Loughries WwTW (2023)

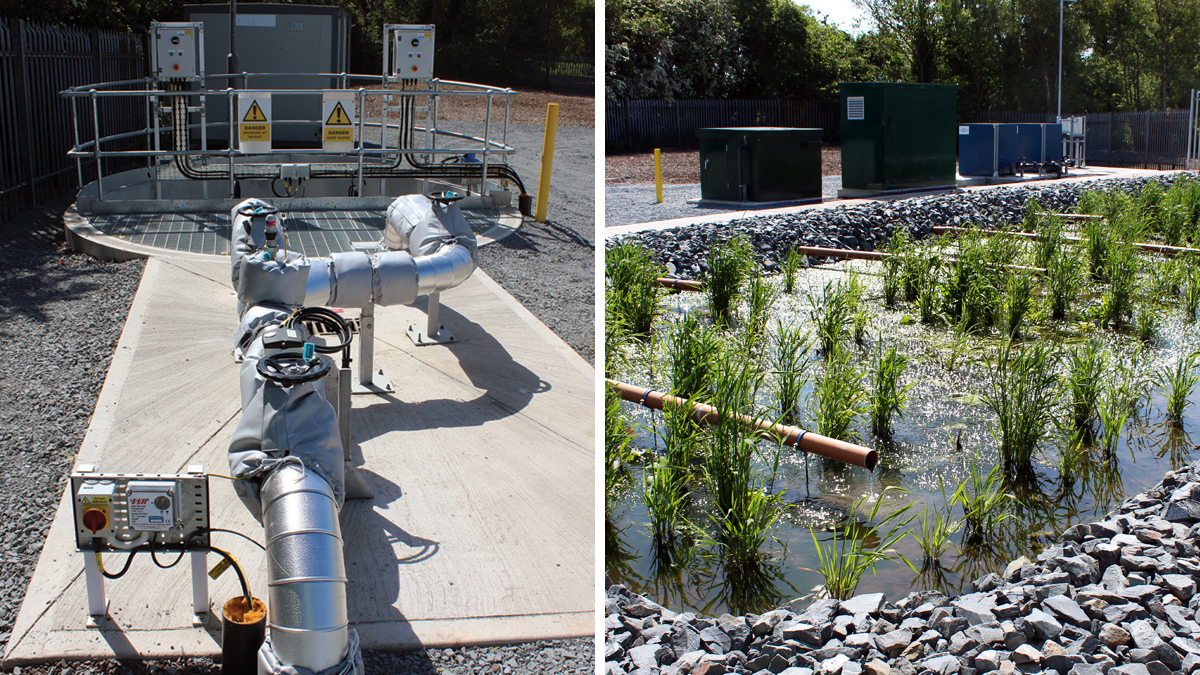

Early aerated reed bed growth (spring 2023) - Courtesy of BSG Civil Engineering Ltd

NI Water has undertaken a highly sustainable project which replaces wastewater treatment infrastructure for the catchment of Loughries, a small village close to the shores of Strangford Lough. Due to its age, an increasing load from the village, and ever-tightening discharge limits being applied, the existing works was in danger of breaching consents. The project involved the design and construction of a new treatment process consisting of a septic tank and aerated reed bed which is a long-term solution to operate as a tertiary final polishing system. The vertical flow orientation of the reed bed minimises the footprint of the required bed whilst aeration provided enhanced microbial treatment to bring the BOD, suspended solids and ammonia site discharges comfortably into consent.

Location

The new Loughries Wastewater Treatment Works (WwTW) is located on the site of the existing works and treated effluent and any overflow at the Formula ‘A’ flume chamber discharges to an adjacent watercourse that is a tributary of Strangford Lough.

Primary drivers

The purpose and drivers for this project were as follows:

- Complying with EU Water quality standards.

- Accommodating the current and future population.

- Meeting tightened Northern Ireland Environment Agency (NIEA) discharge standards.

- Complying with NI Water long term strategy.

Aerated reed bed blowers & FE sample point – Courtesy of BSG Civil Engineering Ltd

Tightened consents

The new WwTW capital works contract comprised the construction, commissioning and testing of a treatment works for a design population equivalent (PE) of 304, achieving a water quality standard of 10:15:3 (BOD/SS/ammonia), whilst treating up to 276 m3/day (Formula ‘A’) and providing 36m3 of an inlet CSO storage volume (SDD storage*). The design complies with all current NI Water specifications and asset standards applicable to each stage of the treatment process.

* NOTE: The SDD (Scottish Development Department) method of calculating the storage requirements is based on the dilution levels that can be achieved in the receiving waters. Options could include passing forward more influent to the treatment process or providing additional wastewater storage within the treatment works. NIEA have adopted this method of calculating the additional storage required at a WwTW to deal with low levels of dilution.

Loughries WwTW: Supply chain – key participants

- Client: NI Water

- Project management: Tetra Tech

- Principal designer/contractor: BSG Civil Engineering Ltd

- Structural, hydraulic & process design: RPS Ltd

- MEICA design: BSG Civil Engineering Ltd

- Aerated reed bed: ARM Ltd

- Aeration blowers: Aerzen Machines

- Septic tank: Kingspan Group

- iMCC: MOTROL

- Access flooring & metalwork: Graham Steelwork & Engineering (GSE) Ltd

- Flow meters & ultrasonics: Siemens

- Pumps: Xylem Water Solutions

- SDD storage storm screening: Eliquo Hydrok Ltd

Scope of works

The WwTW comprises preliminary treatment in the form of 6mm screening and grit removal package plant – the only reused plant items from the existing site – and treats all flows entering the site.

Following 6mm screening and grit removal, Formula ‘A’ flows are balanced and measured by an in-line flume structure whereby sustained flows above this overflow a weir plate and discharge to the adjacent watercourse in line with NIEA guidelines. The Formula ‘A’ flows are split evenly between two 46,000 litre septic tanks, which settle the sludge and require desludging every 2-3 months via the above-ground desludge pipework.

Secondary treatment is provided in the form of a forced bed aeration system to the 250m3 aerated reed bed which includes duty/standby positive displacement blowers. This system forces air through a series of pipes in the bed that increase the level of oxygen in the reed bed, thereby increasing the treatment capacity.

The new WwTW also includes process flow meters, level and quality monitors, ancillary process units to support the main process, intelligent motor control centre (iMCC) with telemetry, programmable logic controller (PLC) and human machine interface (HMI) control system. Power is provided via the existing Northern Ireland Electricity infrastructure with the meter remaining in the existing MCC, which has been modified and upgraded to provide power to the new aerated red bed.

(left) SDD storage pumping station and (right) early aerated reed bed growth (spring 2023) – Courtesy of BSG Civil Engineering Ltd

The full scope comprised

- Tree clearance in adjacent field to allow for access to building new offline works.

- Modification to the existing inlet works to allow for new flow path.

- Inlet works flow measurement chamber and flume.

- Septic tanks for sludge storage and periodic and manual desludging.

- Septic tank inlet and outlet flow splitting chambers.

- Aerated reed bed system and blowers.

- Final effluent (FE) level control and FE sample point chamber.

- LCP and kiosk for aerated blowers.

- Existing MCC modifications and refurbishment.

- Telemetry commissioning.

- Site finishes and access road turning.

- EMS drainage.

- Effluent discharge pipe connecting to existing outfall.

- Boundary fencing with a 2.4m high palisade fence.

- Decommissioning and demolition of the existing WwTW (except inlet works).

- Construction of a new underground SDD storage tank and concrete plinth to accommodate above ground pipework.

- Construction of a bifurcation manhole diverting flow to the new underground SDD storage tank during storm event.

- Installation of associated gravity pipework for underground the SDD storage tank including two inlet pipes, overflow pipe and associated inspection chambers.

- Installation of pumps, above-ground pipework and underground pumping main returning flows from the SDD storage tank to the bifurcation manhole after a storm event.

Local engagement

In advance of work commencing at Loughries, NI Water carried out extensive letter drops in the village and visited the local primary school to provide information on the planned work. During the upgrade, NI Water and its project team from Tetra Tech and BSG organised site visits for some of the local primary school children to educate them on the sustainable approach adopted for the village’s new WwTW. The children heard all about the green credentials of the WwTWs and helped with planting the new reed beds.

(left) The NI Water Project Team, principal contractor BSG Civil Engineering, and consulting engineers Tetra Tech, and (right) local school children help plant out the reed beds at Loughries – Courtesy of NI Water

Conclusion

The aerated reed bed solution provided a low-cost, sustainable solution for treating the catchment of Loughries village. It will provide NI Water with a long-term, low maintenance, low carbon footprint solution that not only secures consents but blends into the rural location providing additional biodiversity and amenity.

Loughries WwTW – Courtesy of BSG Civil Engineering Ltd