Lowdham, Gunthorpe Road, Flood Alleviation (2021)

Bespoke downstream turret manholes - Courtesy of nmcn PLC (now Galliford Try)

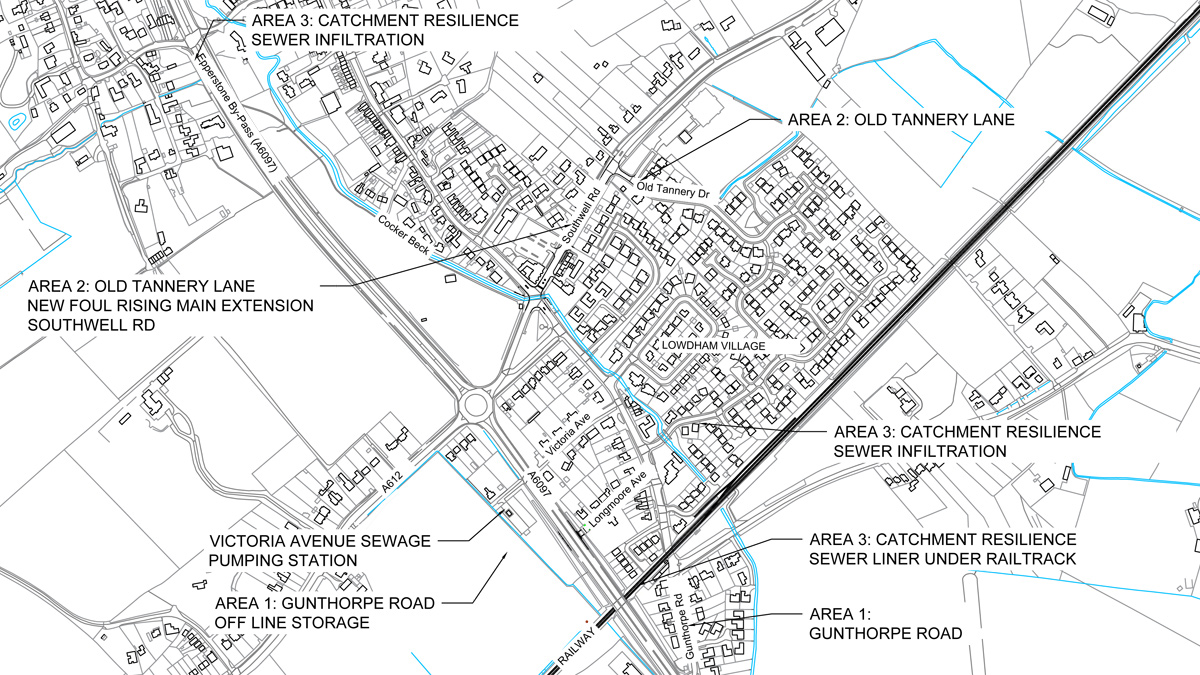

Lowdham is a village in Nottinghamshire that had a history of external and internal sewer flooding to properties, caused by hydraulic incapacity of the combined sewer network. A new 1400m3 offline storage tank was required along with catchment resilience work, which included working in partnership with the local authority to resolve surface water flooding, by implementing a holistic solution to flooding in Lowdham. This £1.6m large-scale, complex, civil engineering project across numerous sites within the village required keeping the impact on the community to a minimum by innovative design and construction methods throughout the duration of the works. Severn Trent (ST) appointed nmcn PLC (now Galliford Try) as the design and build contractor under the AMP6 framework to develop a collaborative and sustainable solution to resolve the flooding issues; the benefits of which will be felt for years to come.

Problem definition

Area 1: Gunthorpe Road: Gunthorpe Road is a residential street in the south of the village where the road surface level is higher than the property curtilage. During heavy periods of rainfall surcharge conditions develop and sewage escapes at domestic inspection chambers resulting in property level flooding. Gunthorpe Road is served by a 300mm foul combined sewer that receives flows (via gravity and pumped mains) from numerous satellite villages. All of the flows in this catchment area then gravitate beneath the Nottingham to Lincoln Railway to Victoria Avenue Sewage Pumping Station (SPS) to the south-west of the village.

To understand the root cause of the flooding, ST built and verified an engineering hydraulic model. Analysis of the model outputs indicated that the flooding within the village was caused by hydraulic overloading of the Victoria Avenue SPS. During storm events flow overload the station resulting in surcharge conditions in the upstream catchment and flooding at domestic properties.

Lowdham Village work areas – Courtesy of nmcn PLC

Area 2: Old Tannery Lane & Southwell Road: To the north-east of the village a number of properties on Old Tannery Drive were also on the ST flooding register. A private pumping station rising main (100mm ID) discharged into a shallow manhole chamber and gravitated to the Victoria Avenue SPS via an under-capacity 150mm foul sewer in Southwell Road. Flooding in this area was exacerbated due to under capacity and structurally deficient highway drains.

Area 3: Catchment Resilience Works:

- Sewer infiltration: During the ST model improvements phase, significant rainfall induced infiltration was found to be entering the foul combined system. This was exacerbating the over-loading at Victoria Avenue SPS and if not resolved would increase the size of the required offline storage. These infiltration issues were resolved by installing CP308 compliant infiltration liners.

- Cleansing and re-lining sewer beneath rail track: All of the flows to the south of the village gravitate beneath the Nottingham to Lincoln Railway to the Victoria Avenue SPS. Site investigation works identified the sewer to be a life expired and heavily encrusted cast iron (CI) pipe. To safeguard future catchment resilience, the CI main required cleansing and a structural liner inserting.

Lowdham, Gunthorpe Road, Flood Alleviation: Supply chain – key participants

- Design & build contractor: nmcn Plc

- Ecology/environmental consultants: RammSanderson Ecology

- Civils subcontractor: Clumber Construction

- Auger boring subcontractor: Active Tunnelling

- HDD subcontractor: JMH Directional Drilling

- Dewatering: Datort Dewatering Services

- Precast manhole turrets and sewers: FP McCann

Development of complex, innovative engineering solutions

Area 1: Gunthorpe Lane protection: There has been a long history of flooding in this area; extensive property level protection had previously been undertaken with sealed chambers, non-return valves and flood boards. These have had limited success, since they defended the intended property but moved flooding to the next lowest release point.

To understand the root cause of the flooding ST built and verified an engineering hydraulic model conforming to WaPUG CoP standards. The storm events modelled included an allowance for future climate change scenarios for both the baseline and proposed scheme solutions. Analysis of the results deemed that further property level protection would only move the flooding to the next lowest release point, which was deemed unsustainable from a social, environmental, economic and wellbeing perspective.

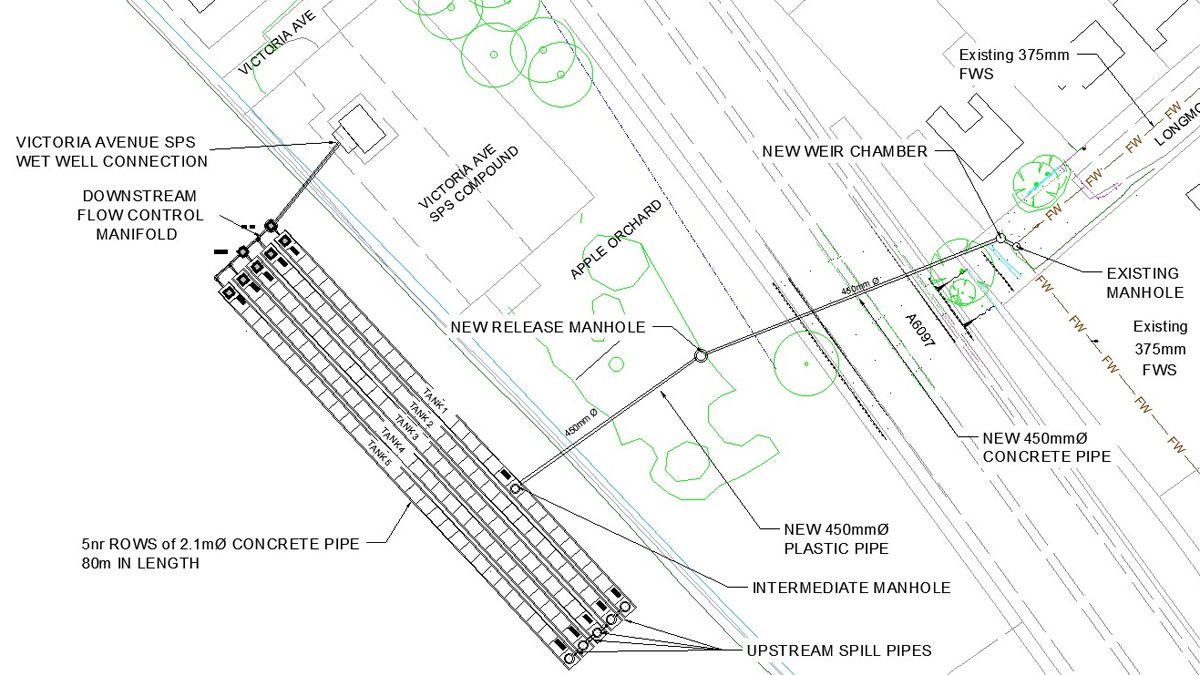

ST developed a notional solution to alleviate the flood risk by installing an offline storage tank with a volume of 1400m3 to hold flows during periods of heavy rainfall and prevent the Victoria Avenue SPS from overloading and provide flood protection to properties. During storm conditions, flows would be diverted into the offline storage via a new weir chamber located in Longmore Avenue and a new sewer installed beneath the A6907. As levels within the catchment fall the tank empties directly into the SPS wet well to be pumped away downstream.

Offline storage general arrangement – Courtesy of nmcn PLC

Off-line storage considerations: Due to the layout of the village the only suitable location for a storage tank of a volume 1400mm3 was to the west of the A6907. ST challenged and encouraged nmcn PLC to design a gravity solution as this would reduce future operation and maintenance cost in comparison to a pumped solution. To achieve this, the design team to proposed a multiple connected piped storage arrangement. There were several complex technical and environmental constraints to overcome. This included but was not limited to:

- Fixed downstream and upstream levels:

- 15.409m AOD at the downstream connection into the wet well.

- 18.28m AOD weir chamber spill point into the offline tank.

- 18.55m AOD upstream soffit level.

- Achieving self-cleansing velocities within all pipework to reduce future maintenance costs.

- Providing a simplistic low maintenance sequential tank filing and emptying design.

- Minimising the impact on an apple tree orchard located around the SPS compound.

- Providing access points for future maintenance.

- Crossing beneath and working in the zone of influence of the A6907 embankments.

- Minimising the impact on two minor brooks.

- Working within the existing ground level profile.

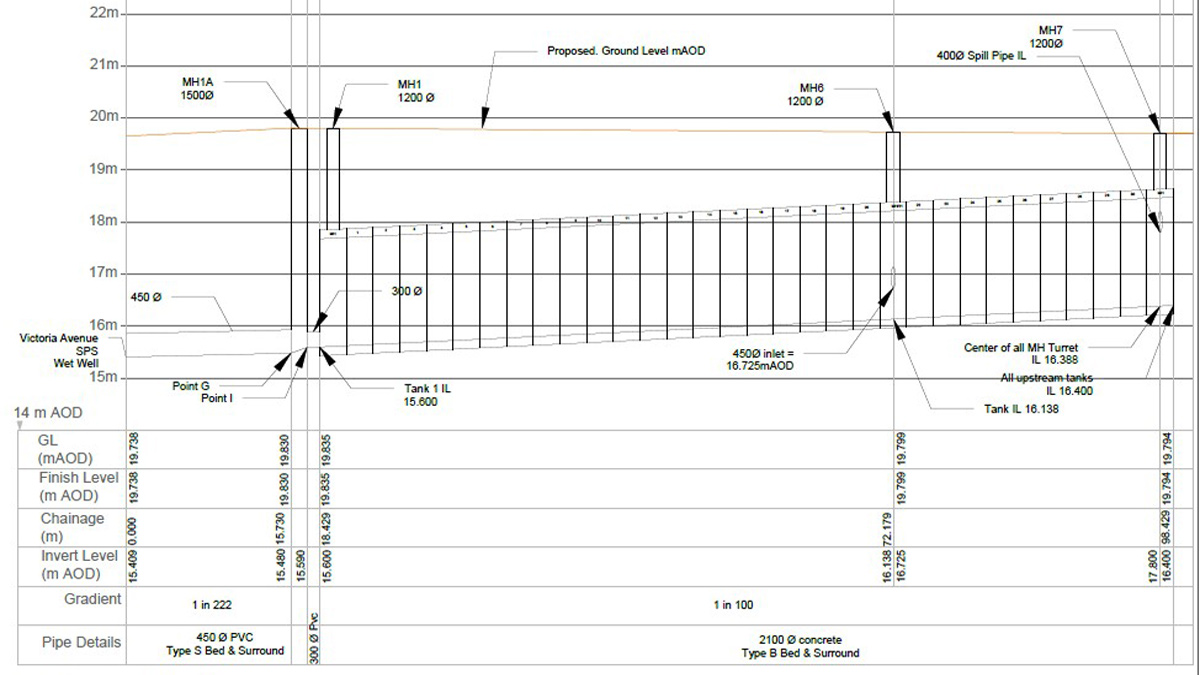

5 (No.) 2.1m Ø x 80m gravity pipe solution: Working with ST’s hydraulic modeler, several arrangements of the piped storage were considered. The final designed solution consisted of:

- A new 1500mm Ø weir chamber in Longmore Avenue.

- A new 450mm Ø sewer beneath the A6907 connecting into Tank 1.

- 5 (No.) 2.1m Ø concrete sewer pipes 80m in length at a 1 in 100 gradient to achieve self-cleansing.

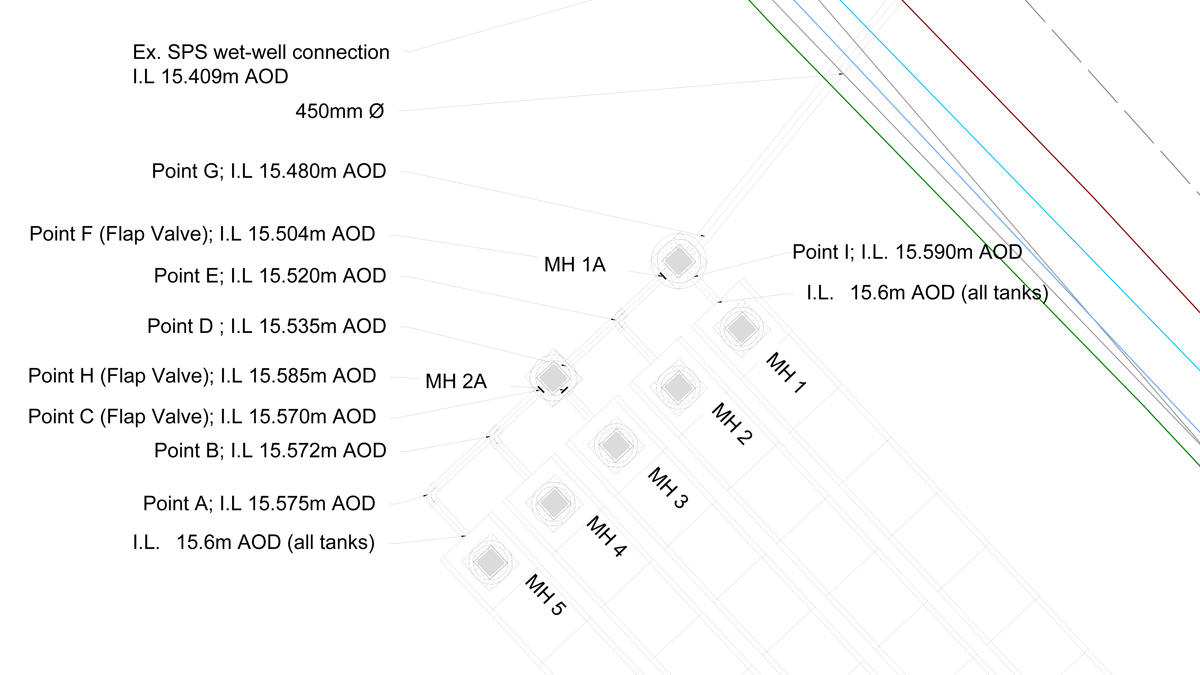

- 5(No.) bespoke precast upstream manholes connected via 400mm Ø PE pipes to allow sequential filling.

- 5 (No.) bespoke precast downstream manholes.

- A downstream gravity flow control manifold to allow sequential emptying.

- A 450mm Ø sewer connecting into the SPS wet well.

The final designed solution was located in a private agricultural field to the south west of the Victoria Avenue SPS. This location minimised the environmental impact on the orchard area, eliminated any impact on the A6907 embankments and increased the available working area. The entire tank was designed to fit within the existing ground profile with sufficient cover to counter act flotation and to allow the majority of the land to be returned to farming on completion.

Offline storage long section – Courtesy of nmcn PLC

Sustainable design considerations: To minimise future maintenance operations, the tank gradients were set at a 1 in 100 gradient to ensure self-cleansing velocities were generated. The weir level in Longmore Avenue was set to protect the properties on Gunthorpe Road as well as maximising the available storage volume in the entire downstream offline storage system.

Auger boring technology enabled the installation of the new 450mm Ø gravity sewer to link to the new storage pipes. This avoided the need for very deep excavations crossing the A6907 and the ecological impact of working in a dense area of trees in the orchard. Plastic pipes require a full (360°) granular material surround, and this quarried material would have needed to be imported to site. The use of concrete pipes instead of plastic pipes provided an opportunity to re-use excavated material as surround material with granular material for the pipe bed only. This design opportunity minimised the associated carbon cost by reducing muck away to landfill by 1500m3 and the imported crushed material by 1500m3.

A new flood release point was incorporated within the design so that if the storage design criteria is exceeded then the system will surcharge and spill in an open area protecting properties from internal flooding.

One of the challenging aspects of the design was to incorporate a low maintenance downstream manifold arrangement to control via gravity the emptying of the storage tanks. The manifold was designed to allow Tank 1 to fill from both the upstream weir chamber and from flows backing up from the SPS wet well. Tanks 2-5 are controlled by only two flap valves minimising future maintenance operations.

Low maintenance downstream manifold – Courtesy of nmcn PLC

Area 2: Old Tannery Lane

Traditional open cut vs no-dig HDD: ST identified that by extending the existing rising main 220m downstream along Southwell Road the flows would discharge into a sewer with more flow capacity reducing the flood risk.

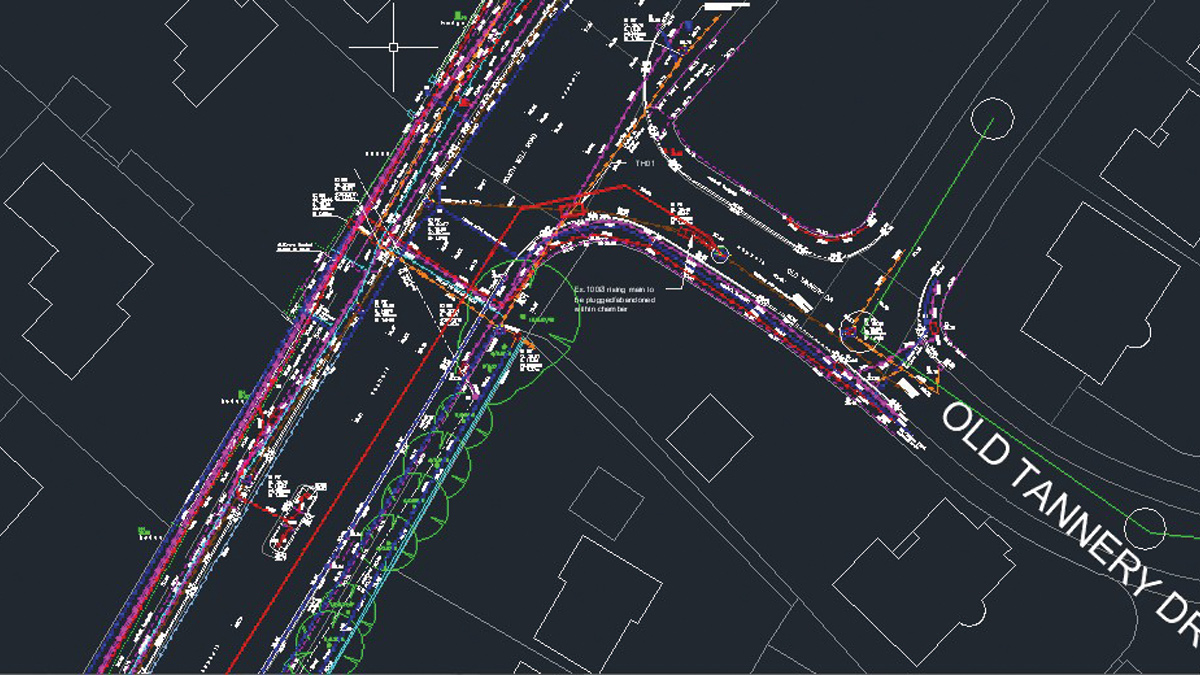

It is usual industry practice when laying pipes in built up areas to use a traditional open cut construction methodology however, a review of 3rd party utility plans highlighted only a small number of buried services within Southwell Road. Encouraged by ST, the nmcn PLC design team opted for horizontal directional drilling (HDD). As part of the design risk assessment, a site investigation (SI) plan was developed to confirm the extent of the services to reduce the risk of service strikes.

A ground penetration rader (GPR) and electromagnetic survey was commissioned to map the horizontal and vertical positions of each service along Southwell Road, this data was then mapped using AutoCAD 3D software and a detailed targeted trial hole phase plan was then implemented. The exact depth and position of each service crossing was confirmed and using the AutoCAD 3D model a profile of the rising main extension was designed.

Early stakeholder management identified this area was also prone to highway drainage flooding. To maximise efficiencies of nmcn’s site presence and mitigate community impact the local authority contributed towards the repair and upgrade of these pipes in the spirit of partnership working.

GPR survey results in AutoCAD 3D model – Courtesy of nmcn PLC

Area 3: Catchment Resilience Works

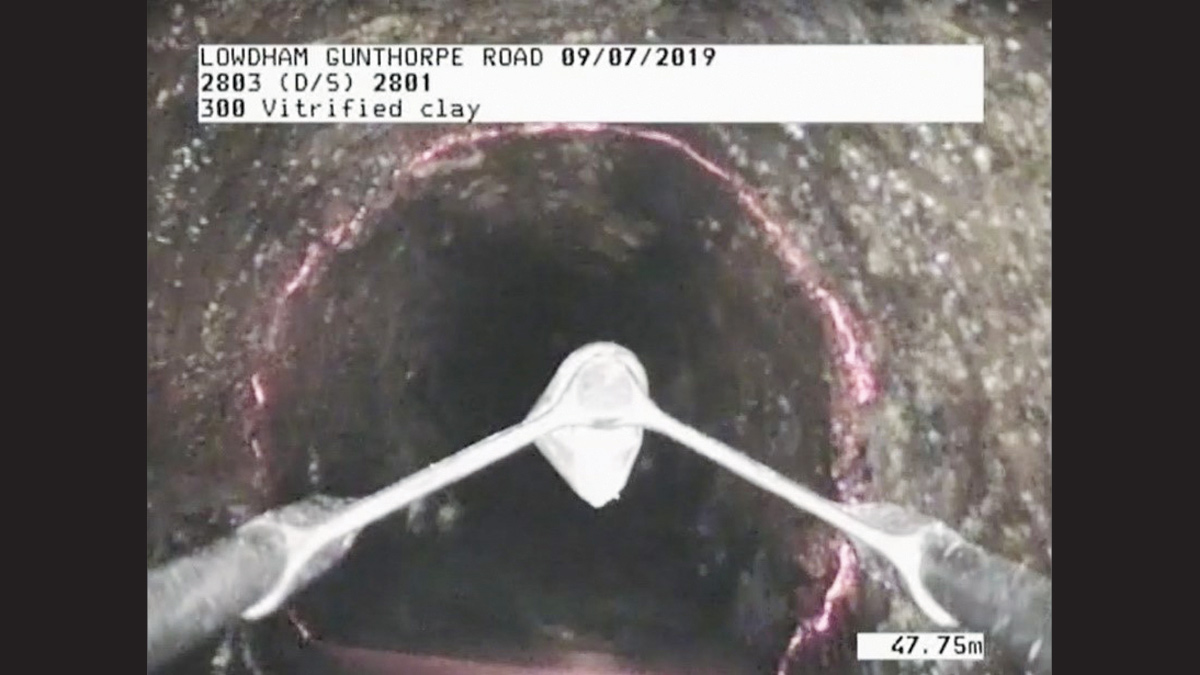

Cleansing sewer beneath rail track: All of the flows to the south of the village catchment including Gunthorpe Road gravitate via a 300mm vitrified clay (VC) sewer beneath the Nottingham to Lincoln Railway. ST records showed that the sewer material changed to a 225mm cast iron beneath the rail track before increasing back up to a 300mm VC sewer.

To safeguard future catchment resilience, the cast iron main required cleansing and a structural liner inserting. There were several technical and social constraints to contend with including but not limited to:

- The upstream manhole was located in a private garden 38m upstream.

- The nearest accessible downstream manhole was 97m downstream.

- The two immediate downstream manholes were buried beneath private garden patios.

- The manholes on the system all had sealed lids to prevent flooding.

- Local residents were apprehensive of us removing the manhole lids to carry out the work.

- The exact diameter change location was unknown.

- Stakeholder (Network Rail) approval to work on the asset required.

The first step taken was to meet with the local residents to discuss the planned works and to under-stand and take onboard their concerns whilst explaining how the work will directly improve the flooding risk to their properties.

In order to survey the sewer, firstly the sewer needed to be cleaned and descaled. Working with Network Rail, a suitable safe method of working to clean the CI sewer beneath the rail track was developed, agreed and implemented successfully.

Surveying sewer beneath rail track: The key piece of information required from the SI phase was to confirm the exact internal pipe diameter and location of the diameter change at ground level. This information was critical to inform the design parameters and installation technique of the structural liner. The position of the diameter change at ground level would also inform the position of a new manhole to facilitate the construction works.

The design team were mindful that a traditional CCTV and radio detection sewer sonding surveys are not very accurate and an alternative new technology might be available to the industry.

Light line survey in action – Courtesy of nmcn PLC

As part of the team’s research, a new technique known as a ‘light-line’ survey was uncovered. Using a specialised CCTV unit that emits a laser, a light line survey can measure up to 1mm in accuracy the internal pipe size including mapping any deformations and encrustations. The additional cost of this type of survey was outweighed with the benefits of reducing the design, installation and cost risk associated with lining this critical asset. The decision to commission the light line survey was justified when the survey results showed that there was in fact no diameter change on the system and that a structural liner could be installed from the downstream and upstream manholes.

Health & safety considerations

As principal designer and contractor under CDM2015 regulations, nmcn PLC held regular reviews to collaboratively identify monitor and reduce risks. A key risk to manage on this scheme was the delivery and lifting of the 2.1m Ø diameter concrete pipes and manhole turrets from the delivery vehicles. The weight of each unit ranged from 7.5T to 13T and due to the size of the units a working at height risk needed to be managed when unloading.

Prior to the casting of the prefabricated units a design review was held with the site team to agree the optimal position for the lifting fixings and pre-slung lifting loops in order to reduce the lifting risk on site. In the interest of quality, the downstream manholes were delivered to site pre-benched. This mitigated the need for site-based staff to work in a confined space and also reduced the quality risk of ‘keying’ in the benching into the precast structure on site.

(left) 2.1m diameter offline storage tanks and (right) bespoke pre-benched manhole – Courtesy of nmcn PLC

In March 2020 COVID-19 spread across the world and at this time construction works were still ongoing on site. The nmcn PLC H&S teams were able to introduce safe working procedures in line with government legislation and guidance in a short period of time to maintain construction activities while also keeping the workforce safe.

Project and resource management

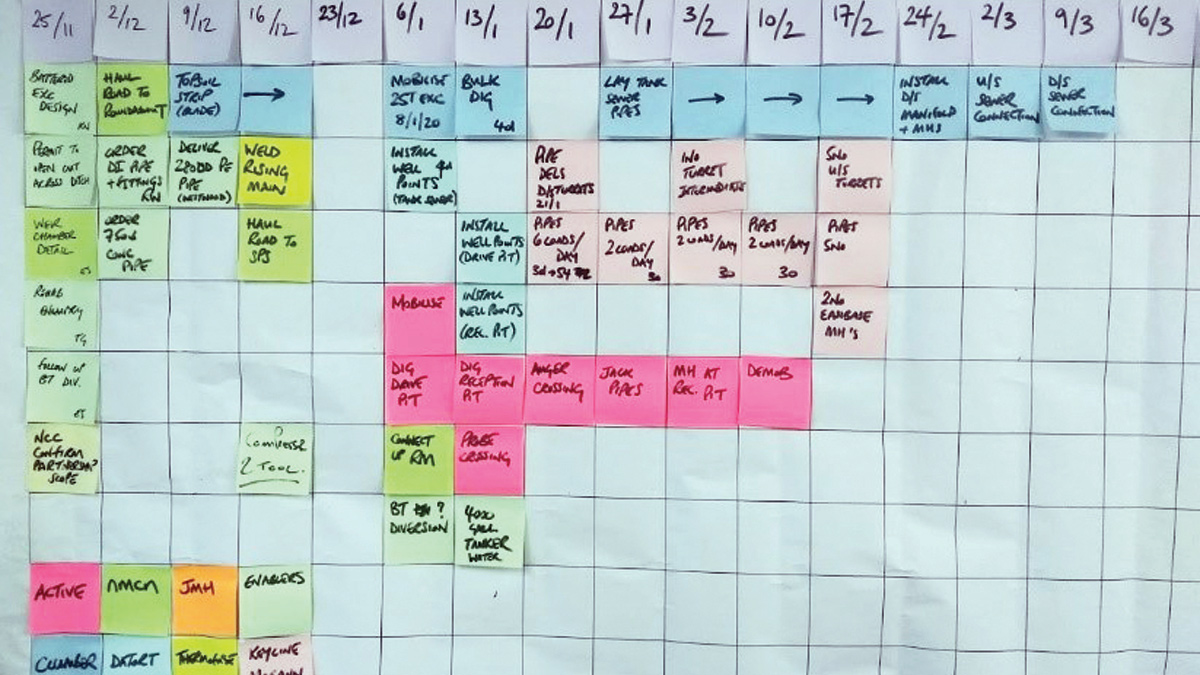

Collaborative planning (CP) was implemented in order to identify and realise efficiencies in the project programme. By being ‘high touch, low tech’, CP creates a ‘blue sky thinking’ programme by utilising easily moved Post-It notes for multiple activities each day.

A key benefit is it allows the site labour to be fully engaged in the planning process which draws on their hands-on experience in pipelaying as well as creating a sense of ownership across the wider team. CP meetings were held throughout the design phase and the construction phase with key-representatives from the supply chain in attendance.

Collaborative planning – Courtesy of nmcn PLC

This was invaluable to understand timescales and product procurement lead times and when submitting three-month advanced notices for road closures and land entry.

During the construction phase a two-week collaborative plan and a daily collaborative plan were utilised to maximise programme and delivery schedule efficiencies due to the limited space available to store materials on site. It was also used to challenge construction sequencing to drive programme efficiencies.

Key facts and figures

- 1400m3 of offline storage.

- 5 (No.) 2.1m Ø concrete sewer pipes 80m in length at a 1:i00 gradient to achieve self-cleansing velocities.

- 135m of new 450mm Ø gravity sewer beneath the A6907 connecting into the offline storage tank, 80m of which constructed by auger boring trenchless installation.

- 5 (No.) bespoke upstream manholes connected via 400mm Ø PE pipes to allow sequential filling.

- 5 (No.) bespoke downstream manholes with gravity control manifold to allow sequential emptying.

- 15m of new 450mm Ø gravity sewer connecting into an existing SPS wet well.

- 220m extension of existing 110mm Ø PVC pressurised rising main.

- Catchment resilience works to reduce rain induced infiltration into the sewer network.

- Cleanse and structural reline of a cast iron sewer beneath a rail track.

- Partnership working with the local authority to line and cleanse 380m of highway drain including installation of 60m of new highway drain.

- The village catchment now benefits from 40-year storm protection against internal sewer flooding and 20-year protection against external sewer flooding.

(left) Works site prior to construction and (right) after construction – Courtesy of nmcn PLC

Lasting legacy and whole project impact

This was a large-scale complex civil engineering project based across numerous sites within a small village setting. The impact on the community throughout the works was kept to a minimum, however the benefit will be felt for years to come.

On completion, the Lowdham, Gunthorpe Road, Flood Alleviation Project will protect a significant number of properties are from internal and external sewer flooding and this societal benefit cannot be underestimated.