Littlehempston WTW (2023)

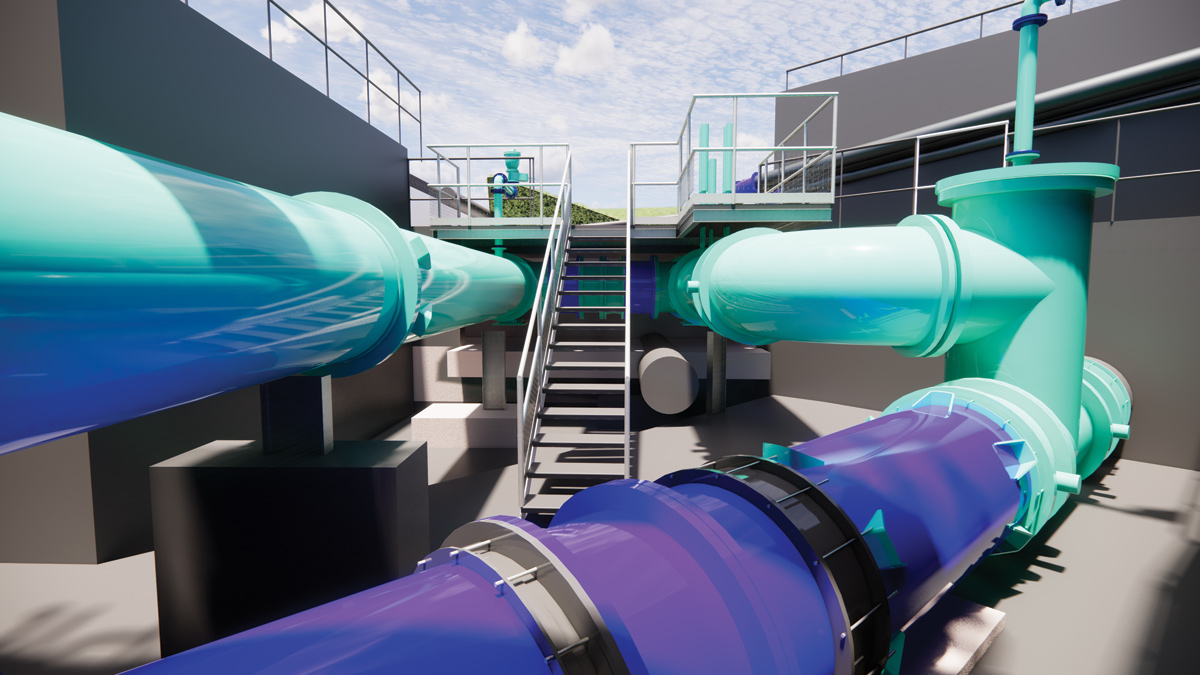

Littlehempston WTW 'bear pit’ - Courtesy of Galliford Try

Littlehempston is a large complex potable water treatment works located near Totnes, South Devon, which has multiple river and reservoir sources. It supplies circa 78,000 properties to an area that includes Torbay, Newton Abbot and Kingsbridge. The original treatment works comprises flat bottom clarifiers (FBC) and rapid gravity filters (RGF), with an additional process stream added later, utilising dissolved oxygen flotation (DAF) and additional RGFs. The current £14.4 million, 2-year project involves intercepting the flows where the two treatment streams join and passing through a new granular activated carbon (GAC) process and ultraviolet (UV) treatment to the improve drinking water quality.

Project drivers

South West Water’s objective to employ granular activated carbon (GAC) has been to address the following:

- Ensure compliance with pesticide standards.

- Target a 25% reduction in total trihalomethanes (TTHMs) in the final water leaving the treatment works.

- Target a reduction in average levels of TTHMs to less than the screening value of 50 µg/l.

- No detections of methyl-isoborneol (MIB) greater then 5 ng/l in final water and target a long-term reduction in taste and odour customer contacts.

At the scoping stage, Galliford Try and Arcadis worked closely with South West Water to establish the most cost-efficient solution when considering both operational costs (OPEX) and capital expenditure (CAPEX) to ensure South West Water achieved the best whole life costs.

21m diameter dirty back wash tank – Courtesy of Galliford Try

Project scope

The project solution includes a new GAC treatment process. Six reinforced concrete contactors, were constructed in situ, and housed within a steel clad, portal frame building. ODEX piles were used to support the structure due to the encountered ground conditions.

The new primary disinfection is to be via ultraviolet (UV) disinfection. The UV building containing the reactors is an in situ concrete structure, supporting a GRP (glass fibre reinforced plastics) kiosk. This kiosk also houses the new control panels for the GAC and UV processes being installed.

Two new precast tanks are being installed, providing dual use as combined interstage pumping and clean backwash water storage. An off-site fabricated, precast solution was used which provided significant programme advantages, and reduced the health and safety risks.

A four-pump arrangement provides duty/standby interstage pumping, clean backwash feed and a common standby which can support both interstage or backwash pumping as required. The duty pressure and flow characteristics of both systems was optimised to allow the same pump to be selected for both operations. This provides South West Water improved flexibility and resilience for future operation and maintenance.

Below ground large diameter pipework required to be installed around existing structures and services – Courtesy of Galliford Try

A further tank will be used for the collection of GAC backwash and rinse. The GAC backwash water is not being combined with the existing site waste and supernatant system, and instead will be returned via new pumps directly to the inlet works. Appropriate sampling is being installed to confirm it is of suitable quality to return and can be diverted into the existing wash water system if required. This sustainability driven solution improves the efficiency of the plant, reducing pressure on incoming water resources whilst avoiding discharges to the environment.

During the outline design phase, an existing redundant structure on site was identified as being suitable for use as a collection tank for GAC regeneration wastewater. Re-using this structure provides improved value for money, whilst reducing the carbon consumption and the environmental impact of constructing a new concrete structure, as per the original concept. The re-purposing works will require some minor inlet and outlet pipework modifications, installation of new pumps and removing of the redundant equipment.

Littlehempston WTW: Supply chain – key participants

- Delivery contractor: Galliford Try

- Design: Arcadis Consulting (UK) Ltd

- Piling: Roger Bullivant Ltd

- Reinforced concrete works: D Wall Construction Services Ltd

- Precast concrete tanks: A-Consult Ltd

- Steel frame building: Hewaswater Engineering Ltd

- Reinforcement: Hy-ten Ltd

- Aggregates & concrete: E & JW Glendinning Ltd

- Plant hire: Plantforce Rentals Ltd

- Ultraviolet reactors: Trojan Technologies

- Underfloor drains & launders: Xylem Water Solutions

- Underfloor drains & launders installation: Western Carbons Ltd

- Stainless steel pipework & galvanised mild steel structures: Alpha Plus Ltd

- Pipework: Freeflow Pipesystems Ltd

- Ductile pipework: Electrosteel Castings (UK) Ltd

- Flow control: Affco Flow Control UK Ltd

- GRP kiosk: Pro-Tect GRP Enclosures Ltd

FRC construction of GAC cells – Courtesy of Galliford Try

Project challenges

As part of the scheme the site team have had to make pipework modifications to intercept flows between the existing RGF filters and primary contact tank. To achieve this, a series of seven independent site shutdowns were carried out weekly to facilitate the modifications needed.

This area, affectionately known as the ‘bear pit’, required detailed planning to develop a suitable solution. The final arrangement includes branch connections to allow the existing flow paths to be kept on-line, the installation of new pipework, refurbishment of redundant pipework, temporary cross-connections to allow commissioning flows to be circulated, and also includes a new static mixer for the relocated dosing point for chlorine and orthophosphoric acid. The challenges were amplified further by the limited access to the area, meaning that pipework had to be fabricated in small sections that could be safely lifted in.

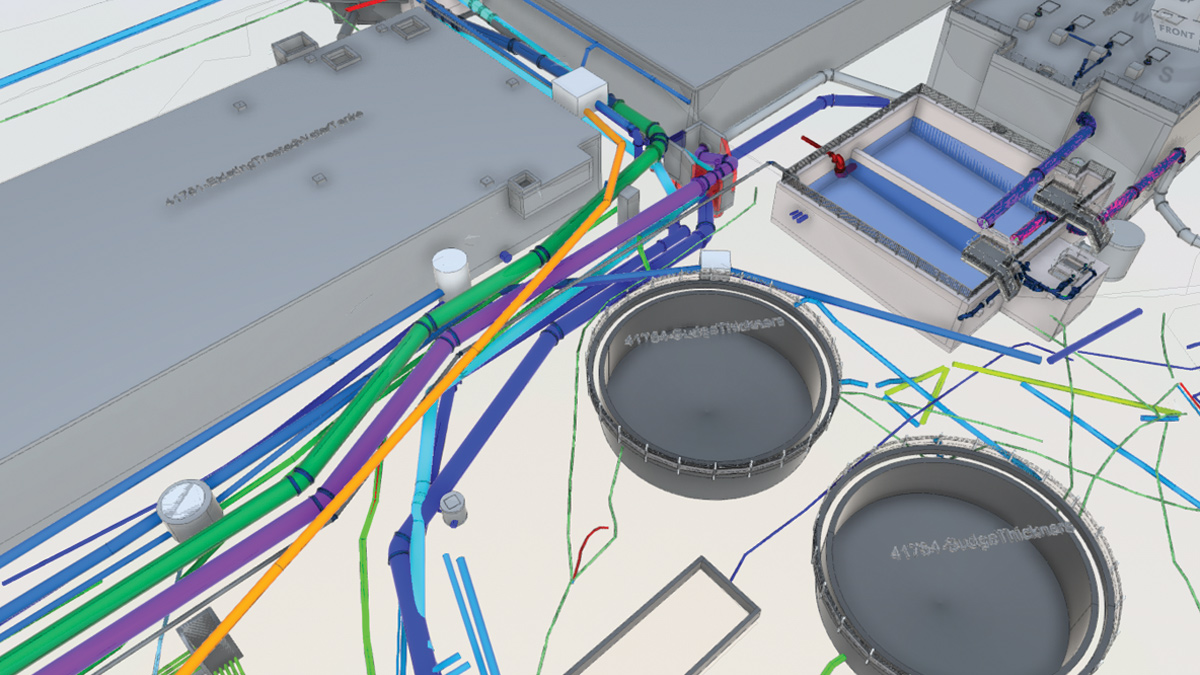

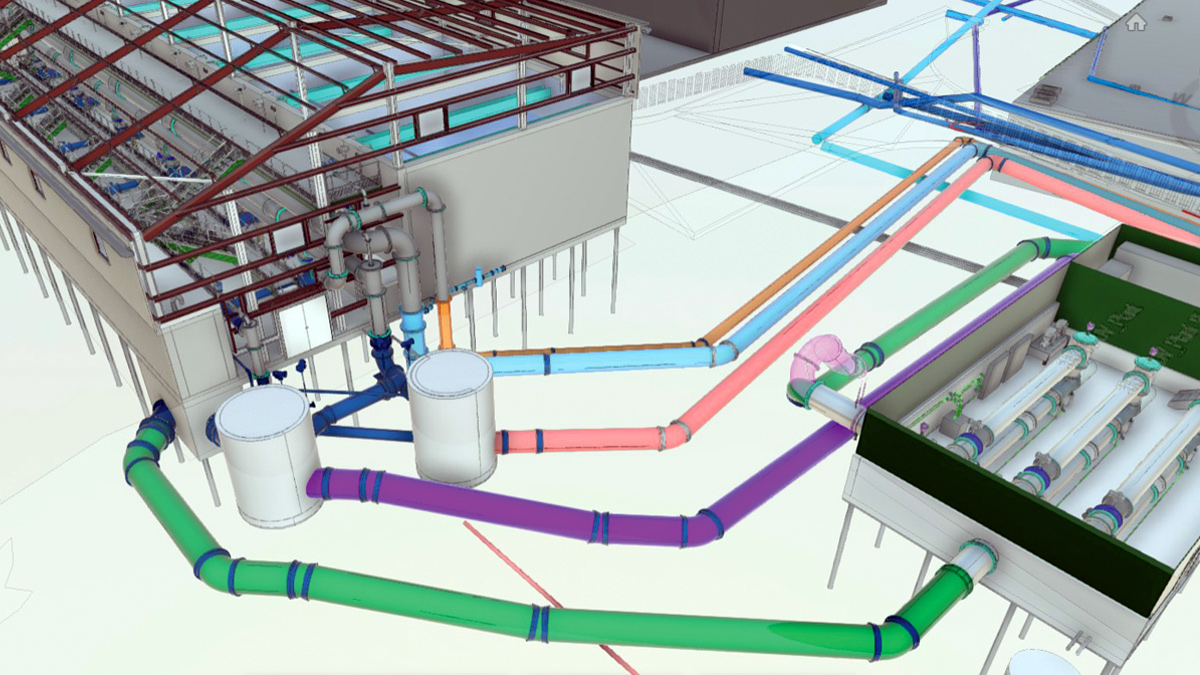

A point-cloud survey of the original pipework was integrated into the BIM model which allowed the concept development. Exact measurements were then verified manually on site before fabrication. A 4D approach was implemented during the design development which allowed for the different phases to be visualised and support the buildability and planning discussions between the project delivery team, and South West Water operations.

Access to site is also incredibly challenging, as the rural Devon location is only accessible with heavy goods vehicles (HGVS) via a narrow single-track road with infrequent passing places for HGVs for approximately 5 miles. This impacted multiple design and construction decisions, limiting the size of rebar, pipework, precast units and various types of plant and machinery that could be used such as piling rigs, excavators and cranes. The site team arranged suitable locations to hold vehicles allowing all HGVs movements to be managed through the narrow lanes. Surrounding business were updated weekly on HGV movements and in return made the site traffic management team aware of their movement so that they could also be coordinated.

GAC building pipework gallery – Courtesy of Galliford Try

Carbon savings and in-house capability

Local resources and materials were used where possible including subcontractors which as a result provided a boost to the local economy during the construction phase. Where local suppliers were not available, Galliford Try endeavoured to use off site build solutions where possible to minimise commuting.

The following in-house resources were utilised:

- Management.

- Electrical design.

- Process control.

- Commissioning.

- Workforce to undertake the following:

- Establish and demobilise site.

- Civils groundworks.

- Hard and soft landscaping.

- MECIA works.

Stakeholder management

At pre-construction phase, all third-party stakeholders were identified and entered onto a management plan. Galliford Try’s Customer Liaison Officer contacted all stakeholders prior to commencement to provide them with the appropriate project contacts should they have questions, queries, or complaints and to establish their requirements and desires throughout the construction phase of the works. As part of the management plan all communications where complaints or agreements are made are formally recorded, resolved, and closed out.

GAC & UV buildings with interconnecting pipework – Courtesy of Galliford Try

Noteworthy

This job was aided by the useful wealth of archived drawings and pictures stored by South West Water on site. The documents gave Galliford Try a useful insight into the history of the water treatment site and proved to be invaluable in the process of locating services. Notably, Galliford Try discovered these documents were stored in a cold-war era bunker making the exercise of ploughing through documents not your average day on site!

Summary

Collaboration between client, contractor, designer and the wider supply chain has been a key factor in resolving significant challenges including establishing pipe routes for large diameter interconnecting pipework, suitable crane platforms for inaccessible areas of the existing operational site and the pipework modifications required during works shutdowns in the ‘bear pit’.

Fit out of the contactor gallery prior to the erection of the steel clad portal frame building – Courtesy of Galliford Try

Currently (May 2023) all the structures are nearing completion, mechanical installations are well advanced with electrical fit outs to commence late summer 2023. Large diameter site-wide interconnecting pipework is currently being laid, with the vast majority programmed to be completed during the summer and early autumn months of 2023 to take advantage of more favourable ground conditions.

Process Commissioning is to commence in late 2023 and is scheduled to be completed well in advance of the Drinking Water Inspectorate (DWI) Compliance Date 31 March 2025.