Lee Road Water Treatment Plant (2023)

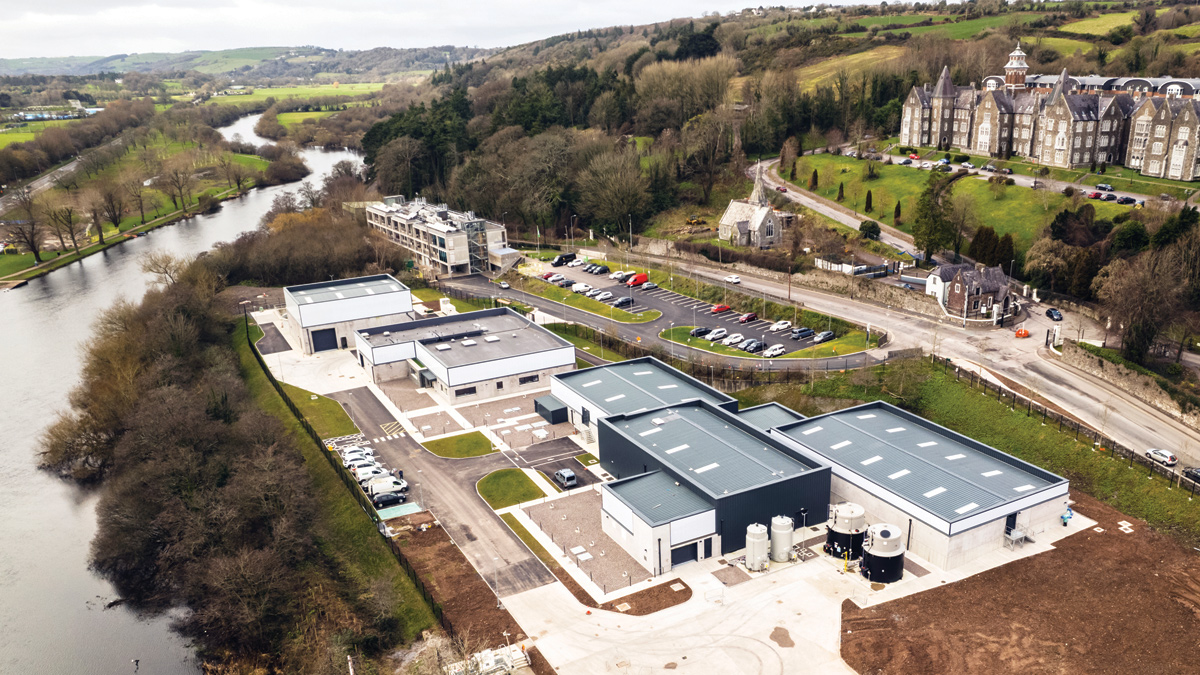

Lee Road WTP site overview - Courtesy of Murphy Ireland

Lee Road Water Treatment Plant (WTP) provides approximately 70% of Cork City’s total treated water supply. Water is taken from the River Lee, treated and then pumped to reservoirs in the north-west of the city through a system of rising mains. Water is distributed to consumers throughout the city via a network of gravity distribution mains. The treatment of drinking water began at this site in 1879, and whilst there have been several upgrades throughout its lifespan, none have been completed since the 1950s. This treatment plant upgrade is the first major investment in over 60 years and will support continued population growth and economic development in the city. The upgraded treatment facilities have safeguarded the water supply for Cork City and the works have enabled the supply to be removed from the Environmental Protection Agency’s (EPA) Remedial Action List.

Undertakings

Murphy Ireland are one of eight contractors that have been on the Uisce Éireann framework to deliver major non-infrastructure projects since 2017. Murphy was awarded the €40m Lee Road WTP contract via competitive tender in 2019 and was required to complete these key works by July 2022, while the existing plant remained in full operation.

Uisce Éireann issued a high-level outline design brief with Murphy responsible for completing the full detailed design. A significant amount of optioneering, value engineering and constructability reviews were undertaken. The end solution offered better value for money and Murphy was appointed Project Supervisor Design Process (PSDP), equivalent to Principal Designer under CDM regulation, and Project Supervisor Construction Stage (PSCS), equivalent to Principal Contractor, for the duration of the project.

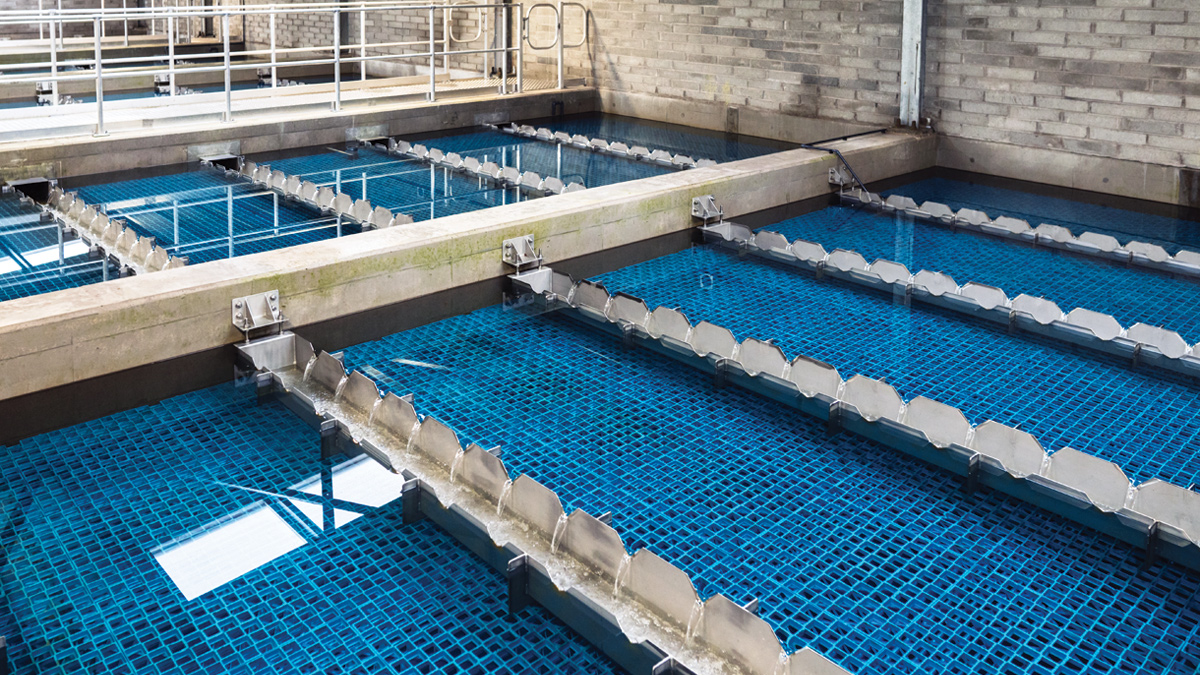

Lamella plate sedimentation tanks – Courtesy of Murphy Ireland

Scope of works

The upgraded facility designed and delivered by Murphy included:

- Reconfigured raw water intake inclusive of a raw water band screen and bypass arrangements.

- Coagulation, flocculation, and clarification system.

- Six rapid gravity filters utilising Xylem Water Solutions’ Leopold underdrain filters.

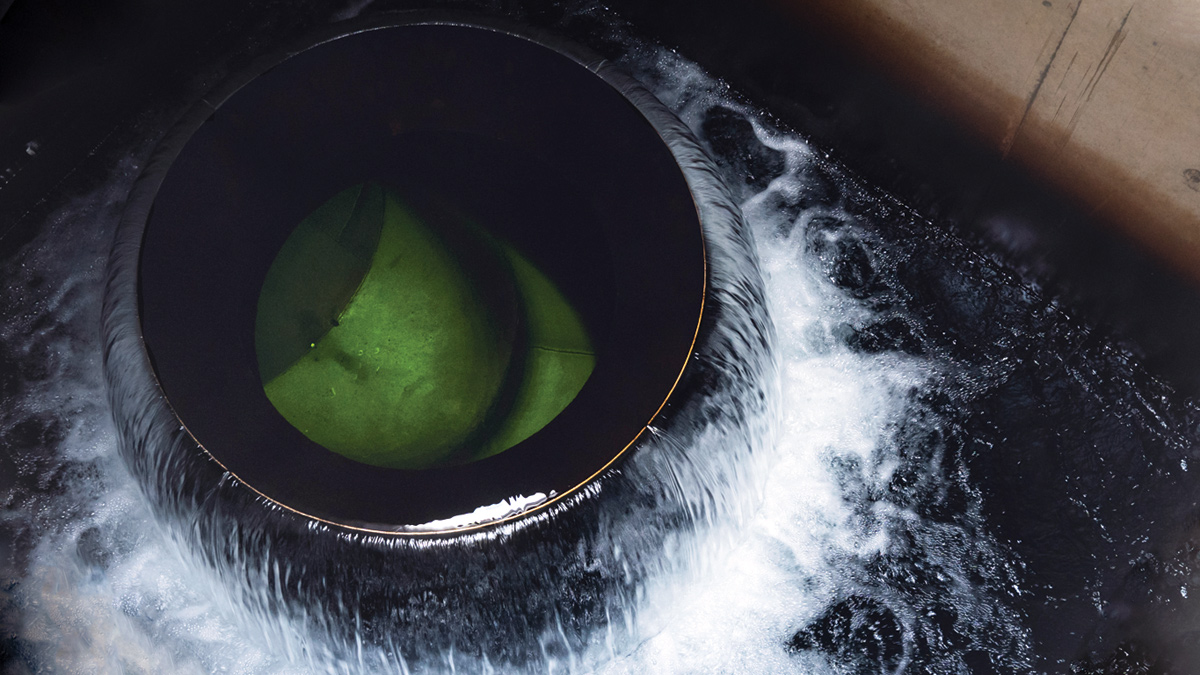

- Chemical and UV disinfection.

- Installation of pH correction facility via dosing sodium hydroxide.

- Washwater and sludge handling facilities, incorporating a sludge plate press.

- New treated water pumping station and refurbishment of existing pumping station, complete with high efficiency frequency inverters and motors.

- EICA infrastructure including PLCs, communication links and SCADA system.

- Prevention measures to protect the works from flooding during extreme weather events.

- Full Murphy managed operation and maintenance of the facility for 12-months.

Construction challenges

All process wastewater is collected and treated, ensuring it is suitable for discharge to the adjacent river Lee within the specified discharge standards.

During construction, Murphy encountered and resolved a number of construction challenges due to the high-water table on the site adjacent to the river Lee. This led to challenging working conditions. Murphy addressed this issue by installing deep sheet pile cofferdams to lower gravel beds and installed a ringed dewatering system to manage groundwater. The site was raised following construction of tank structures to provide a new ground level 2m above previous levels.

Overview of site showing the build complexity – Courtesy of Murphy Ireland

Another key challenge on this project was keeping the existing plant operational for the entire construction phase to its full capacity. It was essential that the works were carried out with no interference to the existing water treatment process.

Working within a city presented several logistical constraints including constrained and restricted site access. Therefore considerate, efficient, and well-planned logistics plans and methodology were integral to minimising disruption for the locality and the smooth running of the construction works. Construction Site Traffic Management (CSTM) was meticulously managed and ensured no interference with the existing plant operations. Staged infill operations were undertaken to minimise this disruption.

Significant off-site construction was undertaken in addition to rigorous off-site factory testing, resulting in a reduced number of construction defects and a smooth and efficient commissioning process.

The commissioning plan was developed throughout the life cycle of the works and signed off by the client three months ahead of planned commissioning. This gave enough time for all parties to be briefed and understand commissioning requirements, durations, key activity outputs and agree standards to be reached.

UV disinfection – Courtesy of Murphy Ireland

Lee Road WTP – Supply chain – key participants

- Principal contractor: Murphy Ireland

- Process/MEICA design & systems integrators: Murphy Process Engineering

- Civil design: Finbarr Gannon Ltd

- Electrical design: Seamus Byrne Electrical Ltd

- Groundwater dewatering: WJGL Ltd

- Groundwater monitoring: Priority Geotechnical Ltd

- Formwork: Hickey Formwork ltd

- Precast concrete tanks: Shay Murtagh Precast

- Sheet piling: Ward Piling

- Steel reinforcement: James’s Street Steel Manufacturing Ltd

- Tower crane hire: Mantis Cranes

- Security fencing: Irish Fencing Services

- General & specialist fabrication: Russell Metal Fabrication Ltd

- Gantry crane: Ballinphellic Engineering

- PLCs & MCCs: Omron CPU35/ASC

- Intake band screens: Beaudrey

- Process pipework: Freeflow Pipesystems UK

- Process pipework: Superior Pipeline Products Ltd

- Sludge plate press: Micronics UK Ltd

- Pumps: Celeros UK

- Flow controls: Rotork

- Inverters & motors: ABB

- Valves: Talis

- Leopold underdrain filters: Xylem Water Solutions

- Air compressors: Atlas Copco Ltd

- UV disinfection: Hanovia

- Chemical dosing: Colberge Water Systems

- Bulk chemical storage tanks: SILOTANK

- Bulk chemical storage tanks: Phaser Limited

- Surge vessels & walkways/access systems: Murphy Design

Protection of assets

Situated beside the River Lee, the existing water treatment plant experienced significant flooding in the past and was at the end of its useful lifetime. The design solution delivered a state-of-the-art treatment facility whilst raising the site by 2m to protect against future flooding during extreme weather events. For instance, the existing ground consisted of porous gravel beds that facilitated easy passage of groundwater. Careful dewatering design ensured good management of resulting groundwater flows.

UV-treated water – Courtesy of Murphy Ireland

Achieving a successful delivery

Collaborative working was central to Murphy’s approach, and in conjunction with Uisce Éireann, continual updating of the three week look ahead and the Master Information Delivery Plan (MIDP), ensured effective planning and minimised unforeseen events.

Murphy’s in-house expertise designed and delivered the project with strict adherence to Uisce Éireann Asset standards, and provided mechanical, electrical, instrumentation and control automation (MEICA), and civil services, including in-house process design, piling, and structural steel design and fabrication.

Mid-programme planning changes were introduced to help achieve an improvement to the delivery programme. The original plan for the project was to reuse the existing sedimentation tanks, however Murphy suggested building entirely new ones as this would provide a better overall product, improving programme, in addition to improving the whole-life cost and de-risking the supply concerns for the locality. The upgrade works on Lee Road WTP will also reduce the energy consumption and running costs by more than 40%.

Sustainability, as on all Murphy projects, was a key part of the strategy at Lee Road. Various measures were put in place to protect local wildlife such as bats and otters, in addition to ensuring, waste material was reused where possible.

Alum bulk storage – Courtesy of Murphy Ireland

Meeting Uisce Éireann’s customers’ needs

Independent testing of raw water, treated water, sludge parameters, noise, and other parameters were undertaken during the Performance period to confirm compliance with EU Drinking Water Regulations.

Murphy provided leadership for the following:

- Uisce Éireann have an ongoing water network upgrade programme around Cork City and Murphy supported Uisce Éireann’s needs to managing reservoir demands, alter final chlorine residual and optimising final water pH.

- Leading demonstrations of shutdown controls, water despatch control and interlocks with service reservoirs during EPA audits.

- Working collaboratively to commission an automated coagulation control system, which optimises use of aluminium sulphate coagulant, yet reacts quickly and efficiently to changing raw water characteristics such as colour, turbidity and UVT.

- Holding regular operational team meetings to agree the O&M programme approach.

- A three-year spares assessment vetted by the client to reach collective agreement.

Rising main pressure vessel – Courtesy of Murphy Ireland

Working throughout the pandemic

With the project being delivered during the Covid-19 pandemic, multiple different challenges presented themselves. For example, throughout the start of the project at peak periods there could be upwards of 80 people working on site at any one time. However, following the onset of Covid-19, Murphy had to adapt the working practices, incorporating social distancing measures, rotas for breaks and shift start and completion patterns. Despite working throughout the Covid-19 pandemic and with the variety of risks, the safety record from the project was exemplary. Across two years of works the team had zero lost time incidents. Lee Road was selected for an external ISO Quality audit by Lloyds Accreditation and passed with distinction.

Community liaison

School visits during the operation phase continued to form a part our interaction with local groups and community, dovetailing with Cork City Council’s adjacent visitor centre which highlights the history of waterworks at Lee Road since the 1850s. During the construction phase local labour was utilised along with local suppliers. During Covid while many other workers in the city were furloughed, construction works continued at Lee Road which was deemed an essential construction project.

The design processes included regular HAZOPs workshops to include at least 20 people from the client ranging from plant operators to statutory body representatives.

Final pumping – Courtesy of Murphy Ireland

Conclusion

Following commissioning, which took place throughout the first half of 2022, water went into supply in July 2022, and Cork now has a new, secure, modern, state-of-the-art water treatment facility that will serve the community for years to come. The flooding risk that pertained has now been removed and the new works at Lee Road is fully integrated with the City and County water reservoir storage system, offering huge flexibility in clean water provision.

The new Lee Road WTP - Courtesy of Murphy Ireland