DCWW AMP6 Water Quality Zone Improvements (2018)

Overall Layout of Connah’s Quay Zonal Study Renewal Works - Courtesy of Waterco Consultants Map data: SIO, NOAA, U.S. Navy, NGA, GEBCO via Google Earth

Of Dŵr Cymru Welsh Water’s 85 (No.) Water Quality Zones (WQZs), 20 (No.) contribute 75% of the company’s targets to improve water quality and reliability. Detailed analysis has been carried out and documented in Zonal Study reports for these zones. These identified specific schemes, ranked in cost benefit order, presented in a standard plan and data format to achieve the company’s measures of success. The majority of schemes are cleansing and renewal schemes. The cleansing schemes improve safety and customer acceptability of water which generally relate to discolouration complaints, usually from iron or manganese. The renewal schemes improve reliability and serviceability in areas that have experienced clusters of bursts. They are in predominantly urban areas but also with some significant rural schemes including some trunk mains. The completed and ongoing delivery of these schemes in AMP6 is the subject of this paper.

Workshop

External designers including Waterco was appointed to work alongside DCWW’s in-house designers, on separate WQZs. Several representatives from all designers attended a 2-day workshop together at the start of the programme in 2015. This provided essential knowledge on the background, drivers, approval processes and tracking systems for the schemes.

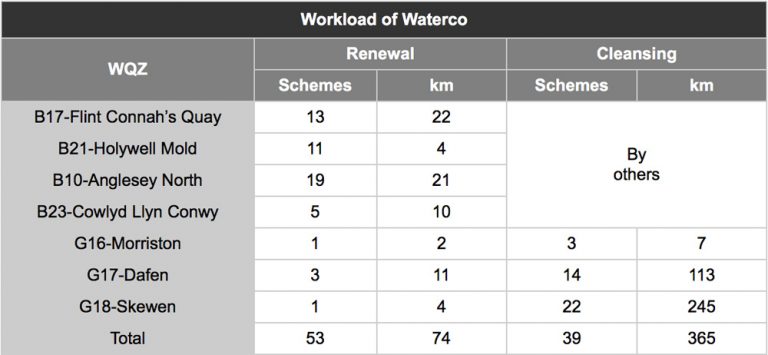

Waterco workload

Design process

The designs are managed and led by the designers to meet the requirements and priorities of DCWW. Scheme priorities are planned together in collaborative planning meetings to ensure interdependencies are considered and that cleansing and renewal schemes are sequenced in order of flow directions.

Key elements of each design are: the selection of the method of renewal; details of connections to existing mains; and commissioning sequences. Client, contractor and designer collaboration is employed in agreeing installation methods including slip-lining, pipe-bursting or directional drilling where appropriate, e.g. directional drilling has been used to cross a Site of Special Scientific Interest (SSSI). Constraints include: the quality and availability of information on pipe sizes, materials, depths and burst records; in-house resources for hydraulic modelling; and contractor resources for trial holes. Key design meetings are:

- Site visits.

- Commissioning.

- Design review/stakeholder sign-off.

The outputs are agreed with DCWW ‘s project managers to suit their standard works information and specification documents with supporting appendices. Following the design and tender stages, gateway approval is required to proceed to construction.

Pipe bursting at Bryn Road, Buckley – Courtesy of Waterco

Standardisation within the integrated process has enabled improved consistency and efficiency. This has covered many areas including the price quotation build-up for the design; the design and approval sequence; the format and content of documents and supporting information; drawing styles and connection details. Design work is carried out on a fixed fee basis for clearly defined sequential tasks. This minimises administration allowing all members of the team to focus on completing the outputs and maintaining the programme. Nevertheless, each scheme is individual and specific details and changes are recorded in key design documents:

- The design record.

- The risk register.

- The designer’s risk assessment.

These are produced collaboratively by the design team and then reviewed with the client before being issued with the tender pack.

Details of the design process have evolved over the programme across different WQZs to manage programme and resource constraints. For the B10 zone, the priority was to get to tender as soon as possible so a ‘lite’ stage of the design was developed, supplemented later by construction and thrust restraint details. This zone included extensive cleansing schemes. Once these were started, significant lengths of unlined ferrous mains were found which were added to the renewal schemes. This required revised and additional drawings and documents to achieve the programme.

Pipe bursting at Bryn Road, Buckley – Courtesy of Waterco

For the latest three zones in the Swansea area, the approach has been modified to minimise inefficiencies. Here, the same designers are investigating the cleansing schemes and designing the renewal schemes. The cleansing schemes are known to include unlined ferrous mains but the confidence in the historical records on the geographic information system (GIS) is variable, with many old pipes, some dating back to the 1860s.

Therefore, trial holes are being carried out to confirm the material and condition of the existing pipes with location, depth and size. Where mains can be cleaned and do not need to be renewed, through-bore hydrants are installed at the same time to facilitate ice-pigging to clean the pipes. Risk and value meetings are held after the investigations to approve any renewal lengths to proceed to design.

Once the risk and value meetings have been held for the whole zone, hydraulic modelling is used to ensure all renewals are correctly sized. Some mains are downsized to increase velocities and some are upsized to accommodate additional demand from development, abandonments or resilience requirements. In some areas dual mains are being replaced with renewed single mains.

Technical solutions

A particular technical challenge for the majority of the renewal schemes is the restraint of polyethylene pipework to contain contraction forces generated through pipeline pressurisation and to a lesser extent, temperature change. Pipe restraint is required principally at connections to existing mains; the preferred method of restraint is to construct a thrust wall cast around a flanged length of ductile iron pipe with a welded puddle flange, connected by pupped stub flanges to the polyethylene main.

In many cases, it is necessary to construct the thrust wall at the location of the existing main. As isolation times have typically been limited to 3-hour periods, careful consideration of connection details is required to minimise the work required during isolations of the network. For example, it is often necessary to install a flanged length of ductile iron pipe in advance of the final connection and connect it temporarily to the existing main to allow construction and curing of the concrete thrust wall.

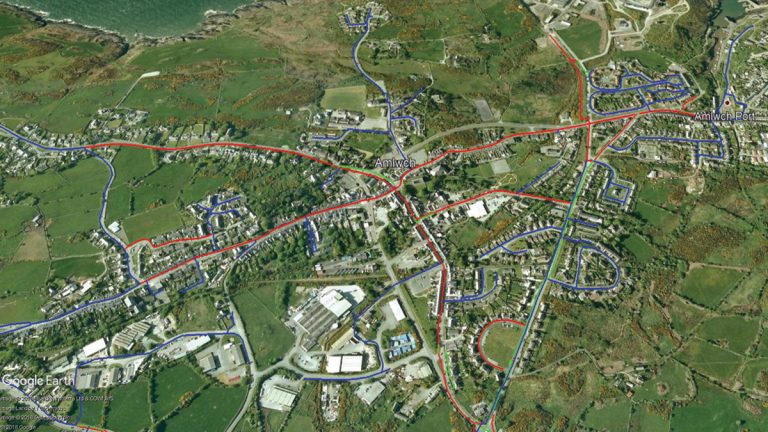

Amlwch fly-through extract – Courtesy of Waterco Consultants

Cleifiog

On larger mains and in poor ground conditions, the thrust walls required can be very large, often to the point where their construction is not practical due to space constraints.

One example of this was at the end-connections at Cleifiog where a DN450 DI main was scheduled for replacement with a 355mm OD PE100 SDR11 pipe.

In this case, it was necessary to restrain the forces imposed by the longitudinal contraction of the polyethylene main as well as the taper thrust forces. The soil at the end connection locations consists of a wet, soft clay which has a relatively low bearing capacity. Additionally, the maximum operating pressure of the main was approximately 9 bar. As a result, a large thrust wall was required to adequately restrain the pipework to prevent a joint failure at the connection to the existing main.

At both end-connection locations there are high pressure gas mains in close proximity to the existing water main. At the western end connection, there are also two buried 132 kV electricity cables in close proximity. This meant that space was limited, and an alternative approach was required as a traditional thrust wall was not practical.

An L-shaped structure was designed with a 5m wide slab section which could be constructed around the existing water main in a 2-phased approach. The slab section also acted as a relatively clean platform upon which the valves and hydrants could be supported.

Detail of ‘L-shaped’ thrust wall at Cleifiog – Courtesy of Waterco Consultants

Llanfechell

At Llanfechell, another technical challenge was a requirement for an air valve at a peak in the water main where it crossed a bridge over a river. The existing 6” cast iron main was located in the footway across the bridge with only approximately 300mm cover.

Based on records obtained from the Isle of Anglesey County Council, the depth of cover to the bridge deck was even less in the carriageway, therefore it was decided that the most feasible option would be to slip-line the existing water main with a 125mm OD PE100 SDR17 pipe. Waterco liaised with the DCWW hydraulic modelling, network and operations teams to ensure that this reduction in pipe size would be acceptable over a short length. However, as the new main would rise up to a peak on the bridge from both sides, an air valve was required on the bridge.

Due to the limited cover available, a standard air valve installation which incorporates a ductile iron tee and isolating gate valve was not feasible. A number of solutions were considered including the mounting of a cabinet to the bridge parapet to house the air valve. The final solution was to install a small single orifice air valve directly onto a 25mm ferrule connection on the new main.

Under-pressure tee installation – Courtesy of Dŵr Cymru Welsh Water

Improvements and innovations

Successful projects and quality management include continuous improvements in processes. One example of this is combining schemes and investigations into more efficient packs. This bundling helps to ensure that tendered costs meet standard target prices produced using DCWW’s developed unit cost database.

The innovations are generated by use of technology. Drawings have usually been produced using CAD packages, but the asset records and data attributes are stored in GIS format. So, GIS plans have been used to create the Streetworks plans and schedules which include bus routes and bus stops, traffic sensitive routes and streets subject to reinstatement restrictions (Section 58s).

This gives clear information for construction and will lead to easier asset record updates in GIS (or BIM) in future. GIS is also used to produce plans showing the sequence of cleansing and renewal schemes. These were overlaid onto Google Earth to create a fly-through video for a public meeting.

An essential part of the work is issuing documents, drawings and tender packs with secure document control. Uploading information directly onto DCWW’s intranet, Infozone saves time for the designers and DCWW and ensures the whole team has access to the current information.

Conclusion

Further improvements are in progress and planned. The use of video conferencing for review and approval meetings is being developed to include the drawing review electronic mark-up facilities currently used internally in drawing production. The ongoing improvement and collaboration will have wider impacts on the processes throughout DCWW particularly in the areas of data quality, asset management and making work more efficient for all.