Durleigh WTC (2023)

Durleigh Water Treatment Centre - Courtesy of Wessex Water

In 2019, Wessex Water launched a £51 million project to upgrade the Durleigh Water Treatment Centre (WTC) in Somerset, which had reached the end of its operational life. This project was crucial in maintaining the delivery of high-quality drinking water to a population of 44,500 and was part of the company’s long-term water supply strategy for the region. Led by Wessex Water’s Engineering & Sustainable Delivery (ESD) department, this was the largest single-value scheme ever undertaken by the company.

This case study focuses on the commissioning of the works and follows on from those published in 2020 and 2021:

- 2020: Durleigh WTC: Wessex Water’s flagship clean water project

- 2021: Durleigh WTC: Project construction update

Introduction

Construction completed in autumn 2021 after which the 12 months planned period of commissioning began, during which all systems were rigorously tested to ensure that the upgraded water treatment centre met the necessary standards for quality and safety.

In late summer 2022, water was supplied to the region and the project was completed within budget and ahead of schedule, providing a valuable additional water resource during the driest summer since 1976. This successful upgrade demonstrates Wessex Water’s commitment to providing reliable water supply of improved quality to its customers for years to come.

Multi-barrier treatment for challenging source water

Durleigh Impounding Reservoir, which provides the raw water for Durleigh Water Treatment Centre, is fed by two sources; Durleigh Brook which runs through agricultural land from the Quantock Hills, and the Bridgwater to Taunton Canal via the Albert Street Pumping Station. The combination of these sources, however, introduces high levels of nutrients and several significant contaminants, leading to highly variable quality source water. Given this variability and the need to remove all potential contaminants, a multi-stage treatment process was required alongside the construction of a new wetland at the head of the reservoir.

New Durleigh wetland – Courtesy of Wessex Water

The wetlands have been designed to filter silt and coarse sediment and reduce levels of nutrients, helping to improve the raw water quality entering the reservoir as well as boosting biodiversity by becoming home to a diverse array of wildlife. An existing wet woodland also acts as a final screening process before the water reaches the reservoir.

The two new habitats, constructed to the west of the water treatment centre and reservoir, have brought about a near 75% reduction in the amount of ammonia present in the raw water, while phosphorus and sediments have dropped by around a third.

Treatment processes

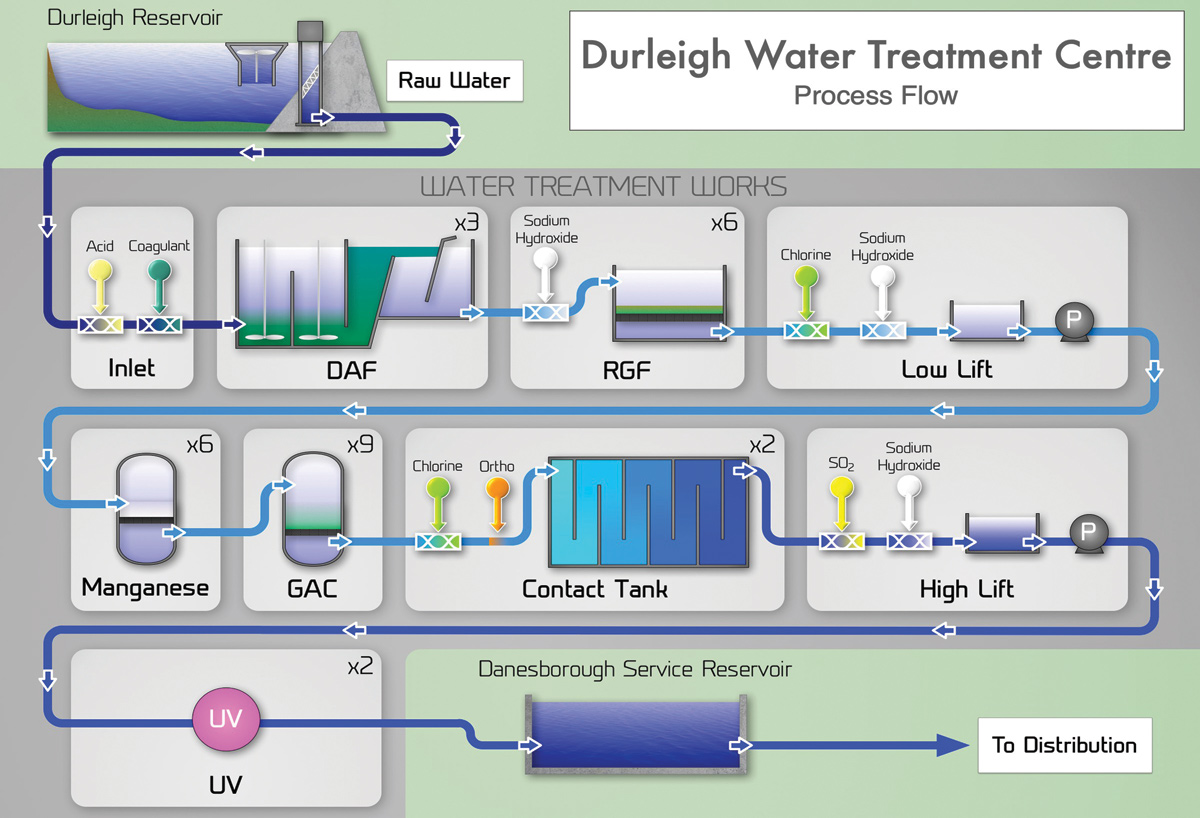

The following treatment processes were then selected:

- Pre-treatment with sulphuric acid and aluminium sulphate.

- Dissolved air filtration (3 x 10 Ml/d streams).

- pH adjustment (sodium hydroxide dosing).

- 6 (No.) dual media rapid gravity filters.

- Oxidation and pH adjustment (sodium hypochlorite and sodium hydroxide dosing).

- Re-lift pumping by 3 (No.) variable speed end suction pumps (duty/assist/stand-by).

- 6 (No.) manganese removal pressure filters.

- 9 (No.) pressurised granular activated carbon adsorbers.

- Orthophosphoric acid dosing (plumbosolvency control).

- Disinfection using chlorine and sulphur dioxide gases (super-chlorination and de-chlorination).

- pH adjustment (sodium hydroxide dosing).

- High lift pumping 3 (No.) variable speed end suction pumps (duty/assist/stand-by).

- Cryptosporidium inactivation using duty/assist UV treatment.

- Duty/duty lamella clarifiers for wastewater treatment.

The combination of the wetland with the multi-barrier treatment process ensures that all potential contaminants are removed from the raw water, providing safe, high-quality drinking water.

Process flow – Courtesy of Project Support Systems

Risk based approach to commissioning

The project team recognised that early consideration of the commissioning process would be critical to ensuring successful project delivery. To achieve this, a risk-based approach was adopted throughout the project starting with the design phase. In-house ESD commissioning staff were embedded in the design team and using the digital data available through the schemes BIM360 delivery mechanism undertook a detailed risk assessment of each commissioning activity to identify areas where the design could be revised to increase the efficiency of the commissioning process. By incorporating these changes into the final design, the team was able to expedite process commissioning and reduce testing time by implementing concurrent commissioning of parts of the treatment process.

To ensure that the design of the control software met the company’s specifications and aligned with the delivery program, the project team took early ownership of this aspect of the project. The Functional Design Specification (FDS) was produced in-house by staff from the ESD Commissioning & Automation teams, as well as staff from Operations and the scheme designers AECOM. The FDS detailed the software requirements for normal and abnormal operation, setpoints, alarms, and interlocks. By constructing the control in a modular and standardised way, the team was able to achieve flexibility for future operations while reducing delivery and testing time through a simple logical code structure.

Instillation of 14/25 sand media into manganese removal filters – Courtesy of Wessex Water

The risk-based approach continued through the construction and commissioning phases of the project. Critical plant that had been identified during the design phase were subject to enhanced testing and inspection procedures to mitigate the risks and prevent any cost or time impacts. The risk-based approach also ensured that where specialist activities were required the appropriate contractors could be engaged in a timely manner to ensure the installation was delivered to their testing requirements.

By utilising this approach, early involvement in the commissioning process, and careful control design, the project team was able to achieve significant cost and program reductions, while also ensuring that the final design met all project requirements.

Collaboration in commissioning

Wessex Water recognises that project outcomes rely not only on technical expertise but also on effective collaboration between engineering and operations teams. Collaboration between the Engineering Department and Operations Team within Wessex Water has played a pivotal role in the delivery of the Durleigh WTC refurbishment project. Key areas where joint efforts have contributed to project success are:

- Design specification collaboration: The engineering department and operations team within Wessex Water worked collaboratively from the project’s initiation to ensure that the design met both engineering standards and operational requirements. By leveraging their expertise, the teams combined engineering principles with operational insights to optimise the facility’s design for efficient water treatment processes.

- Ongoing involvement & secondment: To maintain a continuous exchange of knowledge and promote collaboration, members of the operations team were seconded into the engineering department throughout the project’s duration. This arrangement facilitated the sharing of operational insights and allowed the operations team to contribute valuable input during the project’s progress.

- On-site presence for commissioning: The operations team actively participated on-site several months prior to the completion date to observe and engage in commissioning activities. This early involvement enabled them to gain a comprehensive understanding of the plant’s operations, controls, and processes, ensuring a smooth transition from construction to operation.

Durleigh WTC main treatment building – Courtesy of Wessex Water

- SCADA display optimisation: The operations team collaborated closely with the engineering department to optimise the Supervisory Control and Data Acquisition (SCADA) display. Leveraging their operational expertise, they worked together to customise the interface, aligning it with operational workflows and enhancing usability for the operators.

- Exposure to infrequent and abnormal operations: Through their presence during commissioning and early operation stages, the operations team had the opportunity to observe and gain experience with infrequent and abnormal operational scenarios. This exposure enabled them to develop strategies, protocols, and contingency plans to handle such situations effectively.

- Continuous training for operational excellence: Training was an ongoing process throughout the project, with formal training sessions scheduled after the operations team gained prior experience. This approach allowed operators to apply their knowledge and skills in practical settings, ensuring continual improvement and optimal performance.

The collaboration between Wessex Water’s engineering department and operations team has played a vital role in the success of the project. Through joint efforts in design specification, ongoing involvement, on-site presence, SCADA display optimisation, exposure to infrequent operations, and continuous training, the teams have fostered effective collaboration and achieved project objectives. This collaborative approach serves as an example of how departments within an organisation can work together to drive success and optimise operational outcomes.

(left) High lift pump hall and (right) air saturation test of DAF lane – Courtesy of Wessex Water

Durleigh WTC: Supply chain – key participants

- Principal contractor: Wessex Water ESD

- Principal designer: AECOM

- Process design: Stantec UK

- CFD modelling: The Fluid Group

- Project and O&M documentation: Project Support Systems

- Temporary works & shoring: MGF Ltd

- End suction pumps: SPP Pumps Ltd

- Electrical installation: Field Systems Designs

- MDB/MCCs: GPS Group

- Lamella clarifier: Hydro International

- DAF saturation system: Quantum Engineering Developments Ltd

- Large bore pipework: Powerrun Pipe-Mech

- Large bore pipework: Berry & Escott

- Inlet screen air scour: Eliquo Hydrok Ltd

- UV treatment: Trojan Technologies

- Valves: AVK UK Ltd

- Air blowers: Aerzen Machines

- Polyelectrolyte dosing: Richard Alan Engineering

- Sodium hypochlorite dosing: WES Ltd

- Chemical dosing: DMS Engineering

- Chemical dosing: MBH Engineering

- Access steelwork: Dan’s Engineering

- Tank & vessel manufacturing: Vessco Engineering

- Desiccant drying systems: Aggreko

- Ice pigging: Suez Water Technologies

- WQ monitors: SWAN Analytical UK Ltd

- WQ monitors: Malvern Panalytical

- WQ monitors: Yokogawa UK Ltd

- WQ monitors: ATi UK

- WQ monitors: Metrohm

Durleigh WTC to Danesborough Service Reservoir Trunk Main

The recommissioning of the trunk main connecting Durleigh WTC to Danesborough Service Reservoir presented unique challenges, and required meticulous planning.

- Assessing the condition & risks: The 1.7km long rising main, constructed from epoxy-lined ductile iron, served as the crucial link between Durleigh WTC and Danesborough Service Reservoir. However, the last 80m of the main were unlined and known to be a source of discolouration, with elevated levels of turbidity and iron. Although it had been flushed to a flow rate of 26 Ml/d prior to the old works’ removal from supply, it had been out of service for three years and it was essential to address the remaining risks and restore the main’s integrity.

- Ice pigging solution: Considering the limitations in delivering the required flow with Durleigh WTC still out of service, a decision was made to employ a technique known as ice pigging for the last 80m of the rising main. To execute this task, Wessex Water engaged the expertise of Suez Water Technologies, a specialist ice pigging team. The ice pigging involved the introduction of a 10m3 ice slug into the main, followed by a 90-minute flushing process.

- Effective turbidity reduction: The implementation of ice pigging, followed by flushing, proved highly effective in removing 21kg of solid material from within the last 80m of the rising main. This achievement was crucial in mitigating risks and guaranteeing the quality of the water to the Danesborough Service Reservoir.

Ice pigging flushing samples – Courtesy of Wessex Water

- Comprehensive pressure testing & disinfection: To ensure the integrity and reliability of the entire rising main, Wessex Water’s in-house disinfection team carried out a comprehensive pressure testing and disinfection process. The main underwent rigorous testing over a 72-hour period, subjecting it to stringent protocols to confirm its ability to withstand operational demands and maintain water quality standards.

- Successful restoration & return to supply: Following clear sample results and meeting the required water quality standards, the recommissioning process was successfully completed, and the Durleigh WTC to Danesborough Service Reservoir rising main was returned to supply. This significant milestone was achieved in late September 2022, marking the successful completion of the project.

Conclusion

The successful completion of the Durleigh Water Treatment Centre upgrade project by Wessex Water represents a significant milestone in the company’s commitment to delivering high-quality drinking water to its customers. This ambitious project, the largest single-value scheme ever undertaken by Wessex Water, was executed with meticulous planning, collaboration, and a risk-based approach. Through the implementation of advanced treatment processes and a comprehensive control software design, the upgraded facility ensures the removal of potential contaminants, guaranteeing the provision of safe and reliable drinking water to its customers.

Low lift pumping area – Courtesy of Wessex Water

The project team’s focus on collaboration between the engineering department and operations team, along with their early involvement in the commissioning process, played a vital role in achieving remarkable results. By optimising the design specifications, streamlining the commissioning process, and fostering a culture of continuous learning, the team not only met project requirements but also set a new benchmark for water treatment engineering. This successful endeavour displays Wessex Water’s dedication to sustainable water management.