Oldham & Royton Integrated Strategy (ORIS) (2017)

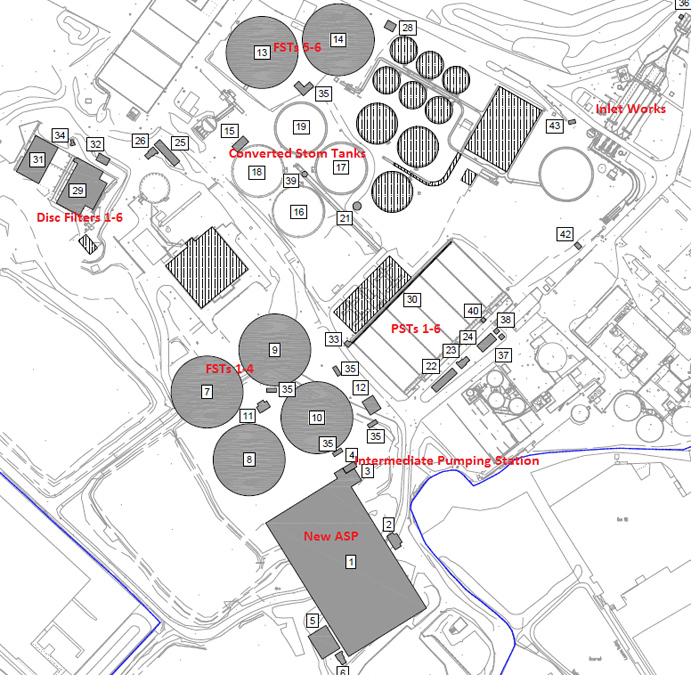

Oldham WwTW - July 2017 - New ASP lanes 1-4 (bottom right), sludge lagoon (left of the ASP), disc filters 1-6 (bottom left), FSTs 5-6 (top left) - Courtesy of United Utilities

United Utilities is the regional water company for the north west of England, delivering water and wastewater services to 7m people from Cheshire to the Scottish border. Oldham WwTW and Royton WwTW are two major treatment works located in Oldham, to the north east of Manchester. The Oldham and Royton Integrated Strategy (ORIS) project combines both wastewater network and wastewater treatment regulatory drivers at these two works into a single integrated solution. The backbone of the solution is to close Royton WwTW, transfer flows 4.2km to Oldham and upgrade Oldham WwTW to treat the combined flows to meet a higher river water quality standard. At both sites, additional storm storage is also required to improve storm discharge. The main construction contract was awarded to Black & Veatch in spring 2015 and the project is now half way through its implementation phase.

Background and need

Both Oldham WwTW and Royton WwTW discharge final and storm effluent to watercourses that are tributaries of the River Irk, and both have regulatory requirements to improve the River Water Quality. Oldham WwTW has a population equivalent of 157,000 and Royton WwTW 28,000.

The Oldham and Royton Integrated Strategy (ORIS) was born out of two regulatory drivers.

- Oldham WwTW Freshwater Fish Directive (FFD): Oldham needs to meet a new tighter final effluent consent of 6mg/l BOD and 1mg/l Ammonia (from 15mg/l and 2mg/l respectively) to meet the Freshwater Fish Directive.

- Oldham and Royton Storm Tank UIDs: Both Oldham WwTW and Royton WwTW storm discharges are classified as UIDs (unsatisfactory intermittent discharge) with a target to improve the River Irk to RE 4 standard.

In addition, many of the assets at both Oldham WwTW and Royton WwTW have passed their asset life and are in need of significant refurbishment and maintenance in the near future.

Oldham WwTW – New layout drawing (redundant assets hatched) – Courtesy of United Utilities

Scope of work: Royton WwTW and Pipeline

- New inlet combined sewer overflow (CSO).

- Retain existing inlet works.

- New FTFT (flow to full treatment) control set to 325 l/s.

- New storm outfall to River Irk.

- New 4.2km gravity transfer pipeline (approximately 600mm diameter) to Oldham WwTW to transfer 325 l/s.

- New 7280m3 storm storage (detention tank).

- Associated HV and LV systems.

- Telemetry.

- Demolition of redundant assets.

Scope of work: Oldham WwTW

- Reception of new transfer pipeline.

- Retain existing inlet works.

- New FTFT control increased to 2245 l/s (an increase of 25% compared to current FTFT).

- Refurbishment of existing primary settlement tanks (PSTs) including new scraper bridges.

- New 6 (No.) deep final settlement tanks (FSTs): 46m diameter, 7.6m deep at deepest point.

- New fully nitrifying activated sludge plant (ASP): 7 (No.) lanes with anoxic zones, 102m x 59m, 7.9m deep (top water level).

- Tertiary filtration by 6 (No.) Veolia Water Technologies Hydrotech disc filters.

- New SCADA for the full site, including sludge processing areas, Royton WwTW and the transfer pipeline.

- Upgrade to HV systems.

- Telemetry.

- Additional 11,800m3 of storm storage provided by converting existing (but redundant) final settlement tanks into storm tanks.

- Demolition of redundant assets.

- Landscaping and invasive species eradication.

Design matters

Black & Veatch is delivering the ORIS project using a BS1192 configured Common Data Environment (CDE) – Bentley ProjectWise, hosted by United Utilities. The benefits this provides are:

- Controls access to documents in strict accordance with the design delivery plan.

- Controls the design deliverables to be authored, checked and reviewed by those individuals named in the plan who have those specific responsibilities.

- Ensures that at any point there is only ‘one version of the truth’, delivering better information management.

- Assigns unique file name and attribute data to each file for storage, referencing and searching.

Oldham WwTW – New primary settlement tank (PST) scraper bridges – Courtesy of United Utilities

Non-graphical asset data is being presented and managed through the use of an intelligent P&ID system – Bentley OpenPlant. Black & Veatch have configured the standard software functionality and are using it to allow asset tagging and data to be synchronised and held in a common database.

Black & Veatch is using their Intelligent P&ID Data Exchange system to manage and manipulate the asset data into equipment schedules for engineering and procurement, and commissioning schedules for work planning.

All this functionality sources data from a common database, ensuring that throughout the project life cycle, the data is current and available at all times. The added value to United Utilities is the digital retention of all essential asset data throughout the asset life cycle, held in a common location for ease of referencing and use in the future following completion of their capital investment project.

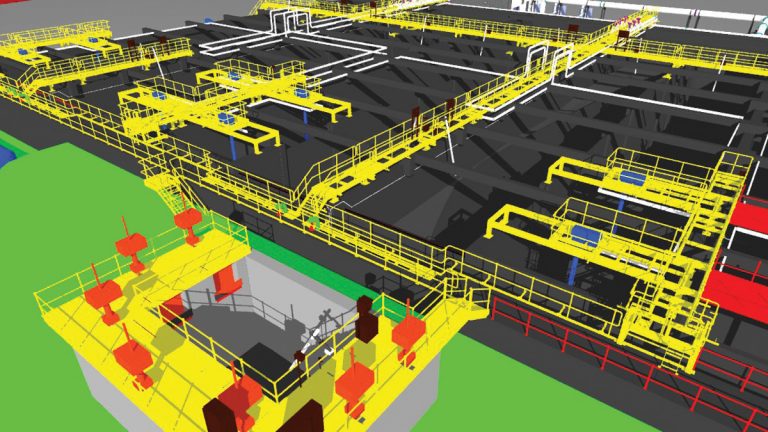

Black & Veatch has built a 3D model of Oldham WwTW with Navisworks software, which has been extremely useful, particularly when threading proposed large diameter gravity buried services through a complex arrangement of existing live buried services whilst minimising diversions.

Oldham WwTW – BIM model snapshot of new activated sludge plant – Courtesy of United Utilities

The 3D modelling has also proved invaluable at safety in operation and access, lifting and maintenance review meetings, and the as-built version will form a key component of the project BIM information.

Hydraulic modelling for the interconnecting process pipework at Oldham has been carried out by Black & Veatch in-house with the aid of computational fluid dynamic modelling for ASP flow delivery and distribution. Black & Veatch has undertaken the sewer network modelling in-house with their specialist team based in Redhill, Surrey. UU have carried out the Integrated Catchment Modelling to check solution compliance with the RE4 water quality target for the River Irk.

A Failure Modes, Effect and Critical Analysis (FMECA) process was adopted, which included a means of ranking the severity of the failure modes to allow prioritisation of countermeasures. This is done by combining severity and frequency of occurrence to produce a measure called criticality.

The 4.2km pipeline design has been undertaken by GHD. The pipeline has a number of level undulations along its length and is designed to operate in a batched sequence; it has a header tank at the higher elevation Royton WwTW end, and control valves at the lower Oldham WwTW discharge end.

The pipeline is kept full and the outlet valve is only opened once the header tank is near full, ensuring that each batch of flow reaches a self-cleansing velocity with an adequate volume to carry any sediment over and beyond individual undulations. Once the header tank is close to being empty, the control valve at the downstream end is closed.

Wince Brook flood mitigation

A consequence of transferring flows for treatment from Royton WwTW to Oldham WwTW is that the final effluent flow rate, and on occasion the storm discharge flow rate, from Oldham WwTW into the receiving watercourse Wince Brook (a tributary of the River Irk) is slightly increased.

Since there is already some predicted flooding in Middleton from Wince Brook during exceptional storms, the design needed to ensure that there would be no exacerbation of that predicted flooding. Jacobs carried out the associated optioneering, flood risk assessment and subsequent detailed design of a storage basin solution.

The proposed storage basin is situated in the north of the Oldham WwTW site. The basin itself has been designed to store the design flood event (the 1 in 100 year flood including an allowance for climate change) whilst maintaining 350mm of freeboard between the top water level and the crest of the embankment.

Key components of the storage basin are summarised as follows:

- The excavation of 6191m3 of material from the an area south of the existing culvert inlet.

- The construction of a bund along the western boundary of the site to a minimum level of 97.99m above Ordnance Datum (AOD).

- The removal of a damaged section of the existing culvert approximately 30m long.

- The installation of an 800mm fixed orifice at the new culvert inlet location.

- The installation of a trash screen at the culvert inlet.

Pipeline construction

ORIS pipeline – Streetbridge Road (Royton) pipe bridge – Courtesy of United Utilities

To transfer flows between Royton WwTW and Oldham WwTW a new ductile iron gravity pipeline is being constructed. This is 600mm diameter, 4.2 km long and falls 24m from Royton to Oldham.

The pipe route was selected to minimize traffic disruption avoiding highways where possible, with as little as 600m laid in roads. To help achieve this, three sections of pipe have been installed in tunnels driven from shafts using a tunnel boring machine of 1450mm diameter to give a 1200mm internal diameter PCC tunnel through which the pipe was pushed in clamped sections.

Directional drilling techniques have also been utilized for installation of fibre optic communication cables. The main section of roadworks were necessary to avoid disruption to the A627M by following Streetbridge Road where the motorway passes overhead on an existing bridge.

The pipe crosses three water courses; the River Irk, twice, on pipe bridges and the Wince Brook where the pipe will be laid under the brook by open cut methods using aqua dams for flow control. The pipeline is twinned on the pipe bridges to provide resilience.

ORIS pipeline – Route avoiding Swallowfields Estates in Chadderton – Courtesy of United Utilities

The majority of the route crosses Local Authority land in the form of public open spaces, parkland, playing fields and school grounds but it also had to pass through private grazing land and a brownfield site where the route had to take account of future planned development of a housing estate and business park.

Through these areas, the pipe was installed by traditional open cut methods for shallow sections and in trench boxes at greater depths or in areas of reduced working space. Where the hydraulic profile required greater depths a mixture of ground reduction and shoring along with well point dewatering was needed.

Royton WwTW construction

At Royton WwTW construction is underway to provide a new detention tank of 7280m3 capacity, a new CSO and a header tank to feed the gravity transfer main to Oldham WwTW.

Royton WwTW – Overview – Construction of the detention tank – Courtesy of United Utilities

Works are being constructed within the existing operational treatment plant with the majority of the construction being off line to minimize impact on normal operation of the plant. The existing inlet screening and detritor will be maintained and once commissioned any redundant plant will be demolished and landscaped.

Works are nearing completion on the detention tank which has been constructed in situ and measures 47.7m by 21.8m on plan and is 9.46m deep internally with external walls 900mm thick and standing 10.46m high overall. The base slab is 1m thick and the total volume of concrete poured for this structure is 2750m3.

The tank has been constructed within an excavation on a sloping site with excavated depths from 9m to 14m through made ground, soils and rock. In all 22,000m3 has been excavated and will be re-used to fill abandoned structures and to landscape the site.

Space constraints, existing operational plant, significant ground water and the presence of rock resulted in a challenging temporary works design. The solution entailed installation and constant monitoring of well point dewatering with a phased excavation of approximately 2m depth per phase with the construction of a reinforced excavation face through installation of steel reinforcing mesh, timber wailers and ground anchors which allowed for a cut face at 55° or 1 in 0.7.

Royton WwTW – Detention tank – Courtesy of United Utilities

Oldham WwTW construction

The new activated sludge plant, final settlement tanks and disc filters are sized for the combined full treatment flows from both Oldham and Royton. These are currently being constructed whilst maintaining the operation of the existing process streams. The new process structures and pipelines are positioned within the limited remaining space on the Oldham site including at the location of a disused sludge lagoon.

Oldham WwTW – New final settlement tanks (No 5 & No 6) – Water drop test on going – Courtesy of United Utilities

At its deepest point the existing sludge lagoon is up to approximately 6m deep and is underlain by a further 5m of soft made ground. The sludge is currently being screened and dried via centrifuge prior to removal from site for use in land reclamation. The soft soil layer will either be strengthened or removed and replaced to provide a suitable formation for the new ASP and FST structures.

The ASP is an in situ reinforced concrete structure with pre-cast concrete baffle walls. The in situ walls are tied using 16m long pre-cast concrete props. Two of the FSTs are complete including the installation of the scraper bridges, the remaining 4 (No.) FSTs will be constructed following clearance of the sludge lagoon. The tertiary treatment disc filters structure is complete and the mechanical installation works are in progress.

Oldham WwTW – 6 (No.) new disc filters during construction – Courtesy of United Utilities

In addition to the new structures, the existing PSTs are being refurbished. Works include the replacement of the scraper bridges and rails, concrete repairs, de-sludge pumps and the construction of a new concrete outlet channel for connection to the new ASP. Delivery of the PSTs has been optimised using collaborative planning workshops with UU, Black & Veatch and the key sub-contractors.

Oldham & Royton Integrated Strategy: Project Key Facts

- Project approved budget: £78.2m

- Construction completion date: May 2019

- Procurement strategy: OJEU Competitive Tender

- Form of contract: Design & Build , I Chem E Red Book

- Main contractor: Black & Veatch

- Royton work package: Farrans Construction Limited

- Pipeline work package: Farrans Construction Limited

- Construction man-hours worked to date (July 2017): c500,000 (lost time accident free)

Oldham WwTW – New disc filters during construction – Courtesy of United Utilities

Conclusion

At the time of writing, half of the sludge in the dis-used sludge lagoon at Oldham WwTW has been extracted, treated and sent to remediation sites whilst preparations are underway to start the construction of lanes 5, 6 and 7 of the new ASP as well as the remaining 4 (No.) new FSTs.

Royton WwTW – Detention tank, header tank (top right) and new CSO chamber (bottom right) – Courtesy of United Utilities

Collaborative planning between UU and Black & Veatch has identified an opportunity to accelerate the entire programme by 5 months by freeing up the existing 4 (No.) FSTs early to be converted into storm tanks while maintaining the Oldham WwTW Environmental Permit compliance.

The transfer main and the Royton WwTW new assets are 80% complete and will be mothballed until the new assets at Oldham WwTW (including the new storm system) are commissioned next year. The project is currently forecasting a delivery on budget in May 2019.