Sherston S101a – First Time Sewerage Scheme (2023)

(left) Shared trench for the gravity sewer and rising main and (right) wet well constructed bottom-up - Courtesy of Wessex Water

Section 101a of the Water Industry Act requires that sewerage providers deliver and fund first time sewerage (FTS) schemes where the current drainage for two or more properties is unsatisfactory and where a public solution is viable. Unsatisfactory drainage includes situations where environmental or amenity problems caused by uncontrolled discharges from septic tanks or cess pits result in pollution of ditches or watercourses, odours and public health problems. The FTS process starts when an application is received by the sewerage provider from residents requesting a connection to the public sewer system. On receipt of the application, engineers will assess the viability of providing a new public sewer system in the area – including environmental, technical and financial considerations. The assessment will cover the polluting properties, but may be extended to others on septic tanks in the immediate area if considered beneficial. If this assessment indicates the scheme is viable, then it will proceed to design and onto construction.

Reasons for an FTS scheme in Sherston

In Sherston, there were a number of properties on septic tanks, including several on a shared septic tank that could only be accessed via a field. This field was only accessible once a year, after crops were harvested, which resulted in the septic tank overflowing raw sewage into an adjacent ditch. This represented a significant risk of groundwater pollution; particularly as the area is within a groundwater source protection zone.

(left) Schematic showing the route of the new gravity sewer and new rising main and location of the new SPS and (right), illustration from the Wessex Water leaflet to property owners showing responsibility split – Courtesy of Wessex Water

Residents in Sherston applied for an FTS scheme due to this pollution, which led to an assessment by Wessex Water which concluded that a public FTS was viable and could be progressed to design and construction. Wessex Water carried this out using their in-house capabilities at a cost of £2m. Although only a few properties were causing environmental and public health issues, Wessex Water included as many properties as possible within the FTS scheme, taking into account the viability of doing so. As a result, 24 properties (estimated population equivalent of 60) currently on septic tanks will be able to connect to the new public sewerage system by July 2023. Wessex Water’s FTS policy is to construct the new public sewerage system up to the inside the property boundary, where it terminates within a demarcation chamber. This chamber denotes the boundary between the public and private drainage system.

Design options

Due to the levels of the existing sewers relative to the septic tank outlet pipework, a sewage pumping station (SPS) would be required as part of the solution to connect the new sewerage system to the existing network.

Penstock ready to be installed over the outgoing pipe (on the left) within a manhole chamber upstream of the wet well – Courtesy of Wessex Water

Several iterations of the design were undertaken to confirm the best route of the pumped rising main, location of the proposed new SPS and access road, as outlined below:

Connection to the existing sewerage network in Easton Town (B4040) – Option discounted

This solution provided the shortest route for the proposed new rising main and access track to service the new SPS. However, the rising main route would need to pass through a narrow driveway between existing houses.

Due to the depth of the excavation, an open cut construction method was discounted as it would be within the zone of influence of the building foundations and consequently had the risk of undermining and causing structural damage to these buildings. Trial holes indicated shallow rock which would have further exacerbated structural damage due to vibration when breaking out the rock.

Trenchless techniques were considered, however due to the rock, only micro-tunnelling would be suitable, and would require a reception pit within Easton Town road, which would cause significant disruption to the community. Micro tunnelling would have also resulted in the scheme becoming financially unviable.

Connection to the existing sewerage network in Sandpits Lane (access via Sandpits Lane) – Option discounted

This solution provided the next shortest route for the access track to service the new SPS, and although the rising main route was extended, it allowed for an additional gravity sewer to be laid within the same trench to connect four additional properties at minimal cost, which increased the cost viability of the scheme.

Prior to submitting a planning application for this option, Wessex Water consulted with the community. Significant public objections were raised due to the visual impact of the proposed new access track and SPS, particularly from those who were already on mains drainage and would not benefit from the FTS scheme. In addition, land purchase negotiations for the access track could not be resolved.

Connection to the existing sewerage network in Sandpits Lane (access via Tetbury Road) – Selected Option

The sewerage network for this option was similar to Option 2, however the access track route and SPS location changed to take into account the points raised from those objecting on the grounds of visual impact and land purchase issues.

This option was confirmed to be both technically and financially viable and no public objections were raised, which was valuable in securing planning permissions.

Scope of works

The selected solution comprised:

- 1073m of gravity sewer.

- 257m of pumped rising main.

- A 280m long access track with post and rail fencing.

- A sewage pumping station to include a below-ground wet well (2.1m diameter, 5m deep), control kiosk, dosing unit (to prevent odour formation) and concrete turning area for maintenance vehicles.

(left) Excavation of shallow rock for rising main and (right) internal view of the wet well before sump benching – Courtesy of Wessex Water

Sherston FTS: Supply chain – key participants

- Designer & principal contractor: Wessex Water

- Civil sub-contractor: Lynwood Civil Engineering Ltd

- Electrical sub-contractor: HM Electrical Services 1996 Ltd

- Pump supplier: Grundfos

- Electrical kiosk supplier: BW Controls Ltd

- Dosing unit supplier: WES Ltd

- Wavin Q-Bic crates: Wavin UK

- Cell pave: Groundtrax Systems Ltd

- Wet well cover slab: Marshalls Civils & Drainage

- PVC pipework: Funke Gruppe

- DI pipework: Saint Gobain PAM UK

- Fittings: AVK UK Ltd

Construction

The SPS was located at the lowest point of the site to allow gravity fed pipework from properties connecting to the FTS scheme. The wet well was 5m deep, and constructed using a ‘bottom-up’ technique due to shallow rock in the area, which was identified during pre-construction geotechnical investigations. This involved excavating to foundation level and building up the shaft in precast 2.1 m diameter concrete rings. The 300mm-thick, 2.85 x 2.6m cover slab was made to order but cast off site.

Where possible, valve chambers are constructed as precast sections to save on build time and cost. However, due to the space constraints and the proposed finished ground profile at this site, the valve chamber had to be cast in situ and dowelled into the wet well to reduce its footprint. The valve chamber was constructed relatively deep at 2.7m deep to avoid the need for air valves on the rising main, which would require ongoing future maintenance.

(left) Shuttering around the wet well in preparation for pouring the final layer of concrete surround and installing dowels into the valve chamber and (right) construction of wet well – Courtesy of Wessex Water

All pipework within the valve chamber was constructed in ductile iron DN80 and the rising main was constructed in MDPE pipe, SDR17, OD 110. The gravity pipework was constructed in PVCu Funke Gruppe pipe (100 mm and 150 mm internal diameter), which was selected to provide due to its light weight and construction durability compared to conventional vitrified clay pipework.

Penstocks were required so that incoming sewerage flows can be controlled, to allow isolation of the wet well for cleaning and maintenance. The penstock was designed to be located within the wet well, however concerns were raised by the site team that the proposed opening for the penstock spindle would be difficult to cast in the correct location during the off-site fabrication of the cover slab. To resolve this, the cover slab design was amended to remove the penstock spindle opening, and it was moved to an upstream manhole, where the penstock could be positioned within the clear opening of the manhole cover.

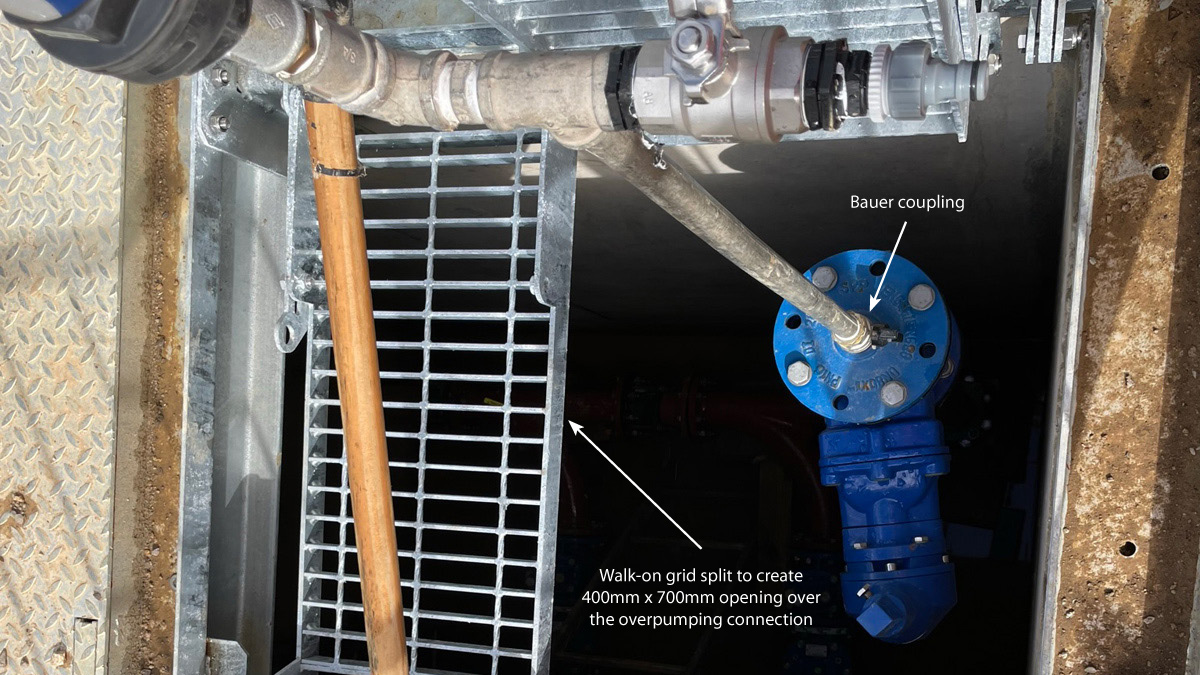

An overpumping connection allows for the temporary pumps to be installed and connected to the rising main via a Bauer coupling on the pipework from within the valve chamber. The valve chamber cover was designed to allow for the safe operation of the Bauer coupling by having a split walk-on grid over the coupling.

This allowed the operator to place the foot on one of the closed flaps, whilst the other flap is lifted, thereby allowing them to position themselves directly over the Bauer coupling. This avoids the operator having to lean over an opening or handling the tankering hose with one hand.

Valve chamber cover, with split walk-on grid over the Bauer connection – Courtesy of Wessex Water

Surface water drainage

A surface water drainage strategy was required due to the impermeable areas created by the sewage pumping station concrete surfaces and turning area. Pre-construction infiltration tests indicated that the ground had permeability ranging from 2.58 x10-6 to 6.59×10-6 mm/s, which was considered suitable for surface water disposal via infiltration.

While it was imperative to keep the turning areas finished in concrete for durability, the straight sections of the access track were able to be constructed of permeable CellPave 50 cellular paving grid system (gravel filled) from Groundtrax Systems Ltd, laid over Type 3 poorly graded stone sub-base to minimise the surface water runoff created by the scheme.

Surface water runoff from the concrete turning areas was collected via a french drain and directed into a 150m2 Wavin Q-bic crate system, which is sufficient to store a 1:100 year storm run-off based on the infiltration test results. The crate system was constructed beneath the SPS concrete turning area to optimise land use within the developed area.

(left) Q-bic system construction and (right) concrete slabs being cast over the crates to form the turning area – Courtesy of Wessex Water

Third party considerations

The project is within the Sherston Conservation area as well as the Cotswold Area of Outstanding Natural Beauty, so it was important to provide a solution in the most environmentally sensitive way possible. Wessex Water undertook detailed environmental archaeological surveys in the early design stages to understand third party constraints and ensure these were incorporated within the design and construction process, including:

- Arboricultural surveys.

- Ecological surveys, including monitoring of stone debris removal to check for reptiles, and phased vegetation removal to check for hedgehogs.

- Archaeological surveys, including a geophysical survey ahead of construction and intermittent archaeological monitoring during construction, due to proximity of a Roman villa complex.

As a result of the construction of the FTS scheme, permanent removal of the following was required:

- Three trees.

- Small area of dense scrub at the SPS location.

- An area of scrub at the edge of an arable field.

Public drop-in session and (inset) 3D model of the new sewage pumping station – Courtesy of Wessex Water

All temporarily affected habitats were seeded with a species-rich grassland and wildflower mix, managed to avoid cutting during the late spring and summer to benefit invertebrates and other wildlife. Off-site biodiversity enhancement measures were also undertaken in Sherston Primary School, including planting of additional trees, wildflower meadow, and providing bird nesting pockets to students.

Close interaction with residents is a key feature of FTS schemes due to the work within private gardens. All residents were contacted prior to construction via face-to-face meetings and community drop-in session to give them the opportunity to ask any queries direct to the Wessex Water Project Team. A 3D model of the proposed sewage pumping station was created and used during the drop-in session to provide more clarity for the public on the proposed solution.

Conclusion

The Sherston FTS scheme has been project managed, designed and constructed using Wessex Water’s in-house teams at a cost of £2m. It comprises of a gravity sewerage pipework from properties which drain to the new sewage pumping station, from where it is pumped via a new rising main to the existing sewerage network.

This scheme has provided 24 properties on septic tanks with a connection to the public sewerage network, which has been enthusiastically received by residents. Environmental damage from raw sewerage overflowing from septic tanks into adjacent ditches and groundwater has also been prevented as a result of this scheme.

Work on site started in October 2022 and completed in July 2023.

The finished pumping station site and access track (August 2023) - Courtesy of Wessex Water