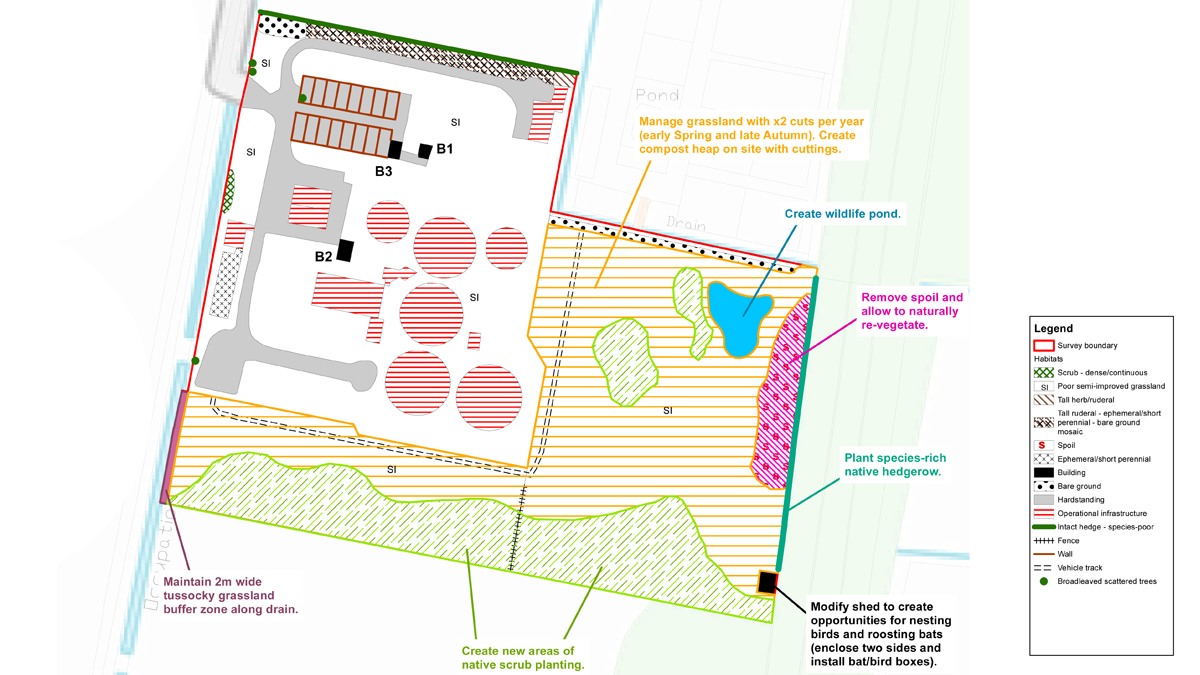

Haxey Graizelound STW (2022)

Biodiversity Enhancement Plan - Courtesy of Penny Anderson Associates Ltd

Located in Lincolnshire east of Doncaster, Severn Trent’s Haxey Graizelound Sewage Treatment Works (STW) serves a residential population equivalent of 5,169 with no trade loads within the catchment. The works receives pumped flows from two pumping stations located in the catchment. The present permit is BOD 25mg/l, suspended solids 45mg/l, ammonia 15mg/l with a dry weather flow (DWF) of 1,100m3/day and a flow to full treatment (FFT) of 37.7l/s. Due to the Water Framework Directive the site will receive a 3mg/l ammonia and 0.2mg/l phosphorous discharge consent, and should chemical dosing be required to achieve the phosphorus removal, a corresponding 4mg/l iron discharge permit will be introduced.

Existing works

The present works consists of a high-level balancing tank that collects the pumped flows from the catchment before transferring the flows to an all-flows screen, grit removal and a flume controlling FFT and storm separation. Assets include:

- 1 (No.) radial primary settlement tank (PST).

- 4 (No.) biological filters.

- 1 (No.) radial humus settlement tank (HST).

- 1 (No.) storm storage tank.

- 2 (No.) co-settled sludge holding tanks

- 1 (No.) works return pumping station.

Technical solution

Due to the tightening of the ammonia permit to 3.0mg/l, any expansion to the existing fixed film biological filtration process was deemed to have a high process risk and was discounted early on. The remaining options considered for the scheme were:

- Retain the existing works with tertiary ammonia removal.

- Retain the existing works with MBBR and reed beds.

- Crude oxidation ditch/activated sludge plant with chemical phosphorus removal.

- Crude oxidation ditch/activated sludge plant with enhanced biological phosphorus removal (EBPR).

- Settled oxidation ditch/activated sludge plant with chemical phosphorus removal.

- Settled oxidation ditch/activated sludge plant with enhanced biological phosphorus removal.

- Activated granular sludge plant.

Following a costs benefit analysis (CBA), a crude pocket ASP with EBPR was selected as the preferred solution.

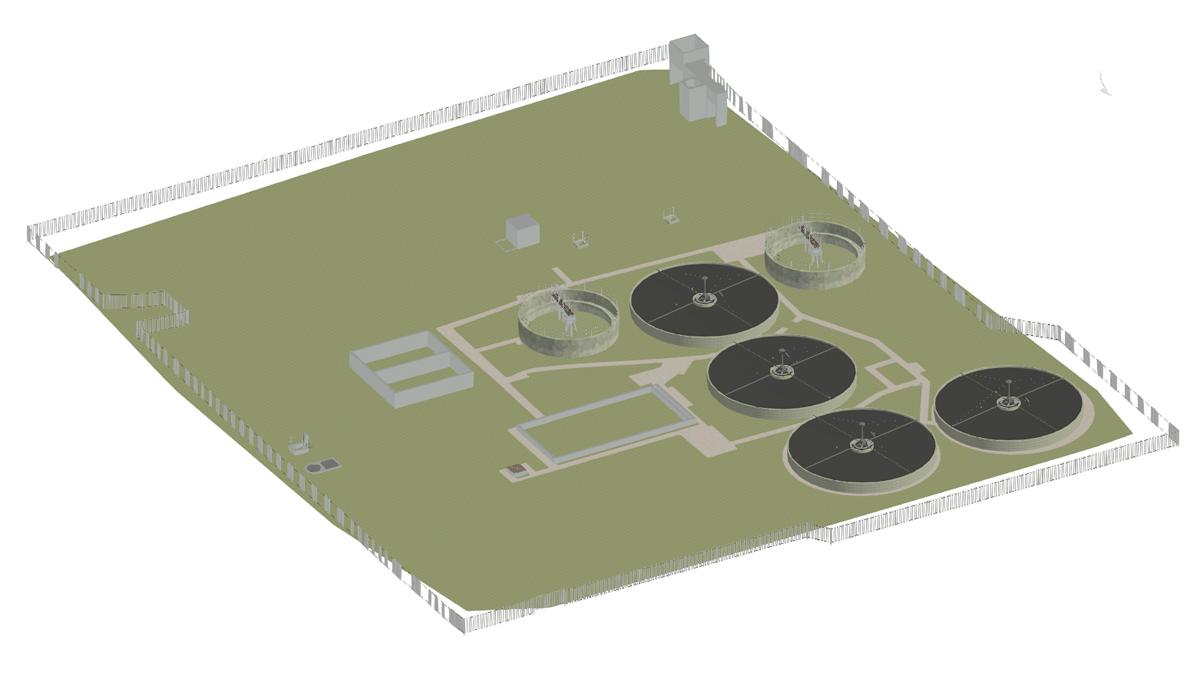

3D model of the existing site – Courtesy of Cloud Conversion Ltd

Design phase

Severn Trent took the strategic decision to bring design back in-house for AMP7 and become an intelligent and informed client.

As with all transformations this became a journey and not an overnight change. Modern-day up to date policies and procedures were implemented to support a design organisation, new designers were recruited, and existing staff members were upskilled in the current world of design. Alongside the development of the design team, the commercial team established new support contracts to allow survey work, ground investigation and environmental data to be collated to feed into the design process.

The internal design team started to cut their teeth on repeatable WFD projects however the skills developed at a rapid rate leading to the designer’s desire to undertake projects which are larger in size, cost and complexity. This led to the team taking on the outline design for the works replacement at Haxey Graizelound STW.

The existing site was surveyed by Cloud Conversion Ltd to produce a 3D building information model (BIM) in software Autodesk Revit, by undertaking a point cloud scan, topographical survey, and underground/utilities survey. This enabled the design team to have a detailed up to date digital twin of the existing site to base the future design on. Intrusive site investigation (SI) was undertaken to determine the extent and the details of the existing decommissioned underground structures on site. In addition, ground investigation (GI) was undertaken to determine the existing ground makeup and to establish the water table in the area.

Cropwell Bishop STW FST: Visiting recent installation to learn lessons and replicate good designs – Courtesy of Severn Trent

The discipline-specific design engineers produced their designs which were fed into the Autodesk Revit 3D model by the Severn Trent internal digital design team, prior to been used for design reviews, Hazard & Operability (HazOp) study and stakeholder engagement. Following design acceptance, 2D sections and details were produced in Revit which were submitted to the Severn Trent cost and estimating team to set a target price (TP) for the project.

The 2D sheets communicate clear designs to allow a robust TP to be set. The design pack was then submitted to the supply chain for tender where risk has been reduced due to the level of design detail provided. This in turn leads to reduced cost risk for Severn Trent and increased confidence from the supply chain in the work they have been asked to undertake.

Haxey Graizelound STW: Supply chain – key participants

- Client: Severn Trent

- Detailed design & construction: MMB

- 3D scans, topographical surveys: Cloud Conversion Ltd

- Ground investigation: Ian Farmer Associates

- Environmental Consultants: Penny Anderson Associates

- Geo-Environmental Consultants: Sirius Geotechnical

3D model of the proposed works improvement – Courtesy of Severn Trent Water Digital Design Team

Sustainability considerations

The internal design team were able to undertake the design process with sustainability at the forefront of their minds. Following the GI, the team were able to reuse an existing area of the site where disused assets were installed, eliminating the need to build on green areas and allowing us to develop these areas to enhance the biodiversity on site. Working with the framework ecologists a biodiversity baseline assessment and a biodiversity enhancement plan were produced, which has led to a design providing a biodiversity net gain of 16% habitat units and 254% hedgerow units.

To support Severn Trent’s journey to net Carbon Zero the team were able to use the newly developed carbon tool to review options to select lower carbon alternatives. This included a stainless steel prefabricated high-level inlet works structure, fabricated off-site and delivered to site, rather than a traditional concrete structure cast in situ.

The internal design team were able to assess the network pumping stations feeding the site to determine the maximum head they could deliver to. This allowed the hydraulic designer to set the inlet level, and when considered with the fixed outlet river level the works was designed to gravitate all the flows through the process. This eliminated the need to install any interstage pumping stations which reduce assets installed, energy usage and provides a more robust process solution.

Winchcombe STW sludge thickener: Visiting recent installation to learn lessons and replicate good designs – Courtesy of Severn Trent

Conclusion

The transformation strategy for AMP7 has achieved its goal of bringing design back in-house with Haxey Graizelound as a great example of what the team can produce. The project has been contracted to Mott MacDonald Bentley (MMB) who, with the support of the Severn Trent Design team, will be undertaking detailed design and turning our design into reality.