Northumberland & Halfway SPS (2020)

A holistic catchment solution. Northumberland 2000m3 storage and Dafen Primary School Bioswale – Courtesy of Morgan Sindall and Arup

Llanelli Wastewater Treatment Works (WwTW) in Llanelli, South Wales, serves the catchment’s 60,000 inhabitants and discharges treated effluent into the Loughor Estuary. The estuary is not only ecologically sensitive, but also a critical natural asset to the local community and to the wider South Wales region. It is a natural capital asset, home to commercial fishing, national sporting events and a range of other recreational uses. Within Llanelli are two key sewage pumping stations (SPS), Northumberland and Halfway SPS, which help to convey the catchment’s wastewater to Llanelli WwTW. Due to a combination of high surface water inflows during storms, high winter infiltration, and aged assets, Northumberland and Halfway SPS were spilling into the Loughor Estuary more than 120 times per year.

Background

Welsh Water’s Capital Delivery Alliance, a coalition between the client, Dŵr Cymru Welsh Water, the designers, Arup, and the principal contractor, Morgan Sindall, was challenged to develop a strategy, then design and deliver an environmentally-sustainable and cost-effective solution that would reduce combined spills to fewer than 30 per year, while being resilient to future changes.

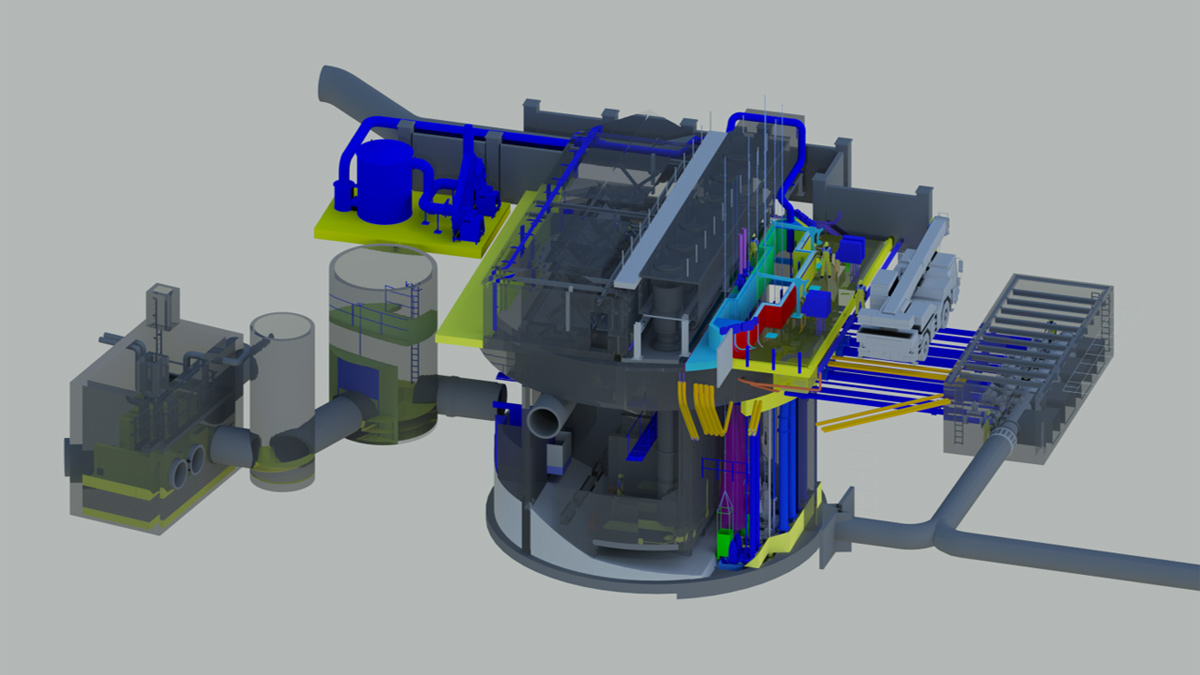

Northumberland SPS 3D model – Courtesy of Arup

Through an extensive optioneering and modelling process, continued close collaboration between the Alliance and Welsh Water Operations, and excellent engagement from the supply chain, the Alliance was able to deliver a £20m holistic catchment solution. This achieved a dramatic reduction in wastewater overflow spills, maintenance costs savings for Welsh Water and social, environmental and economic benefits for the local area.

Llanelli strategy

Welsh Water’s 2050 strategy focuses on sustainable, long-term solutions that deliver multiple benefits. They have shifted the focus away from ‘end of pipe’, large-scale grey infrastructure, and towards a catchment-wide, multiple-intervention approach.

At the start of AMP5, a total of 220 Ha of impermeable area contributed to the Llanelli catchment. The Llanelli strategy, a £115m total investment, included diverting runoff from 46 Ha of this impermeable area from foul sewers to green infrastructure and surface water systems, by the end of AMP6.

The Northumberland and Halfway SPS projects are the two final elements of this overall strategy which has seen Welsh Water championing a sustainable urban drainage systems (SuDS) approach to design. Branded as ‘RainScape,’ Welsh Water’s green infrastructure in Llanelli is a ground-breaking example of the wide-reaching benefits of SuDS.

Dafen Primary School Bioswale, Inlet Forebay – Courtesy of Arup

Key to the success was the Alliance’s initial optioneering and modelling process where they distilled the most attractive surface water removal opportunities, based on a multi benefit assessment, to develop the most optimal solution for the catchment.

Optioneering and modelling

The process began after rebuilding and verifying the catchment’s hydraulic model. A toolbox of hydraulically viable solutions and catchment opportunities was created, all of which could contribute to solving the problem:

- Surface water removal schemes (RainScape).

- Residential roof run off removal schemes (RainScape).

- Bioswales (RainScape).

- Discrete, strategically placed storage.

- Pipe upsizes.

- Increased pump capacity.

- Smart assets (assets able to communicate through telemetry and react to live sewer conditions).

- Asset optimisation (making best use of assets and managing spills between assets within consent/NRW agreement).

- Infiltration reduction measures and land drainage removal.

- Transfer of flow between sub-catchments.

Using the modeller’s toolbox, an Optimised Optioneering Tool was developed which combined all viable elements in every conceivable combination to produce a matrix of catchment solutions. The tool was able to use machine learning to understand how compliant each solution was and could add/remove elements to create the optimal combinations. The tool also included costing and carbon data, giving each combination a whole life cost and carbon metric alongside the hydraulic impact, buildability, and wider benefits.

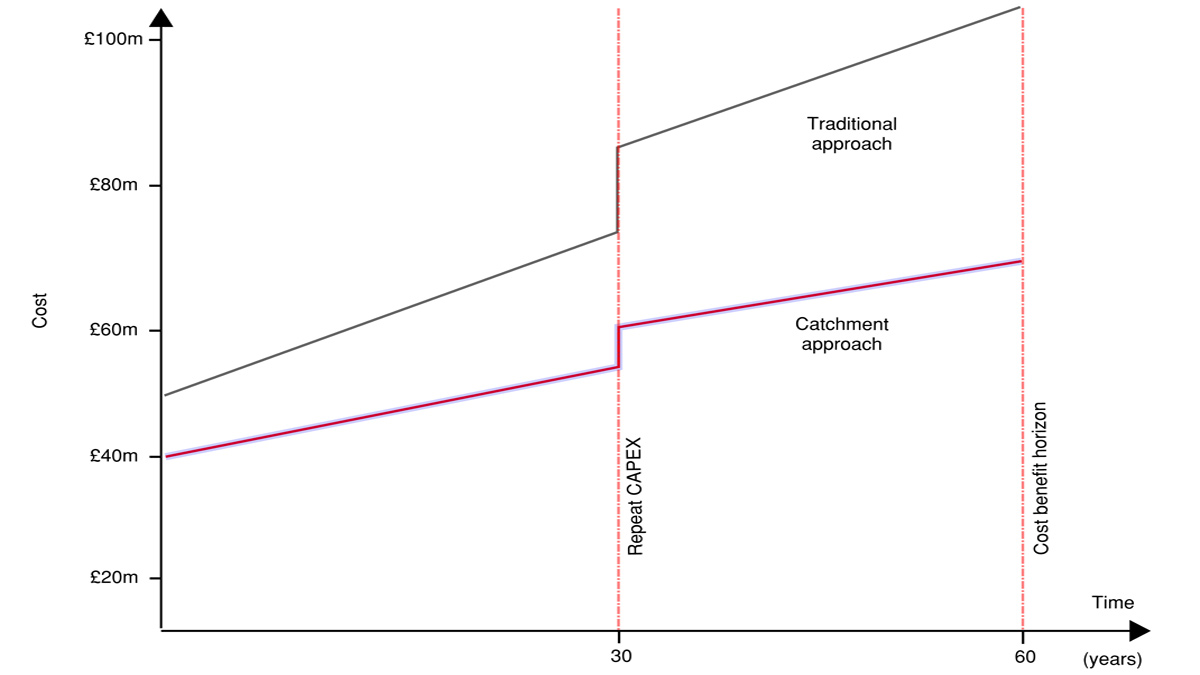

Catchment Approach vs Traditional Approach Solution. Whole life cost forecast shown for total proposed works at Northumberland SPS and Llanelli WwTW – Courtesy of Arup

In total, the tool identified 19 compliant catchment solutions for Northumberland SPS’s catchment and 15 for Halfway. Welsh Water commended the Alliance for exhausting every avenue and ensuring the best value solution could be derived from a wide-ranging array of elements. The tool enabled the Alliance to cast its optioneering ‘net’ wide to investigate the full potential of each catchment and quickly filter options to focus on the best overall value solutions.

Solution

The best value long-term investment for Welsh Water came from an option which capitalised on a wide array of catchment opportunities.

The final solution combined 2.5 Ha of surface water removal, three residential roof runoff schemes, two green infrastructures school schemes, two new storage tanks, upgrading both Northumberland and Halfway SPS, a new smart telemetry link between Northumberland SPS and another Llanelli WwTW terminal SPS, and a new flow-control smart asset.

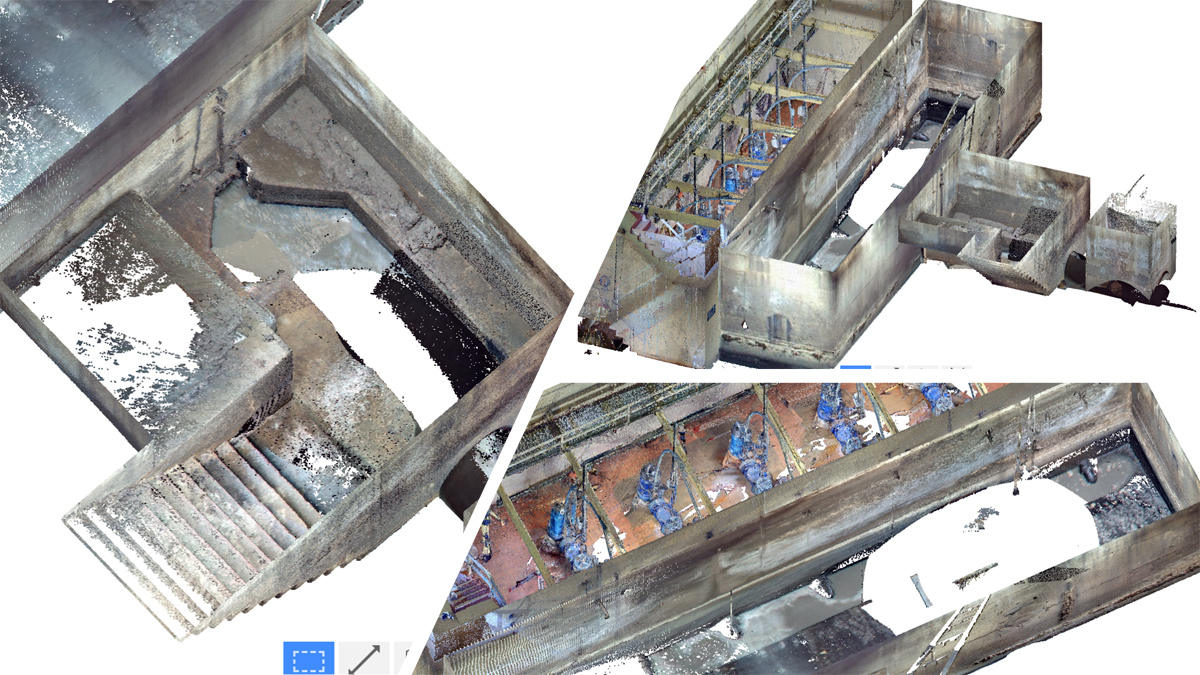

Halfway SPS point cloud – Courtesy of Arup

Design and construction

Green Infrastructure – Welsh Water RainScape: The 2.5 Ha of highway surface water removal was designed to take advantage of existing construction compounds within Llanelli, set up as part of other schemes. This offered significant cost and resource savings in construction/programme. Collaboration with Carmarthenshire County Council was fundamental in planning and carrying out the works. The removed surface water would be redirected into Welsh Water’s new 1km Station Road Storm Tunnel, to be discharged safely into the Loughor Estuary.

The residential roof runoff schemes trialled three new approaches to roof/garden surface water removal on three different streets in Llanelli, with varying levels of customer led design. Public consultations in local pubs proved extremely successful and an excellent means to engage with residents.

Two school retrofit green infrastructure schemes involved retrofitting planters to attenuate the large building’s roofs and constructing a new bioswale at Dafen Primary School. The bioswale, constructed by Dawnus Construction, attenuates runoff from the carpark. Both were community-led projects with involvement from the students to help design the new planting arrangements.

Removing storm runoff and/or attenuating it by replicating natural systems offered an excellent return on investment. Although green infrastructure often costs more in CAPEX, it offers returns by reducing operational costs in pumping and treating stormwater and avoids costly maintenance associated with new storm tanks or treatment capacity.

Dafen Primary School bioswale, post planting – Courtesy of Arup

Northumberland and Halfway SPS: Supply chain – key participants

- Client: Dŵr Cymru Welsh Water

- Designer: Arup

- Principal contractor: Morgan Sindall

- Mechanical contractor: Whitland Engineering Ltd

- Electrical contractor: Hornbill Engineering Ltd

- Electrical contractor: Bridges Electrical Engineers Ltd

- Electrical contractor: Zone Electrical

- Pumps: Xylem Water Solutions

- Temporary over pumps: Pump Supplies Ltd

- Precast storage tank: FP McCann

- VacFlushTM tank cleaning: CSO Group Ltd

- Air mixing System: Stem Drive Ltd

- Actuators, valves & penstocks: Rotork

- CSO screen: Huber Technology

- Access covers: Steelway Brickhouse

- Kiosks: Morgan Marine

- Kiosks: Kingsley Plastics Ltd

- Software: Merlin Systems Ltd

- Physical modellers: Hydrotec Consultants

- Hydraulic analysis: Hydraulic Analysis Ltd

- Odour control: Air-Water Treatments Ltd

- Structural survey: Pebble Engineering

- Structural survey: Socotec

- Green infrastructure civils contractor: Dawnus Construction

- Green infrastructure landscape contractor: Gerald Davies

- Land agents: Cooke & Arkwright

- Ventilation system: FP Hurley & Sons

Northumberland 2000m3 storage tank, base slab concrete pour – Courtesy of Morgan Sindall

Storm storage: A new 2,000m3 precast storage tank was constructed within the Northumberland SPS compound. To utilise existing infrastructure, the tank was installed on site, which in turn presented a series of challenging design constraints. Temporary works involved driving 7m deep sheet piles to create a safe working environment. As bracing works were significant, Morgan Sindall implemented a meticulously detailed lifting plan to lift in and install the precast components safely.

To reduce OPEX costs and improve operational health and safety, a non-entry automatic flush cleaning system was installed to clean the tank. The VacFlushTM system, provided by CSO Group Ltd, works by creating a vacuum column of stormwater once the tanks are full, before releasing it to flush the tank autonomously.

A second smaller 700m3 precast storage tank was constructed close to Halfway SPS. The tank’s volume was maximised given the footprint and the desire to use a gravity return rather than a pumped return. Like Northumberland, an autonomous cleaning system was installed. Air compressors, supplied by Stem Drive, were connected to an array of sparge lines across the tank’s floor. On tank drain down, the compressors operate, discharging air across the tank to agitate sedimentation and avoid septicity.

Halfway SPS 700m3 storage, ground reinstatement – Courtesy of Morgan Sindall

In terms of design, both tanks were subject to an extensive supplier engagement programme where different types and shapes of storage were considered. Site-specific design constraints, hydraulics and buildability eventually singled out precast rectangular tanks in both cases. From there, early involvement from precast tank supplier FP McCann helped to identify constraints and optimise the geometry of each design.

Upgrading pumping stations: Northumberland SPS’s pass forward flow (PFF) was upgraded from circa. 750 l/s to 1,100 l/s and Halfway SPS’s PFF from 180 l/s to 194 l/s. Both assets suffered from an array of hydraulic inefficiencies from poor wet well design to deteriorated pumps and rising main. Historic underperformance was exacerbated by high maintenance costs and a high risk of onsite flooding due to pump failures. The upgrade works were critical to increase the resilience of each asset, while making them easier and safer to maintain.

Due to the age of each asset, as-built records were poor, and existing health and safety issues made surveying problematic. To overcome this, Morgan Sindall carried out full point cloud surveys for each station to facilitate design.

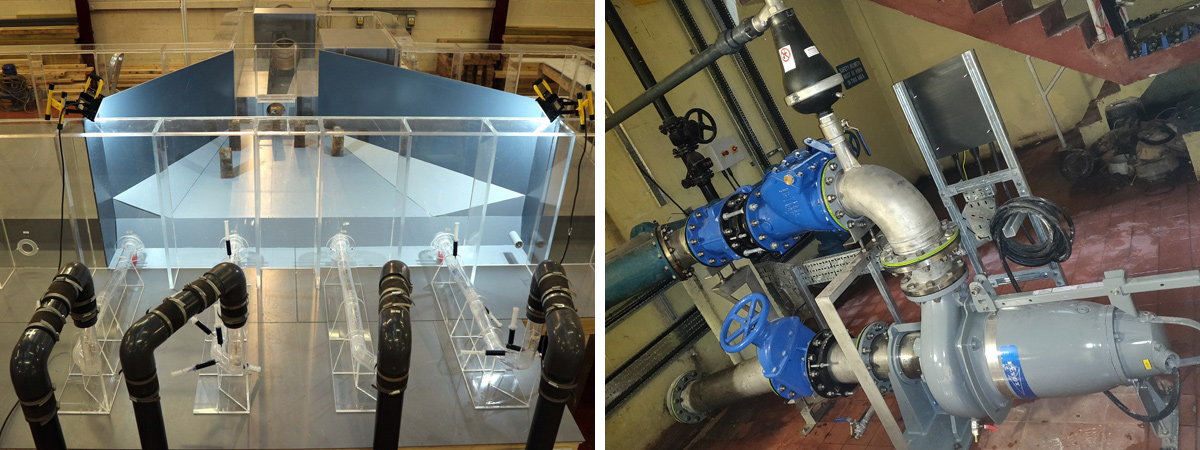

Arup technicians processed the point clouds into 3D models, which formed the basis of the construction drawings and facilitated the manufacture of third-scale, physical models.

Physical models, built by Hydrotec Consultants, were used to optimise each station’s hydraulics by recommending civil modifications within the wet wells and new pipework arrangements.

(left) Halfway SPS physical model – Courtesy of Hydrotec Consultants and (right) the new pumps at Halfway SPS – Courtesy of Morgan Sindall

Further hydraulic analysis of the pump and rising main was carried out by Hydraulic Analysis Ltd to highlight problematic air valves and to ensure that new pumps were fit for purpose. New pump designs, supplied by Xylem Water Solutions, and wet well modifications, installed by Whitland Engineering, ensured that each station now consistently pumps its consented PFF. Maintenance costs have significantly reduced due to no pump failures or blockages.

Temporary over pumping works at Northumberland, supplied by Pump Supplies Ltd, were a significant task in themselves. Northumberland SPS receives peak storm flows of up to 4,000 l/s so to protect the upstream catchment from flooding, it was vital to ensure business continuity while the works were carried out. Morgan Sindall constructed a brand new temporary wet well within the site’s abandoned Archimedes screw chamber to allow the existing SPS to be taken off line and works were carried out in a safe environment.

Northumberland SPS over pumping chamber – Courtesy Morgan Sindall

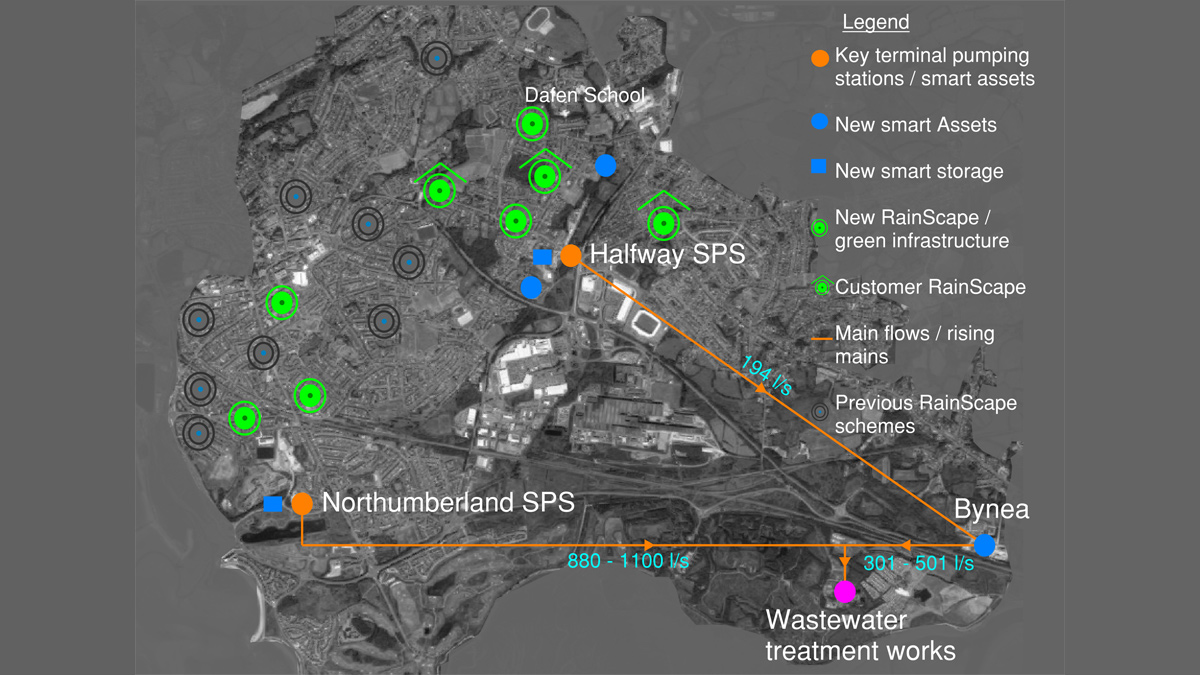

New smart assets: A new telemetry link was established between Northumberland SPS, Bynea SPS (a second Terminal SPS to Llanelli WwTW) and Llanelli WwTW. Hydraulic modelling identified an opportunity to flow-manage the PFF of these stations and utilise their respective storage capacity. Modelling demonstrated that over a 10-year data set, Northumberland SPS PFF could be increased in storm events (from 880 l/s up to 1,100 l/s) if Bynea SPS PFF reduced from its current PFF of 501 l/s by the same amount. The new telemetry link was established to allow each set of pumps to ramp up and down accordingly, based on the other station’s PFF.

In the event of a storm, Bynea’s existing 1,800m3 onsite storage would be utilised to attenuate excess flow. Once the storm ended and Llanelli WwTW able to facilitate it, Bynea could return to maximum PFF to empty the tanks.

Converting the three assets into a smart system, capitalised on their existing capacities rather than building new infrastructure. It also allowed them to react to live storm conditions, optimising their effectiveness. The new system saved £8m in associated Llanelli WwTW upgrades and significant long-term ultraviolet operating costs that would otherwise have been required.

New telemetry link between Northumberland SPS and Bynea SPS – Courtesy of Arup

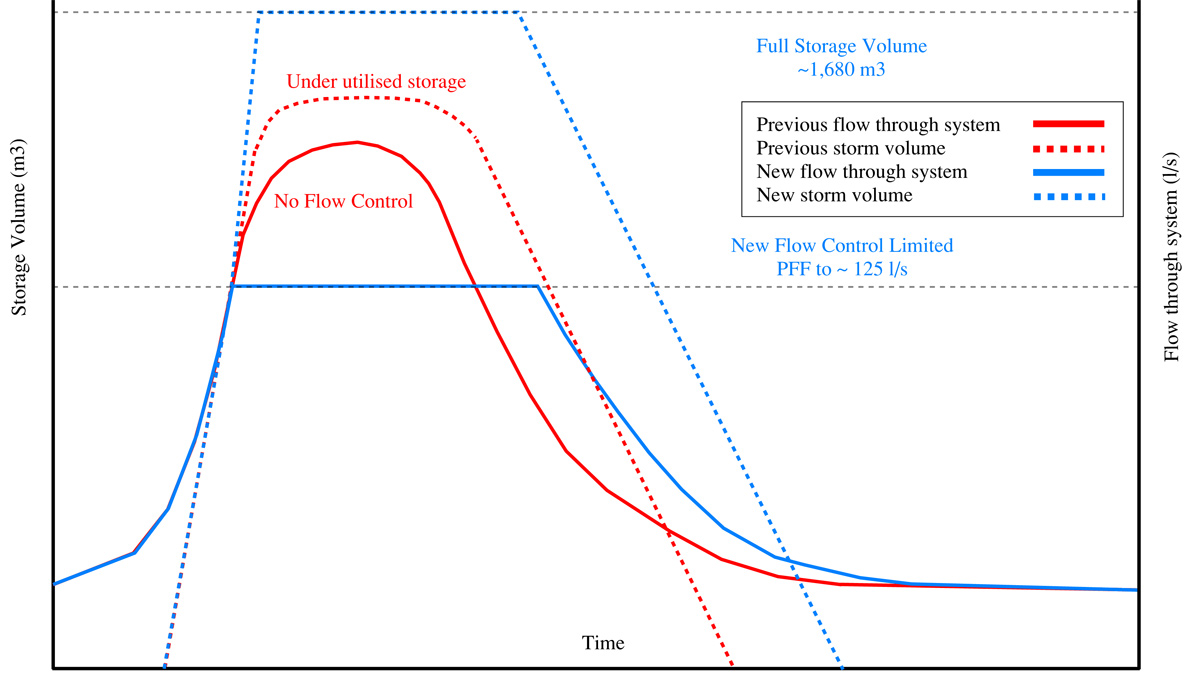

A second smart asset was implemented adjacent to Halfway SPS. A new flow control chamber, consisting of a Rotork actuated penstock and magnetic flow meter, was constructed downstream of an existing 1,680m3 underground storage tank. Historically the tank was not filling effectively during storm events and a loss of potential volume was observed. A new flow control penstock adjusted its setting automatically to ensure tanks filled entirely during storm events, thereby relieving the downstream network.

Performance monitoring

Hydraulic modelling, using a 10-year dataset, has demonstrated the final solution will reduce the combined spills from Halfway SPS and Northumberland SPS to an average of less than 20 and 10 per year respectively. The Halfway SPS works and related schemes are now complete with the final construction works at Northumberland SPS, including commissioning the tank, due to be completed in October 2020.

Initial telemetry data from Halfway SPS shows that overflow activity has been reduced and the new pumps are consistently pumping the designed 194 l/s. The new smart flow control implemented to capitalise on the 1,680m3 storage volume near Halfway SPS is also operating as designed, ensuring the tank is fully utilised during storms.

Halfway SPS utilisation of 1,680m3 storm storage: Previous vs New – Courtesy of Arup

Conclusion

Digital optioneering tools helped the Alliance team cast the solution ‘net’ very wide, very efficiently. At a catchment level, this usually results in a range of complimentary solutions which can be ‘mixed and matched’ to form the best whole-life cost and lowest carbon solution, delivering the widest benefits to the community. Key to this is pinpointing the best opportunities, co-creating with stakeholders and being customer driven. Solutions not taken forward for the current project can be placed into the future resilience toolbox to be revived in the future.

The bespoke catchment approach, design methodology and emphasis on community engagement used in Llanelli will be implemented in other Welsh catchments, with our digital tools also making this unique process a much more realistic proposition nationally.

Looking ahead to AMP7, the Alliance is committed to building on their established best practices while drawing on and contributing to the UK’s professional learning communities. The Alliance will blend digital skills honed in AMP6, with new AMP7 innovations to support Welsh Water in delivering resilience and ensuring the protection of physical and natural assets for future generations.