Stratford St Mary Pumping Station (2020)

Stratford St Mary Pumping Station - Courtesy of NWG

Stratford St Mary Pumping Station is situated adjacent the River Stour in Suffolk. Following an Act of Parliament in 1935, the pumping station was constructed to allow 164 Ml/d of river water to be abstracted and is the primary source of raw water to Abberton Reservoir near Colchester in Essex. The pumping station is owned and operated by Essex and Suffolk Water (ESW), part of the Northumbrian Water Group (NWG). Raw water supplied to the Essex area via the Stour is supplemented by operation of the Environment Agency’s Ely Ouse to Essex Transfer System (EOETS), which transfers surplus water (otherwise lost to sea at the Norfolk Wash) to Essex via a series of man-made watercourses, underground pipelines and natural river channels. Demand from the pumping station varies with season but has a maximum daily abstraction licence of 164 Ml/d and is usually in operation most days of the year. The pumping station is key in ensuring the supply of raw water in North Essex and subsequent potable water supplies fed directly from the company’s Layer Water Treatment Works.

Existing plant, challenges and issues

Since its construction, many changes and upgrades have taken place but fundamentally, the pumping station exhibited several major issues which, mainly due to age and condition, affected the ability to achieve reliable maximum licensed abstraction. The key issues were:

- HV substation situated in the building basement (below high river level) and at high risk of flooding.

- 11kV switchgear almost 40 years old, obsolete and with safety issues.

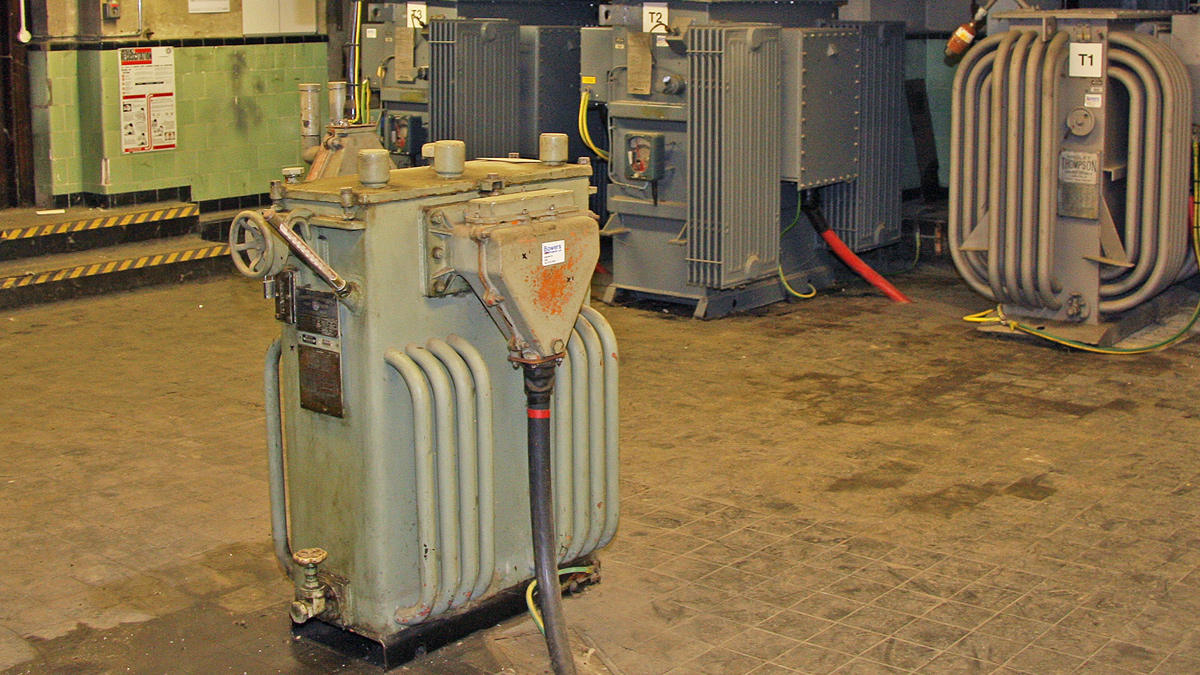

- Five individual pump transformers plus a sixth for building services, the oldest being 1927 and newest 1998.

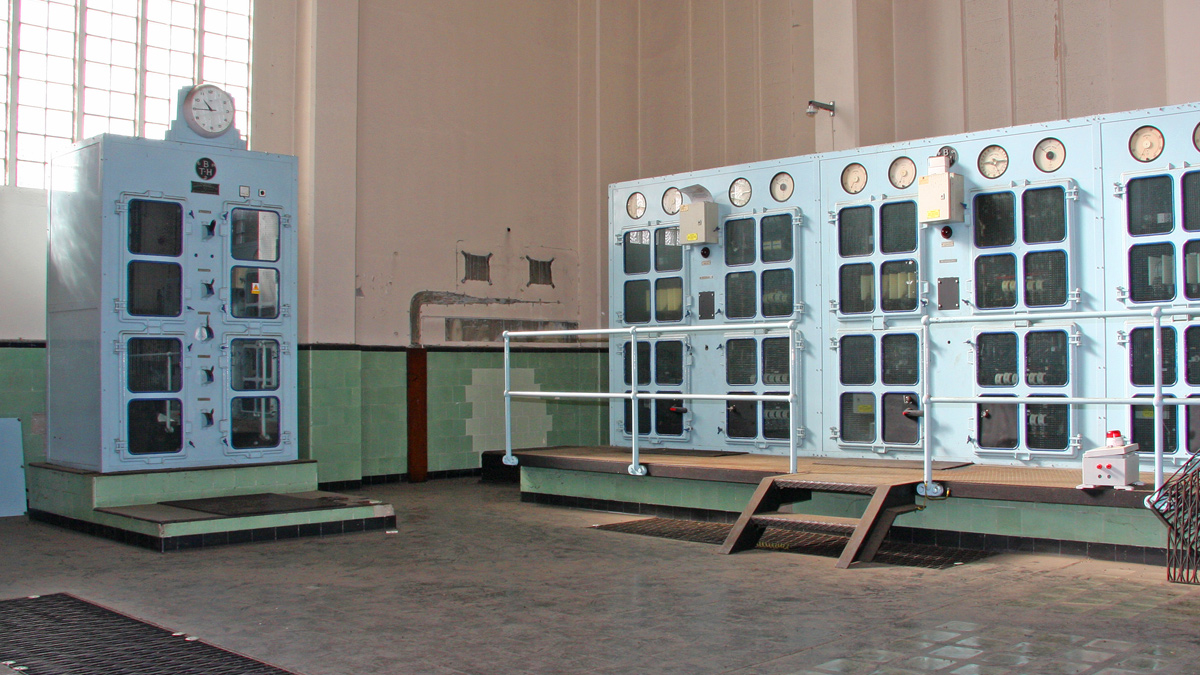

- Age, condition and spares availability for pump starters of which two are operated at 3.3kV via auto transformers, two which are LV soft-starters and one which is a variable speed N-S machine.

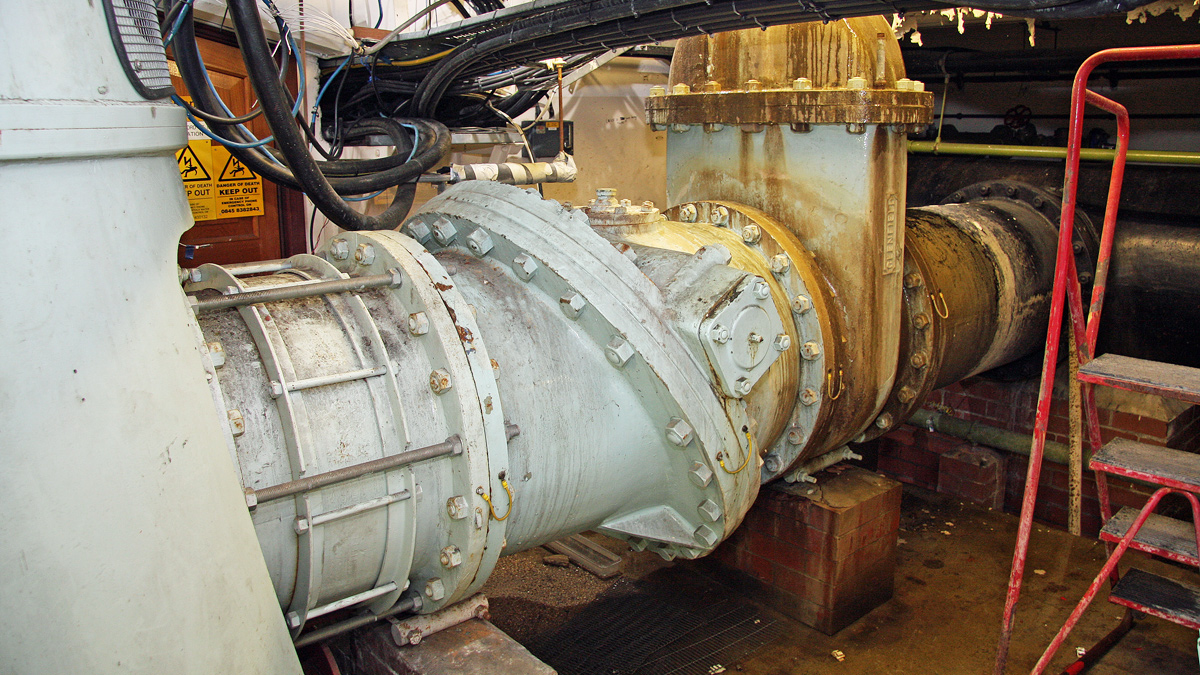

- Age, condition and spares availability for the existing Harland pumps. Three are 1939 suspended bowl types, and two being 1952 volute type with suspended suction and priming systems. The priming system itself was unreliable along with the gland cooling water system.

- Ageing rotating intake bandscreens which do not comply with new regulations.

Existing HV substation in basement – Courtesy of NWG

Investigate and define

Following on from the successful upgrade of two similarly aged treated water pumping stations, Langham and Tiptree, in 2017/18, NWG’s framework partners Integrated Water Services Ltd (IWS) were once again engaged as principal designer and contractor. A significant amount of I&D had already been completed prior to commencement any pumping station work as the original plan had been to let the contract jointly for all three stations. This enabled the Stratford project to get off to a fast start due to the existence of an outline design.

Fundamental to station design is the choice of pumpsets. The original equipment was a mix of variable speed and fixed pumps but had only been able to operate as fixed speed units in recent years due to failure and obsolescence of the drives and various motor changes meaning that operating philosophy was heavily based on on/off increments of abstraction.

The pumping station upgrade gave the chance to re-evaluate abstraction philosophy and a pump selection study was carried out at the commencement of the project which considered hydraulics, efficiencies, CAPEX, OPEX, and whole-life costs. It was decided to install four new pumps in duty/assist/assist/standby configuration, with one variable speed and one fixed speed unit on ‘each side’ of the station (there being two distinct cross-coupled delivery mains). The station can therefore achieve maximum flexibility under varying river conditions providing a wide range of flows from approximately 20 Ml/d to the licenced abstraction limit of 164 Ml/d. This approach was reviewed and agreed technically with NWG Operations & Networks and the project sponsor.

Existing pump control equipment – Courtesy of NWGWG

Electrical power supplies

The site is fed by a single 11KV REC incoming supply originally to an ageing Whipp & Bourne high voltage switchboard located in a below ground-level substation. This in turn fed six individual pump and building services transformers, two of which transformed to 3.3KV to run a pair of the old pumps. It was decided to replace this with a more conventional distribution system located in a new substation above flood level.

The revised HV switchgear system comprises an 11KV Schneider Genie Evo Incomer plus twin transformer feeder sections into a pair of Schneider DCU 11000/433V transformers. These in turn feed a Form 4 Type 2 constructed LV split-board power distribution board (PDB) from Max Wright. Various options were considered for the sizing of both transformers and PDB to enable maximum licenced abstraction of 164 Ml/d as well as best abstraction in the event of a single transformer or switchgear feeder failure. A choice of 1500KVA transformers and a 2500A PDB was made to enable full abstraction, with three pumps and a reduced 130 Ml/d on a single transformer/feed utilising two pumps. The design includes some reserve capacity to allow restricted operation of three pumps under a fault condition to gain a further 20 Ml/d output.

Existing 1939 and 1952 pumps – Courtesy of NWG

Some fundamental choices had to be made regarding positioning of this new system. At the I&D stage it was envisaged that both switchgear and transformers would be situated inside the pumping station either on the upper floor or on a new mezzanine level and that due to the inside location, resin-insulated transformers be used to minimise the risk of oil spillage issues in the event of a fault. Previous experience of resin transformers with heat, noise and efficiency issues suggested that this was less than ideal, yet positioning traditional oil filled units outside would be difficult due to available space and visual impact on the village which is situated within an Area of Outstanding Natural Beauty.

A degree of brainstorming resulted in a novel approach of fitting traditional oil filled transformers outside to the rear of the pumping station on an elevated platform behind the main structure, hence having minimal visual and noise impact whilst gaining the advantage of natural cooling and better efficiency. A fully bunded and alarmed oil catchment system is installed in the event of transformer coolant issues. Additionally, close positioning of the transformers adjacent the internal PDB has resulted in significant reduction of LV feeder cables with significant CAPEX saving.

New transformer location – Courtesy of NWG

Stratford St Mary Pumping Station: Supply chain – key participants

- Principal contractor/designer: Integrated Water Services Ltd

- Systems integrator: OCE Systems Ltd

- Pumps: Flowserve

- HV switchgear: Schneider Electric

- Drives: ABB

- MCC/PDB: Max Wright

- Eel screens: Hydrolox

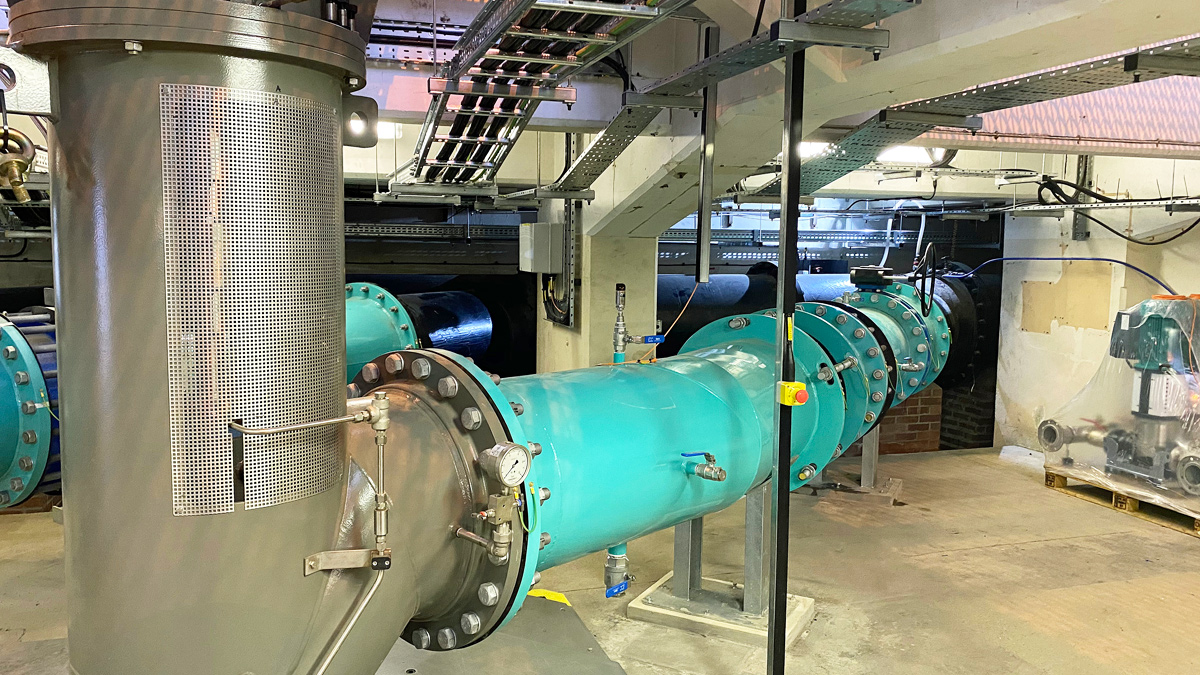

Ageing pipework and valves – Courtesy of NWG

Pumpsets and drives

For consistency and familiarity for maintenance, Flowserve 27ENM vertical turbine pumps were chosen for the project. Similar pumps at the Abberton Reservoir Off-take Pumping Station have shown good reliability and a suspended bowl in a wet well approach means that there is no requirement for pump priming; removing one of the main issues with the old arrangement. Individual pump and impeller sizes were selected to provide 54.67 Ml/d flow at a 50m system head, verified during factory acceptance testing at 86.3% efficiency. All pumps and motors are fitted with pressure/flow/bearing protection and monitoring plus dual axis vibration sensing monitored remotely via the Ethernet enabled communications system all of which alarm via the company’s SCADA system in the event of any issues.

The new variable speed drives are low harmonic 500KW ABB ACS800 series types, consistent with many other drives across NWG, which fall under the ABB service & maintenance agreement already in place within Essex. Control and monitoring is via an industrial Ethernet and the installation includes Allen Bradley Point IO modules to facilitate bearing temperature and vibration monitoring from the pumpsets.

The new soft-start units are 450KW 850A Eaton S811+V85P3S types with internal bypass contacts. The installation includes power factor correction and a similar arrangement of Allen Bradley Point IO modules to handle bearing temperature and vibration monitoring.

New pump arrangement – Courtesy of NWG

Intake screens

The raw water inlet to the site is directly off the River Stour via two ageing 6mm mesh rotating bandscreens operating in duty/standby operation with a removable vertical debris bar screen in each channel. On 15 January 2010, The Eels (England and Wales) Regulations 2009 came into effect which requires that any structure capable of abstracting at least 20m3 of water through any one point in any 24-hour period must adequately protect the life stage of eels present at that abstraction point. Consequently, the Regulations apply to a number of raw water abstraction points owned and operated by ESW, including Stratford St Mary whose abstraction point is located within 30km of the coast and therefore it is determined highly likely that juvenile eels (elvers) are likely to be present. To prevent this life stage of eels being drawn into the intake structure and becoming killed or trapped, ESW are required under the Regulations to install appropriate screening measures as set out in the Environment Agency’s (EA) document ‘Screening at intakes and outfalls: measures to protect eels’.

Existing rotary bandscreens – Courtesy of NWG

To date, Stratford is the third installation in the Essex region at which an eel-friendly screen was required to be installed. Given the life stage of eels that are to be protected and in line with EA best practice, a 2mm mesh aperture is required with a maximum allowable approach velocity flow of 25cm/s. With the available water depth and consistent with other ESW installations, a Hydrolox S1800 positive exclusion rotating screen was selected. The existing old screens were positioned inside a stand-alone building with mass concrete poured apertures which were physically unsuitable to accommodate the new screens and would not satisfy approach velocity requirements under the Regulations. It was therefore necessary to mount the new screens externally into the river. Unlike previous ESW installations, there is no concrete apron protruding onto the riverbed and a dive survey was carried out to establish the topography. The initial design proposal was a complex 3-screen solution supported by concrete supports set into the riverbed. Subsequent review by the project team enabled a more manageable and cost-effective solution whereby the screen is cantilevered off the existing bandscreen building giving the following advantages:

- Incursion into the river is reduced from 3.19m to 1.85m.

- No cofferdam or dewatering required during construction.

- No dredging, meaning minimal riverbed and ecology disturbance with installation achieved by divers.

- Abstraction can continue during installation without need for over-pumping of water.

The revised design allows fitting larger screens hence reducing the number from three to two whilst maintaining the capability to meet abstraction licence flows and approach velocities. Wash water to the screens is via an in-line strainer fed from the station output delivery pipes supported by a duty/standby booster pump arrangement when pressure is insufficient. A support frame/walkway was fabricated off-site and installed prior to screen arrival and install. Power to, and control of, the screen is provided from a Form 4, Type 2 motor control centre (MCC) in an adjacent GRP kiosk, containing two variable speed drives (VSD) to power the screen motors and electrical supply to the washwater booster sets. The MCC also incorporates an ICA section with local HMI screen with an Ethernet connection to main site PLC.

The new Hydrolox eel screen installation – Courtesy of NWG

Infrastructure enhancements

Whilst carrying out this major refurbishment, the opportunity was taken to replace or update some other equipment and functions carried out at the site, namely:

- Replacement of two (one per line) original venturi delivery flow meters with Siemens Sitrans electromagnetic flow meters to conform to MCERTS requirements.

- Actuation of existing external delivery/bypass valves. At times of low river level and/or poor river quality, raw water can be pumped in reverse direction from Abberton Reservoir to nearby Langham WTW simultaneously with intake water pumped forwards to Abberton by careful operation of the twin delivery pipeline valves. Facilitating remote valve control over SCADA will significantly lessen the manual input required by operational staff.

- Installation of replacement site PLC and SCADA interface with Allen Bradley/Rockwell Compact Logic PLC, associated remote Point I/O, Panelview HMI screens and managed Ethernet switches.

Suspended bowl vertical turbine pump – Courtesy of NWG

Conclusions

The project has performed well with construction continuing to schedule despite the emergence of the COVID-19 pandemic and the station having to remain in service throughout the period of refurbishment works. The scope of supply has captured and significantly enhanced the key components of the pumping station which, along with lessons learnt from previous refurbishments and eel screen installations, were incorporated into the Stratford design to provide a mix of innovative and established technologies. With predominantly the same client/contractor team throughout the ‘North Essex 3’ projects (Stratford St Mary, Langham and Tiptree Pumping Stations), it has been a great example of collaboration to achieve a resilient and reliable asset to ensure water supply in Essex for the foreseeable future.