Sunnyhurst & Earnsdale Impounding Reservoirs (2016)

The notch during construction - Courtesy of Suave Aerial Photos

Sunnyhurst and Earnsdale Impounding Reservoirs (IR) are situated 1.5km to the west of Darwen town centre in Lancashire and are owned and operated by United Utilities. Sunnyhurst IR is one of the raw water sources of Fishmoor WTW, which feeds Blackburn and the surrounding areas (population equivalent of 100,000 people). Earnsdale IR provides compensation water to Sunnyhurst Brook. The purpose of this project is to reduce the probability of embankment failure at both reservoirs. At Earnsdale IR the probability of failure has been reduced by constructing a toe berm and filter, thus improving the stability of the embankment and providing a mechanism to control seepage and thereby preventing internal erosion. At Sunnyhurst IR the probability of failure has been removed through discontinuance of the reservoir by notching the embankment, thereby reducing its ability to hold water other than in relation to a prescribed flood condition.

Background

Earnsdale Impounding Reservoir was constructed in 1863 as a homogenous earth fill embankment dam with a capacity of 433Ml. Sunnyhurst Impounding Reservoir was constructed in 1875 with an earth embankment dam containing a pseudo clay core yielding a storage capacity of 436Ml. Both reservoirs are fed by Stepback Brook and their own direct catchments. They are regulated under the Reservoirs Act 1975 and are designated as Category A embankments.

Sunnyhurst notch with overflow structure. The screening chamber can be seen at the top of the photograph – Courtesy of United Utilities)

Seepage and stability studies by United Utilities and a Willowstick survey by Aquatrack identified that there was potential for leakage and stability issues with each embankment. Further geotechnical investigations and toolbox assessments confirmed that both structures had a higher failure probability than the minimum required of 1 in 10,000, placing them in the ‘intolerable’ zone on the Portfolio Risk Assessment (PRA).

It was thus determined that remedial works would be necessary to reduce the risk of failure (slope instability and internal erosion) to an acceptable level in accordance with the ‘Manual for the Evaluation, Investigation and Remediation of Internal Erosion in UU Embankment Dams’. The level at Earnsdale was also to be held 4m below top water level under instruction from the Panel Engineer.

Scheme delivery

The initial design and solution specification for the Sunnyhurst and Earnsdale Impounding Reservoirs project was completed using an in house multi-disciplinary team within United Utilities.

The £2.8m scheme was delivered under a Design and Build CD100 contract with Askam Civil Engineering as principal contractor, GHD as designer and United Utilities as the client.

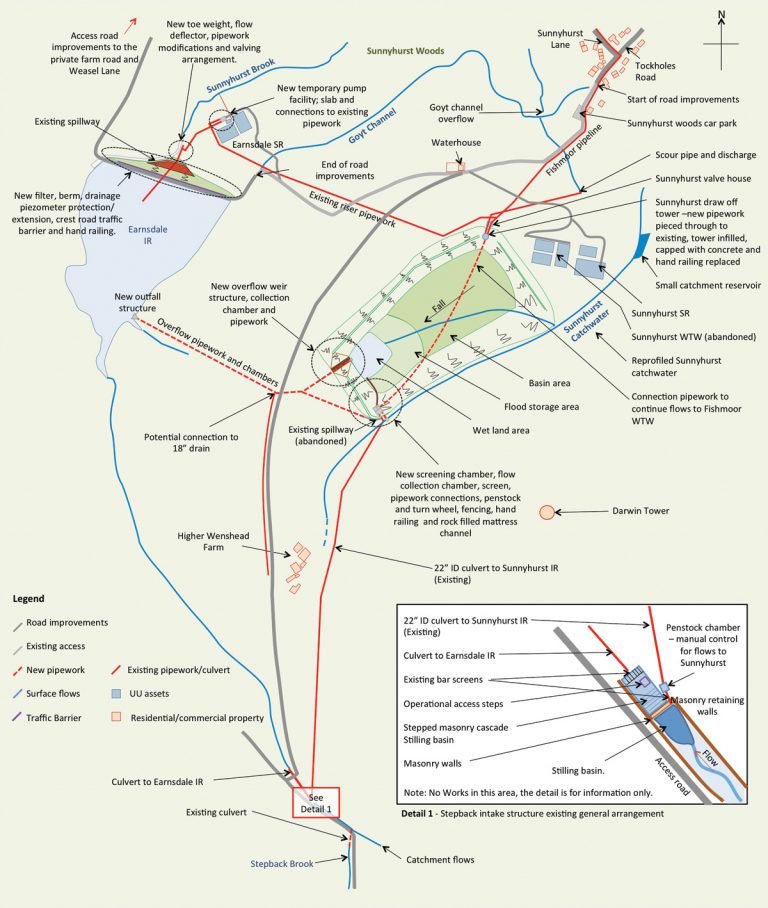

Solution schematic – Courtesy of United Utilities

Sunnyhurst Impounding Reservoir

Sunnyhurst IR has a long embankment measuring some 800m in length which impounds three sides of the reservoir. Various options were initially considered to reduce the risk of failure including combinations of diaphragm and/or sheet pile cut-off walls, reprofiling the embankment by moving the crest upstream or downstream, regrading the embankment and installing a filter/drainage layer.

The length of the embankments meant that these solutions were deemed cost prohibitive. The reservoirs storage capability was no longer deemed necessary due to increased network connectivity, and therefore the decision was taken to discontinue.

The discontinuance options included blading the embankment into the hillside, effectively returning the area to a pre-construction state, or by notching the embankment so it could not impound. After initial consultation with the Environment Agency it was agreed that the scheme had to be flood neutral under a 1 in 100 year storm event.

A hydrological model of the catchment was constructed in the modelling programme ISIS to determine the existing attenuation of the reservoir under the design storm event, which in turn determined the required flood storage volume.

Flood neutrality study

The control point of the study was the flow rate over the spillway at Earnsdale. The solution was developed to retain the required attenuation at Sunnyhurst during a storm event and slowly release the water into Earnsdale using new a 750mm diameter transfer pipeline.

In order to remove the reservoir from the Reservoirs Act and the operational costs associated with such a designation, the stored volume needed to be less than 10ML (to capture the proposed amendments to the Flood and Water Management Act 2010). As such, the embankment was to be notched to its foundation with 1 in 3 slope gradients leading up the crest.

Bathymetric survey data of the reservoir basin was interrogated to determine the required profile of the basin in conjunction with a small retaining structure within the notch, together enabling the storage requirements. This took a number of iterations and was a fine balance between minimising material movement, keeping material on site in situ, keeping the volume stored below 10ML and ensuring flood neutrality.

Sunnyhurst IR discontinued. Earnsdale can be seen in the background, centre left – Courtesy of United Utilities

The study determined that a total volume of 8.3Ml would need to be stored and the basin re-profiled to achieve flood neutrality. The design also considered climate change and a sensitivity analysis to a 1 in 1000 year storm event.

The basin was very flat and needed to be reprofiled so it gently rose away from the notch, reducing the volume retained by the weir whilst providing temporary storage, which drains through the retaining structure (with low level orifice and high level weir) into the transfer pipeline. The final solution included a low level wet land area upstream of the retaining structure to act as a silt trap and increase biodiversity potential within the basin.

To reduce traffic movements through Darwen, site material from Sunnyhurst was reused at Earnsdale. This included pitching stone in the face of the berm and material from the notch in the backfill for the stabilising berm.

Supply capabilities

The UU Asset Manager wanted the some of the supply capabilities provided by Sunnyhurst to be retained. Therefore an intake chamber to accept the current inflows into the reservoir was proposed. Sedimentation within the source water was undesirable so the solution included a stilling basin, which weared over onto a Dulas Coanda screen intake.

This system removes silts and gravels prior to flows entering a new transfer pipeline across the empty basin of Sunnyhurst and into the existing pipeline feeding Fishmoor WTW. The stilling basin can be emptied using a low level penstock to permit the removal of accumulated sediment and to facilitate maintenance activities. Flows greater than the abstraction license weir over the screen and transfer to the wet land area via channel lined with a reno mattress to prevent erosion.

Earnsdale Impounding Reservoir

At Earnsdale an extensive optioneering study was also undertaken to determine the most cost effective solution to bring the risk of failure into the tolerable zone. This included combinations of diaphragm walls and cut off, re-grading the embankment both upstream and downstream (including moving the crest), the installation of a filter/drainage layer and the construction of an additional toe weight with a berm.

The site is tightly constrained within the valley with the spillway running down the western shoulder of the embankment, which is bounded by ancient woodland. The valley has relatively steep sides so most of the reservoirs storage is within the top few metres. This meant that a solution which required moving the crest into the reservoir to re-grade the downstream slope would greatly reduce the storage capacity and was also cost prohibitive. Therefore the preferred option was to construct a filter and drainage layer across the whole embankment to control internal erosion and a toe berm to increase the factor of safety against slope instability.

Filter/drainage layers

Any future potential leakage through the embankment, which could cause internal erosion will now flow through the filter and drainage layers and be collected by new toe drains. Inspection chambers on the toe drain allow flows to be monitored for any changes or any suspended solids (a sign of internal erosion), facilitating robust surveillance of the embankment over time.

Earnsdale during the installation of the filter and drainage layers – Courtesy of Suave Aerial Photos

Over time internal erosion can lead to ‘piping’ and in turn failure. The filter and drainage layers are composed of a granular material, the grading of which is determined by the grading of the embankment material, and are designed to capture small particles transported through the embankment, whilst allowing the water to pass.

The overlaid drainage layer is a coarser graded material and allows water to dissipate to the toe drains.

Flow deflector and toe weight – Courtesy of United Utilities

During construction, there were strict compaction criteria which had to be met and proven with robust in situ testing. The drainage layer was overlaid with a geotextile separator layer to prevent infiltration and contamination of the granular layers by overlying cohesive backfill and finally covered with subsoil, top soil and turf.

Erosion along the outside of the scour pipe was also assessed as an intolerable failure mechanism. As such a filter and drainage layer was also placed around the scour pipe at the toe of the embankment. This included a separate v notch flow measurement chamber.

(left) Base of the berm with the toe drain and PET1000 visible and (right) Earnsdale berm construction on the eastern shoulder – Courtesy of United Utilities

Stabilising berm

The berm is effectively a dead load placed on the toe of the embankment. The outline design by United Utilities, subsequently confirmed by the contractors geotechnical advisers, GHD, determined that the berm needed to be approximately half the height of the embankment to ensure a minimum factor of safety of 1.5 against slips.

The berm is a structural reinforced earth structure with layers of granular material wrapped in geotextile, including a non-structural facing system comprised of stone and steel retaining cages. The backfill of the structural element of the berm is comprised of site won notch material from Sunnyhurst. The berm facing materials and geotextiles were supplied by Tencate and is the first time this product had been used at a reservoir site in the UK. Geoman Ltd completed the berm design on behalf of Tencate.

The berms façade is 10m in height at the toe, the weight of which could lead to excessive settlement. Ground investigation determined that the underlying ground had insufficient strength to a depth of up to 7m below pre-construction ground levels. Excessive settlement also posed a risk to the scour main. The complexity of the berm design was determining how to minimise the settlement of the huge structure.

GHD and Geoman proposed an innovative foundation solution of hit and miss deep soil mixing blocks (DSM), coupled with a load transfer mattress. DSM blends the in situ material with Portland cement, increasing the strength of the foundation material. The load transfer mattress is composed of a strong geotextile, PET1000, placed above and below the drainage layer. The geotextile can span gaps of up to 3m between the DSM cells. The design indicated that potential settlement under this solution was within the agreed parameters. The DSM cells either side of the scour pipe extended below its invert level, minimising loading on the pipe. The filter and drainage layers extended beneath the berm and interface with the embankment.

The completed berm viewed from the crest – Courtesy of United Utilities

An additional weight, composed of granular fill and mass concrete, was placed outside of the discontinued and infilled valve house, downstream of the berm. New scour pipework was placed below the concrete cap to reduce the likelihood of leaks in the future. This included a new hydraulically actuated scour valve for downstream control, housed in secure kiosk, for ease of operation. An existing rising main between the Earnsdale scour pipe and the Fishmoor pipeline has been recommissioned to offset the loss of attenuation at Sunnyhurst.

Earnsdale berm – Courtesy of United Utilities

Hydraulic model

As part of the works a physical model of the spillway at Earnsdale was built to test how it performed under Probable Maximum Flood (PMF) conditions. The model indicated that super elevated flows over topped the spillway channel walls at the toe of the embankment, increasing the risk of erosion. To remove for the potential for this occurring a cantilever slab, termed the ‘flow defector’, was designed to extend over the overflow channel and become utilised during storm events greater than 19m3/s (approximately 50% PMF). The slab deflects the super elevated flows into the centre of the stilling basin to prevent out of channel flow.

Summary

Construction is nearing completion and the site is being reinstated. The contractor proposes to demobilise at the end of June 2016. The project aims have been achieved with the abandonment of Sunnyhurst and the reduction of failure risk at Earnsdale, which is now in the tolerable zone under the owners PRA.