Don Regulators (2024)

Aerial photo showing the complex syphon system by Vanderkamp UK to allow for the construction of the Meadowgate fish pass using 4-tonne precast concrete ‘fish tiles’ from Craven Concrete Ltd - Courtesy of JBA-Bentley

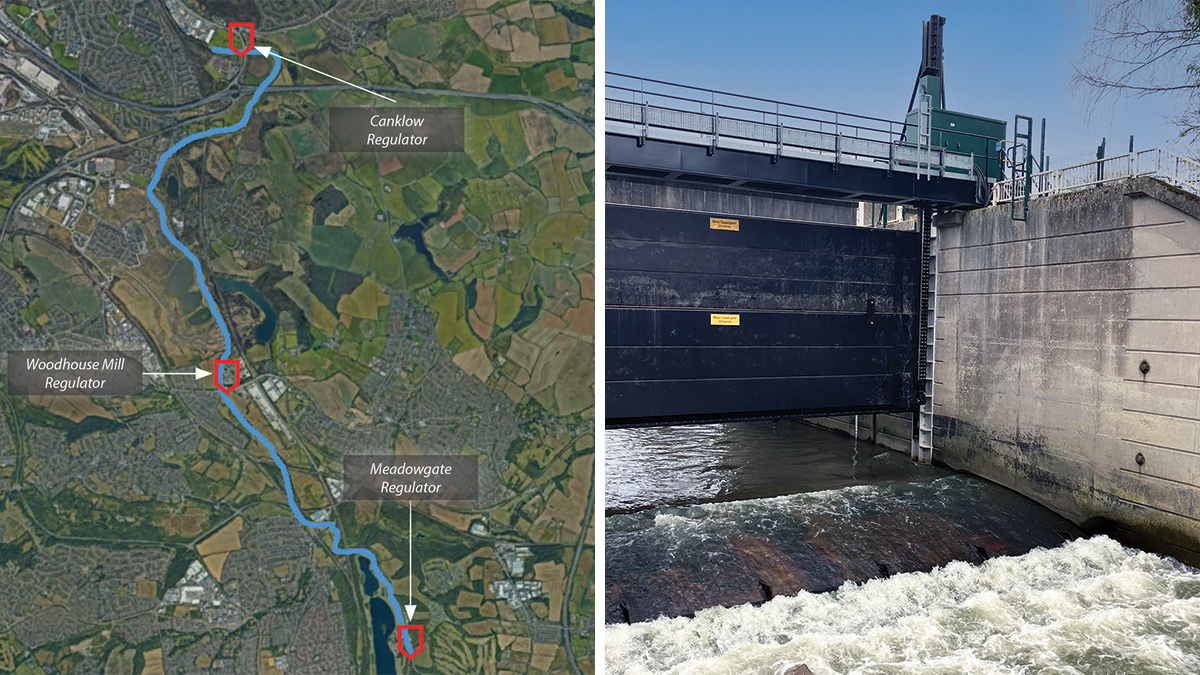

The Don Regulators comprise three regulator gates on the River Rother that are owned, operated, and maintained by the Environment Agency (EA). The purpose of the regulators is to reduce the risk of flooding to settlements within the River Don catchment by attenuating flows in the River Rother. JBA-Bentley has completed the design and installation of the first regulator gate. The detailed design of the second gate is currently being undertaken, while the third regulator is being modelled as part of the optioneering phase. In addition to the installation of the first regulator gate, a bespoke full-channel fish pass has been installed directly downstream to improve migratory fish passage.

Meadowgate Regulator

The Meadowgate Regulator is located within the Rother Valley Country Park. The historic regulator consisted of a single fish belly bottom-hinged tilting gate, operated by a single electrically powered hydraulic ram.

(left) location of the regulator gates and (right) the new Meadowgate top-down vertical control gate

In 2023, JBA-Bentley replaced the gate with a top-down vertical control gate, improving the resilience of the structure. Alongside the regulator gate, a new control building and EA Office have been constructed. Both buildings have green roofs and EV charging. The gate was commissioned in February 2024 and is ready to operate during a flood event.

The gate is operated to ensure a maximum of 60m3/s forward flow is always maintained. When flows exceed 60m3/s the new gate is lowered and water levels in the Rother rise and begin to spill into the washlands located within the Rother Valley Country Park, which can retain approximately 1.5 million m3.

Meadowgate full channel fish pass

The removal of the bottom tilting gate provided an opportunity to improve fish passage on the River Rother through the installation of a unique full-channel width fish pass. This fish pass is designed with 4-tonne reinforced concrete ‘fish tiles’ featuring varied-height upstands supplied by Craven Concrete Ltd.

The tiles were designed with the aid of computational fluid dynamics modelling to ensure they influenced the nature of the flow to allow for varied fish species to migrate upstream while also withstanding hydrodynamic forces during extreme events. The fish species focused on are coarse fish, European eels, brown trout, large migratory salmonids, and lamprey.

The 40m long stilling basin has been removed by building up the existing concrete channel bed and grading out the levels to create a uniform slope. The ‘fish tiles’ have been laid onto the regraded channel. This is the first fish pass of its kind in the world.

Precast concrete ‘fish tiles’ from Craven Concrete Ltd positioned in the channel – Courtesy of JBA-Bentley

Meadowgate temporary works solution: Syphon pumps & contingency planning

The fish pass installation required the full channel as a dry working area. To achieve this, an innovative syphon system, designed by Dutch water specialist Vanderkamp UK, was installed. The solution involved complex temporary works and contingency planning.

To form the upstream dam, the new regulator gate was dropped to bed level, allowing upstream water levels to build up. The gate was designed to operate this way; hence no further calculations were required. Four syphon intake pipes were installed upstream of the gate to divert up to 12m3/s of flow out of the channel for 115m, around the working area.

The syphons were primed using electric vacuum pumps which expelled all the air from the system to draw water through the pipes. By utilizing the existing gate and power supply, the syphons had a far lesser environmental impact than a typical cofferdam and over-pumping solution. The total embodied carbon associated with the syphon solution was 464 tons.

Due to the scale of the flows being diverted, the loads imposed on the riverbanks by the pipes when full were considerable. JBA-Bentley and Vanderkamp UK worked together to design a temporary support system involving ground-bearing improvements, steel and timber supports, and retaining structures. Checks were also carried out on the existing channel wall where the forces from the syphons acted upon it.

(left) The dewatered channel and (right) ‘fish tile’ installation – Courtesy of JBA-Bentley

In addition to work to ensure the stability of the syphons, an energy dissipation system was designed and installed at the syphon outlets to combat scour, and a bubble curtain was installed upstream to deter fish from entering the syphons. The installation of the system was done via a temporary crane pad. Due to the nature of the site and its space constraints, this was a challenging design. JBAB worked closely with the landowner, Rother Valley Country Park, to balance the desire to allow continual access into the park with ensuring the crane was safe to carry out the required lifts. To achieve this, the crane had to be placed in close proximity to the riverbank. Slope stability modelling and bearing capacity calculations were undertaken to ensure the crane could be operated safely.

Recent storm events have recorded flows higher than the syphon capacity. To manage the risk of this occurring during the programmed works, a contingency plan was developed.

The basis of the plan was developed from a bespoke JBA flow forecasting system, which forecasted the flow over a 2-day period. Using the data from the forecasting system, flow monitoring data provided by Vanderkamp UK, upstream gauge data, and the storage capacity of the washlands upstream of the gate, JBAB could make informed decisions on whether the gate needed to be raised to allow flow to pass forward.

This decision was made with the aid of hydraulic calculations and decision flow charts within the contingency plan, allowing for quick and effective decision-making, ensuring flood risk was not impacted upstream and the safety and well-being of the site team working in the channel was never put at risk.

Syphon outlet – Courtesy of JBA-Bentley

Don Regulators: Supply chain – key participants

- Client: Environment Agency

- Project delivery: JBA-Bentley JV

- JBA Consulting

- JN Bentley Ltd

- Principal designer: Callsafe Services Ltd

- Gate design: Aquatic Control Engineering

- Syphon design: Vanderkamp UK

- Electrical installations: IMAC Ltd

- Building design: JP Chick & Partners

- Building design: Peter Wells Architects

- Supporting ECC Supervisor with new gate & associated equipment: KGAL Consulting Engineers Ltd

- Precast fish pass tiles: Craven Concrete Ltd

- In situ concrete works: Bells Construction Ltd

- Metalwork fabrications: Fabtek

- Green roof: ABG Geosynthetics Ltd

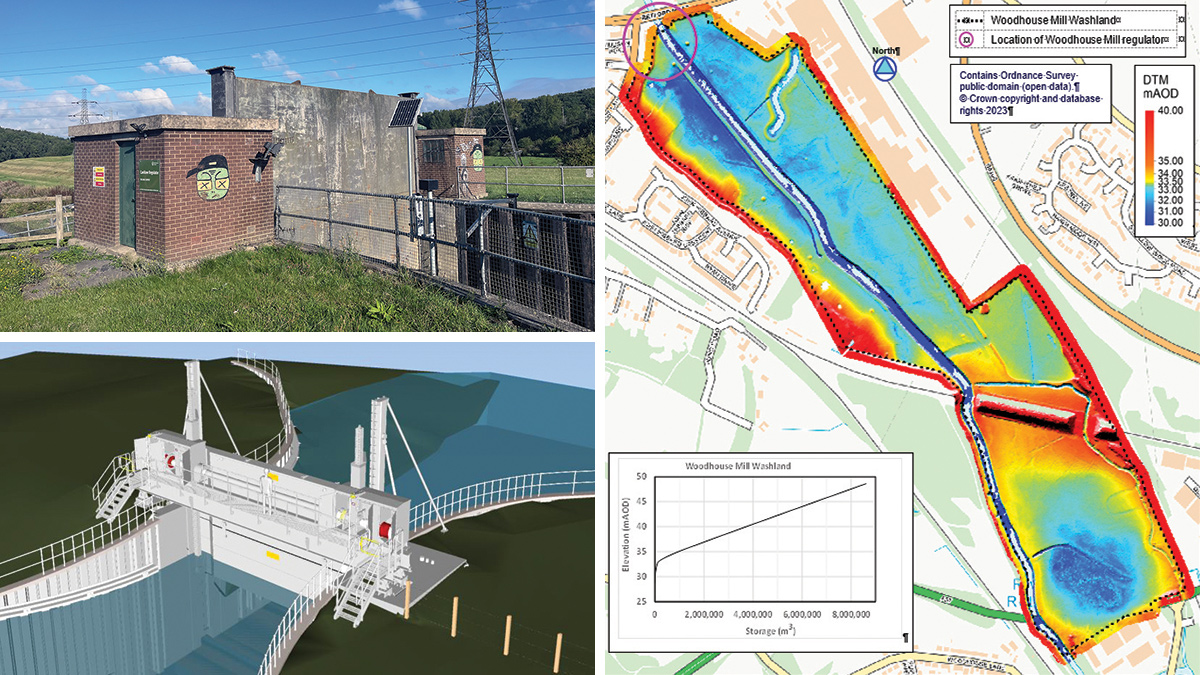

Canklow Regulator

The Canklow Regulator is the furthest downstream of the three Regulators, approximately 3.5km upstream from the confluence of the River Rother and the River Don at Rotherham.

The existing structure consists of a single electrically powered vertical lifting sluice gate operated by an electric wire rope hoist, comprising a drive motor gearbox assembly, cross shaft with integral rope drums, and support bearings.

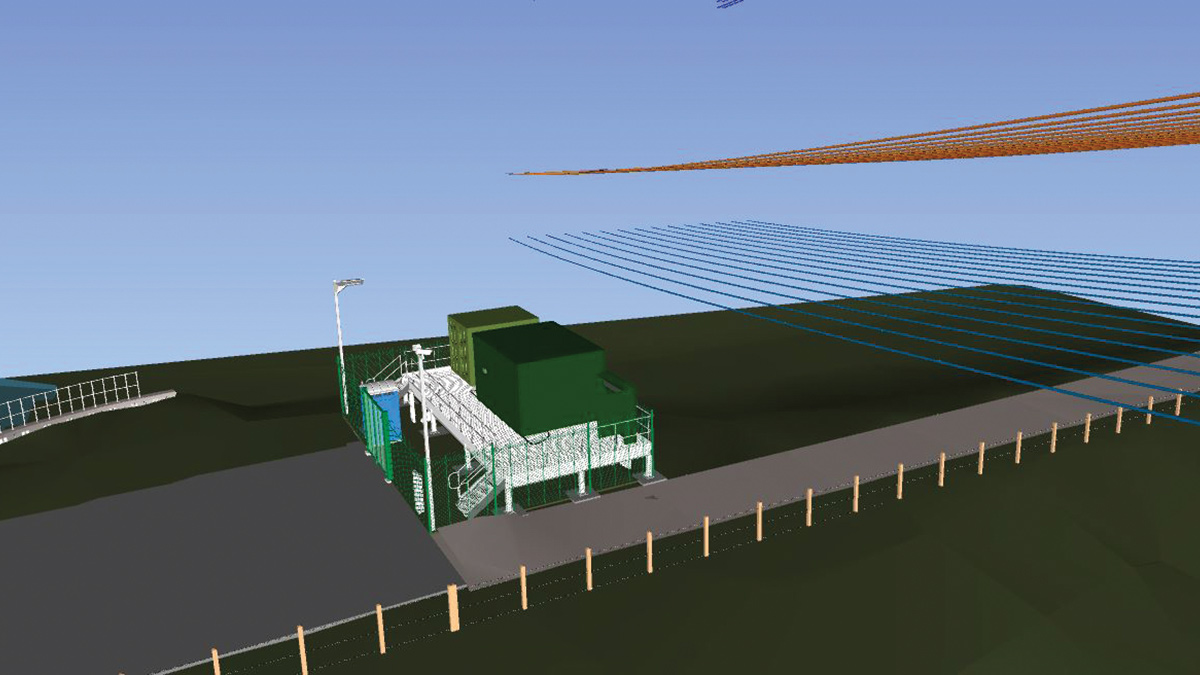

To improve resilience and the operation and maintenance of the asset, JBA-Bentley is completing the detailed design and build of a new vertical regulator gate and associated MEICA and civils infrastructure.

The MEICA structure consists of a 20.3-ton vertical gate, mounted on a new steel bridge and working platform, which shall also house 13.5 tons of drive equipment for operating the gate.

Two 4kW motors, working in a duty/standby configuration, will provide drive to the gate via bevel and gearboxes, which turn a single driveshaft spanning the width of the gate. On this driveshaft, one at either end of the gate, are rack and pinion gear assemblies, which convert the rotation of the driveshaft to the vertical motion of the gate. The total gear ratio from motor to driveshaft is an approximate reduction of 4410:1, allowing relatively small motors to be specified.

(top left) the existing Canklow regulator gate (bottom left) 3D model of the new Canklow Regulator and (right) bathymetry of Woodhouse Mill Washland – Courtesy of JBA-Bentley

The power supply to the gate will be a three-phase supply routed via a new MCC, which will contain the control modules, centralised drive units, and the telemetry system for remote monitoring and operation of the gate. The operation of the gate will be from on-site or via telemetry, with some semi-automated functions. The facility for future full automation of the site has been incorporated into the design. The MCC and electrical components will all be located within a kiosk mounted on a raised steelwork platform to lift the electrical components above the 0.1% AEP flood level. Also on this raised platform will be the DNO kiosk bringing power onto the site from the national grid, and a standby generator to provide resilience in case of power failure.

To support the new gate structure over the next 50 years, a new anchor restraint system has been designed. A buried sheet-piled ‘dead-man’ wall will be installed with ten 36mm anchor rods, evenly spaced, connecting to a waling beam on the wet side of the existing channel wall. This will be mirrored on both riverbanks.

The new infrastructure replicates the existing system, which has been determined to be past its design life and insufficient in supporting the new gate.

The existing superstructure of the control houses will be demolished, the foundations will be retained and extended where required to support the new gate structure using cast-in bolt sets.

A new permanent crane pad will be constructed on the south bank for the construction, maintenance, and decommissioning of the gate. This will double as parking spaces for EA operatives when not being used by a crane.

The JBA-Bentley team worked collaborative to optimise the delivery. This meant that site constraints were identified, and the design was completed with buildability and safety as the focus. A key constraint on the scheme is the proximity of the Northern Power sub-station and overhead power lines. The design of the dead-man walls, crane pad, and steelwork platform was completed to ensure that the plant and temporary works required for construction and installation were outside of the powerline exclusion zones.

Overhead power exclusion zones within model – Courtesy of JBA-Bentley

Woodhouse Mill

The Woodhouse Mill Regulator is situated between Canklow and Meadowgate. It uses a single electrically powered vertical lifting gate to retain water. This gate is operated by an electric wire rope hoist, which includes a central drive motor and gearbox assembly, half shafts, spur and pinion driven rope drums, and support bearings, all counterweight assisted.

JBA-Bentley is currently carrying out hydraulic modelling on behalf of the EA as part of the optioneering phase. The options include passive solutions, such as a baffle or orifice plate spanning the width of the channel to continue to utilize the upstream storage. Due to the size of the Don catchment, the modelling required three individual models to be run together:

- The Rother.

- Don/Dearne.

- Lower Don.

Multiple return periods are being considered, resulting in hundreds of models runs. The modelling also uses a continuous simulation approach, which adds to the complexity of the model runs.

Summary

The upgrading of infrastructure of the Don Regulators will ensure continued flood risk benefits into the future for the Don Catchment and surrounding area with improved resilience and reliability of the new assets. Alongside the reduction in flood risk, the environment and biodiversity will improve in the River Rother as a result of the Meadowgate Fish Pass.

Existing Woodhouse Mill Regulator - Courtesy of JBA-Bentley