Ormeau Avenue Sewerage Upgrade (2019)

Sheet piled cofferdam for open-dig section of 1200mm combined sewer and 900mm overflow pipelines - Courtesy of DAWSON-WAM Ltd

An article published in the 22 April 1881 edition of the ‘News Letter’, one of Belfast’s leading newspapers, still in circulation today, remarked: “Time was when the Blackstaff [River] ran through the suburbs little more polluted than a mountain burn. Now it has become the greatest eyesore in the town.” This self-same article also published ambitious plans to culvert the Blackstaff, a scheme advanced by a Mr Montgomery, the borough surveyor, entailing the diversion of the river, the construction of a double culvert and the levelling and reclaiming of adjacent ground. In the opinion of the article’s author, the culverting of the Blackstaff was not before time, a key project driver of the day being that its “noxious exhalations shall no longer be allowed to poison the air”. Like many urban watercourses of the era, the Blackstaff had obviously become something of an open sewer, and smelled accordingly.

Background

A substantial reach of the Blackstaff was duly culverted by 1882, including a reach below what would become Ormeau Avenue in Belfast city centre. As part of the original design, a section of what would nowadays be termed a ‘critical sewer’ was constructed within the northerly culvert’s benching. Lateral combined sewers from four city centre streets entered the culvert from high level before turning downwards and dropping vertically to the hidden sewer, the diameter, invert levels and condition of which, to this very day, remain unknown.

Wind the clock forward to the present day, and it was suspected that the inaccessible sewer had deteriorated and was suffering from blockages, possibly exacerbated by an abundance of fats, oils and grease (FOG) from a number of nearby food outlets. This issue was causing a number of combined sewer overflows (CSOs) in the area to discharge prematurely to the Blackstaff and the Belfast Stormwater Tunnel (a major storm water interceptor project completed in 2010) even during dry weather. Water quality monitoring by the NI Environment Agency (NIEA) indicated an ongoing problem, with significant traces of sewage present in the culvert at Ormeau Avenue. Hydraulic modelling estimated sewage discharges to the Blackstaff to be in the region of 350-450,000m3/year and the NIEA classified 5 of the CSOs discharging to the Blackstaff as high priority unsatisfactory intermittent discharges (UIDs).

In addition to the blockage issues, storm flows from the four lateral combined sewers were overloading the hidden sewer, resulting in increased risk of out-of-sewer flooding in the catchment. NI Water had also been requisitioned to provide first time storm sewer connections for a number of city centre developments in the area.

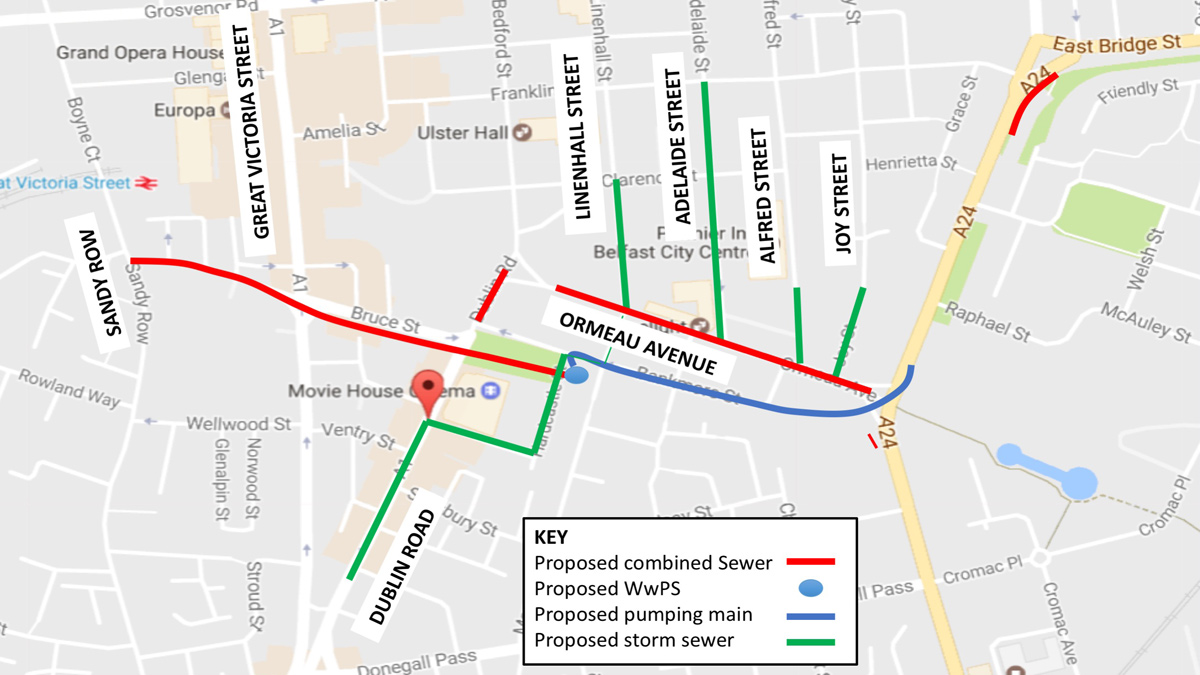

Project location and schematic – Courtesy of NI Water

Project appraisal

In 2013, NI Water appointed WYG to provide professional services and to develop the outline design, as recommended in the Drainage Area Plan prepared by Atkins. The final scope included:

- A new wastewater pumping station to pump to an existing combined trunk sewer at Cromac Street.

- 63,000m2 of storm separation.

- Upsizing critical combined sewers.

- Upgrade of 2 (No.) CSOs.

- Closure of 3 (No.) CSOs.

- Storm sewers to serve new residential/commercial developments.

Early contractor involvement and enabling works

WYG managed the ‘early contractor involvement’ (ECI) stage of the project, preparing the ECI specification and contract as well as project managing and supervising the enabling works. ECI works involved the gathering of site information to help define the final design and scope of works and developing the construction methodology.

The scope of the ECI contract comprised of a range of measures to determine existing ground conditions and the location and nature of existing underground services, including:

- Geotechnical investigations.

- Road cores.

- Consultation with other utilities.

- Slit trenches.

- Tracing and marking.

- Ground penetrating radar.

- Topographical and (sewer and culverted watercourse) CCTV.

- Man-entry and dye surveys.

Construction methodologies within the challenging city centre environment were also considered at this stage of the project.

(left) Example of congested services encountered while pipe laying and (right) precast concrete CSO chamber at Cromac Street – Courtesy of DAWSON-WAM Ltd

Project management

Due to the complexities of the project, the NEC3 Engineering and Construction Contract, Option C: Target Contract with Activity Schedule, was chosen for the main construction contract.

Upon completion of target cost negotiation, NI Water selected DAWSON-WAM Ltd, who were involved the ECI, to deliver the contract.

WYG developed the scope of works for the construction contract, which included drafting site information, pre-construction information, works information and contract documentation – all in accordance with NI Water Asset Standards and Engineering Specifications. WYG also provided project management, site supervision and health & safety advisory services throughout construction and NI Water appointed Capita Real Estate and Infrastructure to provide cost management services.

Ormeau Avenue Sewerage Upgrade: Supply chain

- Client: NI Water

- Projects management/professional services: WYG

- Main contractor: DAWSON-WAM Ltd

- Mechanical & electrical contractor: Murphy

- Tunnelling contractor: Bonnar

- Precast tunnelling pipes: Tracey Brothers

- Precast MH rings & pipes: FP McCann

- Precast CSO: Macrete

- DI pipes fittings: APP

- Surfacing contractor: Northstone

- Traffic management contractor: HBS

Construction

DAWSON-WAM Ltd was awarded the construction contract in December 2017. Contract works involved the installation of a variety of combined, storm and foul sewers, ranging in diameter from 150mm to 2100mm, in a busy, densely populated, urban environment, as well as design and build of the new wastewater pumping station.

Certain elements of the project proved extremely challenging, none less so than the installation of a 1200mm diameter combined sewer across Great Victoria Street and 1200mm diameter combined and 900mm diameter overflow sewers across the Dublin Road. DFI Roads would not permit closure of these two arterial routes, which are key to the functionality of traffic movements in the city centre.

DAWSON-WAM Ltd explored various trenchless options for these pipe installations in collaboration with the project manager and NI Water. The technique of pipe jacking, using an open-face excavation shield at the head of each drive, was chosen, as it provided the capability to manually access and remove any unidentified underground obstructions encountered. The technique really proved its worth where drives encountered old timber piles, which were easily cut out. Other methods would not have provided access for the removal of such obstructions and run the risk of costly and extremely disruptive recovery of tunnelling equipment and completion by open-cut.

At the dig face of an open face shield where obstructions if encountered were easily accessible – Courtesy of DAWSON-WAM Ltd

Estimated surface settlements and face stability assessments for each drive were calculated in advance to provide assurances on ground and carriageway stability risks. All tunnelling and pipe jacking work was executed successfully, with pedestrians and commuters remaining blissfully unaware of the extensive civil engineering operations happening right beneath their feet (and wheels) throughout.

Sheet piled temporary cofferdams were essential for the safe installation of some of the deeper, open-cut sewers. Sheet piles are not always suited to an urban environment, due to vibration and noise produced during their installation. However, DAWSON-WAM Ltd, through their extensive experience and access to their modern piling fleet, were able to assess the risks by driving test piles in various ground conditions and analysing vibration and noise outputs, and were able to establish their suitability. For example, assessment proved that the installation of piles through ‘Belfast Sleech’ would be within acceptable limits. In some of the stiffer boulder clays, the ground required pre-augering, using DAWSON-WAM’s cased auger system, prior to pile installation.

As the local sewerage network suffered a long history of extensive Fats, Oils and Grease (FOG) and ‘fatberg’ problems, NI Water’s operations team requested a non-stick solution for the new wastewater pumping station walls, with the aim of reducing the accumulation of FOG, reducing the maintenance burden and promoting efficient operation. Construction using segmental shaft sections would not have provided the uniform, joint free, surface required for the successful application of the proprietary non-stick coating products. DAWSON-WAM Ltd therefore developed a secant piled circular cofferdam design, with a single face, in situ, internal reinforced concrete lining. This proved a successful design solution, with the lining providing a smooth finished internal concrete surface for the application of ‘Sika Poxitar F’, the non-stick product recommended by DAWSON-WAM and accepted by NI Water.

(left) Secant piles installed for the WwPS and CSO chamber at Bankmore Square and (right) pipe jacking launch pit inside a sheet piled cofferdam. Great Victoria Street trenchless crossing – Courtesy of DAWSON-WAM Ltd

Where possible, DAWSON-WAM Ltd opted to use precast concrete construction for CSO upgrades. This technique provided the benefits of reduced construction time, and associated disruption, in comparison to traditional in situ reinforced, not to mention the safety benefits associated with reduced site-traffic movements and off-site manufacture.

Despite the strenuous efforts during the ECI phase to mitigate construction risks, approximately 75% of all underground services encountered were uncharted. These were a mixture of live and dead, cables, gas mains and water pipes which all had to be treated as live for safety reasons. This reduced productivity on the construction programme’s critical path and resulted in previously agreed traffic constraints and traffic management plans having to be renegotiated due to programme changes.

Additionally, during sewer laying, a significant number of hitherto undiscovered foul to storm sewer lateral misconnections were uncovered. NI Water seized the opportunity to resolve all these misconnections, some of which were quite substantial, as construction progressed, and deliver further significant environmental benefits.

Removal of jacking shield following the installation of a 1200mm overflow trenchless pipeline under Dublin Road – Courtesy of DAWSON-WAM Ltd

Communications and community engagement

It was obvious from inception that, engineering challenges apart, one of the key challenges for the project team would be constructing the works within this very busy area of Belfast City Centre. Effective consultation with stakeholders, which included road users, local businesses, nearby residents, the general public and affected landowners, would be key to the minimising disruption and to the project’s successful delivery.

Several pre-construction consultations were held with approximately thirty statutory and non-statutory stakeholders including: local traders; Department for Infrastructure (DfI) Roads Traffic Management (to develop Traffic Management Plans); Belfast City Centre Management; Belfast City Centre Business District; SUSTRANS NI cycling; BBC fibre optic cable operators; DfI Water Policy Unit; Belfast City Council; NI Housing Executive and DfI Rivers. Consultations, carried out through NI Water’s internal communications team and members of the project management team, included public drop-in meetings and approximately 3,000 letter drops.

Completed Bankmore Square WwPS & CSO chamber with Sika Poxitar F applied to WwPS walls – Courtesy of DAWSON-WAM Ltd

A project of this size and complexity will always have a significant local impact and it was important that the project team proactively engaged with the community for the duration of the project. Initiatives to promote engagement included: Charity fund raising, for example the Chest, Heart and Stroke Association; Inviting local street artists to practice their talents on the site hoardings; Holding ‘Open House’ events, including educational site tours; Safety talks by members of the delivery team at local schools. The project was also registered on the Considerate Constructors Scheme, where it achieved a Certificate of Excellence.

Other forms of communication, including common forms of social media and presentations by NI Water staff, were used to educate the public about the issues of FOG and unsuitable materials in sewerage systems.

Conclusion

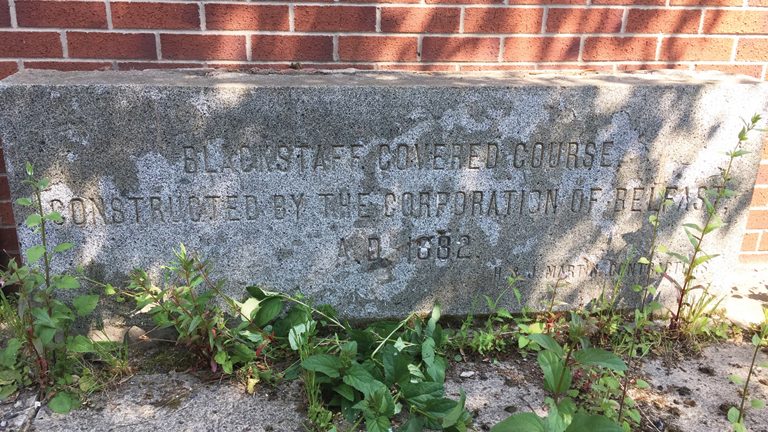

Stone erected to mark the completion of the Blackstaff River culverts in 1882 – Courtesy of DAWSON-WAM Ltd

At the time of writing (May 2019) the new WwPS is in operation and most of the pipelines have been commissioned, with final completion of the overall project expected by August 2019. The project was a prime example the eventual need to upgrade faithful, long-serving Victorian infrastructure to 21st century standards.

Once complete, the project will provide multiple benefits, including enhanced environmental protection, provision for new development and network maintenance cost reductions; particularly those associated with the formation of ‘fatbergs’. A positive, healthy and collaborative, team spirit massively contributed to the success of this challenging project in the heart of the City.