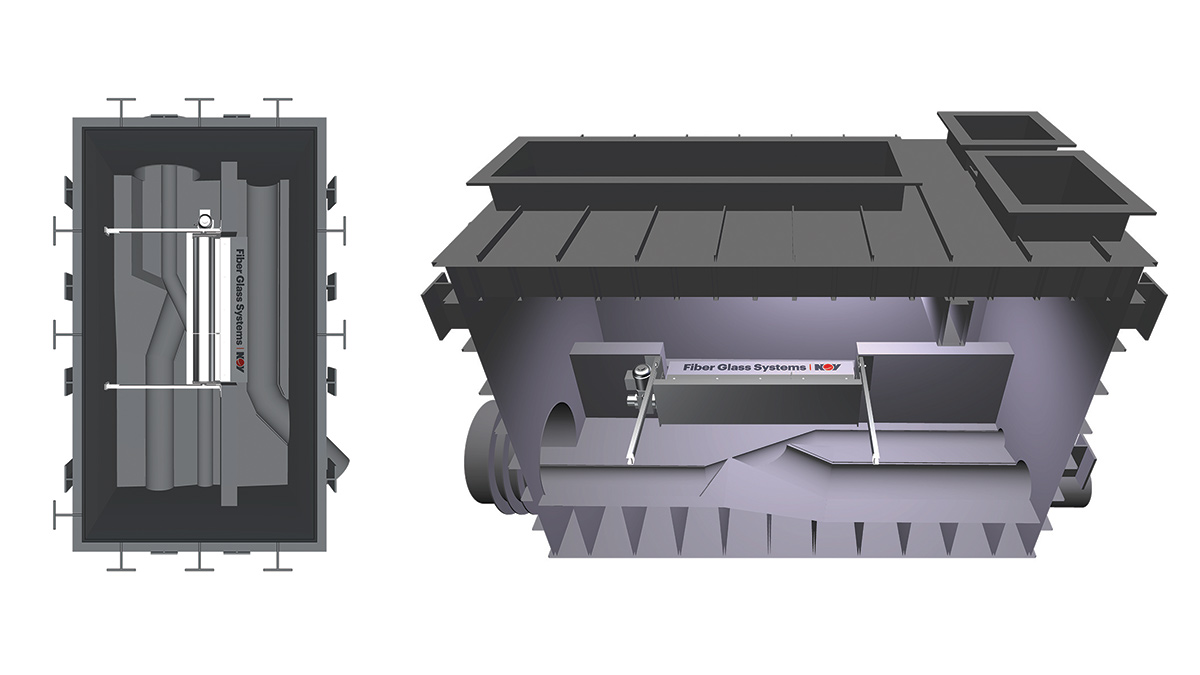

3D internal plan render of CSO chamber including screen from Huber Technology – Courtesy of Galliford Try

A new WaPUG-compliant CSO chamber was proposed, designed around industry best-practice principles. Crucially, the design enabled the integration of a motorised screen from Huber Technology, addressing a key shortfall in the previous setup, which lacked any screening. The new screen removes gross solids and high-impact pollutants, dramatically improving discharge quality.

Compared to the original plan, the revised solution offered clear advantages:

- Lower design, construction, and operational costs.

- Reduced need for temporary works and heavy machinery.

- Shallower excavations, improving health and safety.

- Lower material use and simpler site logistics.

In parallel with the redesign, Galliford Try worked closely with hydraulic modellers to validate the concept and optimise key design elements. The CSO’s inlet was upsized to a 900mm pipe laid at a shallower gradient, with a 225mm dry weather flow (DWF) channel to maintain self-cleansing conditions and improve flow control. A new weir wall and realigned twin continuation pipes (225mm and 400mm) were installed alongside a reconfigured overflow connection, eliminating the risk of early spills and boosting hydraulic efficiency.

Hydraulic modelling confirmed the effectiveness of the new design. Annual spill events are projected to drop from 41 to just nine; a 75% reduction in spill volume, which is equivalent to approximately 20,000m3 of unscreened discharge avoided over 10 years. The remaining spills will now pass through a high-efficiency, Rotamat RoK2/300-1000 storm screen from Huber Technology; significantly enhancing discharge quality.

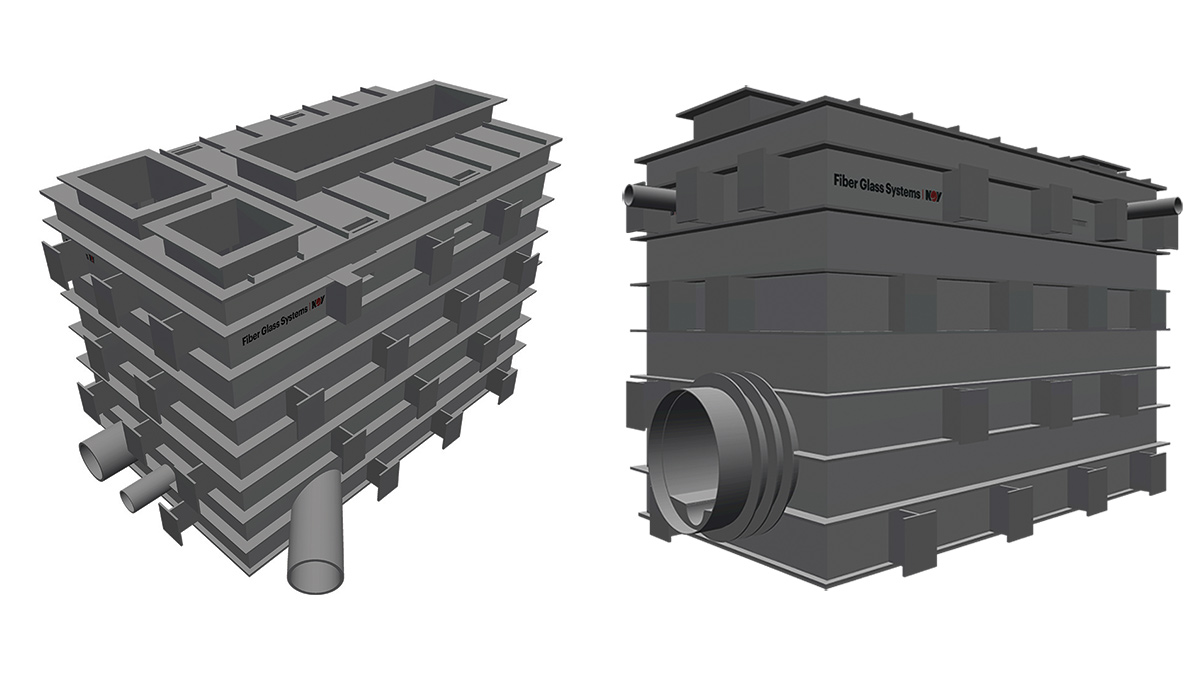

3D external render of CSO chamber – Courtesy of Galliford Try

Cricket Inn Crescent CSO: Supply chain – key participants

- Design Consultant: GHD

- Delivery contractor: Galliford Try

- Main works subcontractor: Carter Taylor Civil Engineering

- Pipe jack tunnelling: KIAMM Ltd

- Hydraulic modelling specialist: RES Environmental

- Temporary works/shoring: Mabey Hire Ltd

- Electrical contractor: Main Electrical Ltd

- Control panel & enclosure: Bridges Electrical Engineers Ltd

- Motorised screen supplier: Huber Technology

- HDPE CSO supplier: NOV Fiber Glass Systems

- HDPE pipes: Polypipe

- Bespoke chamber covers: Steelway Brickhouse

- Vegetation management: Landscape Maintenance Services

Innovative off-site construction enhances efficiency & safety

With a robust design finalised, the team evaluated construction methods to identify the most efficient and low-risk approach. The solution was for off-site prefabrication of the CSO chamber by NOV Fibre Glass Systems; experts in bespoke, factory-built infrastructure.

This strategy delivered major benefits across quality, safety, and programme delivery. Manufacturing the chamber in a controlled environment ensured precision, enabled more complex design features, and significantly reduced on-site works. Constructed entirely from high-density polyethylene (HDPE), a lightweight, durable, and chemically resistant material, the chamber was delivered fully assembled, complete with benching, pipe penetrations, electrical ducts, and weir walls.

Completed off-site manufacture of prefabricated CSO chamber – Courtesy of Galliford Try

A key innovation was the pre-installation of the Rotamat RoK2/300-1000 screen from Huber Technology within the chamber, reducing on-site risks and complexity. The use of HDPE not only supported a durable design, but also improved on-site safety. Its lightweight properties reduced the need for heavy plant and simplified lifting operations. Integrated dry weather flow (DWF) channels within the pipework further eliminated confined space working typically required for installation.

For the 900mm pipe section, a trenchless auger bore technique was used, avoiding disruption to critical underground utilities, including high-voltage cables, a medium-pressure gas main, and a water main, significantly lowering risk to operatives in a complex urban setting.

Long-term operability was a key design focus. Through hazard studies and access, lifting and maintenance reviews, the team engaged with future maintenance crews to incorporate ergonomic and safety-focused features. This included bespoke access hatches and fall-arrest grilles, allowing routine maintenance without the need for confined space entry.

Careful planning of temporary works and sequencing reduced the need for live sewer connections and exposure to high-flow sewage environments, further improving safety.

Programme delivery was accelerated through parallel workflows, off-site fabrication progressed alongside on-site pipe installation. The prefabricated chamber required minimal integration on arrival, reducing open excavation times and speeding up construction. This approach also delivered cost and resource efficiencies through reduced site labour, shorter temporary works durations, and more streamlined logistics.

On a highly constrained urban site, limiting plant, materials, and personnel helped create a safer, cleaner, and more efficient work environment.

Delivering sustainable outcomes & lasting social value

Sustainability was at the heart of the project from the final design through to construction. A key improvement was the removal of the need for a pumped shaft tank and its associated concrete and mechanical infrastructure. This change reduced the need for extensive temporary works and heavy transportation, significantly cutting embodied carbon and simplifying site operations.

(left) Trenchless auger bore installation of 900mm inlet pipe within large temporary works excavation and (right) prefabricated CSO chamber crane lift into temporary works excavation – Courtesy of Galliford Try

The project team focused on optimising existing network assets, minimising the construction footprint, and enhancing performance. The CSO was upgraded to a compliant, mechanically screened system, helping protect the environment and improve water quality, both above and below the surface, in line with national and global sustainability objectives.

Using HDPE pipes from Polypipe and a prefabricated HDPE CSO chamber from NOV Fibre Glass Systems, the project reduced overall carbon emissions by around 60% compared to traditional concrete components. Additional savings came from improved transport efficiency and faster, modular installation. To streamline delivery, a standard-design motor control centre was used, allowing off-site assembly with less waste and better quality control. The revised solution also replaced two 2.5kW pumps with a single 0.63kW motor for the screen, cutting energy demand and supporting long-term operational sustainability. Engaging local contractors further reduced transport emissions and boosted the local economy.

Although four trees had to be removed for safety reasons, the project was considered ‘permitted development,’ so it wasn’t required to meet the 10% biodiversity net gain rule. Nonetheless, Galliford Try worked with Sheffield City Council (SCC) to plant eight new trees, with a two-year maintenance commitment and provisions for replanting if necessary.

Proactive communication with SCC ensured minimal community disruption. Road closures were planned, publicised, and managed effectively, and SCC supported the project by providing a nearby council-owned site for welfare facilities and a construction compound, further improving efficiency.

Prefabricated CSO chamber in position with bespoke access covers temporarily positioned – Courtesy of Galliford Try

Aiming to leave a lasting legacy, Galliford Try collaborated with local schools to install rainwater terrace SuDS units. These units help manage stormwater and serve as educational tools for the students. Both Arbourthorne and Hillsborough primary schools embraced the initiative, incorporating it into lessons on the urban water cycle, sustainability, and planting. At one school, captured rainwater is now used to irrigate a herb garden, supported by funding from Galliford Try. The response has been overwhelmingly positive, with schools expressing interest in expanding rainwater harvesting initiatives.

The project was also aligned with several United Nations (UN) Sustainable Development Goals (SDGs), including:

- SDG 3: Good Health and Well-being.

- SDG 4: Quality Education.

- SDG 6: Clean Water and Sanitation.

- SDG 9: Industry, Innovation, and Infrastructure.

- SDG 11: Sustainable Cities and Communities.

- SDG 13: Climate Action.

- SDG 14: Life Below Water.

- SDG 15: Life on Land.

The project’s planning and execution reflect Galliford Try’s dedication to these global goals, aiming to deliver resilient, inclusive, and environmentally responsible infrastructure.

The completed works – Courtesy of Galliford Try

Conclusion

This project showcases the power of integrated design, stakeholder collaboration, and sustainable construction in delivering long-term environmental and social value. Involving 31 companies and aligned with eight UN SDG’s, the project was completed with zero Health & Safety incidents from construction through to commissioning.

The upgraded CSO is predicted to reduce spill frequency and volume by 75%, equating to approximately 20,000m3 over a 10-year period. A 60% cradle-to-grave carbon saving was achieved through the use of prefabricated HDPE components and off-site manufacturing. Beyond engineering benefits, the project left a positive local legacy. Eight trees were planted to replace four removed, and 844 students were engaged in sustainable drainage education. This project exemplifies how smart infrastructure can deliver lasting, measurable benefits for both people and the environment.