Hanningfield WTW – Washwater System (2022)

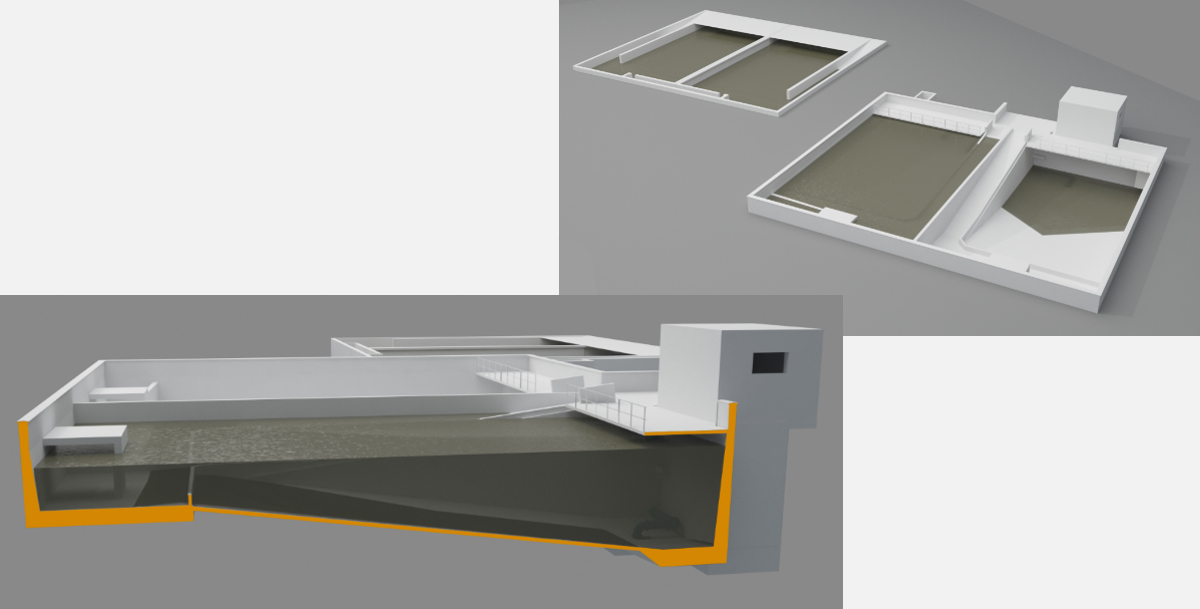

The new Hanningfield washwater tanks - Courtesy of Essex & Suffolk Water

Hanningfield Water Treatment Works (WTW) is the largest water treatment facility operated in the Essex & Suffolk Water supply area. It has been expanded over numerous phases and is currently in need of improvements to its washwater treatment plant in response to changing influent water quality. Hanningfield WTW draws water from Hanningfield Reservoir which is, in turn, supplied by pumped flow from river sources to the north. The treatment works’ processes comprise pre-ozone, pulsator clarifiers, rapid gravity filters (RGFs), main ozone, granular activated carbon (GAC) and chlorine disinfection. Before the project started, dirty backwash water from the RGFs and GAC discharged by gravity to two settlement tanks. Supernatant from the settlement tanks was pumped to Hanningfield Reservoir. Settled material was transferred to sludge tanks for onward pumping to the Whitelillies reed beds facility, which provides low energy sludge treatment and supplements the diverse ecosystem that Essex & Suffolk Water has nurtured over many years.

The problem

The washwater system was at risk of contravening its consented discharge parameters. This was due to changing influent water quality to the treatment works, largely due to the algal load from the Hanningfield Reservoir. The blooms have become longer, more intense and increasingly problematic, particularly for ‘filter-blinding’ algal species that, as the short-hand name suggests, coat the surface of RGFs long before the dirt loading on the bed would ordinarily require backwashing.

Operational practices to cope with filter-blinding algal events required increasingly frequent washing to maintain the production capacity of the works. These specific wash events were of a shorter duration than conventional filter wash events but they increased overall washwater production. The increased washwater production arising from the algal challenge at Hanningfield further exacerbated plant reliability affecting the articulating floating arm draw-offs and pump performance of the washwater system.

Modelled views showing existing and additional washwater tanks in their ‘settle’ and ‘fill’ phases with two further tanks holding GAC conditioning water – Courtesy of Stantec UK

The project

The existing washwater tanks operate with continuous inlet flow and draw-off by periods of supernatant pumping (via floating arm draw-offs) and subsequent periods of settled material pumping. New consent parameters of 50 mg/l suspended solids and 30 mg/l Fe now apply, including the caveat that no chemicals will be added to aid settlement. To achieve these new consent requirements, extensive lab and full scale in situ tests using the existing washwater settlement tanks were undertaken to ensure a good understanding of the existing washwater production and the time needed for natural settlement to occur. The findings were positive, showing that settlement unaided by chemical addition was satisfactory, paving the way to the recommended fill-settle-draw solution with the two existing washwater tanks to be supplemented with two additional tanks and a new pumping station.

Concept design

The in-flow rate, settlement time and time to pump out the tank were all critical to the development of the design arrangement. A rudimentary approach could be to consider the fixed time to achieve sufficient settlement for supernatant draw-off, in this case, 30 minutes, and dedicate one tank to filling and one tank to emptying for a 3-tank arrangement, with each tank sequentially rotating through these stages.

The size of the existing tanks, however, could not accommodate a peak 30 minute in-flow and a more innovative approach was needed if existing assets were to be re-used.

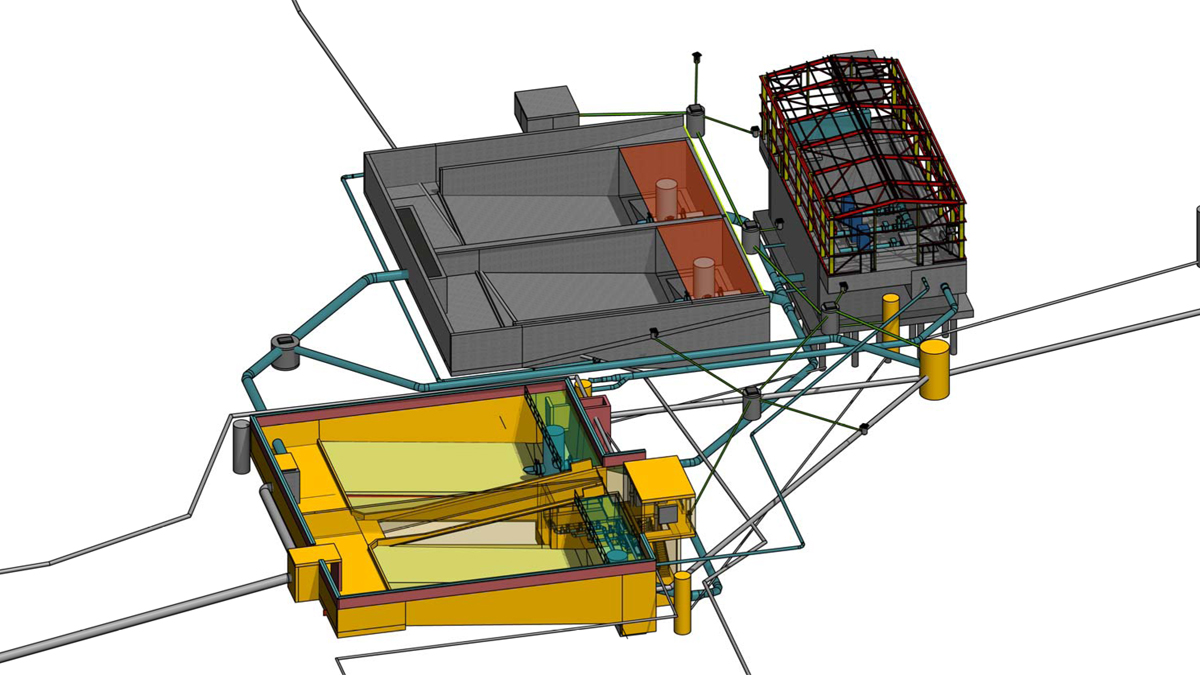

Model showing the existing washwater tanks (Tanks 1 and 2 – mustard colour) and the new tanks (3 and 4 – grey) with the new supernatant pumping station. The complex arrangement of new and existing pipework can also be seen – Courtesy of Stantec UK

Washwater flow monitoring data was available over several years and provided a wealth of data. The instantaneous flow rate for the RGF and GAC backwashes was known but this was intermittent and irregular. The most challenging volumetric event would be the short duration, but frequent, ‘rapid wash’ regime for clearing the filter-blinding algae. Even here though, clean washwater availability would be finite, being limited by the time needed to re-fill the clean washwater tanks.

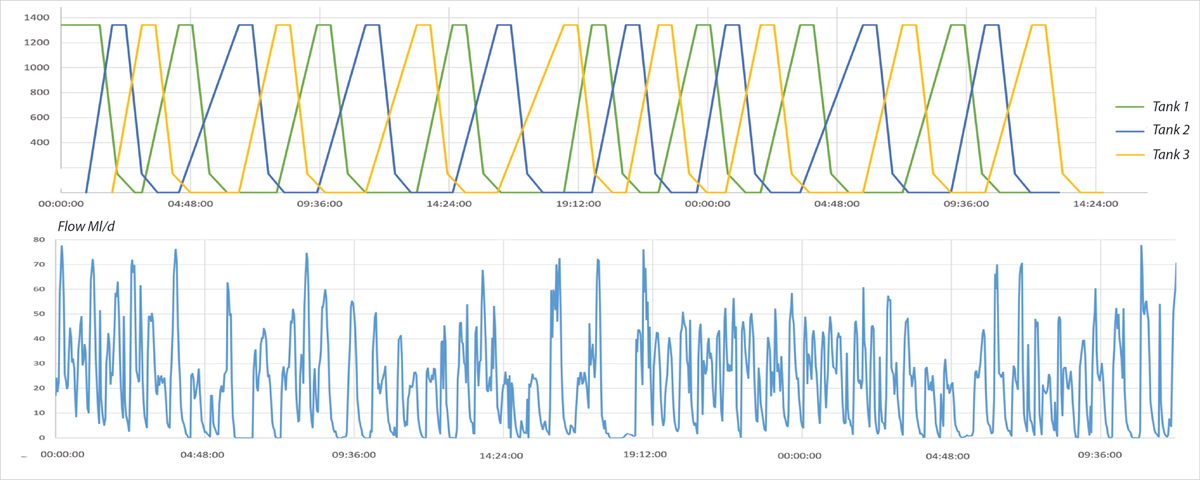

By analysing historic flow events and assessing a longer data set of washing events that had been recorded in SCADA against site records, the flow patterns for a variety of operating conditions were identified. For the worst-case flow events, a peak in-flow rate would be observed, followed by a reduction in flow that would be the inevitable result of the restrictions in re-filling the clean washwater tanks. This type of data was then used to model the fill-settle-draw arrangement in such a way that they could be illustrated in graphical form. For example, Figure 1 (below) shows that the fill-settle-draw arrangement could be accommodated with tanks of a similar size to the existing tanks so long as a given tank could be emptied before it was necessary to re-fill i.e. the peak filling events are expected to be short in duration and subsequent in-flow rates would be lower providing a longer time for subsequent tanks to fill and providing the time necessary for the first tank in this sequence to complete its settle-draw stages.

A design that could accommodate peak flow conditions with three tanks available would also be suitable for normal flow conditions using only two tanks. For this two-tank mode, the time needed to fill the first tank would be sufficient for the second tank to both settle and be emptied prior to its filling.

(Figure 1) Graph shows tank levels for three tanks operating a fill-settle-draw mode against historic washwater inflow – Courtesy of Stantec UK

A further design condition was the storage of GAC-conditioning water following a GAC delivery where the fines would not generally be suitable for return direct to the reservoir. Two tanks would need to be allocated to receiving this GAC conditioning water. So long as GAC conditioning was during normal water quality periods (and not the high algal loading periods) only two washwater tanks would be necessary for the fill-settle-draw sequence while two tanks were required for GAC conditioning. In this way, four tanks in total would be needed to address the operational situations anticipated.

A single ‘duty’ pump would be sufficient for pumping out supernatant under normal operation with normal water quality and with all four tanks available. This would reduce pumping flow rate and reduce headlosses in the supernatant return main. However, if washwater production increased, pumping with an ‘assist’ pump would be initiated.

Detailed definition

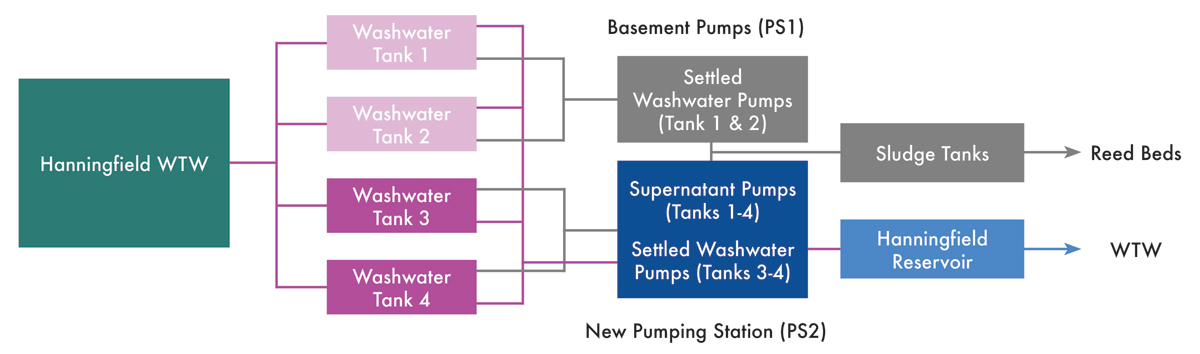

The concept design phase approach included two new tanks (Washwater Tank 3 and Washwater Tank 4) and a new pumping station (PS2) while the existing supernatant and settled washwater pumps, located in the basement of the existing pumping station (PS1) for Tanks 1 and 2, would be removed and replaced with settled washwater pumps for those tanks only to keep suction lines as short as possible. Supernatant from all four tanks will be removed by the new supernatant pumps.

Figure 2: Schematic of new washwater system

Further modelling of the fill-settle-draw arrangement assisted with the final control philosophy for the works. Details of the sequencing considered the impact of inlet penstock opening and closing times and the time between supernatant pumping and settled washwater pumping to remove the remaining settled material before the tank would receive the next ‘fill’.

The supernatant draw-off requires new outlets comprising a draw-off tower with vertically separated large diameter ports for the removal of the supernatant, each port operating only when appropriate to remove the upper-most portion of supernatant following settlement. The lowest draw-off port was equipped with a deflector plate to minimise the risk of drawing settled washwater from the lowest part of the tank following the settlement phase. The existing and the new tanks are all to be equipped with this draw-off arrangement.

The proposed site was especially constrained by existing site infrastructure and other features including above ground and buried assets and sites of high ecological sensitivity, particularly related to the presence of large numbers of reptiles. This imposed various constrictions on the form of the final design.

The construction phasing and commissioning of the works needed to be carefully planned to ensure continued operation of the works throughout. The new washwater tanks 3 and 4 and the new pumping station (PS2) could be constructed off-line with minimal impact on the existing assets, however, the final connections would require the flow to be diverted to the new and operational works allowing the existing tanks to be temporarily removed from service so that the existing pumping equipment could be removed and replaced with the new settled washwater pumps along with installation of the supernatant draw-off towers.

Pumping station internal view – Courtesy of Essex & Suffolk Water

During this time, the fill-settle-draw capability would be undertaken by the new Tanks 3 and 4 only and, on completion of the works to Tanks 1 and 2, the commissioning of the whole system can commence.

The impact of both embodied carbon and operational carbon was considered. The extent of new build was minimised by ensuring existing assets were re-used thereby minimising waste production. The existing washwater tanks along with the return mains to Hanningfield Reservoir were included in the upgraded works.

Attenuation tanks ensured green-field run-off rates were not exceeded thereby ensuring no increase in flow to downstream natural drainage channels. The southeast facing roof pitch was suitable for the installation of photovoltaic cells which, via a feed in unit as part of the MCC, will off-set grid electricity usage for the local pumping plant or, when this plant is not in operation, will feed into the wider electrical infrastructure.

Hanningfield WTW: Washwater Tanks & Pumping Station: Supply chain – key participants

- Designer/main contractor: Farrans TES JV

- Process design: Stantec UK

- MEICA design: TES Group

- Cost management: Turner & Townsend

- Civil design: Pell Frischmann

- Earthworks/groundworks: RB McGeary Contracts Ltd

- CFA & sheet piling: Murphy Group

- Reinforced concrete/formwork: Murform Ltd

- Superstructure steelwork: AC Bacon Engineering

- Washwater pumps: SPP Pumps Ltd

- Flow Control: Hydro International

- Penstocks: Ham Baker Group

- Valves: Glenfield Invicta

- Flow controls: Auma Actuators Ltd

- Pipework & access platforms: Franklyn Yates Engineering

- MCCs: TES Power

- System integration: OCE Systems

- Transformer/RMU: Schneider Electric

- Flow meters/instruments: Siemens

- Pressure instruments: GEMS Sensors

- Cranes & lifting: ABUS Crane Systems Ltd

- Photovoltaic system: Solar UK Ltd

- Fire alarms/security: Openview Security Solutions Ltd

- Lightning protection: Bacon Group

Project delivery

From commencement, it was recognised that the delivery of the project would take several years, particularly given initial site preparation and ecological works. An advanced earthworks contract was prepared and delivered through IWS and using ALD to prepare the site ahead of the main contract. This also allowed the varied ecological surveys and clearance works to commence.

Completion of ground works – Courtesy of Essex & Suffolk Water

The ecological works was managed by Essex & Suffolk Water’s Environment and Conservation team and engaged local ecology resources to assist. Reptile investigations, involving the placement of reptile mats and their subsequent inspection, can only be carried out during periods of reptile activity i.e. not too cold, when reptiles will take cover further below ground.

Reptiles, including slow worms in particular, were found in large numbers throughout the site area. An extensive period of inspecting the site area and removal of reptiles to outside of the reptile fence continued until clearance was complete. Again, this work was only possible during periods of suitable activity by the reptiles encountered. The need to work within specific windows of time required significant advanced planning and agreement.

The tender design, developed by Stantec UK in close collaboration with Essex & Suffolk Water, was predominantly to deliver a detailed design with a number of areas to be supplemented during the delivery phase. Farrans/TES Joint Venture were appointed to deliver the contract with Pell Frischmann providing the detailed design support to the contractor. The NEC3 contract is being administered by Turner & Townsend.

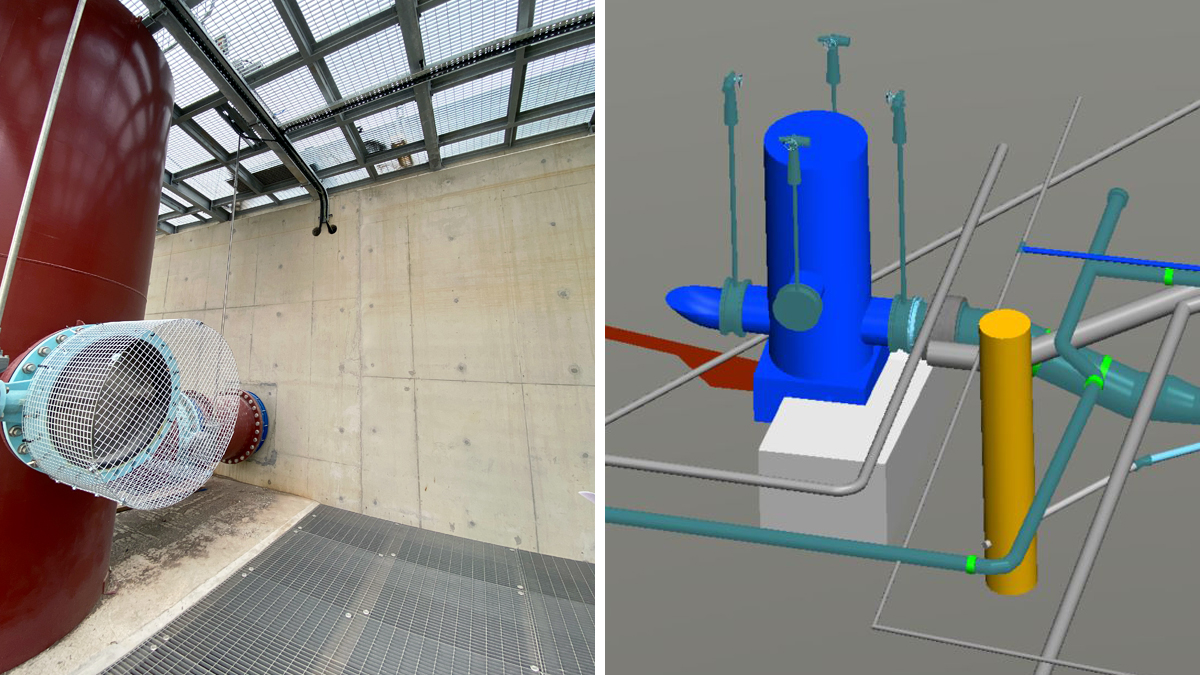

As built an model of the supernatant inlet port with debris screen – Courtesy of Essex & Suffolk Water and Stantec UK

Current status

At the time of writing (August 2022) the switch to the new washwater tanks and pumping station is approaching, to be followed by the stripping out and re-equipping of the settled washwater pumping equipment for the existing washwater tanks.

Hanningfield WTW remains a pivotal part of the long-term security of water supply in the region and this project will further remove any bottlenecks for resilient water supply in the decades ahead.