Tideway East – TBM Delivery (2021)

TBM Selina being transported on the Ravestein BV Skylift 3000 jack-up barge - Courtesy of Tideway

The Thames Tideway Tunnel is a new storage and conveyance tunnel running through the centre of London, mostly under the River Thames. The main tunnel, which is approximately 25km long with an internal diameter of 7.2m, will run from Acton in the west through to Abbey Mills in the east. The project has been split geographically into three main construction contracts, which correspond to the anticipated tunnelling conditions beneath the capital. The East section is the deepest part of the project, reaching depths of 65m and runs 5.5km from Chambers Wharf in Bermondsey to Abbey Mills Pumping Station where it will connect with the Lee Tunnel; ultimately transferring flows to Beckton Sewage Treatment Works. The East section also includes a 5m internal diameter connection tunnel of around 4.5km running from Greenwich Pumping Station to the main tunnel at Chambers Wharf. This paper focusses on the delivery of tunnel boring machine Selina to the East section main tunnel launch site.

Background

Perhaps one of the most complex engineering tasks in any tunnelling project is the delivery and installation of the TBM shield to the drive site. With smaller diameter TBMs, it is often possible to deliver the shield whole or in larger assembled sections. However this is not usually possible for larger diameter TBMs, as the size and weight of the various major components (cutterhead, main bearing, erector, shield sections, etc.) can make it impractical or impossible to deliver the shield whole, or even partially assembled.

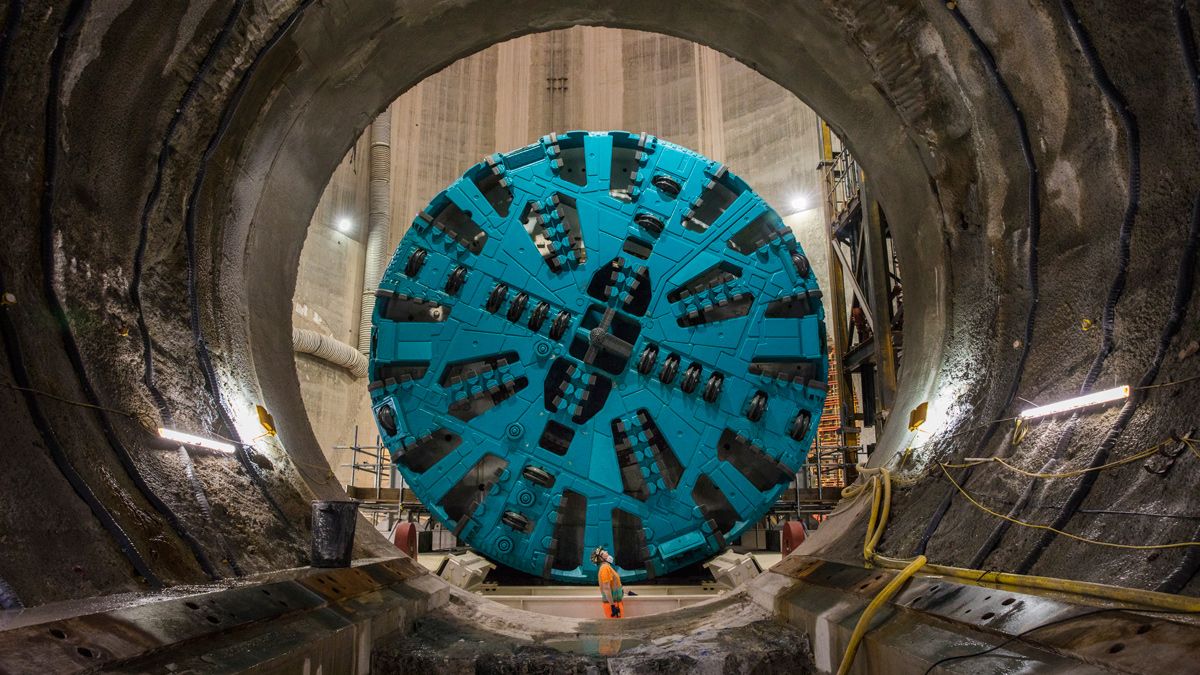

Close up of the cutterhead on Herrenknecht TBM Selina – Courtesy of Tideway

Chambers Wharf site

Owing to the Chambers Wharf site being on the River Thames and located down stream of Tower Bridge, the opportunity to deliver the shield of the TBM in its entirety was not possible. It was, however, practical and in-line with the Tideway strategy of maximising delivery by river. Post factory assembly and testing, the shield and back-up were relocated from Schwanau in Germany to the Port of Rotterdam, ready to be easily loaded onto a sea-going and river-going vessel for delivery to the UK.

This was to be a unique challenge, however; how do you safely and efficiently design, procure and execute the delivery of nearly 900 tonnes of TBM shield from Rotterdam, the busiest port in the Europe, across the North Sea, which is one of the world’s busiest for marine traffic, into central London, which has one of the world’s most recognisable rivers and sights?

Delivery

The TBM supplier Herrenknecht had a close working relationship with Mammoet, who are renowned across the globe for being able to lift and shift large plant material. As such, Mammoet was a good choice to execute both the delivery of the TBM and the lowering of it into the shaft. In addition to their key role, the delivery would require a number of bespoke engineering solutions to be developed, as well as detailed planning and collaboration with the river regulators, and engagement with a multitude of stakeholders to ensure success.

Consideration of the delivery had been embedded in the design of various elements of the site: the height of the flood defence was to be maintained, the gantry crane and acoustic enclosure structural envelope was to allow delivery under or over in addition to its longer term purpose and the main door of the acoustic enclosure was designed to accommodate the delivery in multiple ways. Mammoet and CVB developed two concept delivery options:

- Option 1: Delivery of the shield and gantries 1 & 2 on a standard barge, with lifting to the site by an 1800 tonne capacity marine crane, lift over the site gantry crane structural envelope and strand-jacking to shaft.

- Option 2: Delivery of the shield and gantries 1 & 2 on a 3000 tonne jack-up barge with a direct drive off via SPMT onto the site, with sufficient height under the site gantry crane structural envelope and strand-jacking to shaft.

Both methods were put into value engineering assessment and although the marine crane option was technically the more favourable option, as it required less engineering solution development to the site, it was not chosen as the size of the vessel and the disruption its operation would cause to the river traffic on the Thames was not acceptable to the Port of London Authority.

(left) Herrenknecht TBM Selina at Chambers Wharf and (right) adjacent to the cofferdam at Chambers Wharf – Courtesy of Tideway

Chosen option – engineering challenges

Delivery using the Ravestein BV Skylift 3000 was put into detailed planning and engineering design development. Notable engineering challenges that needed assessment and solution development were:

- Design of the passage from Rotterdam to Chambers Wharf, including considerations of the TBM sea fastenings, tidal performance, weather and dimensions of the Skylift passing under the London City Airport TO/LD paths, through the Thames Barrier and beneath the Emirates Skyline cable car.

- Detailed design of the Skylift sail in, mooring and jack up against the cofferdam with special consideration for the position and height of the gantry crane structure and effects of tidal flows and weather,

- Assessment of the cofferdam performance with the Skylift spud legs driven into the riverbed and then subsequent performance post removal (including embedment depths, possible settlement and the need to backfill the penetration post leg removal),

- UXO and archaeological surveys to confirm spud locations were not at risk of encountering UXO or missed archaeological items,

- Assessment of the roll on-roll off (RO-RO) ramp from the Skylift deck to the cofferdam and its bearing loads against the cofferdam bearing capacity and the on-deck performance of the barge,

- Assessment of the floating and jack-up levels of the Skylift to permit sufficient clearance to the underside of the gantry crane structure, but also permit allowable height and RO-RO ramp grade.

- Design, installation and operation of a flood defence gate which was to maintain the cofferdam flood defence height but also permit the RO-RO ramp to be installed and utilised.

- Bearing capacity of the cofferdam for the TBM shield, cradle and SPMT loadings for drive off and transition to the installation position.

- Structural assessment of the shaft capping beam and shaft permanent secondary lining to sustain the strand-jacking system loadings during the lowering operation.

Herrenknecht TBM Selina being transported on the Ravestein BV Skylift 3000 jack-up barge – Courtesy of Tideway

Overcoming regulators’ concerns

Detailed planning and engineering assessments for the delivery commenced in late autumn of 2019 and close engagement and collaboration with the river regulators (the Environment Agency, the Marine Management Organisation, and the Port of London Authority), being undertaken throughout the planning and design phase. The key engineering issue that was prevalent with all three regulators was spud leg penetration into the riverbed. The concerns raised by the regulators included:

Performance of the cofferdam with the spud legs installed into the riverbed:

- To what depth would they penetrate? How would that affect the cofferdam bearing capacity?

- Would the legs penetrate deep enough to create sufficient bearing capacity for barge stability?

- If the legs penetrated deeper, could it cause a pathway to an underground aquifer?

Performance of the cofferdam once the spud legs were removed from the riverbed:

- Backfilling the penetrations or leaving them to naturally close with tidal movements?

- What materials would be suitable for the backfilling & what pollution could the backfill cause?

- How would CVB guarantee backfilling would not cause obstruction to marine traffic?

All these concerns were valid and the performance of the spud legs and cofferdam were easily assessed as suitable, however there was not a consensus between the regulators as to whether to backfill, how much to backfill or what backfill material should be utilised. Reaching a final solution that was agreeable to all three regulators required negotiation and further design input from WHP, with the eventual solution being to backfill the two penetrations closest to the cofferdam with washed single size river aggregate. In early summer 2020, consent for the delivery was agreed by the regulators.

Herrenknecht TBM Selina at Chambers Wharf – Courtesy of Tideway

Tideway East TBM delivery: Supply chain – key participants

- Client: Tideway

- Principal contractor: CVB

- Costain

- Vinci Construction Grands Projets

- Bachy Soletanche

- Client representative: Jacobs

- TBM supplier: Herrenknecht

- TBM delivery subcontractor: Mammoet

- Jack-up barge subcontractor: Ravestein BV

- Marine tug subcontractor: S Walsh & Sons

- Cat 3 checker: Wentworth House Partnership

- CVB TW designer: OTB Engineering

- CVB principal designer: Mott MacDonald

Transportation timetable

The Skylift departed Rotterdam on 7 July 2020 and arrived at Coldharbour Jetty at 12:30 on 8 July. The SkyLift then departed at 14:30 and sailed up the River Thames, arriving at Chambers Wharf at 17:00 where it was temporarily moored. On 10 July the Skylift was repositioned and jacked up into the off-load position and removal of the sea fastening commenced. At 14:15 on 11 July, TBM Selina was driven over the RO-RO ramp and onto the Chambers Wharf Cofferdam where it was temporarily stored until the shaft and launch adit were ready for lowering and installation.

Delivery of the TBM shield and gantries 1 & 2 was planned for late June/early July, however due to the COVID-19 pandemic, work at Chambers Wharf to prepare for the arrival and lowering had been delayed due to the national lockdown and then subsequent slow return to work with COVID-19 control measures implemented. This meant that the lowering of the TBM was postponed until the middle of August whilst the sprayed concrete lining activities to prepare the launch adit were being undertaken.

Detailed planning and engineering assessments for the strand-jacking system in parallel with the delivery required a review of the systems performance as well as the bearing capacity of the shaft and cofferdam to support the operation. During planning, it became apparent that an outstanding NCR relating to the secondary lining works was going to have a significant influence on the system and its performance.

Herrenknecht TBM Selina was successfully lowered to the bottom of the shaft at Chambers Wharf – Courtesy of Tideway

The shaft secondary lining was constructed using a double-sided slip formwork that was raised up the shaft. This method produced an annulus gap between the shaft primary lining and secondary lining that was to be filled with structural grade concrete to provide confinement. Unfortunately, during the final stages of this work, a substantial non-conformance meant the annulus could not be filled to the top of the secondary lining.

Investigation and subsequent review of potential remedial actions had commenced, however the programme for lowering the TBM was now at risk, so a decision was taken to halt remedial works in relation to the NCR and implement a review of the un-confined secondary lining to sustain the strand-jacking system loadings.

Detailed investigation and analysis were conducted between Mott Macdonald, OTB and CVB and a new temporary works solution was devised to resolve the situation promptly. The solution involved a steel stool being fabricated and placed in fixed bearing locations along with an anti-bursting dowel being drilled into the lining below to sustain the temporary loading. This solution proved to be quite effective and easily installed, mitigating the programme risk and allowing the strand-jacking system to be installed.

Mammoet mobilised again to Chambers Wharf on 7 August and the TBM was successfully lowered on 28 August 2020.