Morecambe WwTW Catchment Strategy: Part 3 (2020)

Morecambe WwTW: August 2019 - Nereda® Reactors 1, 2 & 3 - Courtesy of United Utilities

Operated by United Utilities, the Morecambe sewerage system collects at Schola Green Wastewater Pumping Station (WwPS) located in the west end of the town. From there, flows for treatment are pumped via a 6km long pipeline to Morecambe Wastewater Treatment Works (WwTW), which is situated to the south, near to the village of Middleton. Both sites have sea outfall pipelines which discharge effluent into Morecambe Bay. The Schola Green outfall is a storm overflow (which operates intermittently when the system is overloaded) and the Middleton outfall discharges treated effluent from the WwTW.

Project needs

The primary driver for the project was to limit spills at Schola Green PS to no more than two per bathing season (15 May-30 September) and ten per annum. The construction work activities (which included the construction of a new Nereda® plant at Morecambe WwTW) associated with that driver are covered in a previous article published in the UK Water Projects 2019 edition. Part of this present article covers the commissioning and optimisation phase of these new assets.

Furthermore, at low tide the four diffusers at the end of the Morecambe WwTW outfall pipeline were not submerged and therefore the Environment Agency (EA) had also required a solution to ensure effective dilution of the final effluent by March 2020. This required the introduction of a tidal pumping system at the treatment works: final effluent tidal storage and tidal pumping station to discharge treated effluent at sea, only when the outfall diffusers are fully submerged at high tide.

Additionally, as a secondary objective, the existing wastewater treatment process at Morecambe WwTW was outdated and needed to be upgraded. The population is predicted to grow and Morecambe WwTW needed to be capable of meeting its regulatory discharge requirements for the increased flows and loads up to a 2036 design horizon.

Both the regulatory outputs associated with the project have been successfully delivered by their regulatory dates.

Morecambe WwTW – August 2019: (left) elevated inlet works and (right) inlet screens – Courtesy of United Utilities

Morecambe WwTW upgrade scope

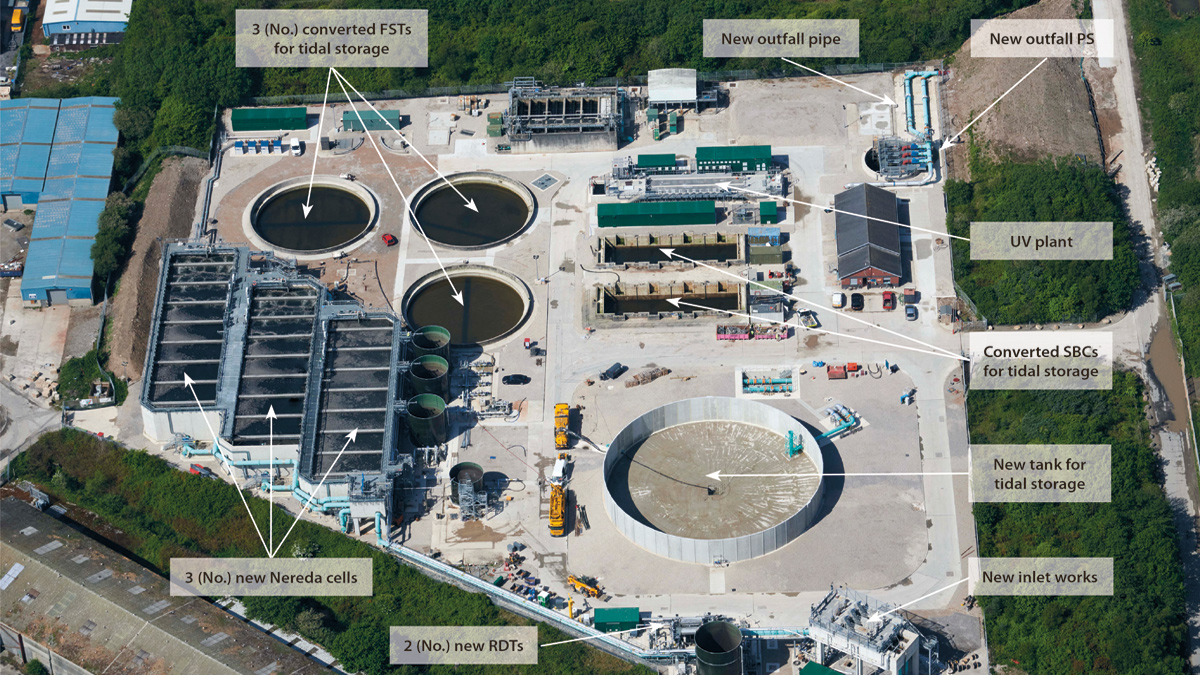

The upgrade solution (FTFT increased from 350 l/s to 580 l/s) at Morecambe WwTW includes:

- New elevated inlet works: 3 (No.) 6mm mechanical screens.

- New Nereda® plant: 3 (No.) 4000m3 reactors.

- New UV plant.

- New outfall pumping station: 1000 l/s output.

- New outfall pipeline: inshore section).

- Upgrade of the existing outfall pipeline: offshore section.

- New tidal storage system: approx 10,000m3.

- New sludge thickening system: 2 (No.) rotary drum thickeners.

Morecambe WwTW: Scope of work overview – Courtesy of United Utilities

Nereda® commissioning and optimisation during existing process treatment

Morecambe WwTW existing process treatment was not performing effectively for several years, especially in relation to the suspended solids and BOD content. This reduced treatment capacity was due to ageing assets and problems with the existing biological process of rotating biological contactors (RBC). Due to this, the start-up of the Nereda® process was accelerated as much as possible.

To enable the commissioning of the Nereda® reactors earlier than scheduled, temporary 600mm pipework and air compressor pipework from the blowers to each reactor was installed to allow the reactors to start treatment, prior to the permanent infrastructure being in place. All the inlet flows up to 350 l/s were then passed through the new inlet and onto the Nereda® process in April 2019 with the reactors beginning their treatment on a startup ‘recipe’ designed by the technology provider Royal HaskoningDHV.

Morecambe WwTW: Site Layout – Courtesy of United Utilities

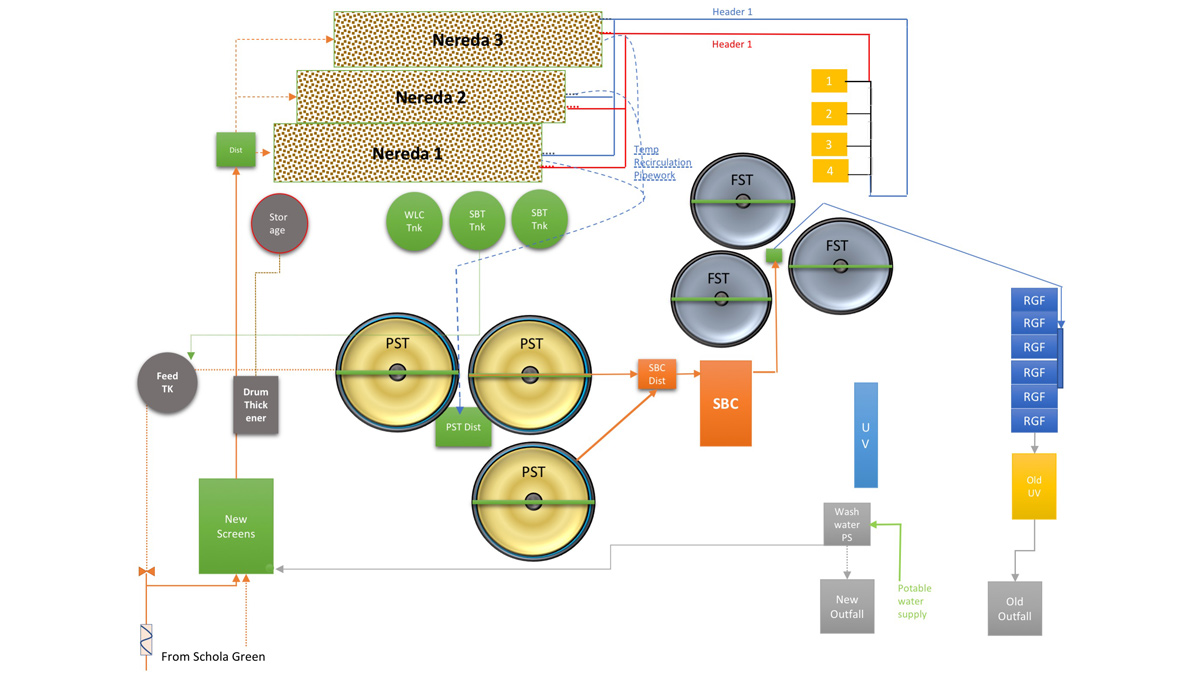

The flows from the Nereda® process were then redirected through the existing process stream of primary settlement tanks (PST), RBC’s and humus tanks, ensuring that whilst the Nereda® process was maturing and biological treatment was increasing that the existing treatment streams were also being offered a certain amount of biological load. Once the Nereda® treatment reached the current site permit and the completed site infrastructure was in place, the flows were then directed only through the new process stream allowing the old process stream to be gradually de-commissioned and re-purposed as tidal storage.

The biological treatment process very quickly improved the effluent quality and by July 2019 the process was receiving the required inlet flows of 580 l/s and the additional recirculated flows from the site surface water, RDT filtrate and rapid gravity filters (RGF) backwash of up to 710 l/s.

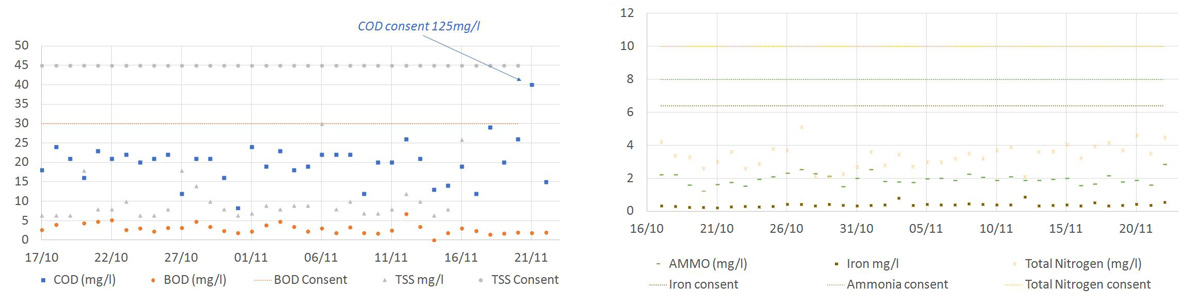

From July 2019 to the present date the process has continued to be optimised for all seasonal changes whilst granulation has improved and adapted to the changing inlet loading rates. Performance testing was carried out in October and November 2019 and the process passed on all testing requirements, including against the additional ammonia (8 mg/l) and total nitrate (10m g/l) permits due to be enforced in March 2020.

The process has continued to improve and has met all permitted effluent levels in the time since March 2020 with no exceptions.

Nereda effluent performance versus Morecambe WwTW permit levels: (left) BOD, COD and TSS and (right) ammonia, total nitrogen and iron – Courtesy of United Utilities

Tidal storage solution

The proposed solution involved providing a nominal 9,187m3 of tidal storage on site at Morecambe WwTW. The tidal storage would be used during low tide events with automated control switching between discharge and storage based on a time window system once annual tide cycles are input into the software. The outfall discharge system comprised the following elements:

- New final effluent pumping station at Morecambe WwTW, which pumps to outfall when both predicted astronomical tide level is above -1.7m AOD and final effluent storage volume is available at the WwTW.

- Modifications to the diffuser arrangement to raise the level of the outlets above current bed level and mitigate the risk of blockages from sediment movements. These works had already been carried out during 2018.

- Final effluent storage at the WwTW when not pumping to outfall. Storage volume determined to limit pumping to the receiving water body when the tide level is below the highest point of the diffuser orifice, set at -1.7m AOD, to less than 5% of the year.

The level of the outfall diffuser ports is above both mean low water springs (MLWS) and mean low water neaps (MLWN). However the level of the ports was selected to achieve the best balance against the following constraints:

- Maximise the time when the ports are submerged, and the outfall pumps can operate.

- Minimise the period where the effluent is pumped to storage on site at the WwTW.

- Optimise the volume of tidal storage.

- Mitigate the risk of the outfall port discharge being compromised by changing sea bed levels in Morecambe Bay.

Morecambe WwTW: February 2019 – New tidal tank in construction – Courtesy of United Utilities

The discharge period when the final effluent pumps can pump to outfall was defined from predicted astronomical tides. The effect of meteorological conditions which result in actual tide levels being above or below predicted levels was not accounted for, due to the difficulty in determining actual sea levels with sufficient accuracy.

The control philosophy for the discharge of final effluent to the receiving water was set as follows:

- When predicted tide level at the diffusers is above -1.7m AOD (highest point of the diffuser orifice) the final effluent pumps pump all flows received at the works, plus flows required to drain down any stored final effluent in the tidal tanks, to the receiving water.

- When the predicted tide is below -1.7m AOD all flows at the site are directed to tidal storage until the tidal storage tanks are full.

- If the tidal storage volume of 9,187m3 is fully utilised prior to the predicted tide level at the diffuser ports rising to -1.7m AOD, the final effluent pumps are activated to discharge to the receiving waters.

The number of pumped discharges to the receiving water when the tidal storage tanks are filled but before the predicted tide level rises to -1.7m AOD will depend on rainfall in the catchment and will vary annually.

Advanced design and constructability reviews identified that the optimum solution could make use of the now redundant two 25m long by 8m wide submerged biological contactor (SBC) tanks and three 22m diameter FSTs as tidal tanks providing approximately 3,500m3 of storage volume. Additional benefit also being gained with the new outfall pumping station TWL being higher that the hydraulic fill levels within the existing five tanks, thus allowing a gravity fill and empty mechanism.

Morecambe WwTW: October 2019 – Removal of an old SBC cartridge to allow the conversion of the SBC structure into a tidal storage tank – Courtesy of United Utilities

It was initially intended that the balance of the storage volume would then be provided through conversion of the three existing 22m diameter PSTs, which had also been made redundant following commissioning of the new Nereda® process. However significant modification works would have been required to raise the walls on these tanks in order to achieve the required storage volume. The project team therefore reviewed the options and concluded that a more optimal solution would be to construct a single new storage tank. This element of the storage would be pumped for the fill stage, pumps activated on reaching TWL in the outfall pumping station or SBCs, and then gravity empty though common pipework connected to proposed five gravity tanks.

Further constructability reviews identified the optimum solution for a new storage tank to be a post tensioned precast concrete tank with in situ base slab providing the shortfall of 6,500m3 of storage.

The existing elevated PSTs were decommissioned and demolished to existing road level, with all materials passed through an on-site screen for recovery and re-use in a reinforced 1100mm thick mattress to eliminate differential settlement post construction and filling of the new pumped tidal tank. The construction of the in situ base slab, design, manufacture and installation of the 200mm thick, 6m high walls and post tensioning of the panels were completed by Shay Murtagh Precast.

Morecambe WwTW: January 2020 – Conversion of an FST to tidal storage – Courtesy of United Utilities

Conversion of the existing FSTs and SBCs required full decommissioning and removal of the existing process fluids and sludges. The existing process fluids provided mass against the risk of flotation so the methodology for removal required a staged approach to negate this risk both in a temporary and permanent state. As such 300m3 of underwater concrete was placed into each of the five tanks. All process fluids were then analysed and pH corrected before removal off site. An additional 400m3 of reinforced concrete was then poured to the new levels to ensure gravity draining of all tanks and permanent anti flotation in the empty condition.

All interconnecting pipework (with diameters ranging between 400mm and 800mm) between the gravity tanks/pumped tank to the outfall pumping station, valve slabs and valve chambers was installed by C2V+. The above ground pipework was completed by Mectec Engineering Ltd, electrical installation was undertaken by Eric Wright Water Ltd and the system was commissioned by C2V+ and Tata Consultancy Services.

Morecambe WwTW: July 2019 – Outfall pumping station construction – Courtesy of United Utilities

Morecambe WwTW Catchment Strategy: Supply chain – key participants

- Main construction contractor: C2V+

- Geotechnical investigation: Geotechnics Ltd

- Nereda® process design and consultancy: Royal Haskoning DHV

- General MEICA Installation: Eric Wright Water

- Access steelwork: VolkerBrooks

- Tank base, walls & post tensioning: Shay Murtagh Precast

- Inlet screens and compactors: Huber Technology

- Penstocks and stoplogs: Glenfield Invicta

- General process valves: AVK

- Tideflex valves: MeasurIT Technologies

- Rotary drum thickeners: Andritz

- Polyelectrolyte storage and dosing: NPS

- Nereda® internals: Suprafilt

- Aeration blowers: Aerzen Machines

- Pneumatic compressors: Cooper Freer

- Pneumatic Valve: Islands Metalwork

- Inter-process above-ground pipework: Powerrun

- Above ground pipework: Mectec Engineering Ltd

- UV disinfection system: Xylem Water Solutions – Wedeco

- Washwater booster system: Grundfos Pumps

- Outfall and transfer pumps: Sulzer Pumps

- Electromagnetic flowmeters: Siemens

- Transfer main non-return valves: MGA Controls

- Centrifugal and submersible pumps: Xylem Water Solutions – Flygt Pumps

- SAS thickened sludge, thickener feed and tanker loading progressive cavity pumps (Morecambe): SEEPEX UK Ltd

- Glass-coated steel tanks: Goodwin Tanks

- RDT buffer tank air mixing: Utile Engineering

- Thickened sludge tank mixing: Hidrostal

- Systems integration: Tata Consultancy Services

- MCCs: Lloyd Morris Electrical Ltd

- Transformers: ESE

- RMUs and HV switchgear: Schneider Electric

Morecambe WwTW: Sept 2019 – Outfall upgrade (beach section) – Courtesy of United Utilities

Morecambe WwTW general commissioning August 2019-Summer 2020

Following successful achievement of plant in use and turning of full flow to treatment through the new treatment process in July 2019, the next priority for the team was the decommissioning of the existing PSTs, SBC lanes and humus tanks for conversion to tidal storage. This involved the gradual disposal of the remaining contents through the new process plant without negatively affecting the performance of the maturing plant and to allow the placement of concrete for the conversion works with a chemical dosing and sampling regime to monitor and adjust the pH, solids and septicity levels through September and October.

Once the process was performing consistently below the permit level requirement the commissioning team worked with the site operations team to focus on optimising the collective performance of the various process units. This included optimisation of the pumping regime from the Schola Green WwPS, the prediction model in the Nereda® controller, the UV dosing regime to reduce power consumption and the sludge thickening plant and blower control to reduce power and chemical consumption.

A detailed training-needs analysis was undertaken to identify the various discipline requirements, especially as the Nereda® and dual channel UV channels were new asset types. This identified 27 modules to be created in line with the latest client requirements and delivered to 56 client staff as a combination of classroom and practical training. These were delivered over 6 weeks to suit staff scheduling and were received very positively. The operating team has integrated well into the commissioning team to help develop understanding of the new process and sampling requirements.

The commissioning team has provided 24/7 coverage to ensure any issues were responded to quickly with the configuration and testing of over 2500 signals to give visibility of plant alarms and trends remotely. A control penstock actuator failure on the UV system and a leak on one of the Nereda® aeration grids captured important lessons learnt, now included in the site specific instructions developed for the site.

The tidal storage system and increased discharge flow of up to 1000 l/s was brought into service in March 2020 with the priming and operating regime established to meet the required permit conditions and to suit the existing outfall rising main. The team is now finalising the handover documentation in anticipation of operational takeover in October 2020.

Morecambe WwTW: August 2019 – New UV plant – Courtesy of United Utilities

Project handover and closeout

At the time of writing (September 2020), the new assets at Morecambe WwTW are in the process of being handed over to United Utilities’ Wastewater Process Operations (local operations and central operations) with a final acceptance (project closure) of October 2021.

The project is a success and is on target to be closed out slightly below the initial budget.