Flag Fen WRC (2025)

Inside one of the new stainless steel stormwater storage tanks - Courtesy of Anglian Water’s @one Alliance

Flag Fen Water Recycling Centre (WRC), located in Peterborough, is a vital part of Anglian Water’s regional water management system. Named after the nearby historic Flag Fen archaeological site, the WRC’s function is to process and treat wastewater from the city and surrounding areas, ensuring the safe return of clean water to local rivers and ecosystems. Serving both a growing population and industrial sector, the facility is integral to maintaining high environmental standards and supporting the region. The facility serves as a critical hub, managing significant volumes of wastewater and stormwater while maintaining stringent compliance with environmental standards. Over time, the changing climate and urbanisation have intensified the challenges related to the WRC’s stormwater capacities, risking overwhelming existing infrastructure.

The issue

As Peterborough continues to grow, Flag Fen Water Recycling Centre remains a forward-thinking facility, providing essential services to the community while protecting natural resources for future generations.

The existing infrastructure at the WRC has been increasingly insufficient for managing the demands placed upon it. Storm tank capacity had become a pressing concern, with flows during peak periods often exceeding the current capacities limits. Without sufficient storage, excess stormwater risked being discharged untreated into the local water courses, which impacts our surrounding ecosystems, plus goes against the current environmental regulations.

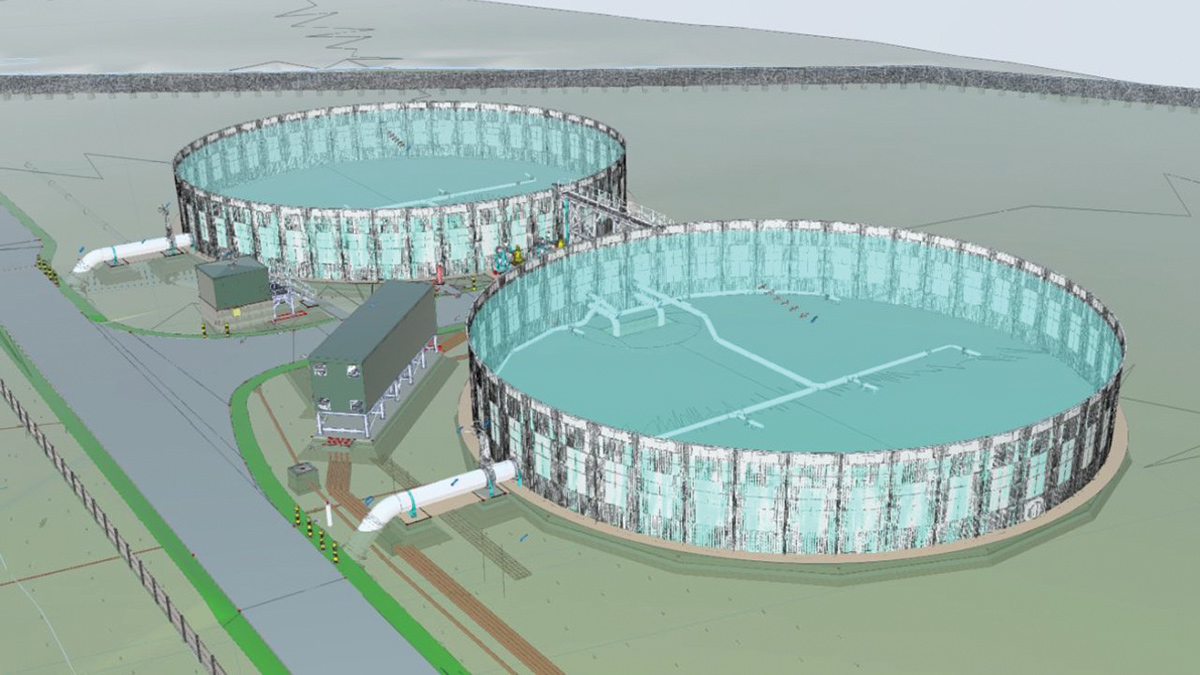

3D render of the new tanks – Courtesy of Anglian Water’s @one Alliance

Additionally, aging systems required significant modernisation. The storm tank cleaning mechanisms and control systems were outdated, leading to inefficiencies and elevated maintenance costs. The WRC needed to integrate its operations more effectively with modern telemetry and automation technologies to enhance reliability and performance.

Compounding these issues were regulatory obligations. Under the WINEP flow driver, the WRC was mandated to increase its storm tank capacity by 7625m3 by 31 March 2025, ensuring compliance with permitted dry weather flow (DWF) levels. This requirement was further complicated by the need to manage stormwater flows under a 30-year design storm scenario while incorporating climate change projections.

The solution

To meet these challenges, Anglian Water tasked the Anglian Water’s @one Alliance to implement a £10m extensive upgrade to the stormwater storage and management systems. The solution required the installation of two new stainless steel storm tanks, each designed to provide 4,027m3 of additional storage, for a combined total of 8,055m3 as well as improvements to the storm tank cleaning systems, control mechanisms and electrical infrastructure.

Stormwater storage tanks: The new stainless steel tanks from Hayes GFS Ltd measure 37m in diameter and have a sidewall depth of 5.63m. Gravity-fed return flows are directed to the screw pump wet well by intercepting the exiting pipeline from the DWF weirs, ensuring seamless integration with existing operations. The tanks were constructed on 400mm thick, concrete base slabs, covering 1,150m2, with 120 kilograms of reinforcement per cubic meter. A 300mm gravel layer was installed around the tanks to enhance stability and facilitate drainage.

The new pipelines connecting to the tanks to the inlet works ensure efficient flow management during peak storm events.

Bell Formwork finalising the stormwater storage tank base – Courtesy of Anglian Water’s @one Alliance

Storm tank cleaning system: A new cleaning system was installed to the new stainless steel storm tanks; maintaining the functionality and hygiene of the tanks, and allowing Anglian Water Operations to be able to clean the storm tanks after usage.

The system featured eight new ejector nozzles in each tank, fed by four Flygt NT3202.180 dry-mounted submersible pumps from Xylem Water Solutions. Each cleaning pump provided a recirculation rate of 235 l/s, ensuring effective debris removal and minimising the need for any manual intervention.

Electrical & automation upgrades: Significant upgrades were made to support the new storm tank infrastructure and to ensure operational reliability. Firstly a dedicated storm tank cleaning motor control center (MCC) was installed in a raised kiosk to mitigate the potential flood risks. This system included ultrasonic transducers, pressure switches, and access platform lighting to enhance functionality and safety.

Alongside this, the team designed and installed a new 1,000 kVA transformer, along with modifications to the existing transformer. This in total increased the WRC’s power capacity from 2.6 MVA to 3.1 MVA.

A new fully automatic control system was added into the WRC’s existing telemetry network. This system automated storm tank emptying sequences and provided real-time monitoring for efficient operation.

Raised MCC kiosk – Courtesy of Anglian Water’s @one Alliance

The benefits of this solution

The implementation of the upgraded stormwater management system delivered a wide range of benefits, addressing immediate challenges and positioning the WRC for long-term success.

Regulatory compliance: By increasing storm tank capacity by 8,055m³, the facility met its obligations under the WINEP FLOW driver UIMP6. Achieving compliance by the mandated deadline (31 March 2025) not only avoided regulatory penalties but also demonstrates a proactive commitment to Anglian Water’s environmental investments.

The design of the new storm tanks ensured full compliance with permitted DWF levels and storm sewage consent conditions.

Enhanced operational efficiency: The new storm tanks and cleaning systems significantly improved operational reliability by reducing the downtime and ensuring the tanks remained ready for use after each storm event.

The solution provided many benefits from an operational efficiency’s standpoint, including:

- By incorporating gravity-fed and gravity-return systems, stormwater management was streamlined by reducing the energy consumption and operational complexity.

- The use of the advanced telemetry and control systems enhanced real-time monitoring and reduced the need for manual interventions.

- The increased stormwater return rate of 442 l/s represents a marked improvement, and enables faster recovery after peak flow events.

The new stormwater storage tank and raised MCC kiosk – Courtesy of Anglian Water’s @one Alliance

Environmental protection: The upgraded system will be able to prevent untreated stormwater from being discharged into the local water courses during high-flow periods. This ensures that local watercourses and ecosystems are safeguarded by providing high infrastructure that will be resilient against future environmental challenges. The risk of localised flooding in surrounding residential and industrial areas will be reduced, protecting the public health and properties of the public in Peterborough.

Flag Fen WRC: Supply chain – key participants

- Client: Anglian Water

- Project delivery: @one Alliance

- Watching brief: Cotswold Archaeology

- Civil works: Bell Formwork & Civil Engineering Services Ltd

- Over pumping: Selwood

- Storm tanks: Hayes GFS Ltd

- Tank cleaning system pumps: Xylem Water Solutions

- MEICA: Kemada Project & Contract Services Ltd

- Epoxy pipework: Freeflow Pipesystems Ltd

- Epoxy pipework: Powerrun Pipe-Mech Ltd

- Access steelwork platforms & design: Cobra Engineering (UK) Ltd

- VSDs, HMI & MCCs: CEMA Group

- Kiosk & kiosk route survey: NPS Engineering Group

- Power upgrade: Power Testing

- Temporary generator for power upgrade: Stuart Power

- Scaffolding: Tubes Scaffolding Ltd

- Permanent Fencing: Burn Fencing Ltd

One of the new stainless steel stormwater storage tanks – Courtesy of Anglian Water’s @one Alliance

Conclusion

The £10m upgrade to the Flag Fen WRC’s stormwater management system has addressed critical infrastructure needs, while ensuring compliance with environmental and regulatory standards. The installation of two new stainless steel storm tanks, alongside the advanced cleaning and control systems, will transform the facility’s operational capabilities.

The solution had to be fully compliant with stringent environmental standards, accommodating no-detriment scenarios under a 30-year design storm with allowances for climate change. The stormwater return rate being increased from 388 l/s to 442 l/s represents a significant improvement in operational performance.

The solution minimised the visual and environmental impact of the new infrastructure by included landscaping, new access paths, and a screening bund. Additionally, the new stainless steel tanks were painted green to fit in with the surrounding landscaping features.

These measures improved the overall aesthetics of the new storm tank infrastructure.

This project highlights the importance of innovative engineering and sustainable practices in modern wastewater management. By enhancing storage capacity, improving efficiency, and protecting the environment, the WRC not only will resolve the immediate challenges but also positioned itself as a resilient and adaptable WRC in the region. Through careful planning and execution, the project delivered lasting benefits for the environment, the community, and future generations.

Finalising the tank base - Courtesy of Anglian Water’s @one Alliance