South Ferriby Flood Alleviation Scheme (2021)

Installing the sliding flood gate - Courtesy of DC Imaging and (inset) flooding following the tidal surge December 2013 - Courtesy of the Environment Agency

South Ferriby lies on the south bank of the Humber Estuary, approximately 12 miles from Hull. During a tidal surge in December 2013, the existing flood embankments were inundated causing £50m worth of damage by flooding 129 properties, the CEMEX cement plant, 500 hectares of agricultural land and the A1077. Residents were left fearing for their lives in two-foot deep flood water and some residing in temporary accommodation for up to two years. CEMEX also spent tens of millions of pounds on the recovery of their site across four years. The aim of the project is to provide better protection to 150 residential properties, the CEMEX factory and 3,000ha of agricultural land from tidal flooding from the Humber, for up to a 1 in 200-year tidal event.

Overview

A mix of defences have been selected to construct a continuous flood defence across South Ferriby with connections made from earth embankment into sheet piles into concrete flood wall.

Approximately 2.75km of new flood embankments have been installed, 200m of sheet pile walls, 150m of reinforced concrete flood walls, a large 13m wide sliding flood gate, demountable defences across the sluice and some existing defences were strengthened.

West and CEMEX embankments – Courtesy of DC Imaging

Earth embankments

The embankments provided the bulk of the front-line defence of the scheme, stretching in total approximately 2.75km. Close collaboration with CEMEX saw them supply approximately 240,000 tonnes of clay for the embankments from their on-site quarry as their contribution to the flood defence works. The clay was quarried less than two miles from the flood embankment and eliminated the need to import material, significantly reducing the scheme’s carbon footprint. By using this material, the project was made financially viable as over 240,000 tonnes of material was required, and to import would have conceded a great cost. As the material did not align with specification of Series 600 Earthworks, a trial embankment was constructed to understand how the materials would perform once compacted within SHW600 and therefore determine their suitability for use in the engineered flood bund and inform the placement and compaction methods employed.

Scheduled monument – South Ferriby sluice and lock

The South Ferriby sluice is a scheduled ancient monument at the centre of the proposed defences, so solutions had to be sympathetic to the 150-year-old existing structure, which is also a functioning navigational lock. As part of the initial design development, a CFD model was created of the proposed tidal defences where they tied into the lock gates. During high water levels in the Humber, the flow will overtop the existing lock gates with demountable defences erected on top of the sluice to continue the defence and direct the flow into the Ancholme. A 3D simulation was undertaken to understand the weir affect over the lock gates.

The original concept design utilised demountable flood barriers across the main road through South Ferriby either side of the sluice, which would protect properties but allow flood waters to spill onto the road and flow into the adjacent River Ancholme for flood storage. In an aim to ‘build less’ and reduce operational input and disruption to the public during a flood event, existing assets were utilised to become part of the defence.

The existing sluice parapet was already at defence level height and by using SockFix anchors, this was strengthened along the entire length to withstand the flood loads and became part of the defence. This removed the need for two of the flood barriers across the road.

Drone image of pile installation – Courtesy of DC Imaging

Flood gate

The third concept design demountable defence across the A1077 road at South Ferriby was sited just west of the CEMEX plant. Through design development this was changed to a sliding flood gate across the A1077. The benefits of changing the solution greatly reduces deployment time in a flood event and minimises manual handling and working at height risks when installing and removing the flood defences. The construction of the concept design also forecast several weeks of full road closure requiring residents to take a 30-mile diversion route which received large numbers of objections. The design and construction team were therefore challenged to come up with a solution which would allow the gate install to be completed in a maximum one-week road closure.

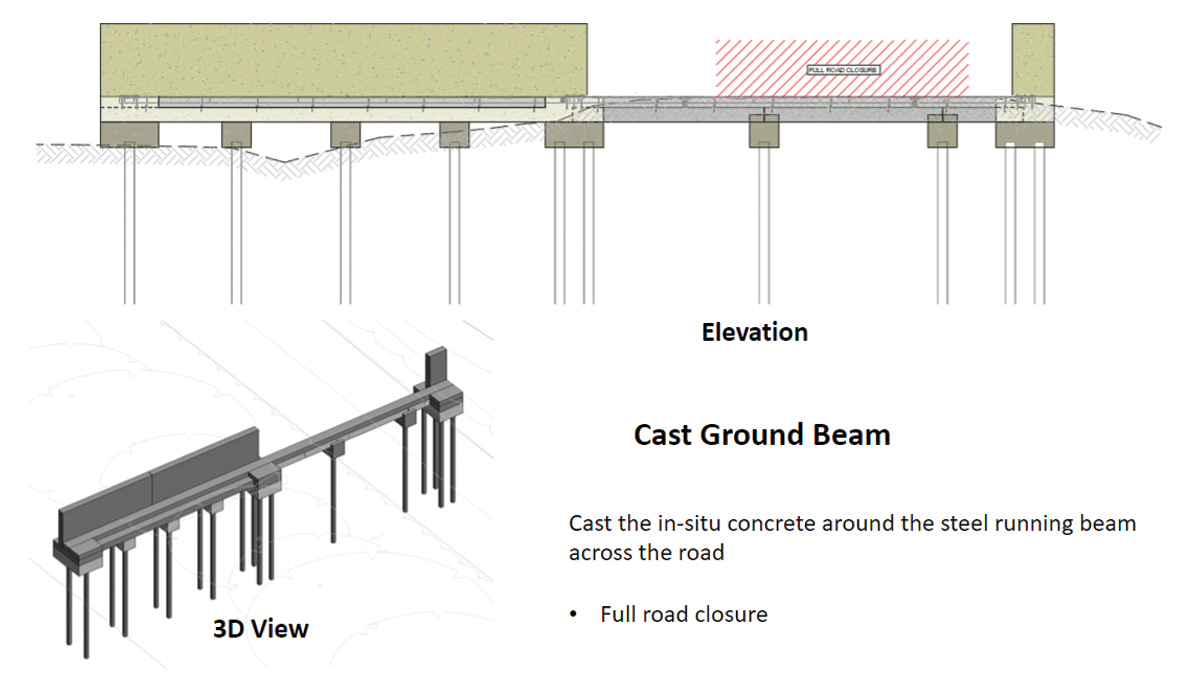

With the constraints of soft underlaying ground conditions and small tolerances for the gate running rail, a piled foundation was preferred to prevent settlement and allow much of the works to be undertaken outside of the highway. A beam was cast in situ across the road supported on two bearing piles located in the centre of each lane, avoiding the services and enabling the work to be completed under a lane closure of either carriageway.

Working collaboratively between the designers, construction team and the specialist piling and flood gate suppliers, a construction phasing plan was produced utilising the 3D model of the gate and foundation followed by interactive virtual design workshops to modify and streamline the design. During these sessions clashes between the reinforcement and running rail fixings were identified and design modifications undertaken. A detailed planning session was then held with each layer of the 3D model split out in sequence to create a visual programme aid.

Sliding flood gate – Courtesy of JBA Bentley

During the one-week road closure, the remaining work involved removing the temporary road surface, installing and casting in the running rail, installing the gate posts, lifting the gate into position and commissioning and training operatives on how to deploy the new gate.

The adjacent road surface either side of the gate was then removed and re-profiled up to the new running rail. The detailed planning and collaborative interaction in advance of the works culminated in the successful installation of the foundations and gate within the tight schedule.

Modelling technology

The scheme was modelled through Civil 3D and Revit to provide visualisations of the extent of the scheme for clients and locals, encouraging engagement and buy in. The suppliers also were able to share their models so that the construction could be meticulously planned during the challenging programme for the construction of the flood gate to minimise disruption to the local community. The model also allowed us to accurately forecast the materials required to construct the embankments, due to the material being supplied by the CEMEX plant, there was a limited opportunity to secure the required volume of material to be able to complete the scheme.

Flood gate phasing plan extract – Courtesy of JBA Bentley

South Ferriby FAS: Supply chain – key participants

- Design & construction: JBA Bentley (JBA Consulting and JN Bentley joint venture)

- Structural design support: Stirling Maynard

- Bird monitoring: Cutts & Hemingway

- Demountable suppliers: IBS Engineered Products

- Flood gate suppliers: Flood Control International

- VRS suppliers: Arbus Ltd

- Telemetry supply: Circle Control & Design Systems

- Sockfix anchor suppliers: Peter Cox

- Fencing suppliers: Burn Fencing

- Ground investigation: Dunelm Geotechnical & Environmental Ltd

- Bottom driven piles: Green Piling

- Archaeological surveys: Wessex Archaeology

Challenges of the scheme

Throughout the scheme a temporary line of defence had to be maintained to ensure that the residents of South Ferriby remained protected, as well as building flood walls within a tidal environment. There were also significant ecological constraints due to the works being adjacent to the Humber Estuary SSSI and a Daubenton bat maternity roost, as well as water voles and other protected species. Under agreement from Natural England the works had to be programmed to meet prescribed ‘working windows’ to avoid disturbance to the various species.

Local liaison

Throughout the scheme the Environment Agency and JBA Bentley worked with South Ferriby Parish Council providing fortnightly updates that were published on their website to keep local residents informed of the scheme’s progress and any planned traffic management. Compensatory tree planting will provide the locals with an orchard. Public Engagement events were held to engage with residents on scheme developments and understand any concerns surrounding the works.

Protecting properties – Courtesy of DC Imaging

Conclusion

The works were completed in July 2021. Through the challenges of the Covid-19 restrictions and environmental constraints, the team have delivered the project on programme and below target cost.

Through improving existing assets where possible there has been both commercial, time, and carbon savings from the original outline design. The collaborative approach between the client and JBA Bentley, suppliers and consenting bodies has provided a great result helping the Environment Agency reach their target of 300,000 homes better protected.