Wilmington STW (2024)

Wilmington STW ARMPhos™ media filter bed in operation - Courtesy of Galliford Try

Due to an upcoming reduction in the permitted phosphorus discharge levels introduced under the Water Industry National Environment Programme (WINEP), and the existing aluminium permit on-site, an upgrade was required at Wilmington STW to ensure that the Environment Agency consent permit was achieved. This required the installation of an additional process within the boundaries of the existing sewage treatment works. Galliford Try achieved this by implementing a new, low carbon phosphorus removal process.

Process selection and scope of works

For some time, South West Water had been looking for alternatives to chemical dosing to meet the new phosphorus targets. ARM Ltd (specialists in wastewater treatment using constructed wetlands, reed beds and natural wastewater solutions) had been promoting its ARMPhos™ technology, and Wilmington STW was just the right size and location for trialling the UK’s first full-scale reactive media reed bed. South West Water’s board approved Galliford Try to work with ARM Ltd to carry out this innovative solution.

The main interventions delivered by Galliford Try to make these improvements under the WINEP programme were as follows:

- 20m3 storm tank with return pumping station.

- 6m3 media bed feed batch tank and pumping station.

- ARMPhos™ media bed for P removal to meet the new phosphorus permit of 2.5 mg/l.

- Auto de-sludging for the site.

- The addition of recirculation and washwater systems.

(left) Levelling media layers and (right) ARMPhos™ media filter feed pump station – Courtesy of Galliford Try

Wilimington STW: Supply chain – key participants

Galliford Try provided a complete design and build package, acting as lead designer for process, civils and MEICA, and principal contractor for the construction and commissioning of the new treatment works, using in-house skilled labour.

- Main designer & contractor: Galliford Try

- Reed bed designer & contractor: ARM Ltd

- Civils design: Eastwood & Partners

- Temporary works: D Wall Construction Services

- Piling: Saxton Drilling Ltd

- MCC & software: Galliford Try

- Kiosk: GR PRO Precision Manufacturing

- Flow meter: Siemens

- Pumps: Xylem Water Solutions

- Ductile iron pipework: Saint Gobain PAM UK

- Lagging/trace heating: Jade Insulation

ARMPhos™ filter

ARM Ltd was contracted by South West Water to design and construct an ARMPhos™ reactive media bed to remove phosphate discharged from the wastewater treatment system, the use of which was the first in the UK for reducing phosphate levels to meet the new Environment Agency consent targets.

The ARMPhos™ reactive media bed operates downstream of the existing works as a tertiary process and reduces phosphate via chemical reaction with the ARMPhos™ media layer. The system operates on a 40% bypass philosophy (40% treated through the bed and 60% by-passed), with flows being re-mixed in the level control chamber.

As part of the design considerations the media filter bed outer perimeter banks were raised by 930mm to form a flood protection bund around the perimeter of the filter in order to mitigate/reduce flood risk.

ARMPhos™ Phosphorus Removal System overview

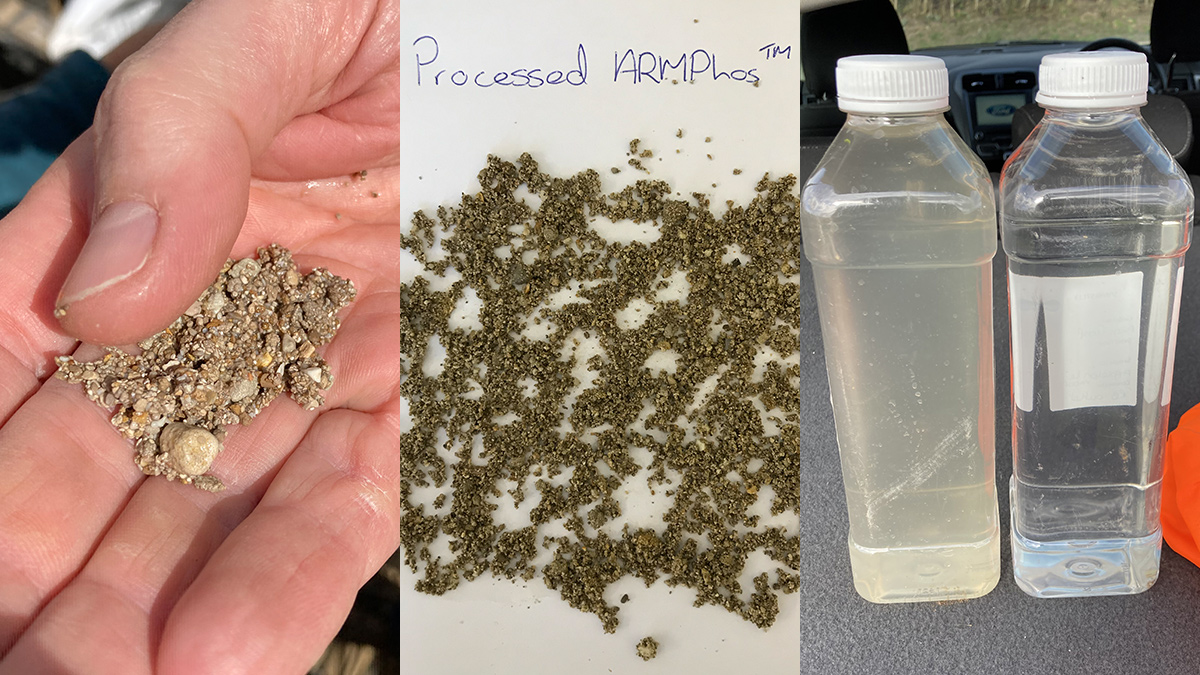

The reactive media, based on apatite, offers two modes of action; an initial adsorption/crystallisation phase of phosphate onto the apatite, which stimulates the second phase of crystallisation of complex calcium/phosphate out of solution onto the adsorbed crystals.

The adsorption phase is driven by attraction of phosphate ions to the naturally occurring cations, principally aluminium and iron, occurring within the apatite. These bind the phosphate to the apatite until all the binding sites become saturated. The loading rate up to saturation is understood and depending on the P loading rate and volume of media it can take several years before this stage is complete. The bound phosphate subsequently crystallises which seeds the second mechanism which is the crystallisation of calcium/phosphate complexes which form naturally in solution. There is some overlap of these two mechanisms. The adsorption phase is finite, but the crystallisation phase goes on indefinitely and system performance is ultimately limited by the reduction in hydraulic conductivity of the media.

At this point refurbishment is required though this may occur 10-15 years after commissioning if the system is designed and installed correctly and loads remain within design parameters. Traditional reactive media P removal solutions using slag or other naturally occurring minerals generally only display the adsorption step.

Media filter feed pump station and filter bed – Courtesy of Galliford Try

Carbon savings

This nature-based solution has an extremely low carbon footprint. The process is passive, and apart from pumped flow to the bed it consumes no other power. Apart from changes of the depleted media (currently estimated every 10 to 15 years) the process has a very low carbon footprint. The process also benefits from further carbon reductions compared to other phosphorus removal processes as it requires no regular deliveries of chemicals or produces any sludge for export.

Galliford Try also reduced its carbon footprint during construction, as all excavated material generated was re-used on site in the construction of the filter. This not only reduced carbon associated with the export of spoil, but also vastly reduced the quantity of imported material required, including concrete.

As can be seen in the desktop study below, the reactive media bed process can provide significant reductions in operating carbon when compared to other P-removal options.

| Phosphorus removal options | Chemical dosing | Chemical dosing & TSR | ARMPhos™ |

| Power (kgCO2e/yr) | 196 | 1327 | 544 |

| 0.233 kgCO2e/yr (UK Government GHG Conversion Factors for Company Reporting 2021) | |||

| Additional sludge transport | 582 | 582 | 0 |

| 0.96 kgCO2e/yr for HGVs, 80km round trip (GHG Conversion Factors for Company Reporting 2021) | |||

| Chemical transport | 1635 | 1635 | 0 |

| 0.96 kgCO2e/yr for HGVs, 800km round trip, 4 deliveries/year plus proportion of bulk delivery | |||

| Chemical manufacture | 1716 | 1716 | 0 |

| Total additional operating carbon | 4129 kgCO2e/yr | 5260 kgCO2e/yr | 544 kgCO2e/yr |

Green Apple Award

Galliford Try competed against more than 800 other nominations in the International Green Apple Awards and won a gold International Green Apple Environment Award. They were presented with their trophy and certificate at the Houses of Parliament in November 2023. As a result of this success, Galliford Try have been invited to accept Green World Ambassador status and have their winning paper published in The Green Book (the leading international work of reference on environmental best practice) so that others around the world can follow their lead and learn from their achievement.

The judges said:

“Galliford Try and ARM developed an innovative, UK-first technology to reduce phosphorus discharge levels. This was installed at an existing sewage treatment plant. Achieving exceptional phosphorus removal and ecological enhancement, it’s now being considered for larger-scale applications, reducing chemical usage, costs, and carbon emissions”.

This will also entitle Galliford Try to represent their country in the Green World Environment Awards that are held in a different country every year. The Green Apple Awards are run by The Green Organisation; an international, independent, non-profit, non-political environment group that began in 1994 to recognise, reward and promote environmental best practice around the world.

(left & middle) Processed media and (right) final effluent samples: pre and post passing through media filter bed – Courtesy of Galliford Try

Summary

This innovative scheme provided the Galliford Try Team with many challenges in design and delivery as described above. However, by November 2022 the plant was in the final stages of process commissioning, and initial survey data undertaken by South West Water-appointed Nijhuis Aquatic, show significant reduction of Total P ensuring the site easily meets the new consent limits. All subsequent testing in 2023 showed the ARMPhos™ bed continued to significantly reduce the phosphorus levels pre and post bed.

Due to the success of the project, this technology is now being used at Lamerton STW where construction commenced 2024. This works will treat a greater flow from the installation installed at Wilmington STW. The use of this technology removed the requirement for any additional chemical-based treatments. This reduces not only day-to-day operator interventions but also removes the constant costs and carbon impact of maintaining a chemical style treatment process.

This solution achieves the phosphorus permit without risking the aluminium permit and reduces reliance on poly-aluminium chloride and ferric; both of which are hazardous materials due to acidity and which require storage and handling. They pose a serious risk to aquatic life if they enter waterways directly or via surface water drains. It is also safer for operators as there is no requirement for them to handle chemicals.

With this being an installation of a naturally based reed bed, this also provided an ecological enhancement to the existing site environment and its surroundings. The technology also enabled the total carbon to be reduced in comparison to traditional phosphorus removal methods, this allowed Galliford Try to reduce the total carbon by 52%. The use of this system also allowed Galliford Try to reduce their operational maintenance hours as well as achieving a low visual impact.

The completed project helped to reduce phosphorus discharge into the local river, whilst not having any detrimental effect on alkalinity levels or increases in aluminium content, which would be commonly found in traditional methods of removal.