Fisherman’s Walk Rising Main (2016)

(left) Looking down the cliff and (right) lining prior to insertion - Courtesy of Wessex Water

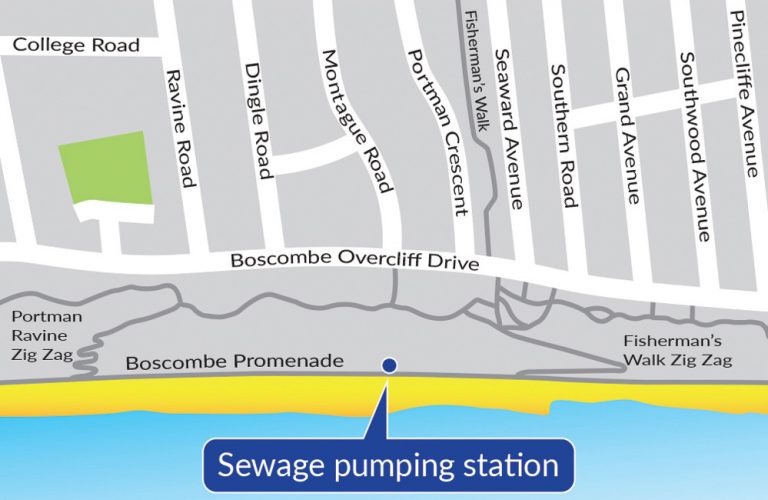

Situated on the Boscombe promenade in Bournemouth on the south coast of England, one of Wessex Water’s sewage pumping station serves a small number of toilet blocks and cafés, connecting them to the main sewerage network. The pumping station is located at the bottom of a steep cliff, 35m high, with a 100mm cast iron rising main located within the cliff. The rising main is 52m in length and was laid in 1977. The pumping station is a standard two-pump pumping station with submersible pumps in a wet well, run duty/standby. The pumping station delivers flows of 8l/s.

Burst rising main

Land slips frequently occur in the cliff face along the Jurassic south coast. In February 2015, minor cliff movement disturbed the structural integrity of the rising main, resulting in a burst and loss of service. Internal CCTV of the pipework confirmed the burst to be 6m upstream of the SPS wet well and approximately 4m deep.

To ensure sewerage services were maintained Wessex Water Operations organised tankering for the duration of the rising main repair works.

Location plan – Courtesy of Wessex Water

Potential repair solutions

Wessex Water’s engineering and construction department were asked to consider potential repair solutions. Given the depth of the rising main and the poor stability of the cliff, careful consideration had to take place. The options considered were:

- Dig down and repair the burst rising main.

- Install a new rising main within the cliff by open cut.

- Installing a new rising main on pillars above ground.

- Directional drilling a new rising main into the cliff.

- Rising main diversion.

- Install a CIPP lining and associated enabling works.

The option to dig down to repair, install a new rising main within the cliff, above ground or installation by directional drilling would have required working on the cliff face. These options were discounted due to the access difficulty and safety of the workforce working on a high risk cliff face prone to movement, even with an erected scaffold. Furthermore, directional drilling could have caused a significant land slip and affected a large area.

It would have been possible to open cut a new rising main and discharge to a different part of the sewerage network. However, this would have involved the installation of 950m of new rising main, within the Boscombe promenade during the Easter/summer period. The diversion would have cost in excess of £900k and would have caused significant disruption.

(left) Set up at the top of the cliff – Courtesy of Wessex Water and (right) Backfilling with concrete and grout – Courtesy of Matt Durbin Associates

It was agreed to pursue the installation of Wessex Water’s first sewage rising main CIPP lining, despite Wessex Water successfully rehabilitating 22km a year of gravity sewers. Wessex Water has not installed a CIPP lining into a rising main previously because of longevity concerns dealing with negative pressures, during the on/off pumping regime.

Solution

Onsite Services Ltd was contacted to design and install a CIPP lining with input from Julian Britton of the WECS Rehabilitation Team. In the absence of an agreed worldwide design protocol for CIPP pressure liners, it was recognised the design methods for fully deteriorated linings behind ASTM F1216:09 were the most appropriate, to also include a loading application representing -1 barg vacuum due to potential slam on the NRV.

In advance of the release of the new BS EN ISO 11297 for lining main manufacture and installation, currently in draft form, the intrinsic need for understanding cyclic fatigue was also considered.

Due consideration was given to classification of liners available via EN ISO 11295 and, due to the location, the design had an element of belt and braces to ensure the liner would be firmly independent as a AWWA Class A solution (after Gumbel and Oxner, Saskatoon 2005).

This design did not rely upon any residual structural characteristics of the host pipe. Consequently, the independence of the liner had to be considered, as did the adhesive hose liner conditions, due to the nature of the epoxy.

The design encompassed a two-layer liner, 100mm diameter and 5.5mm thick. The innermost was 3.5mm thick and constructed of plain felt/PVC. The outer layer was a polyurethane coated glass reinforced lining 2mm thick assembled around the inner. The lining design included impregnation with an epoxy style resin to be pulled into place by a winch, within the wet well chamber. This would also require curing at 0.8 bar using steam.

The extra 2mm thick liner was designed for easier installation and improved stiffness once cured. However, to install the lining, complex enabling works were required.

A 45o and 17.5o bend was located outside of the brick wet well chamber 2m into the cliff. Without the removal of these bends it would not have been possible to install the lining, due to difficulty in winching the lining through the bends. It was neither practical nor safe to excavate from the cliff to replace the bends, and thus a timber heading required construction.

Curing the lining – Courtesy of Onsite Services Ltd

Timber heading

The complexities surrounding the timber heading required a specialist service from Matt Durbin Associates, to prepare a design and undertake the construction. The timber heading had to be large enough to remove the two bends and take account of increased pressures from working at the bottom of a cliff and within fine sands. The solution was a 2m long tunnel approximately 1.2m2.

Geotechnical, structural and health & safety advice was also sought to ensure the timber heading design was acceptable from the engineering and construction department.

Construction

Construction works began 16 March 2015 and took 5 weeks to complete.

The submersible pumps, guiderails and associated pipework required removal by Northavon M&E, prior to construction works, to allow access within the wet well to erect a scaffold working platform. The scaffold working platform was level to the bottom of the timber heading.

Despite the small size of the timber heading, this took five days to construct because of the complexities of dealing with very fine sands. Matt Durbin Associates confirmed the timber heading on the Fisherman’s Walk project was one of the most difficult timber headings the company has encountered.

The engineering and construction department removed the pipework from within the timber heading allowing the lining to be winched into place the following week. The lining took two days to install.

Engineering and construction returned to install the replacement 100mm ductile iron pipework within the timber heading. This was then backfilled by Matt Durbin Associates with concrete and injected a cementous grout into any voids surrounding the timber heading. The opening of the brick wet-well chamber was rebuilt with glazed brickwork.

The removed pipework and guiderails from the wet well chamber dated back to 1977 when the pumping station was constructed. This was not suitable for reuse due to heavy corrosion and therefore Northavon M&E installed new pipework and new Flygt pumps from Xylem Water Solutions.

(left) Curing the lining – Courtesy of Wessex Water and (right) Steaming lorry – Courtesy of Onsite Services Ltd

Construction constraints

To ensure the safety of the public and workforce, Wessex Water worked closely with Bournemouth Borough Council, to produce a traffic management plan to ensure safe access along the Boscombe promenade, a safe working zone and continue to provide a sewerage service.

Undertakings

The key participants involved with the Fisherman’s Walk Rising Main project were:

- Client: Wessex Water

- Principal contractor: Wessex Water’s Engineering & Construction Department

- Contractor (lining): Onsite Services Ltd

- Contractor (timber heading): Matt Durbin Associates

- Contractor (M&E): Northavon M&E

Conclusion

The pumping station has been in operation since 18 April 2015 and is working well. The outturn cost of this project was £110k, with the majority of this made up of tankering costs. It is estimated that the comparable drilling or open cut solutions on the cliff face could have been twice this cost, even if the stability and safety issues could have been overcome.

Given the success of this project, where appropriate Wessex Water is considering the lining of rising mains in the future.

The engineering and construction sewer rehabilitation team is currently undertaking a study to prepare a Wessex Water technical standard, suitable for the design of sewer rising main linings. This project also highlighted the significant cost savings of constructing a short timber heading to facilitate this repair.

In April 2016 further along the cliff near Bournemouth Pier, a significant landslide occurred, giving further evidence that the no-dig option undertaken on this project was the correct approach to ensure the safety of the site team and limit damage to the environment.