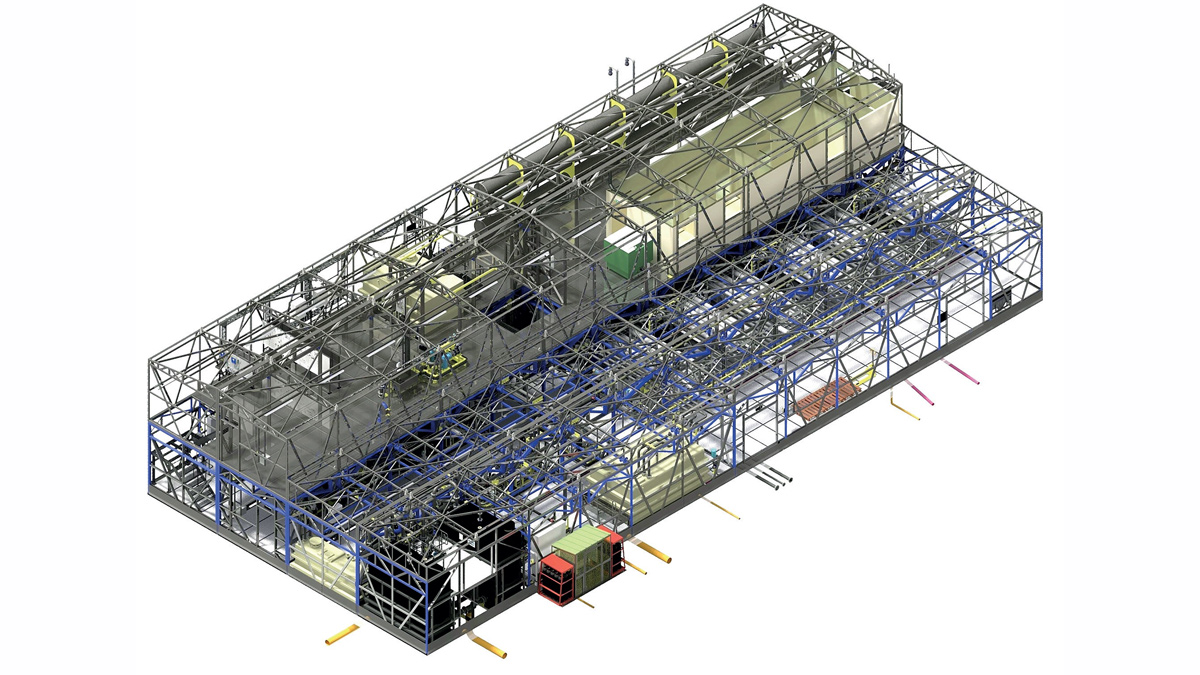

Lochmaddy WTW (2019)

Membrane stacks within WTW - Courtesy of Scottish Water

Lochmaddy is the main town located on North Uist, which is one of the islands forming part of the Western Isles. This project involved the design, installation, construction and commissioning of a new water treatment works (WTW) on a greenfield site beside the existing site. Additionally, some of the works were within South Lewis, Harris and North Uist National Scenic Area. The project also had potential to directly impact on the qualifying features of Loch nam Madadh SAC & SSSI and Mointeach Scadabhaigh SPA & SSSI. Scottish Water awarded Ross-shire Engineering the contract to deliver the new Lochmaddy WTWs.

Project drivers

Scottish Water has invested £15m to provide a single, improved drinking water supply for customers across North Uist and Berneray. Both the old Lochmaddy and Bayhead WTWs were coagulated Dynasand plants with a history of water quality issues in relation to:

- Cryptosporidium.

- Aluminium residuals.

- Disinfection control.

- An on-going risk of high trihalomethane (THM) levels in the network.

The project replaces the ageing water treatment works on the island and ensures compliance with increasingly stringent regulations, safeguarding current and future water supply to homes and businesses.

Access track during construction – Courtesy of RSE

Undertakings

The new water treatment works supplies both Lochmaddy and Bayhead areas (1000 properties) and was delivered by Ross-shire Engineering (RSE). Bayhead will be supplied via a strategic link main from the clear water tank (CWT) at Lochmaddy which is being delivered by Caledonia Water Alliance (CWA).

Both teams are proactively working together to ensure interfaces are clearly identified.

Brief description of works

Due to the potential risk to water quality, Scottish Water identified Lochmaddy and Bayhead WTWs as requiring investment to offer improved security of supply for the communities it serves and ensure that customers continue to receive high quality, great tasting drinking water into the future.

Rock crushing machines – Courtesy of RSE

Following extensive optioneering and value management sessions the scope of the new works comprised of the following:

- New abstraction from Loch Fada.

- New 1.0 Ml/d (capability to upsize to 1.3 Ml/d) nanofiltration water treatment works, including chemical dosing.

- New 600m3 clear water tank (CWT) storage adjacent to new WTW (2 x 300m3 glass coated steel tanks).

- New pumped main from the existing storage tank to serve Bayhead WSZ.

- Connection to existing Lochmaddy storage tank to serve Lochmaddy WSZ.

Design

Scottish Water’s capital investment staff, based in Inverness, and local operational staff on North Uist worked collaboratively with Ross-shire Engineering’s design team as an integrated project delivery team.

The Lochmaddy WTW comprises:

- Raw water abstraction (permitted via a Scottish Environment Protection Agency (SEPA) Controlled Activity Regulation (CAR) Abstraction Licence) via new 2mm intake wedge wire screen within Loch Fada, a raw water pump station (RWPS) with variable speed control pumps, on the shore of the loch which transfers the raw water 1km to the WTW building.

- The WTW is a 1.0 Ml/d nanofiltration membrane plant with a capability of producing 1.3 Ml/d in the future. The building houses:

- 2mm raw water basket strainers.

- Raw water tank.

- 3 (No.) membrane streams of CA202 membranes from PCI Membranes in C10 modules (252 modules, 42 modules per stack, 2 stacks per stream).

- Chlorine disinfection via sodium hypochlorite.

- Chlorine contact pipe.

- CO2 dosing for pH correction.

- Remineralisation tanks

- Ammonium sulphate dosing to achieve chloramination requirements.

- Re-lift pumps to transfer to the 600m3 clear water tanks (constructed by Reliant Installations).

The final water to supply from the CWTs are transferred to the Bayhead Service Reservoir (SR) via a new main (5km laid under this project, the remaining 17km under CWA contract), Lochmaddy SR and the Sollas distribution network via 3 (No.) separate sets of variable speed pumps located within the building.

Waste streams including membrane reject water, instrument waste and chemical waste are discharged via a sea outfall, permitted via a SEPA CAR Discharge Licence.

Lochmaddy blast of the WTW site – Courtesy of RSE

On-site construction and off-site modular build

The project has been delivered using an off-site modular build approach, never before deployed on this scale in the UK water industry. By carrying out much of the work at Ross-shire Engineering’s state-of-the-art, carbon-neutral facility at Muir of Ord, the environmental impact on a sensitive site and small rural community has been minimised.

There was a considerable amount of civil work required to prepare the site, this included blasting the area for the WTW’s building to create a platform for the works and constructing a 1km access track to the RWPS. These tasks were able to run concurrently with the off-site fabrication. Scottish Water’s rural framework was utilised for the civils construction via local company MacInnes Bros Ltd.

Lochmaddy base slab for modular building – Courtesy of RSE

Assembling and testing the water treatment works under factory conditions offered major advantages compared with a much longer, more complex and less controlled traditional construction method on site. The off-site fabrication alleviated much of the negative health, safety and environmental impact of the construction process and delivered multiple additional benefits such as a shorter programme and significant cost savings, alongside improved water quality.

Utilising BIM, DfMA, and 3D walkthrough design for client approval pre-construction makes the process more efficient and effective. At key meetings (HAZCON, HAZCOM and HAZOP), covering construction, commissioning and operation is far simpler with reference to the fully modelled, dimensioned plant than conventional 2D drawings.

Lochmaddy WTW – 3D model – Courtesy of RSE

Logistics and benefits of off-site modular build

The project has been delivered using a DfMA approach and at 870m2 it is the largest plant of its type to be commissioned in the UK. Due to its modular nature, the entire plant is road transportable. This allowed the final units to be moved by road and ferry from Muir of Ord to North Uist, a distance of around 150 miles, in 17 shipments.

By contrast, a typical on-site build of this scale would have required in excess of 100 shipments; therefore a vast amount of materials transportation and its associated environmental impacts has been avoided.

Unit 6 being lifted by crane – Courtesy of Scottish Water

Another advantage of the modular plant is that should network demands on the island change in the coming years, the modular nature of the plant allows additional capacity to be added to accommodate this.

Alternatively, should changes to the network make the plant surplus to future requirements, the entire plant can be demobilised from its present site and relocated, either on Uist or elsewhere in Scotland. It is a robust and valuable asset.

Lochmaddy WTW building and CWTs – Courtesy of RSE

Stakeholder engagement

There were a number of communication publications on the run up to the units being delivered to site, to minimise any disruption caused. By engaging with key external stakeholders early in the project any potential blockers/issues were raised early and resolved, examples of stakeholder consultation were: land owners, SEPA, Comhairle nan Eilean Siar (local authority), SSE, BT, Scottish Natural Hertiage, archaeological departments and the Fisheries Trust. Working together ensured all the necessary requirements were in place when needed.

Local community engagement was key to making this a successful project, RSE managed this well as the face of Scottish Water whilst on site for 20 months.

RWPS during construction at Loch Fada – Courtesy of RSE

Conclusion

The project gained CAPEX 3 approval in June 2017 and construction started in July 2017 by Scottish Water Tier 1 delivery partner Ross-Shire Engineering. The project is now complete and achieved water into supply in April 2019. At the time of writing (May 2019) the Bayhead main out is forecast to be delivered in the coming weeks. The existing works has been decommissioned now that the new works has been constructed and commissioned. The total investment was in the region of £15m.

The way in which this project was delivered is a great example of Scottish Water and Ross-shire Engineering working together in an innovative way to deliver lasting benefits for customers.