Teversal S101a – First Time Sewerage Scheme (2022)

Wide angle shot of vacuum station - Courtesy of Galliford Try

In September 2014 Severn Trent received an application under Section 101A of the Water Industry Act to provide first time sewerage to 11 properties in the Nottinghamshire village of Teversal. The outcome of an assessment of the existing sewerage provisions identified environmental or amenity problems at 18 properties and concluded that the provision of a public sewer was the most appropriate solution. Severn Trent promoted a project with the desired outcome to install a new public sewerage system for Teversal Village. As the project developed, additional properties were added, resulting in 22 duty and 17 non-duty properties in the village being able to connect to the new sewerage system. Optioneering, solution and outline design, was undertaken by Severn Trent’s design team, with detail design and construction being awarded under framework agreements with Galliford Try.

Optioneering and outline design

Teversal Village is situated in a hilly terrain and the nearest public sewer is on the opposite side of a river valley. This meant that a gravity-only solution was not possible, and that pumping would be required to transfer flows from the village to the public sewerage network. Further investigations of options revealed that due to the topography of the village, a traditional gravity sewerage system would require 4-5m deep gravity sewers and multiple pumping stations. This led the team to investigate the provision of a vacuum sewerage system.

The in-house Severn Trent design team’s approach was to review the performance of existing vacuum systems throughout the Severn Trent region and undertake an appraisal of alternative available vacuum technologies.

Compared to alternative gravity and pumped solutions, the provision of a vacuum sewerage system enables a number of construction risks to be reduced including:

- Reduced health and safety risks and the extent of trench support needed with the vacuum system laid at a nominal depth as there is no need for deep excavations in the highway.

- Reduced risk of structural damage and other such negative impacts to homes, listed buildings and other features of historical significance in the narrow village streets.

- Reduced noise and vibration associated with excavation in sandstone, with rockhead as shallow as 0.5m in most areas.

- Reduction in the size of excavation plant required, and plant movements through the village.

- A shorter overall construction period, reducing the length of time that customers and road users were exposed to construction risks associated with roadworks and plant movements.

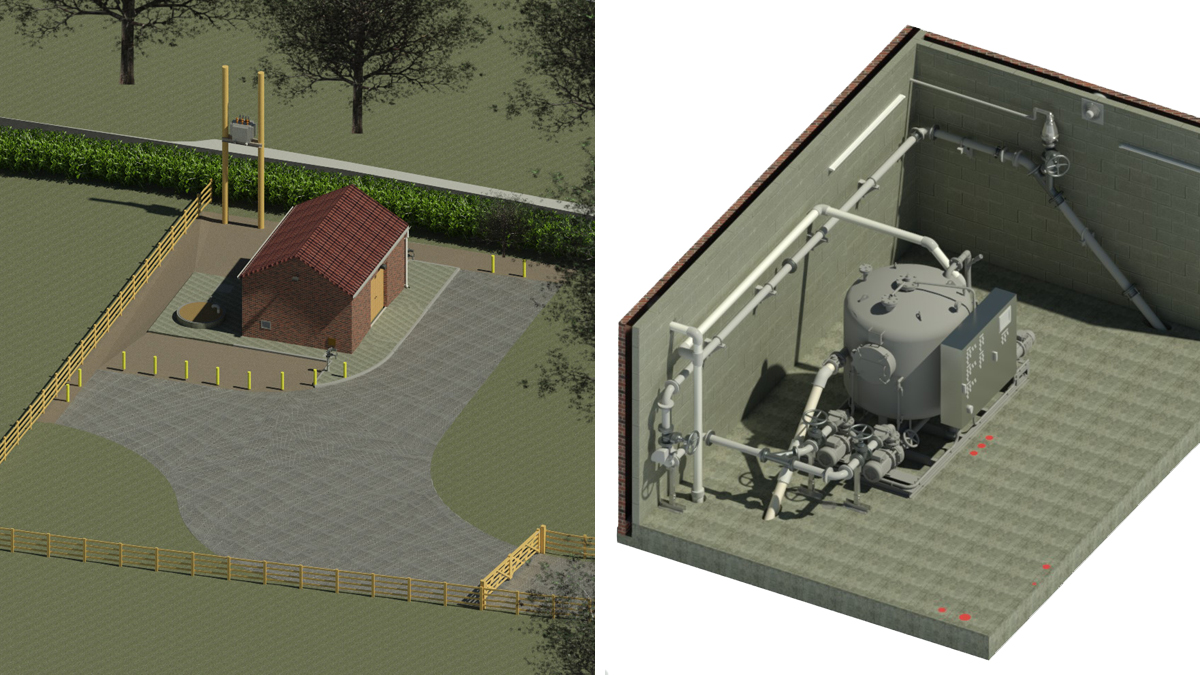

(left) 3D proposed site render and (right) vacuum station building internal view render – Courtesy of Galliford Try

The vacuum sewerage system

The outcome of the optioneering process identified a number of benefits provided by the Roediger Vacuum Sewer System as supplied by New Forest Solutions. A key feature is the electronic monitoring and management system which allows real time monitoring of collection sump and valve status, counting of valve cycles and chamber operation, and raising an alarm output where required. The system provides options for self-checking of the monitoring module, automatic resolution of some chamber malfunctions, remote visualisation of the chamber status, with remote control of vacuum valve and automatic chamber cleaning cycle.

These features enable the system to detect issues in the network and attempt to rectify these, reducing the requirement for an operational visit. Where the system cannot self-rectify issues, and a visit to site by an operator is required, the chamber management system enables remote operation of the valves in the collection pots from the control panel in the vacuum station building. This can negate the need for operatives to lift covers of individual pots, avoiding work in the public highway and removing the risk of contact with raw sewage.

The Roediger Vacuum Sewer System demonstrated the lowest whole life cost solution, being the most environmentally friendly option with the lowest embodied and operational carbon footprint. As this system had not been employed within Severn Trent before, a detailed deviation request was required to get all ‘non framework’ items and the new system approved for use.

Teversal Pastures SSSI lies in between the village and the existing public sewer. Severn Trent engaged in early communication with Natural England to explain the importance of the project and develop early relationships as a key stakeholder. A no-dig solution was promoted in the outline design to install the rising main, avoiding any disturbance to the SSSI.

Vacuum package plant arriving on site – Courtesy of Galliford Try

Teversal S101a Project: Supply chain – key participants

- Client & feasibility/outline designer: Severn Trent

- Principal designer/contractor: Galliford Try

- Vacuum system design: New Forest Solutions

- Vacuum system supply: Roediger

- Building design: Eastwood Consulting Engineers

- Directional drilling: JMH Directional Drilling

Detail design and construction

The Roediger Vacuum Station Type 360 used at Teversal is a complete packaged system which was delivered to site ready for connection, having been factory tested prior to delivery. It was supplied with a vacuum tank, three vacuum pumps, two discharge pumps, control panel and all associated instrumentation mounted on a skid. The unit is installed within a small building, and the need for any below ground structures is eliminated.

This has benefits for both the construction and operational aspects with everything accessed above ground level making it safer and easier to both install and maintain. A biological filtration system is provided outside the building for treatment of vacuum exhaust gases before release to the atmosphere.

Teversal Village is designated as a conservation area, and the new vacuum station building is located on the outskirts of this area. Following extensive consultations with the county council conservation officer and local planning officers, the new building was designed to reflect the traditional appearance of other buildings within the village. This comprised of walls constructed in red brickwork to English garden wall bond, with a red pantile roof, and cast-iron guttering.

The rising main design was subject to a specialist hydraulic analysis in order to optimise its operation in conjunction with the pumps located in the vacuum station. Due to the vacuum station being significantly higher than the point of discharge, the rising main was designed as a predominately gravity system with the pumps only lifting flows a very short distance to a high point within the building. A double orifice sewage type air valve (AV) is provided immediately following the start of the descent which can freely allow air both into and out of the system.

A 125 mm OD pipe was installed on the drained (downhill) section, being sized to allow liquid to flow along the invert of the pipe leaving a path at the soffit of the pipe for air to migrate back towards the air valve. The pipe diameter was reduced to 90 mm OD at the lowest and subsequent rising sections in order to achieve self-cleansing velocities minimising the risk of settlement of sediment in this section.

(left) Vacuum sewer and cable duct and (right) vacuum sewer laying through the village – Courtesy of Severn Trent

Following further discussions with Natural England, pipe alignment changes were made reducing the impact on the SSSI and mitigating any restrictions imposed as part of the Land Drainage Act for crossing beneath the River Meden. The whole pipeline from the vacuum station to the discharge point was installed in six sections by direction drill. Drill pits were located outside the SSSI avoiding any need for excavation within this sensitive area.

New Forest Solutions visited site and spent one week with the site team running through all aspects of installation, giving an overview of the vacuum system to all operatives and guidance on installation of the system.

Vacuum pots were installed at property boundaries, where owners had chosen to connect to the new system. Almost 1,000m of vacuum sewers were laid, through the village, connecting the vacuum pots to the vacuum station, comprising of 312m of 90mm diameter, 320m, 110mm diameter and 343m of 125mm diameter HDPE SDR11 pipe. The pipes were laid at nominal depth, in relatively level lengths with lift sections at key points. The sewer lifts ranged between 200mm and 450mm, formed by two 45 degree bends with a section of pipe in between to give the required vertical lift. A cable duct was laid alongside the vacuum sewer containing a multicore cable for providing telemetry and remote management system for the vacuum pots.

During construction the team faced a number of challenges, working within the conservation area, close to historic buildings and listed structures. The required route passed along, close to, an unstable existing brick wall leaning some 70mm out of vertical towards the proposed pipe. It was not possible to remove the wall, so the team set up alarmed vibration monitors, exclusion zones and reinforced the wall using six tonne bags of sand strategically placed along the length. The pipe was successfully completed in short lengths of trench with no detriment to the wall.

Vacuum pot – Courtesy of Galliford Try

Summary

Successful delivery of the project required extensive stakeholder management, from receipt of the first time sewerage application through to completion of construction on site. Public meetings and exhibitions were held at key points of the project with letters and emails sent to provide regular updates on progress.

The Severn Trent project manager arranged a Community Day in June 2021 with volunteers from the project team undertaking a litter pick and maintenance works at St. Katherine’s Church in appreciation of the villagers understanding during the disruption caused by the works.

Operation of the system will be monitored, to provide feedback on performance and inform the decision process for adopting this system on future vacuum sewer installations.