Kinnerley WTW (2023)

Kinnerley WTW - completed installation of the full filter gallery - Courtesy of the Kinnerley Project Team

Kinnerley WTW is located in rural Shropshire, approximately 10 miles north-east of Shrewsbury. The site treats around 4 Ml/d from a single groundwater source, after which it is pumped to Pant DSR to supply. The existing water treatment process on site includes two aeration towers, chlorine gas, three iron and manganese pressure filters, a balance tank, and two high lift pumps. The original iron and manganese pressure filters date back to AMP2 (1997) and were installed to meet new limits on acceptable water quality implemented by the European Union.

Project drivers

The iron and manganese filters at Kinnerley WTW perform a vital role in removing suspended metal deposits within the abstracted groundwater. The filter contains a specially designed media which captures the iron and manganese deposits, however over time, the Birm media has become congested which has led to an increase in differential pressure across the filter and a reduction in flow.

In normal operation, the filter enters a backwash approximately every four-weeks, which scours a high proportion of the metal deposits from the media and into the waste stream. This backwash process means an average batch of media can generally last around 10 years before the backwash process becomes less effective at removing deposits and the media ultimately requires replacement.

The filters at Kinnerley WTW were reaching this stage of their operational life, with site output being reduced from 50 l/s to 35 l/s to help control turbidity. This reduction in site output was putting additional output demand on other sources in the area. Water resource calculations completed early in the optioneering phase of the scheme identified a six-hour intervention limit for the site. This ultimately meant that in order to both deliver the scheme and maintain customer supplies, a broader suite of enabling options needed to be considered.

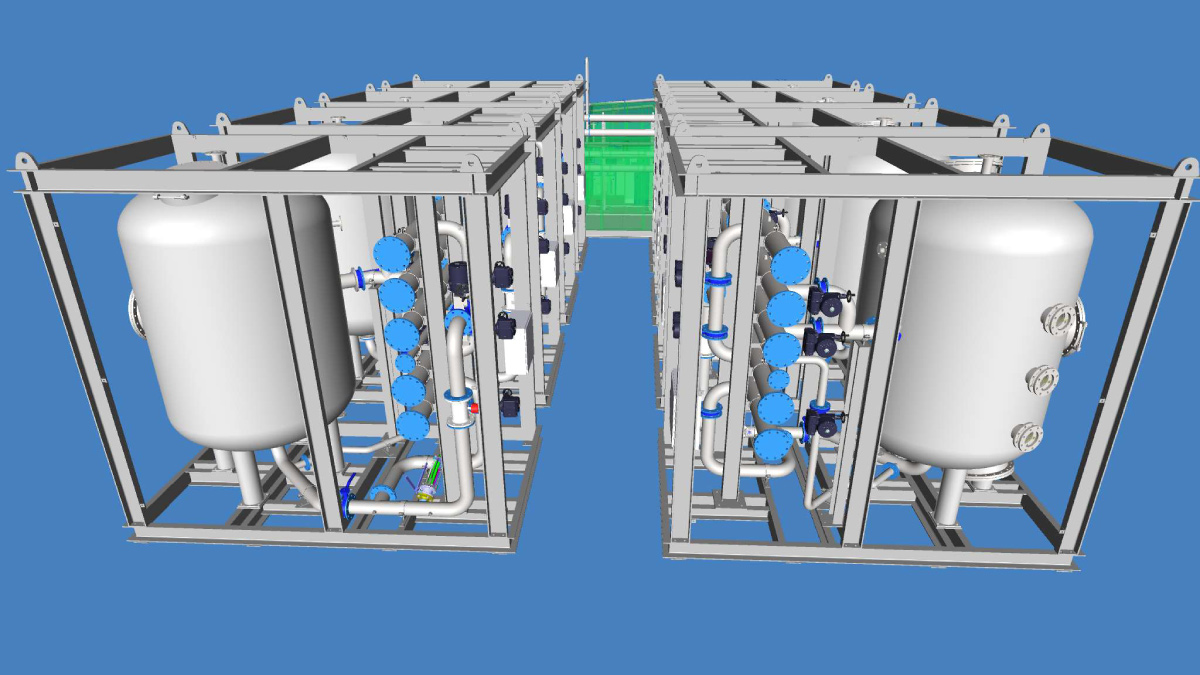

Initial 3D model developed from initial design concept aligning to Severn Trent’s design standards parameters – Courtesy of the Kinnerley Project Team

Enabling options

The enabling options that needed to be considered were:

- Increase flows from Pentre WTW to allow one of the iron and manganese filters to be removed from service at a time for replacement. This option was discounted as the output demand impact on other sources (particularly Shelton WTW) would be detrimental. Furthermore, obtaining interventions required to complete the work would be difficult.

- Increase flows from Mardy WTW into Oswestry which would reduce demand at Shelton WTW. This would allow Shelton WTW to support Kinnerley more heavily and allow one of the iron and manganese filters to be removed from service at a time for replacement. This option was discounted as, similar to option 1, the demand impact on other sources would be detrimental and intervention requirements with the enabling option would likely remain extensive.

- Import water from a neighbouring water company to allow flow reduction from Kinnerley and for one iron and manganese filter to be removed from service at a time for replacement. This option was discounted as perceived timescales required to agree increased imports did not align with the urgency of replacing the iron and manganese filter media. This option would also require flow reversals which would increase risk of discolouration.

- Install a temporary filtration system capable of treating full flow (6 ML/d) to allow all iron and manganese filters to be removed from service for replacement: This option was taken forward because it minimised output demand impacts on other sources and would provide Severn Trent with a mobile filter system to deploy and enable similar schemes in the future.

(left) Interlinked modular manifolds and (right) viewing window with media loaded to filter vessel – Courtesy of the Kinnerley Project Team

System design and development

The temporary filtration system would be both multi-functional and modular in its design. This would give Severn Trent the ability to expand the systems treatment capacity or capability in the future, and also allow the system to be deployed to various sites by its modular design. The design would have to be completely bespoke, as nothing existed in the market to meet the treatment requirements or deployable output required at Kinnerley WTW.

Constrained site

Kinnerley WTW is constrained site in terms of space available for further development. The site is surrounded by agricultural land to the north, south and west, all of which is owned by local farmers. To the east is a single-track road.

Severn Trent appointed Fisher German LLP to explore options for land rental of a field neighbouring the site; with the idea that the land would be rented for the duration of the temporary filter system deployment. After consultation with a local farmer, Severn Trent were able to enter into rental agreement of a field to the south of site, providing much needed space to site the temporary filter system and construction compound.

Kinnerley WTW: Supply chain – key participants

- Client: Severn Trent

- Main design & contractor: Avove

- Land & planning: Fisher German LLP

- Design support: WISP Global Ltd

- Design support: Wood Environment & Infra UK

- Commercial support: Turner & Townsend

- Filter vessels: Charles Thompson ltd

- Filter media: Western Carbons Ltd

- Mechanical: Alpha Plus Ltd

- Precast concrete products: Elite Precast Concrete Ltd

- Blower package: Aerzen Machines

- Booster pump set: Dutypoint Ltd

- Main control panel & remote IO: Blackburn Starling Ltd

- Control & automation: Total Automated Solutions Ltd

- Plug & play connections: Bulgin

- Valves & actuators: Rotork

- Kiosks/enclosures: Pro-tect GRP Enclosures Ltd

- Instrumentation: ABB

- Instrumentation: Hach

(left) Left hand side of the filter gallery and (right) quality instrumentation and flow control – Courtesy of the Kinnerley Project Team

Looking ahead…

The filters are due to enter into supply May 2023, allowing the permanent filters to be isolated from the process stream for replacement of new filters. Bringing the filters online will allow full site output to be maintained for the duration of the works. The full capital maintenance scheme at Kinnerley WTW will commence over the next few months and is due to be completed winter 2024.