Hayfield & Barton WwTWs (2021)

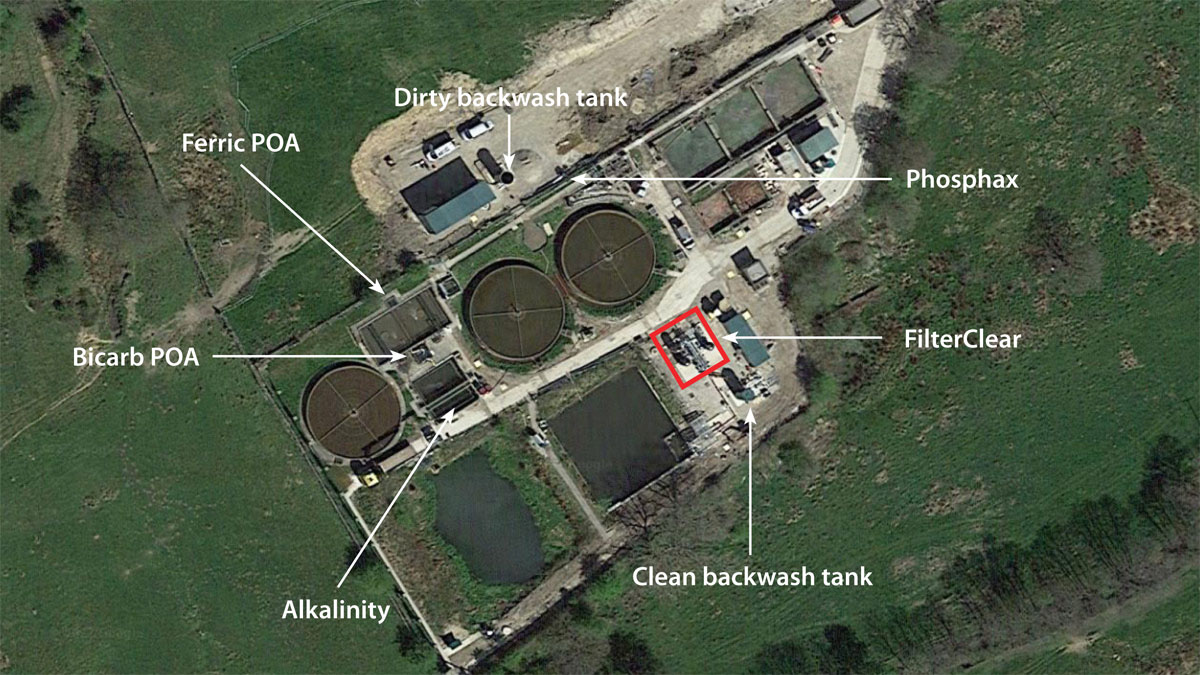

FilterClear installation at Barton WwTW - Courtesy of Bluewater Bio Ltd

In recent years, phosphorus discharge limits have been tightened to improve the surface water quality, particularly to address eutrophication issues. Before 2015, only a small number of sites in the UK had a total phosphorus (TP) permit as low as 1 mg/l under the Habitats Directive. Since then, TP permits have been continuously tightened in order to achieve the ‘good status’ required by the Water Framework Directive (WFD). In AMP6 and AMP7 a big step change of more stringent TP permits as low as 0.1 mg/l have been introduced.

Background

Phosphorus can be removed biologically or chemically. For large activated sludge plants (ASPs), biological P removal is often an economic and sustainable approach, supplemented by chemical dosing when the TP limit is below 0.5 mg/l. In the UK however, nearly 90% of WwTWs are below 10,000 PE, and many of these are tricking filter works which rule out the Bio-P solution. Consequently, chemical P removal has become the predominant solution.

To achieve TP of 0.5 mg/l or lower permits, the majority of water companies specify a two-point chemical dosing regime, coupled with a tertiary solids removal (TSR) plant. However, recent projects has demonstrated that this TP permit can be met by single point ferric dosing instead; resulting in capital and operating cost savings.

Google Earth image of Hayfield WwTW showing location of FilterClear plant

Collaboration

All successful projects require constructive collaboration between client, main contractor and the technology providers. In AMP7, United Utilities (UU) needs to improve P removal at over 60 sites required by the WFD; two thirds of which are new to P removal. About 30 sites will have a TP permit below 0.5 mg/l, and more than 10 sites will have a TP permit of 0.25 mg/l.

Mott Macdonald Bentley (MMB) is one of UU’s delivery partners. Across the UU Region, MMB delivered six P removal projects in AMP6, ranging from small sites of 3,000 PE to large sites over 38,000 PE, with the installation of chemical dosing systems and a range of tertiary solids removal (TSR) technologies.

Hayfield and Barton WwTWs were two of the P-removal projects delivered at the end of AMP6. Based on whole life cost (WLC) and design for manufacturing and assembly (DfMA) assessments, Bluewater Bio Ltd’s (BwB) FilterClear was selected as the TSR solution.

Bluewater Bio Ltd was able to provide a TP guarantee instead of a surrogate total suspended solids (TSS) guarantee, which offered UU and MMB the simplest and clearest assurance of meeting the final effluent permit as well as being contractually most straightforward. The contracts were awarded in mid 2019, and the FilterClear plants have been in operation since mid 2020.

Project background

Both Hayfield and Barton WwTWs are trickling filter sites, and are required to meet a new TP permit of 0.5 mg/l.

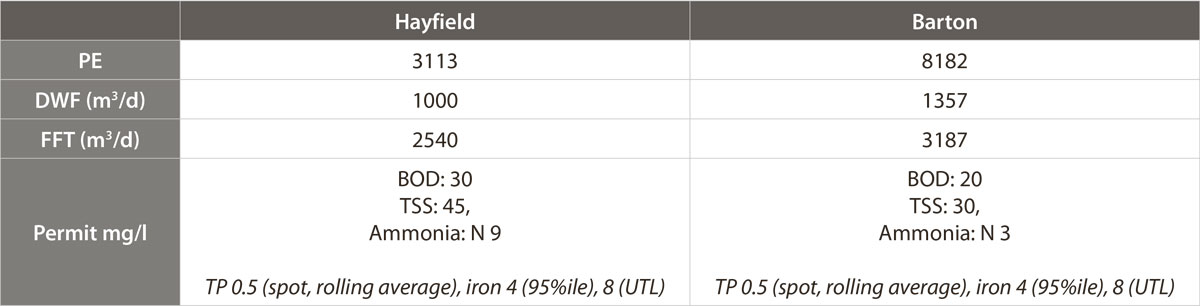

High level background information for both sites

UU and MMB undertook detailed option studies of various tertiary technologies, evaluating aspects such as CAPEX, process reliability, delivery programme, power demands, chemical consumption and maintenance requirements. Bluewater Bio Ltd’s FilterClear was identified as the preferred solution at Hayfield and Barton.

The FilterClear plant design has taken into account of the following criteria:

- To treat the peak flow while one filter is in backwash.

- To ensure the minimum runtime is adequate under the worst-case scenario.

- To manage the interfaces with tertiary pumping and chemical dosing.

- To minimise the whole life cost and footprint.

- To maximise the benefits gained from DfMA.

- To enable safe and easy access, lifting and maintenance.

All of these requirements had to be balanced with the overall costs of the project. Throughout the project delivery, efficient and constructive communication was maintained between all parties.

FilterClear for phosphorus removal

FilterClear is a four-media depth filtration technology. The influent is pumped to the top of the filter and flows through four layers of media; anthracite, silica, alumina and magnetite, which have decreasing particle size and increasing density. This configuration provides an equivalent of 4-stage filtration in a single vessel, allowing the filter to operate at a much higher filtration rate (up to 35 m/h) and achieve a better effluent quality than conventional sand filters.

(left) FilterClear vessel showing media arrangement and (right) installed FilterClear package – Courtesy of Bluewater Bio Ltd

The key benefit of depth filtration is to enable the solids to be removed progressively through the entire depth of the 4-layer filter bed, extending the run-time and reducing backwash frequencies. The layer structure is maintained after backwashing due to the carefully selected density and particle sizes of the four media layers.

FilterClear has an average operating pressure of 0.4 bar, offering a low energy demand and a low operational carbon footprint. It only requires coagulant dosing for P removal; no polyelectrolyte or ballast material is required.

For chemical P removal, good coagulation and flocculation are critical. Many TSR technologies need purpose-built coagulation and flocculation tanks with mechanical mixing, and some will also require polymer dosing.

In comparison, as large flocs are not essential for depth filtration, a flocculation tank or mechanical mixing is not required by FilterClear. Chemical dosing can be added directly upstream of the FilterClear plant via an in-line static mixer and flocculation will occur in the headspace inside the filter vessel, above the media bed. This minimises the FilterClear footprint, and also makes the solution simpler to build and operate and eliminates the operational and maintenance tasks associated with a separate flocculation tank.

FilterClear installation at Hayfield WwTW – Courtesy of Bluewater Bio Ltd

Design for manufacture and assembly (DfMA)

Increasingly, clients and their tier one partners are looking to minimise site construction activities and durations. FilterClear plants are designed to allow factory assembly and testing, then delivery to site as a package plant. The compact nature of the FilterClear solution makes it ideal to fit on site.

Where possible, the complete filter gallery, including backwash pumps, blowers, actuated valves, instruments and controls are skid-mounted and transported fully assembled. Site activities are then limited to coupling the filter vessels and adding the media. This DfMA approach ensures both quality and safety are well controlled and ultimately delivers a better solution in a shorter time at a lower overall cost.

Health and safety was an integral part of the design process, ensuring that all equipment is safe to install, operate and maintain. Filtration and backwash of the FilterClear plant is fully automated, with minimum operational input. The filters are enclosed, with no moving parts or serviceable components within the vessels and need minimal operator intervention. Due to the enclosed, fully automated design, risk of operator exposure to wastewater or chemicals is minimised. Furthermore, all machinery is at ground level for easy access.

Throughout the project, the design teams worked closely with UU on the ALM assessment to ensure that the plant is operator-friendly. Particular attention was paid to eliminating hazards during operation and maintenance.

Ferric dosing: single-point vs. two-point

At Hayfield and Barton, FilterClear plants designed to meet the 0.5 mg/l TP discharge permit were installed downstream of the existing trickling filter works.

FilterClear features at Hayfield and Barton

Early stage jar tests had indicated that the TP permit could be met with only single point ferric dosing at Hayfield. Keen to embrace UU’s CAPEX and OPEX challenges MMB weighed up the risks and opportunities in conjunction with Bluewater Bio Ltd and elected to install single point dosing. Space only provision was made for installing second stage dosing should this be required at a later stage either as a result of changes to the wastewater over time or future tightening of works consent. As FilterClear is able to meet TP permit levels of 0.1mg/l with only changes to dosing and control, this future proofing of the asset was particularly attractive.

Jar testing results for Barton were less convincing and therefore 2-point ferric dosing was installed at this site. The FilterClear plants at both sites are very similar. The key features of both sites are listed in the table above.

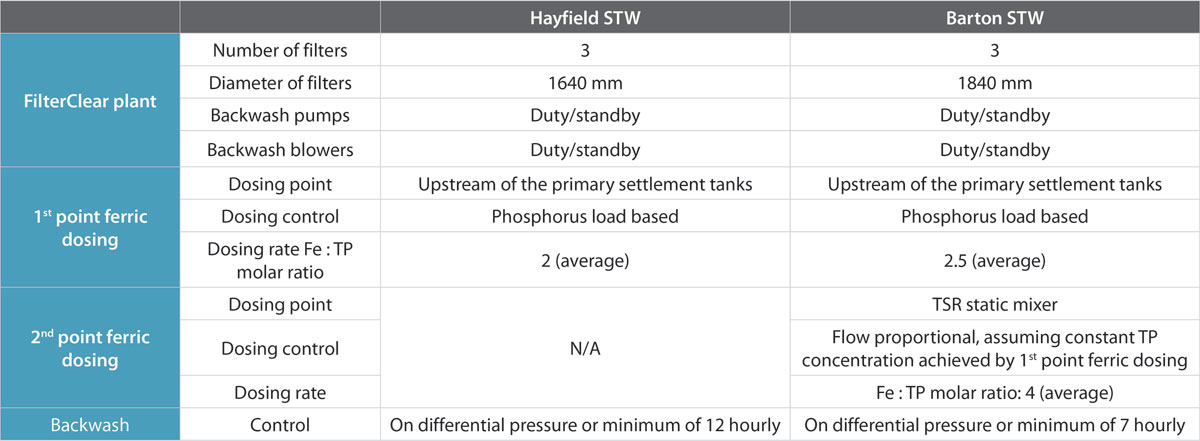

Hayfield performance

The performance at Hayfield is robustly within the permit conditions. This graph shows the effluent spot samples during the performance testing. The crude sewage TP was around 6 mg/l on average. FilterClear has achieved an average effluent TP concentration of 0.2 mg/l against a TP permit of 0.5 mg/l. Effluent iron was 1.3 mg/l on 95%ile, well below the permit of 4 mg/l.

Performance at Hayfield WwTW – Courtesy of Bluewater Bio Ltd

As the captured suspended solids accumulate in the filter bed, the pressure increases gradually from 0.2 bar to 0.9 bar. Filter backwashing is initiated when the inlet pressure reaches a pre-set value, or on timer control. These values were set at the time of commissioning and are operator-adjustable.

A further benefit of single point ferric dosing at Hayfield, is that the chemical solids contribution and the total TSS loading onto the FilterClear plant is minimised, as a consequence, backwash demand and return is reduced. Furthermore, the installation and dosing control is also simplified.

The backwashing procedure takes approximately 20 minutes (including air scouring). The FilterClear effluent is drawn from a clean backwash tank by the backwash pumps and pumped upwards through the filter media to the dirty backwash tank located near the inlet works, and then returned to the head of the works by gravity.

Barton Performance

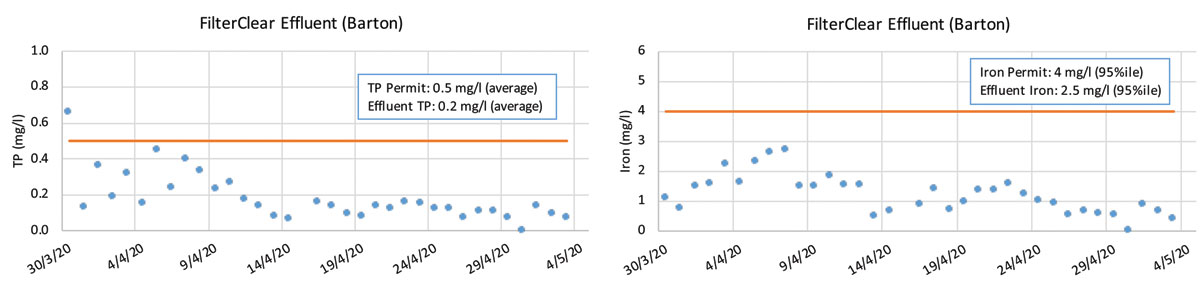

A tight delivery programme at Barton meant that the commissioning duration was unusually short. In addition, the crude sewage TP averaged at 9 mg/l. The FilterClear plant stabilised quickly. The effluent TP concentration started at 0.6 mg/ and quickly dropped below 0.2 mg/l. Since commissioning both the TP and iron permit have been achieved with good safety margins. Over time, the reserves of P within the trickling filters have diminished and the ferric dosing has been reduced.

Performance at Barton WwTW – Courtesy of Bluewater Bio Ltd

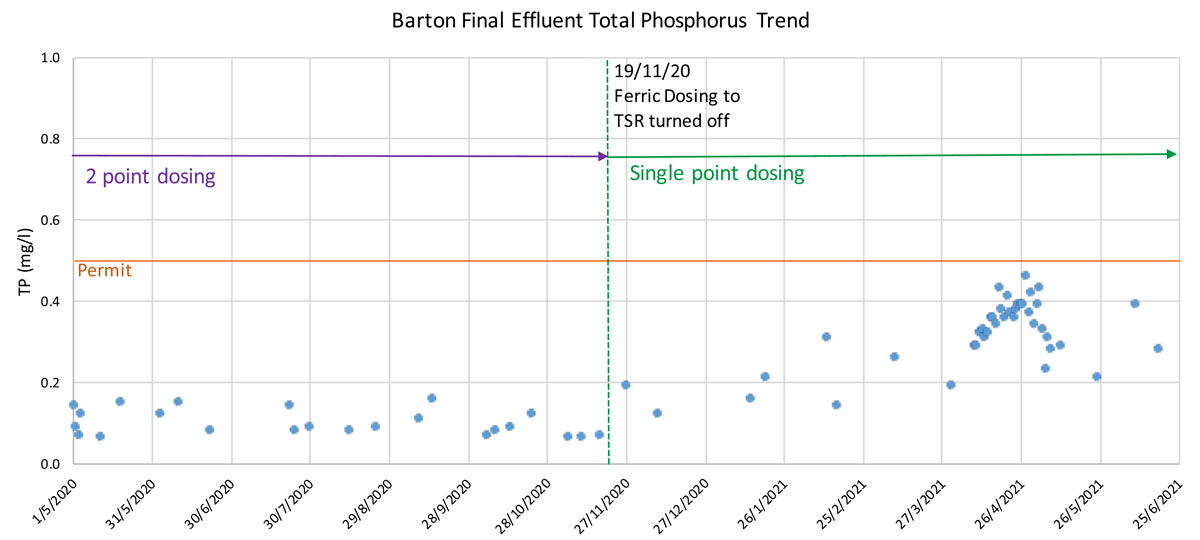

The two ferric dosing points at Barton enabled the works to achieve less than 0.2 mg/l TP against the 0.5 mg/l permit. This ‘over-achievement’ of the permit required significant caustic dosing to balance the ferric dosed, which in turn was causing pH issues on the site. The impact of turning off the second ferric dose on spot sample results is shown in below . Final effluent TP increased when the second ferric dose was turned off but has remained compliant.

The associated reduction in caustic did not solve the pH issue; this was resolved by moving the caustic dosing from downstream of the primary tanks (PSTs) to upstream, adjacent to the ferric point of application (POA).

The intensive sampling in April-May was during a second period of performance testing to prove the system, and corresponded with a period of hot, dry weather where the works was challenged with TP up to 10 mg/l.

Barton performance – comparison of single and two-point dosing – Courtesy of Bluewater Bio Ltd

Futureproof

The projects at Hayfield and Barton have demonstrated that FilterClear plants can reliably achieve a TP permit of 0.5 mg/l with single point ferric dosing, with overall ferric dosing rates significantly lower than anticipated at Barton. This will both provide OPEX savings, and more importantly make the solution future-proof. Should the TP permit become tighter in the future, Operations can increase the ferric dosing accordingly, or the plant can be easily upgraded by adding the second point ferric dosing. This offers the client a means of reducing Capital and OPEX spend whilst adding future flexibility.

In AMP7, there are over 700 sites in the P removal programme nationally, with an increasing number of sewage treatment works being required to meet tighter TP permits. This will no doubt drive the tertiary TP removal technologies to evolve and improve, addressing the need to enhance reliability on largely unmanned sites and to minimise the use of chemicals whilst meeting increasingly stringent standards.

Both these two projects ably demonstrate that close collaboration between key parties is essential to meet increasingly stringent consents, across numerous sites in a short space of time.