Ludham Licence Reinvestment (2021)

The completed Horstead storage reservoir with the original water tower and booster station - Courtesy of @one Alliance

Ludham WTW supplied 2.1 million litres a day (MLD) of treated water to 2,464 properties in Ludham and Martham whilst originally being fed by Ludham boreholes, with emergency supply coming from East Ruston boreholes. This £7.6m scheme addressed area growth and abstraction licence challenges by combining different schemes to deliver an efficient solution for customers in Ludham and Martham, whilst factoring in future demand on supply. The scheme met Anglian Water’s requirement to stop borehole abstraction at Ludham WTW by March 2021 as per its obligations under the Habitat Directive.

Background

Historically, abstraction licenses in the UK have been largely based on need, but under the Habitats Directive, some watercourses were protected as Sites of Special Scientific Interest, therefore presenting the challenge to secure resilient supply from alternative sources.

This was the case with Ludham when the Habitat Directive led to a review of consents by the Environment Agency, resulting in an imposed sustainability reduction from the aquifer; with licences being revoked for Ludham, East Ruston and Hoole House boreholes as well including a requirement for Ludham WTW to be decommissioned. Without sourcing an alternative water feed, this would have left the area with a 4MLD supply deficit.

Thinking strategically when developing the solution

The challenge to find alternative water sources was on the table and an initial solution was developed to build a 2 million litre (ML) reservoir and a two-pump pumping station, but the project team wanted to look at the local need more holistically. The project management team worked with the Asset Delivery Planning and Modelling teams to review plans for projects within the AMP period, local assets and expected growth in the surrounding area.

The original Ludham WTW and Water Tower – Courtesy of @one Alliance

Their research showed that East Ruston, North Walsham, an Albert Bartlett Potato farm and Place UK fruit farm, were all expected to increase the demand on supply from Horstead over the coming years. The decision was then taken to invest in land to support growth for all these areas as well as build in a power upgrade to cover growth and increase storage for East Ruston as part of this project rather than deal with each element separately; saving money and reducing the impact on customers in the locality.

After reviewing the data, the Modelling team put forward the option of installing a 4ML reservoir at the Horstead Water Tower site, with 2ML for Ludham and 2ML for East Ruston. There was a future growth project planned for East Ruston but by bringing it forward, they could increase supply for both areas, in one solution, saving cost, time and carbon, whilst reducing impact on customers.

The delivery plan

The scheme was split into a series of projects with MWH Treatment being made the principal contractor for the main non-infrastructure works; Horstead Storage Reservoir, Ludham WTW and Spixworth, and Barhale as the principal contractor for infrastructure works and direct delivery for civils, including the installation of the new water main.

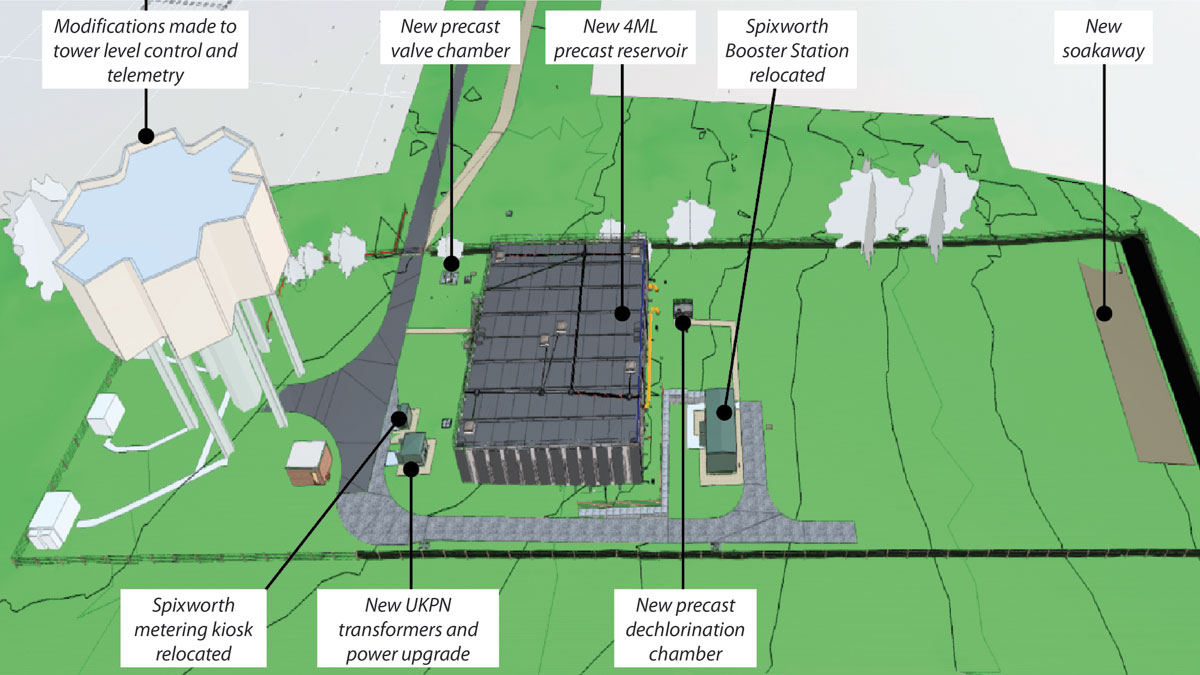

The plan of proposed works at Horstead Water Tower – Courtesy of @one Alliance

Ludham Licence Reinvestment: Supply chain – key participants

This project was undertaken by the Anglian Water @one Alliance, a collaborative Alliance made up of seven partner companies; Anglian Water, Balfour Beatty, Barhale, MMB, MWH Treatment, Skanska and Sweco, to deliver over half of Anglian Water’s capital investment programme.

- Principal contractor Horstead Storage Reservoir, Ludham WTW & Spixworth: MWH Treatment

- Principal contractor infrastructure works and direct delivery for civils: Barhale

- Reservoir base and precast installation: Bell Formwork

- Precast concrete reservoir, dechlorination and valve chambers: FLI Carlow (now FLI Precast Solutions)

- Mechanical contractor: Waveneys

- Electrical contractor: Glasswell & Last

- Independent quality checks on precast concrete: Mott MacDonald

- MIECA contractor: Cema

- Roof membrane: Concrete Repairs Ltd (CRL)

- Temporary roof: Tubes Scaffolding

- Reservoir access hatches: Technocover

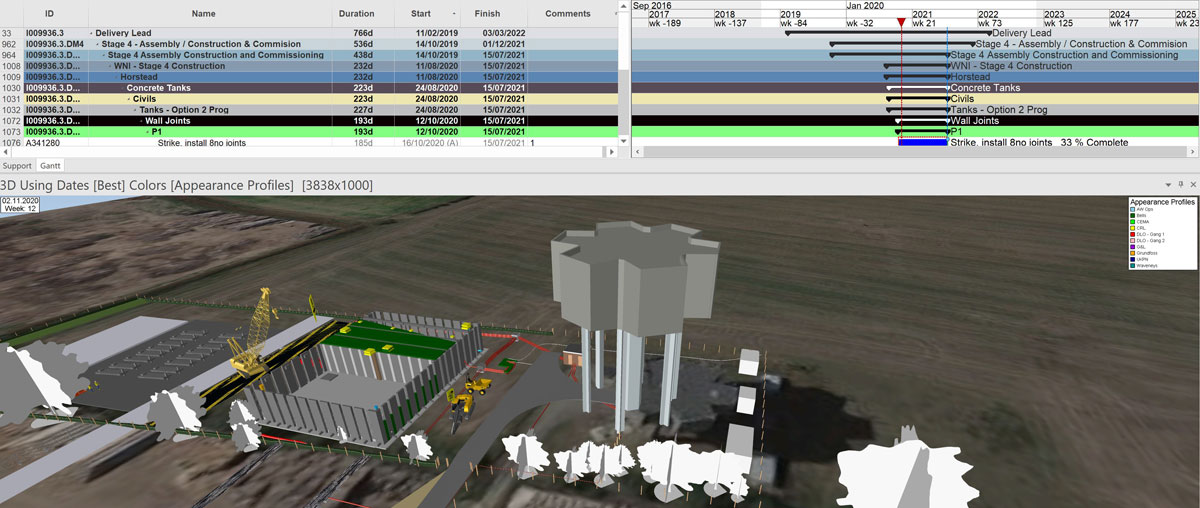

Synchro Pro 4D construction scheduling software – Courtesy of @one Alliance

New water main installation

The initial infrastructure phase focussed on installing 4.2km of new 280mm diameter water main pipes that would connect up to both Stalham and Catfield, which also included the installation of 180mm diameter pipework to connect into Ludham Water Tower.

Horstead Storage Reservoir

The land adjacent to Horstead Water Tower was chosen as the optimal location and a new 4ML precast storage reservoir was built on land purchased to accommodate growth. The land purchase also provided room for a second 4ML storage reservoir in the future as demand grows, which has been landscaped in keeping with the surrounding fields.

Synchro Pro (4D construction scheduling software) was used to accurately timeline each process at Horstead, turning the 3D model and programme into a fully integrated visualisation and simulation of the ground works, assembly and commissioning sequences. This allowed for greater involvement between Operations, site and project teams throughout project delivery. This drove commitment and ownership of the programme at every stage, allowing the team to protect the delivery dates and provide delivery intensity.

The work at Horstead started with Bell Formwork preparing the groundwork and the base slab for the new storage reservoir.

Groundworks at Horstead Storage Reservoir – Bell Formwork preparing the groundwork and base slab – Courtesy of @one Alliance

The new storage reservoir was assembled, creating two tanks built using pre-cast concrete panels that were made by FLI Carlow (now FLI Precast Solutions) in Ireland.

FLI Carlow carried out the full design works associated with the reservoir structure and were integrated within the @one Alliance design and project teams from an early stage to provide their knowledge and experience of potable water reservoirs, utilising their semi-precast reservoir system. A 3D model of the structure was created by FLI Carlow and was integrated into the main design model to ensure accuracy and assist in the project rehearsal accuracy. Having delivered numerous types of these schemes in the region previously with Bell Formwork as an approved installer the process was very efficient, allowing all parties to capitalise on their mutual knowledge and experience.

The project team worked with @one Alliance partner, Mott MacDonald, to inspect the concrete panels in Ireland prior to shipping to the UK, saving the time and cost of sending UK-based colleagues (proving essential during the COVID-19 pandemic). They were checked for a second time on site at Horstead and this was achievable largely due to the amount of land available to lay them out prior to assembly, allowing them to stock 25% of the precast concrete at any one time. Checking for defects or damage in this way saved unnecessary delays later should anything be discovered as they were due to be installed and gave greater assurance of the programme. Each concrete panel was lifted into position using a crawler crane positioned on a designated crane pad.

Precast concrete panel walls of Horstead Storage Reservoir being craned into position – Courtesy of @one Alliance

While the final walls of the storage reservoir were being craned into place, the pipework was being laid on site, on the north edge of the reservoir. The wet concrete pour between each panel had commenced so the pour sequence was rescheduled to allow the pipework to be laid and connected ahead of schedule.

As the concrete pour on the west tank was completed, the columns were installed in the reservoir, followed by precast roof slabs and upstands for the Technocover hatches, which would normally be poured in situ; reducing health and safety risk on site related to working at height. The east tank then followed until the structure was ready for the main roof concrete pour.

The project team were aware of adverse weather conditions closing in, so a temporary canopy was erected over the structure to allow for the installation of the roof membrane along with the final shingle surface safely and in dry conditions, preventing the need to down tools on site. The installation of this canopy was instrumental in keeping the project on programme.

The adverse weather protecting canopy being installed at Horstead Storage Reservoir – Courtesy of @one Alliance

The stairwell and security fencing were then completed as the site was stripped of plant and cabins ready to be tidied and landscaped ahead of handing back to the landowner. A large soakaway was built at the southern extent of the site using a plastic crate design.

Spixworth Booster modifications

The project team were able to save significant time and costs by repurposing equipment from Spixworth by modifying a redundant booster station and metering kiosk for use at Horstead. These were modified on site at Spixworth and lifted using a Versalift onto a low loader, saving the time and expense of hiring a traditional crane as well as working around space constraints on the roads at Spixworth. These were both then installed on site at Horstead ready to be connected.

The generator on site was also decommissioned, ready to be used on another Anglian Water project in Ludham, sharing redundant resources and saving time and cost.

The team at Spixworth saved on cost and time by rethinking the way they would lift the assets. The original solution required the team to hire land, install a crane pad and hire a crane to lift the assets onto a low-loader. Instead, the team decided to use Versa Lifts instead, thus eliminating the costs associated with the traditional crane. This saved around £25,000 and took 6-8 weeks off the programme.

This best practice was then shared with the rest of the Anglian Water @one Alliance through a Commercial Alert.

(left) Inside the relocated Spixworth Booster Station, installed at Horstead and (right) Technocover access hatch – Courtesy of @one Alliance

Ludham WTW and Water Tower

The directive was to decommission elements of the water treatment works at Ludham, so the project team drained down the pressure filters, removing the media and creating air gaps to stop any physical connection back to the network, they also decommissioned the chlorine and orthophosphate dosing and removed the cylinders and dosing rig. The original backwash pumps and tanks were then decommissioned, leaving behind the high lift pumps and the contact tank. The team installed a new wall-mounted control panel, new 100v distribution board and added modifications to the software.

The existing generator on site was kept as a standby, but the Ludham borehole was isolated and locked off, as per the Habitats Directive and associated pipework was installed instead to connect the network.

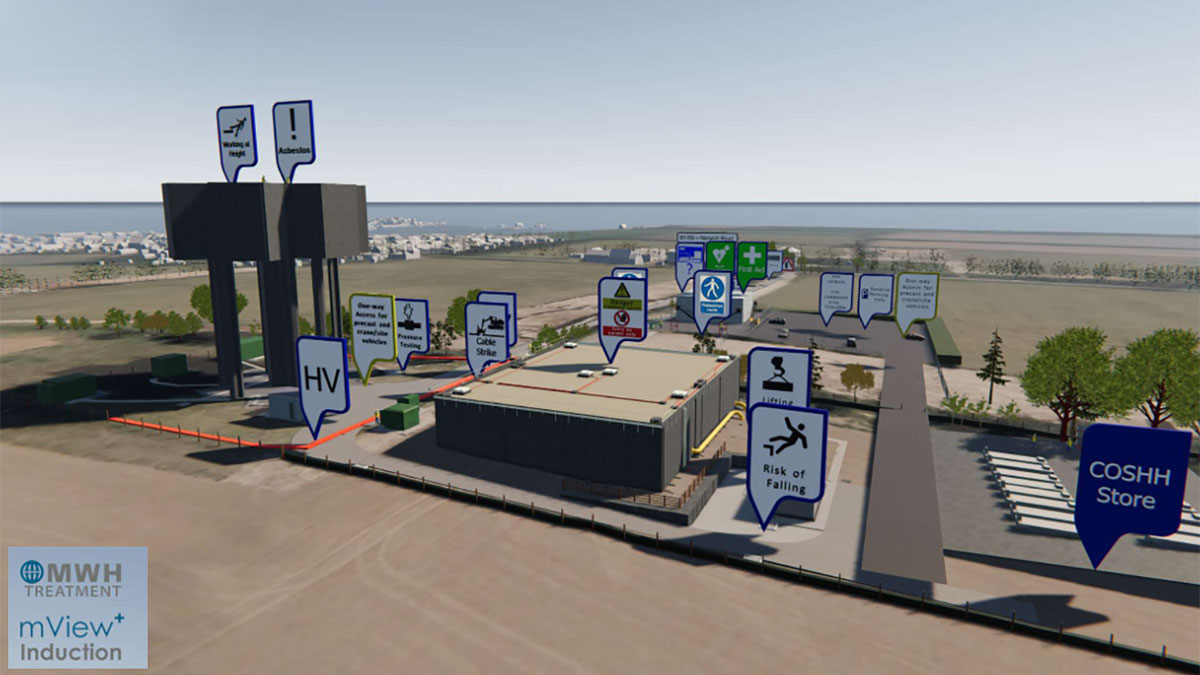

The digital solution – driving H&S performance

It was clear that in order to deliver a project with several moving parts and varying degrees of complexity, the project team would need to deliver information across the scheme in a highly interactive, intelligent and engaging way; allowing for greater assurance of programme and commercial ownership, as well as demonstrating clear roles and responsibilities across all activities. Using expertise developed by non-infrastructure Principal Contractor and @one Alliance partner, MWH Treatment, the team were able to adopt the digital toolkit mView+.

This was the first time that @one Alliance had adopted an induction system that fully integrated the project data within BIM360; providing all stakeholders with any information they required at the touch of a button.

In order to create a fully immersive and digital induction of the site, a 4D model was created which demonstrated the full programme of works and constraints, as well as where subcontractor interfaces occurred; this was integrated with a Bluesky model for context capture and combined using gaming technology.

Hazards were clearly identified with symbols within the model to ensure mitigation measures were taken early. This digital induction provided a full immersive experience.

mView+ has been developed by MWH Treatment to provide a fully immersive site induction capable of communicating crucial information, including:

- 4D visualisation of the whole project.

- H&S, environmental and customer risk.

- Logistics routes to all sites within the project.

- Temporary works.

- Interfaces with existing operational assets.

- PPE requirements for each activity.

The mView+ MWH Treatment digital induction – Courtesy of @one Alliance

Not only did the use of mView+ provide greater assurance of safety on site, it also freed up the Site Manager to dedicate his time to delivering the complex project. This digital solution was able to demonstrate the project in its entirety in one place at the right time, enabling individuals to make smarter safer decisions.

The highly visual way in which health and safety messages were communicated on this project resulted in greater engagement and led to zero incidents across the entire project. This can be directly attributed to all stakeholders being able to fully understand and visualise the scope of works, hazards and plant interfaces before stepping foot onto site.

The completed Horstead Storage Reservoir with the original water tower – Courtesy of @one Alliance

Conclusion

This scheme demonstrates how efficiency savings can be realised when growth is looked at holistically across the whole portfolio. The collaboration between project teams at each site and the interaction with the supply chain and Anglian Water Operations teams have made this project a success.

Before developing the solution, the team looked at lessons learned from similar schemes and challenged how they can build quicker and better. It was calculated that purchase of additional land could result in materials being stored on site rather than waiting for delivery and potentially encountering delays in assembly. This meant 25% of materials could be stored on site at any one time. The team also decided to use precast concrete to make on-site assembly quicker and safer and manufacture the mechanical pipework off-site to arrive ready to be installed.

This solution has not only been efficiently delivered, factoring in future growth, but it has also helped drive down carbon by maximising the use of existing and redundant assets and processes and using off-site build techniques.