Nereda

Helea® (2022)

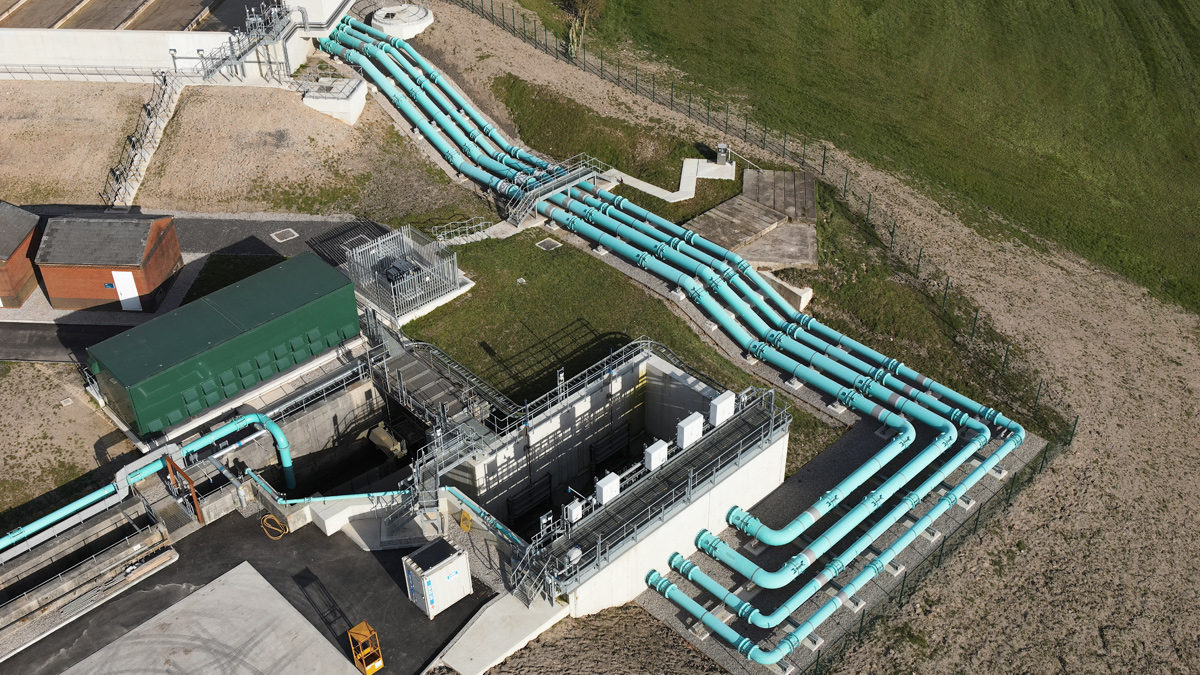

Helea® plant at Anglian Water’s Cliff Quay site - Courtesy of Royal HaskoningDHV

With the environmental and climate changes that surround us, there is an increasingly urgent focus on resource recovery and energy efficiency. Every wastewater treatment plant produces sludge as part of its treatment process and the treatment and disposal of these biosolids is expensive; representing up to 70% of a plant’s operating costs. With budgets squeezed, water companies are looking to reduce operating costs where possible. As part of the water industry’s drive to achieve Net Zero by 2030, water companies are keen to exploit every available opportunity to reduce a plant’s carbon footprint too. Helea® is an efficient and sustainable biological hydrolysis and pasteurisation process from Royal HaskoningDHV that provides water companies with a technology that has significant benefits, in terms of process efficiency, capital and operational savings and environmental benefits.

The background

10 years ago, searching for a more affordable and sustainable route to advanced digestion, Anglian Water developed HpH (heating, pasteurisation and hydrolysis) digestion technology and implemented it at four of its sludge treatment centres. Many years of operational experience have proven the efficient performance and reliability of this technology across these sites, giving best-in-class advanced anaerobic digestion. In the first step of a unique long-term partnership between Royal HaskoningDHV and Anglian Water, the two companies entered into a cooperation agreement to bring this technology to market in the UK and abroad.

Now, ownership of the HpH technology has been transferred to Royal HaskoningDHV and the proven benefits of this award-winning, sustainable technology, now called Helea®, are available globally to the water industry. This is helping support water companies to meet their Net Zero targets, by offering a more affordable and sustainable route to advanced sludge digestion.

Helea® significantly increases the biogas yield when compared to conventional digestion, typically achieving a more than 25% increase in volatile solid (VS) destruction and biogas production. At the same time, it transforms the remaining biosolids into an enhanced quality biosolids resource that can be safely recycled for agriculture as a sustainable nutrient source and a soil conditioner. The process reduces operating costs and a plant’s carbon footprint too.

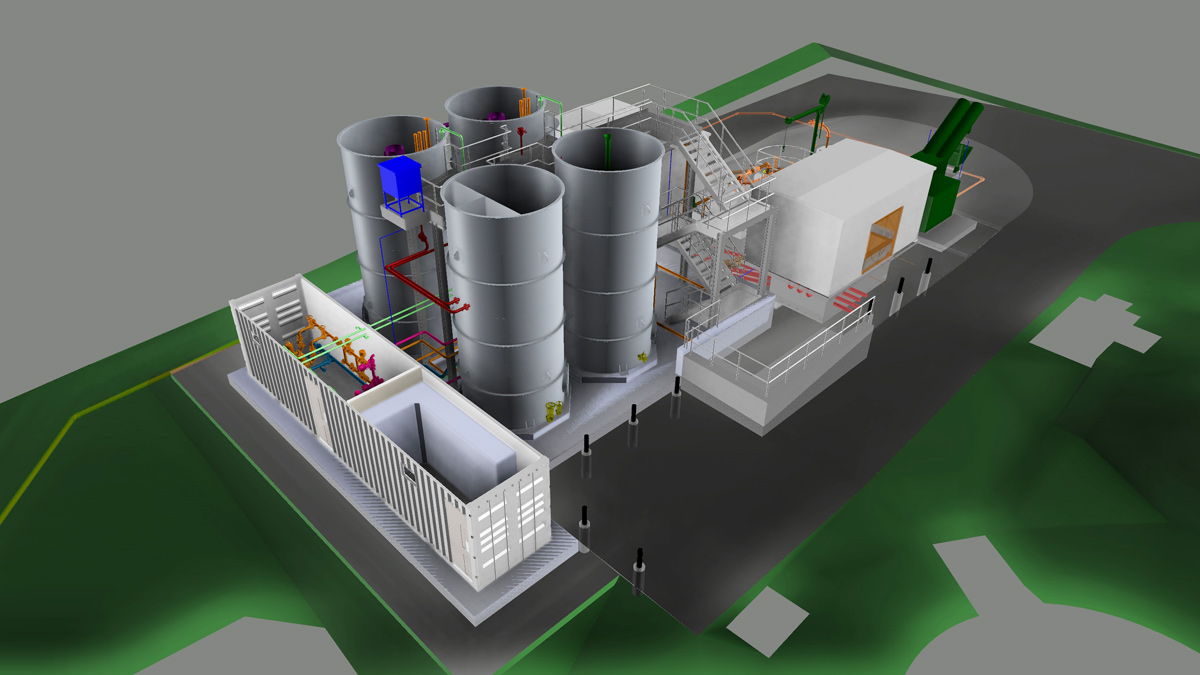

Helea® ensures optimum performance, stability and reliability – Courtesy of Royal HaskoningDHV

A three-stage process

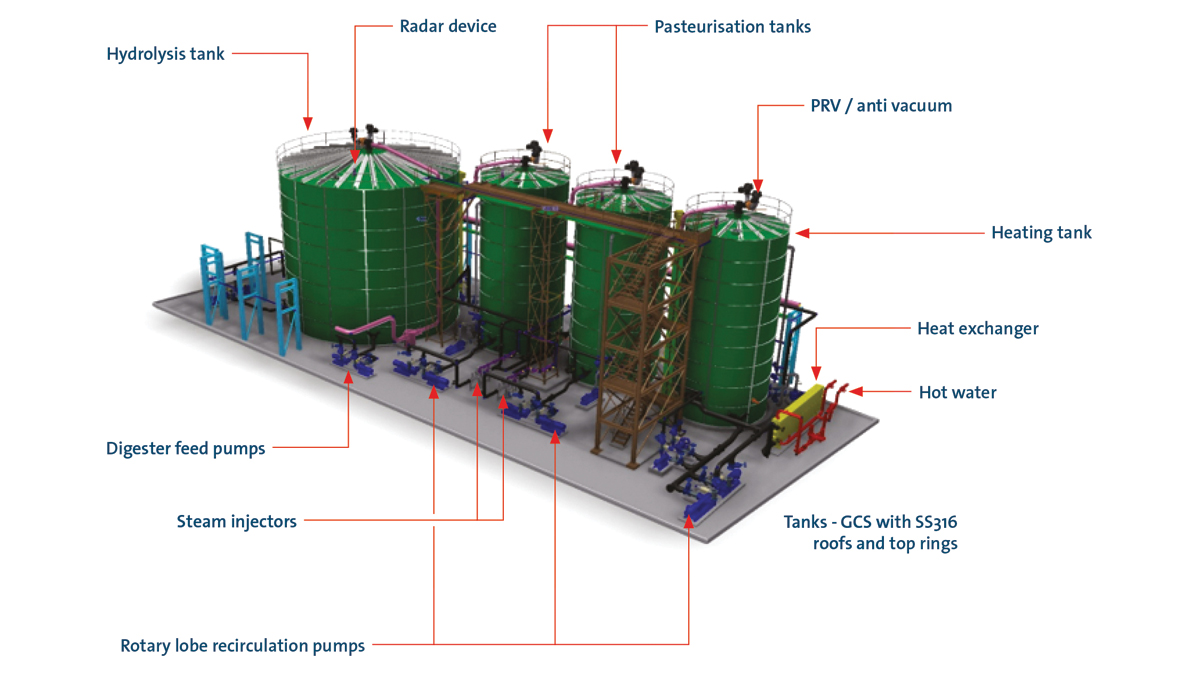

Helea® is a simple and reliable three-stage process, involving heat recovery, pasteurisation and biological hydrolysis. Effective integration of these steps with specially developed process monitoring and control features has resulted in industry-leading levels of availability, safety, flexibility and energy efficiency.

Thickened raw sludge is pumped into the heating tank where the temperature is raised to approximately 40-45°C. Here, the sludge is simply recirculated through a heat exchanger using hot water recovered from combined heat and power (CHP) engines. Overall, no additional support fuel is needed, making the process energy self-sufficient and optimising carbon benefit.

The pre-heated sludge is pumped forward to the pasteurisation tank where it is heated to 55°C by recirculating it through a steam injector. Here, the steam is raised using a waste heat boiler to recover heat from the CHP exhaust gas. Once the pasteurisation tank is full, the sludge is transferred to the second pasteurisation tank where it is held for five hours to achieve pasteurisation. After five hours, it is transferred to the hydrolysis tank. Within this tank, the pasteurised sludge is recirculated and cooled to 38-42°C to provide optimum conditions for biological hydrolysis. Variable level control allows the pasteurised sludge to be held in the hydrolysis tank for the required retention period, independent of the sludge load being treated. The optimum hydrolysis conditions are typically 1.5 days at 42°C. The pasteurised and biologically hydrolysed sludge is pumped forward to the digesters at an adjustable feed rate, depending on the requirements of each sludge treatment centre.

Typical Helea® plant diagram – Courtesy of Anglian Water

Buffering the sludge through the process ensures optimum performance, stability and reliability. Since the process does not require high-pressure vessels, there is no need for annual scheduled shutdowns for safety checks and maintenance.

Helea® is a pre-treatment before the anaerobic digesters, allowing them to operate at significantly increased organic loading rates, and achieve higher solids destruction and additional biogas production. Less digested sludge solids mean lower costs associated with dewatering and the safe recycling of biosolids to local farmland. Helea® provides optimum conditions for pasteurisation and biological hydrolysis, with the resulting sludge more amenable to anaerobic digestion. It separates the sludge digestion into two phases, optimising biological hydrolysis before maximum methane production in the digesters, allowing for higher levels of volatile solids destruction and higher production of biogas, with reduced CAPEX and increased operational savings.

Biomethane flow to grid

Further developments are underway to minimise heat and power requirements for future plants. These include using heat recovery and heat pumps to minimise heating requirements and allow more of the biogas to be upgraded to biomethane to be used in the grid or for bio-vehicles. This maximises biogas revenue, further progressing towards energy-self-sufficient wastewater treatment.

Operational benefits

Helea® is now well-proven with the following operational benefits:

- Saves money and reduces carbon footprint, helping meet Net Zero targets.

- Maximum efficiency in biogas production.

- Simple safe process, easier to operate and maintain compared to other pre-treatment technologies.

- Less energy is required for process heating.

- Direct steam heating for pasteurisation.

- Built-in flexibility to deal with variations in sludge load and quality.

- Advanced control for optimum performance and remote monitoring.

- Operational flexibility for optimising performance in terms of increased solids destruction and biogas yields, and recycling of enhanced quality biosolids.

- High availability, no routine shutdowns of plant required.

- Supports lowest carbon option, such as ‘biomethane to grid’ and alternative heating sources.

- Health and safety benefits due to lower operating temperatures without elevated pressures.

- No odour nuisance, fully contained process.

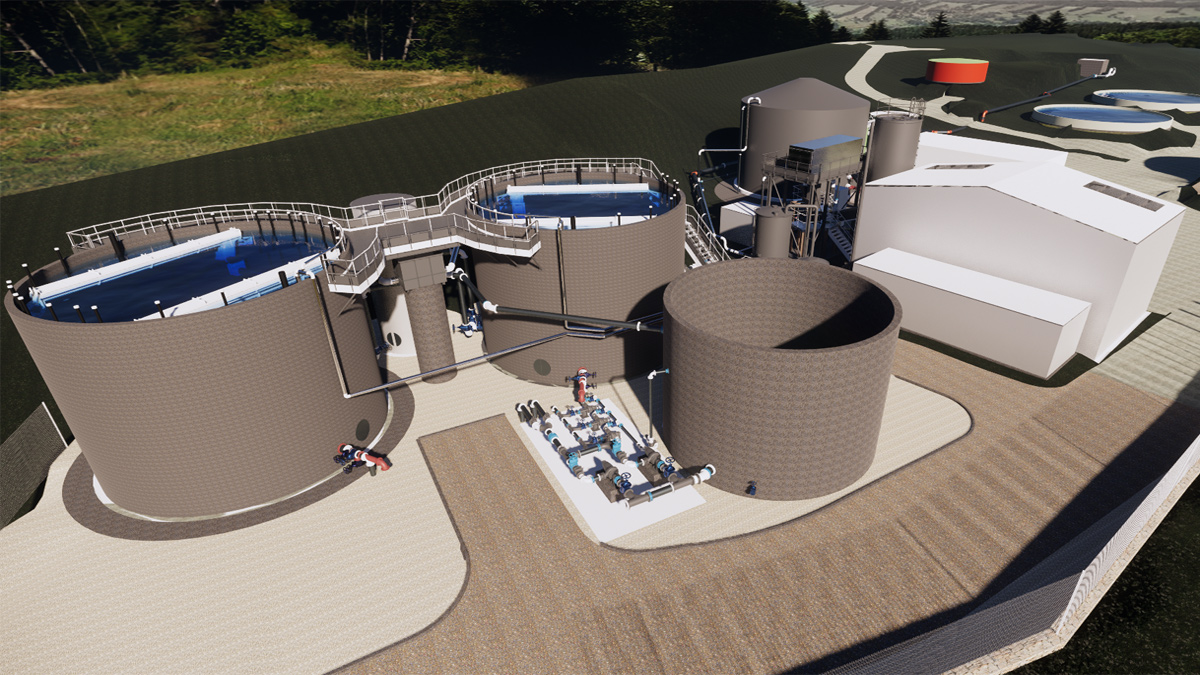

Helea® – helping to meet Net Zero targets – Courtesy of Royal HaskoningDHV

Four full-scale case studies

Originally developed by Anglian Water, Helea® is now a well-established technology, with a proven track record of over eight years of reliable operation in the UK water industry, over a wide range of operating conditions.

The technology was successfully installed at four full-scale sludge treatment centres in Anglian Water and has demonstrated efficient and reliable performance over nine years of operation. Each plant can achieve 1 MWh of electricity (or 2.5 MWh of biogas energy) per tonne of dry solids treated. Gas yields have been some of the highest in the industry, when compared with conventional anaerobic digestion systems, seeing an approx. 25% increase, along with significantly lower operating costs and lower capital costs. The plants deliver a lower whole-life cost compared to the alternatives, such as thermal hydrolysis advanced digestion plants (THP).

These four plants’ performance is also significantly more reliable than THP, as Helea® does not require pressure vessels, relying on atmospheric pressure instead. This means that no annual inspections requiring shutdown are needed as Helea® is designed to operate 24/7, 365 days per year. The sludge treatment plants where this system is operating are:

-

- Basildon: 10,300 TDS/yr – commissioned 2013.

- Cliff Quay (Ipswich): 15,000 TDS/yr – Commissioned 2014.

- Colchester: 15,000 TDS/yr: Commissioned 2014.

- Pyewipe (Grimsby): 17,500 TDS/yr: Commissioned 2014.

Helea® – the sustainable, energy efficient route to advanced digestion – Courtesy of Royal HaskoningDHV

Helea® and Ephyra®, a winning combination

To maximise the whole-life cost benefit of Helea®, and drive further improvements in volatile solids destruction, biogas yield and reduced dewatering and recycling costs, Royal HaskoningDHV is integrating its Ephyra® plug flow digestion technology downstream of Helea® in its latest advanced digestion designs.

The patented Ephyra® technology includes operating anaerobic digesters in series, giving plug flow conditions with minimum short-circuiting. An AI-controlled small flow of digested sludge is recirculated from the final digester to the first digester to increase alkalinity and biological performance, for improved process stability.

Ephyra® configuration allows the sludge throughput to be significantly increased without digester stability issues. This technology is now well-proven at full scale and has been selected to optimise the performance of some of the largest advanced digestion facilities, such as Ringsend, Dublin.

Overall, Ephyra® has been found to increase the biogas yield of advanced digestion plants by 10-15%. It also reduces the remaining digested sludge solids by 5-8% (reducing recycling costs) and reduces downstream emissions, to reduce the overall carbon footprint. Helea® and Ephyra® combined will result in up to 33% improvement in volatile solids destruction and biogas yields when compared with conventional digestion. They will take advanced digestion even further, with the opportunity to process more sludge.

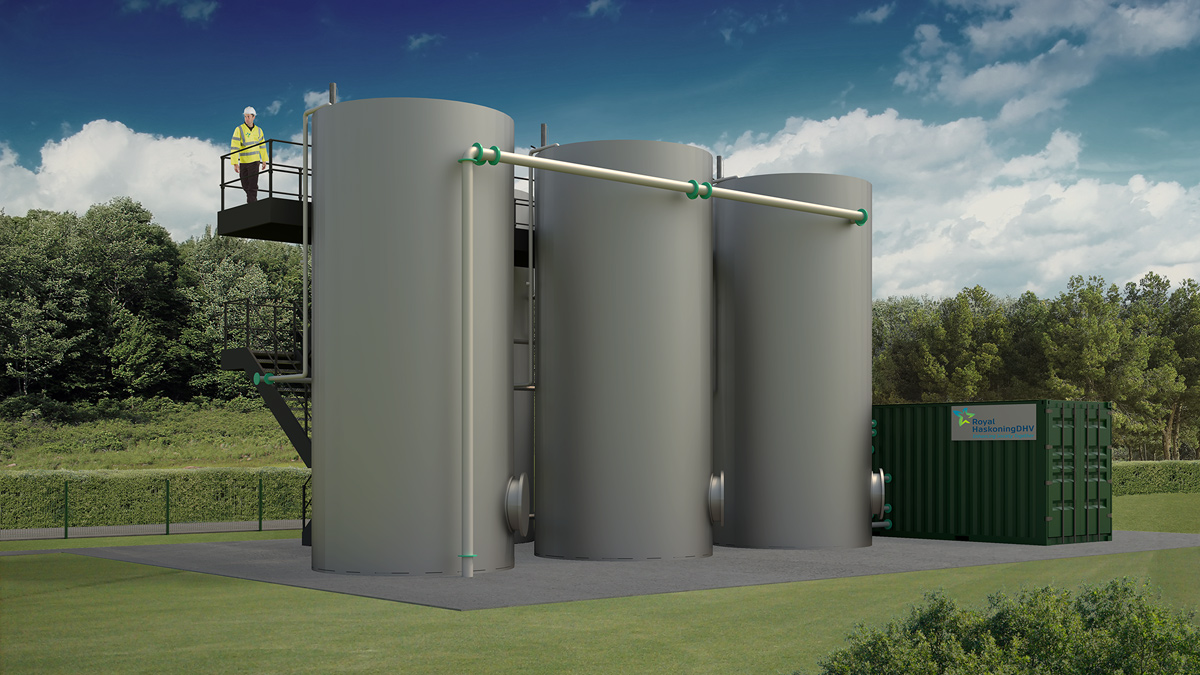

Helea® instrumentation – Courtesy of Royal HaskoningDHV

Conclusion

Helea® has proved to be a cost-effective, efficient and sustainable route to advanced digestion with safe use of enhanced quality biosolids in agriculture. With increased biogas production and combining renewable power generation and heat recovery for pasteurisation and biological hydrolysis, Helea achieves power and energy surplus performance, effectively reducing the carbon footprint of wastewater treatment.

Compared with other advanced digestion pre-treatment technologies, Helea® is more sustainable and energy self-sufficient, delivering significant capital and operational savings.

The full-scale Helea® plants consistently produced ‘best in class’ levels of biogas production with energy yields of approximately 2.5 MWh per tonne of dry solids processed. This gives 1 MWh of renewable power per tonne DS when using CHP. With a lower carbon footprint than alternative technologies, Helea is the sustainable energy efficient route to advanced digestion, supporting the water industry’s journey towards Net Zero.

In summary, Helea® provides:

- Significantly higher biogas yield than conventional anaerobic digestion.

- Operational carbon savings.

- Enhanced quality biosolids for safe recycling to agriculture.

- Competitive CAPEX and significant OPEX savings.

- A well-proven, safe, reliable and easy-to-operate process.

- Between 20-30% saving in CAPEX when compared to equivalent THP pre-treatment.

- Operational savings of £50 per tonne of dry solids treated in comparison with equivalent THP plants.

Helea® – helping to meet Net Zero targets – Courtesy of Royal HaskoningDHV

Royal HaskoningDHV and Anglian Water’s long-term partnership means Helea® can be offered across the water sector. This will allow Helea® proposals to be supported with long-term, full-scale proven performance data that shows it to be an efficient, resilient, safe and reliable pre-treatment technology that outperforms THP, and is ideally suited for the journey to Net Zero.

This paper was prepared by Barry Oliver, Nereda Regional Sales Director – EMEA with Royal HaskoningDHV, and Steve Riches, Portfolio Lead Bioresources – Asset Delivery Planning with Anglian Water.

For more information: Royal HaskoningDHV | +44 (0)121 709 6521 |www.nereda.net