Childrey Warren WTW Abstraction Closure (2019)

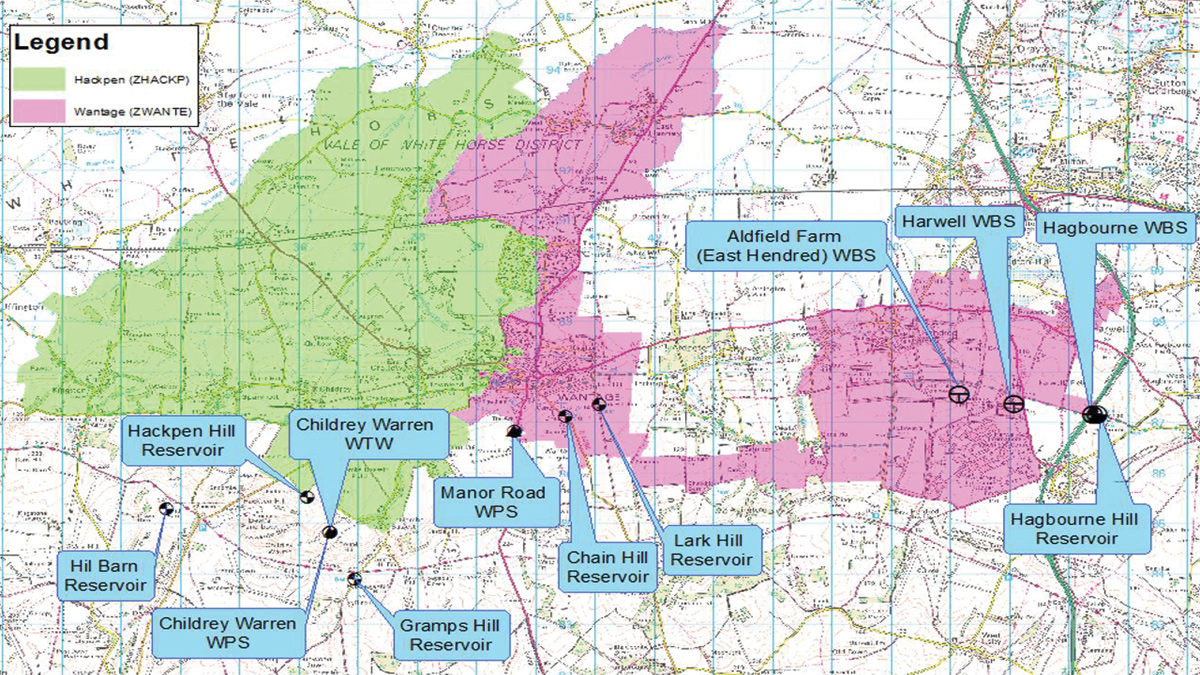

Figure 1 – Overview of Hackpen & Wantage supply zones - Courtesy of SMB

During AMP4, Thames Water Utilities Ltd (TWUL) undertook low flow investigations for the Letcombe Brook, in the Wantage area (Oxfordshire). It was determined that the abstraction at Childrey Warren Water Treatment Works (WTW) was having an adverse impact on the river flows and the local environment. A subsequent review of options which included augmentation, works closure and river remediation identified the most cost beneficial to be the full cessation of abstraction at Childrey Warren and utilisation of available resource within the wider SWOX (Swindon and Oxford) Water Resource Zone. Under the National Environment Programme this resulted in an agreement between TWUL and the Environment Agency that abstraction would cease by the end of AMP6 (March 2020). Closure of the works as an abstraction site was promoted and subsequently supported within the TWUL PR14 Business Plan.

Childrey Warren supply zone

Childrey Warren primarily supplies the western parts of the main demand centres of Wantage and Grove via Hackpen Hill Reservoir. Two significantly smaller reservoirs (Gramps Hill and Hill Barn) are also supplied from Childrey Warren via high lift pump sets at the site. The eastern parts of Wantage and Grove are supplied from Manor Road WTW and Hagbourne Hill Water Booster Station (WBS) via Lark Hill and Chain Hill Service Reservoirs. An overview of the Wantage and Hackpen supply zones and operational sites are shown in Figure 1 (above).

Optioneering

The optioneering for the scheme began in early 2017, developing on the business plan proposal for a circa. 7.5km new potable water cross-country pipeline in the western part of the network, providing capability to transfer additional water between the Wantage and Hackpen zones. A pipeline route assessment was completed, culminating in a final route alignment between Lark Hill reservoir and Childrey Warren WTW (6.1km) being put forward for an Environmental Impact Assessment (EIA) Screening Opinion to the Vale of White Horse District Council in late 2017. This was returned in early 2018 confirming a full EIA was not required, although significant archaeological investigation works would be undertaken as part of the mitigation works prior to main construction activities taking place.

Modelling and design

Hydraulic modelling and outline design was completed in parallel to the route assessment to confirm pumping requirements throughout the network. The assessment concluded that the new pipeline could be operated as a gravity system from Lark Hill to Childrey, with a new WBS located at Childrey to boost water on to Hackpen Reservoir via the existing network, as is currently undertaken by the Childrey borehole pumps. The Wantage and Hackpen zones are due to see a significant rise in demand over the coming 25-year project design horizon, with an increase of approximately 5,600 households in addition to the existing 12,700.

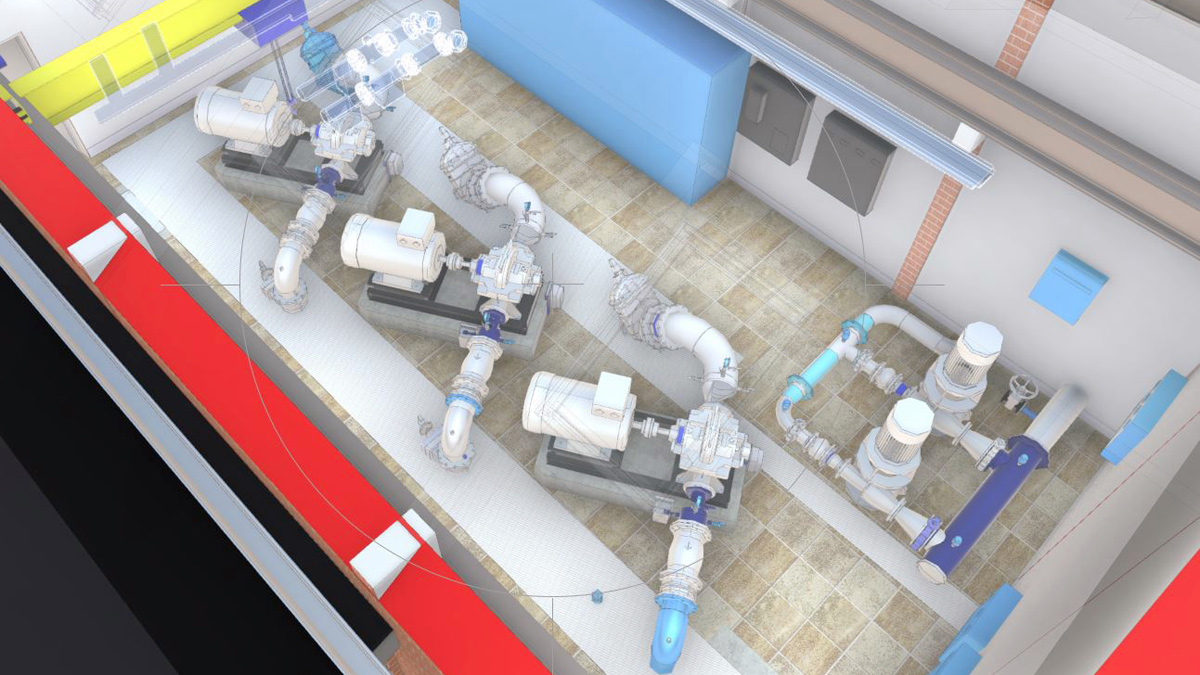

For sufficient water to be available to supply the current and future demand a key component of the scheme would be to significantly increase the operational capacity of Hagbourne Hill WBS. An overview of the full scheme solution can be seen in Figure 2 (below).

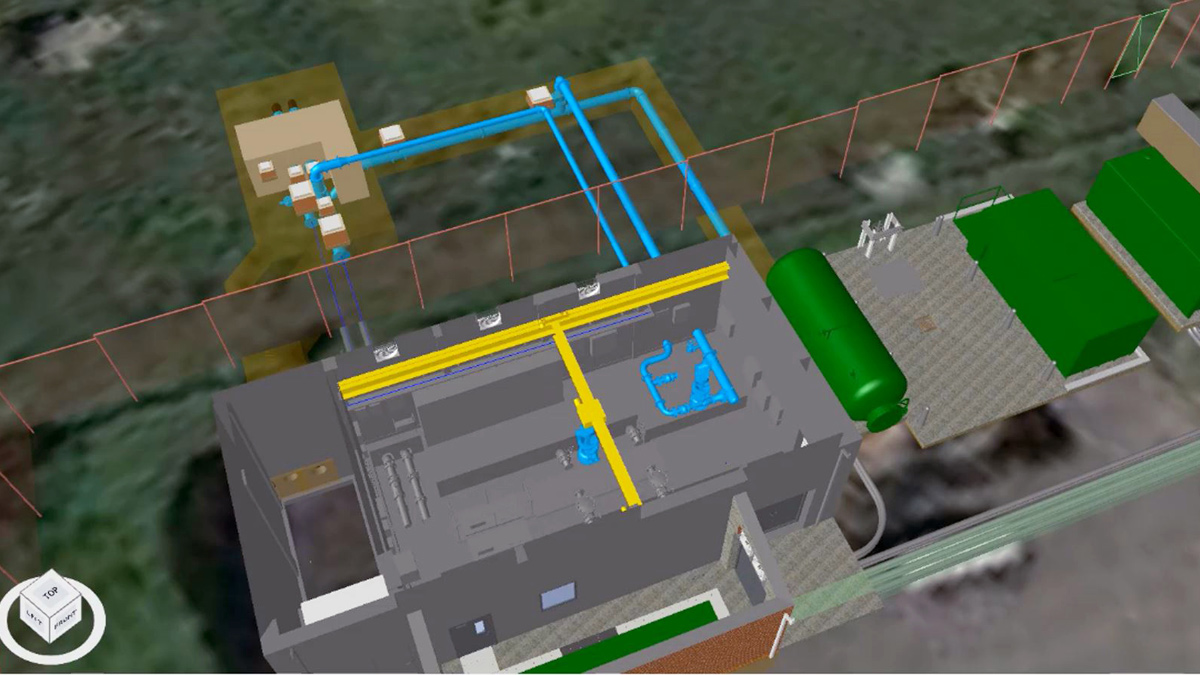

Hagbourne WBS BIM model proposed layout – Courtesy of SMB

Undertakings

The scheme forms part of the design and build programme of works being delivered through eight2O, an alliance formed to deliver capital investment works for TWUL through AMP6.

SMB (Skanska, MWH Treatment, and Balfour Beatty), one of the two joint ventures within eight2O, are responsible for delivering the scheme and act as both principal designer and principal contractor.

Detailed design of the full system was undertaken throughout 2018 to enable a five-month archaeological investigation programme to begin on site in August 2018. A Professional Services Contract was awarded to Bridges Ltd to undertake detailed design of the MEICA works as an extension to the Stantec project design team.

Main works tender packages were prepared and sent out to the market in late 2018 for a planned start on site date of April 2019.

Bridges contract scope was extended to undertake the supply and installation of all MEICA works and J Browne Construction Ltd were appointed to deliver the civils scope across the scheme.

Childrey Warren WTW Abstraction Closure: Design phase supply chain

- Client: Thames Water Utilities LTD

- Principal designer/contractor: SMB JV (Design consultancy – Stantec UK)

- MEICA coordinator: LJR Engineering

- MEICA ECI subcontractor: Bridges Ltd

- Civils ECI subcontractor: J Browne Construction Ltd

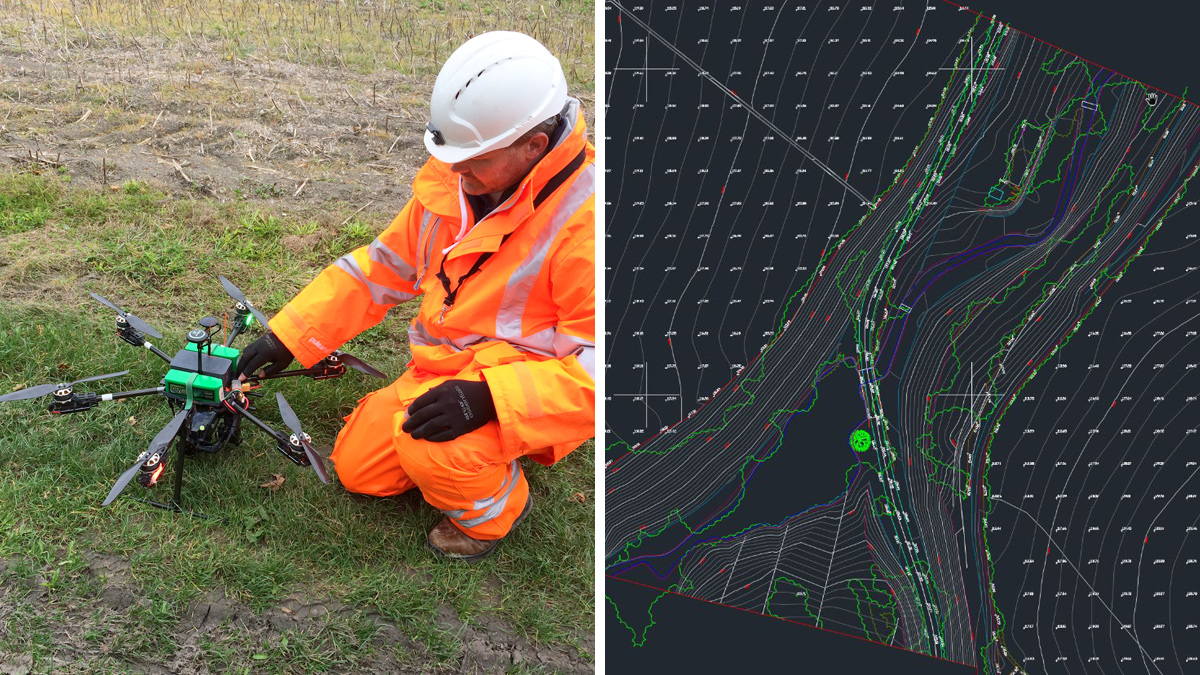

- Drone Surveying: DroneTech Aerospace

- Photogrammetry: Atkins Geomatics

- HPPE Pipe: Aliaxis UK (formerly GPS PE Pipe Systems)

Hagbourne WBS point cloud model – Courtesy of SMB

Project scope

Pipeline between Lark Hill Reservoir and Childrey Warren WTW: New 6.1km 450mm OD SDR17 HPPE gravity pipeline. The pipeline route crosses predominantly agricultural land via open cut method. The route incorporates 3 (No.) horizontal directional drill (HDD) sections totalling approximately 630m.

The HDD method is to be utilised to cross the A338, Letcombe Brook/Bassett Road and Holborn Hill Road.

A route corridor appraisal was undertaken which considered a suite of environmental, third party, engineering and construction constraints that formed the basis for identifying potential pipeline route corridor options. The route corridor appraisal approach embraces sustainability principles in that it takes account of social, economic and environmental factors to achieve a balanced outcome.

Route options were considered linking Lark Hill reservoir direct to Hackpen Hill reservoir as a pumping main, siting the new WBS at Lark Hill reservoir. Subsequent to further reviews and assessment the final route option to Childrey was chosen based on minimising overall construction impact (reduction by approximately 1.5km route length) and utilisation of existing site infrastructure at Childrey Warren WTW for the new WBS which includes HV power supply, on-site back-up generator and access for maintenance.

The new pipeline will operate as a dedicated transfer trunk main between Lark Hill and Childrey, extending the existing Hagbourne to Lark Hill system. The design of the pipeline incorporates on-line ancillaries including line valves, washouts and air valves.

(left) Survey drone and pilot and (right) topographical survey output – Courtesy of SMB

The detailed topographical survey of the route alignment was completed by drone survey, undertaken by DroneTech Aerospace and photogrammetry completed by Atkins Geomatics. Utilising drone technology for the survey in this instance has yielded significant benefits over traditional surveying techniques, such as average easement survey widths of 100m compared to 30-50m (particularly in areas difficult to access such as the Letcombe Brook valley) and collation of the latest HD imagery for the area compared to lower resolution historical sources such as Google Earth.

Additional to the primary use of the data for route alignment and gradient design, the imagery has been utilised in a number of outputs to benefit customer engagement such as fly-through animations and virtual site visits.

Childrey Warren Water Booster Station: New 4.5 Ml/d (53 l/s @ 50m delivery head) booster station comprising 2 (No.) variable speed centrifugal pumps operating in a duty/standby arrangement. Pumps are orientated horizontally to incorporate flywheels for surge suppression, located in a large walk-in kiosk, approximately 9m x 8m footprint located within the site boundary of Childrey WTW.

The kiosk will be subdivided to create a separate MCC and plant room; the latter incorporating an overhead gantry crane for plant installation and maintenance.

Other on-site works at Childrey include the WBS suction pipework connection from the new pipeline, WBS discharge pipework connection to the existing site pipework, flow meter and bypass arrangement and electrical/ICA connectivity back to the existing site MCC.

Lark Hill Reservoir: Works at Lark Hill Reservoir include the end connection of the new pipeline incorporating a flow meter and bypass arrangement, new control panel housed within a walk-in kiosk and upsizing of 2 (No.) existing reservoir flow meters and associated access chamber.

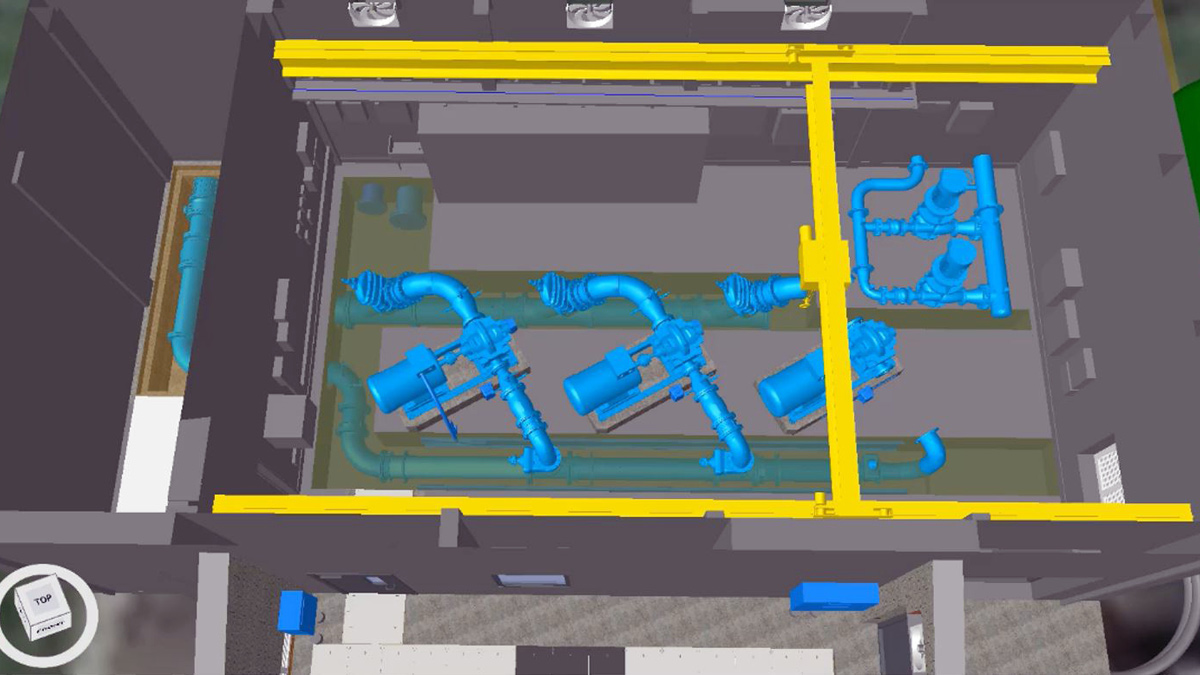

Hagbourne Hill WBS: Full upgrade and extension of existing WBS (duty/standby fixed speed pumps providing approximately 60 l/s) to provide a future capability of 15 Ml/d (170 l/s @ 85m delivery head) comprising 3 (No.) variable speed centrifugal pumps operating in a duty/assist/standby arrangement.

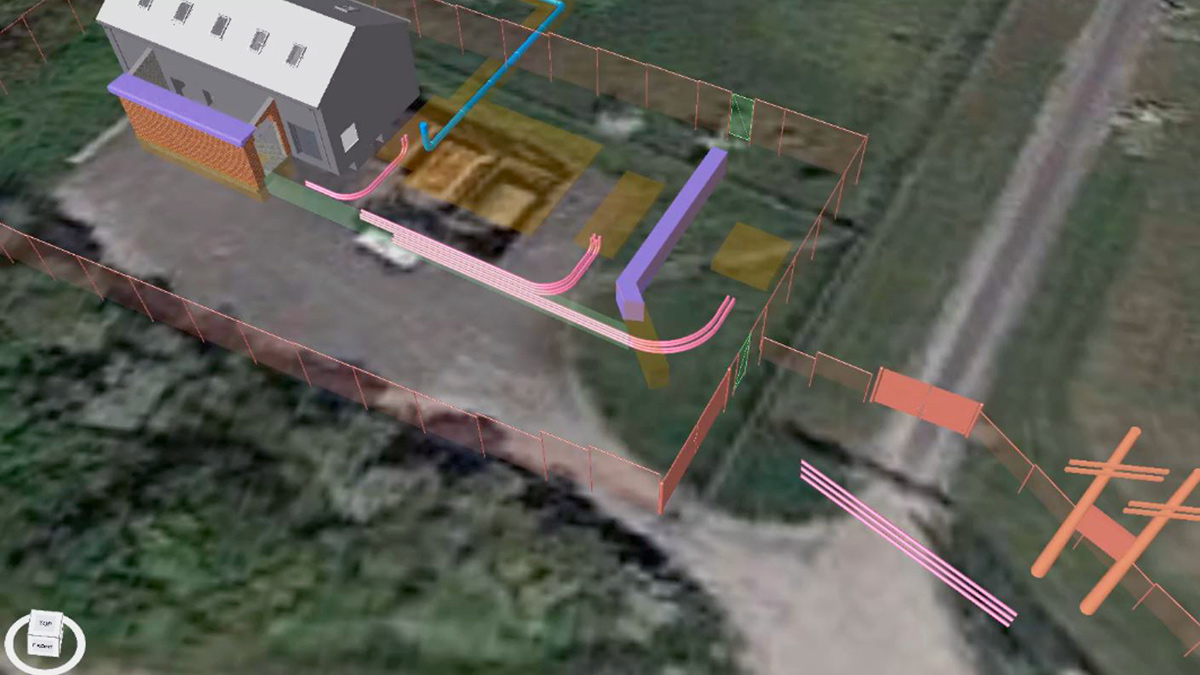

Hagbourne WBS 4D Synchro screenshot – Courtesy of SMB

The existing site will be completely remodelled with an extension to the existing building to create a dedicated MCC room, extension of the pipe manifold trench, motorised overhead gantry crane, new external plant comprising surge vessel, generator and fuel tank, fuel delivery area, extension of site hardstanding and creation of dedicated SSE compound for new HV transformer.

The remodelling of the WBS required detailed assessment to understand how it could be maintained as an operational site throughout the works. The initial proposal was to construct a separate temporary containerised booster station in adjacent land to facilitate taking the site offline. The extent of the existing site was 3D laser surveyed and a 3D BIM model built.

Further reviews and utilisation of Synchro 4D software enabled the design team to promote a more efficient solution.

Hagbourne WBS 4D Synchro screenshot – Courtesy of SMB

The existing pumps could be retained in a different temporary arrangement, providing sufficient room within the existing pump hall to complete the upgrade. Detailed sequencing was reviewed with all parties to ensure any clashes and constructability issues were fully understood before committing to the final design and construction drawings prepared. Collaborative use of the BIM model between Stantec, Bridges and the supply chain has been accommodated through the use of Autodesk 360 Glue.

The sequence of works will start with the removal of all existing redundant plant, construction of new external pipework connections and building extension, installation of new surge vessel (to facilitate removal of existing) and initial phase of civils works to facilitate the relocation of the existing pumps to their temporary arrangement.

With the main works area cleared the second phase of works can then begin, comprising the installation of overhead gantry crane, extension of pipe trenches, installation of new pipework manifold and pump sets and completion of all external civils and new plant installation. Following commissioning and trial period of the new pump sets the temporary arrangement will be removed and final site reinstatement works can be completed.

Hagbourne WBS existing layout – Courtesy of SMB

Summary

The Childrey Warren Abstraction Closure Scheme will deliver outputs from what TWUL term infrastructure and non-infrastructure delivery quadrants, packaged from the outset as a single scheme which is required to look at a wider zonal solution outcome.

With a regulatory date for delivery and a defined construction period to work within, it has been crucial to ensure the design is fit for purpose and construction sequencing fully understood to ensure right-first time on site.

Hagbourne WBS 4D Synchro screenshot – Courtesy of SMB

Communicating and working with numerous internal and external stakeholders has only been achievable by utilising digital transformation technologies.

The use of technologies such as drone and 3D laser surveying has provided the opportunity to work smarter and more efficiently in the optioneering and outline design phases, gathering huge amounts of data in short periods of time. Subsequent use of shared BIM models and 4D sequencing has fostered collaborate working between a widespread team to complete the detailed design with full confidence in the deliverables. This has ensured the correct long-term solution for TWUL and their customers is taken forward for delivery.