Finham STW Activated Sludge Plant (2019)

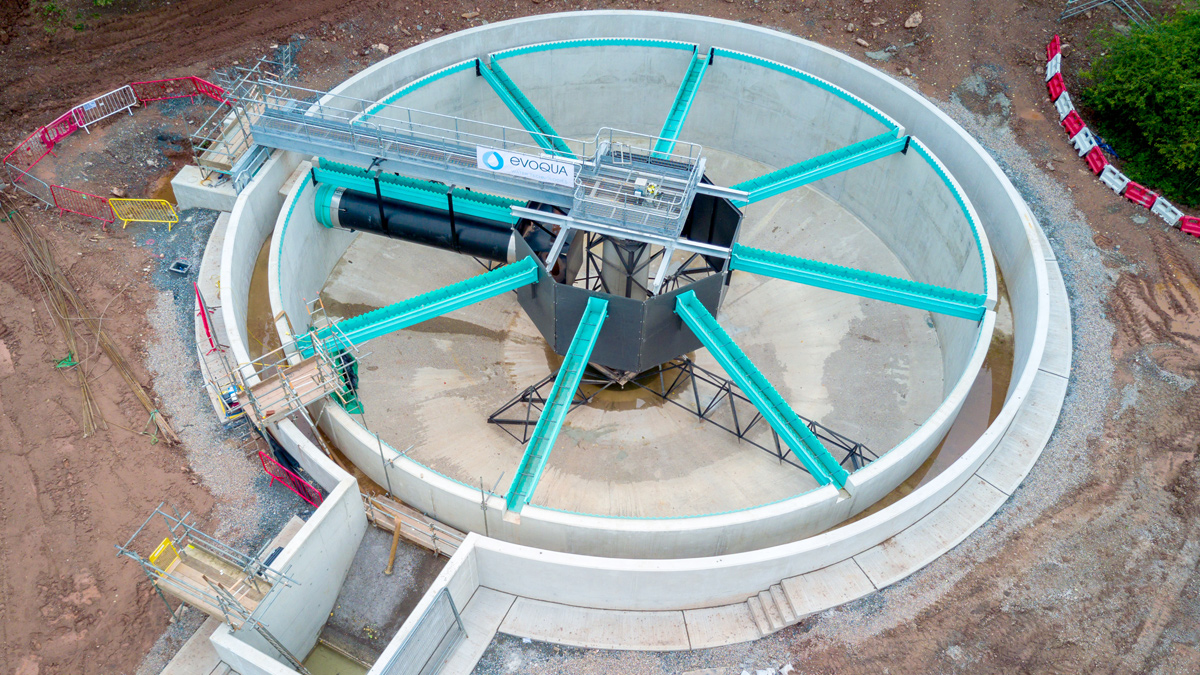

Tertiary treatment process (COMAG) - Courtesy of Costain

Finham Sewage Treatment Works (STW) serves a population equivalent of 430,470 for Coventry and its environs. The existing processes include preliminary treatment, primary settlement, a plug flow activated sludge plant (ASP) and final settlement tanks. The site is also a sludge reception centre and has the capability to treat indigenous and imported sludges. The sludge treatment facilities include thickening, mesophilic anaerobic digestion (MAD) dewatering and cake storage for export. In AMP6, Severn Trent are delivering a major capital investment project at Finham to upgrade the existing desludging and thickening facilities, increase resilience against increasing load by upgrading the ASP and providing a new tertiary treatment process. The project drivers are a tightening total phosphorous (TP) consent, growth and capital maintenance.

Site permit and undertakings

The site permit is currently 15 (BOD), 20 (SS), 3 (ammonia), 1 (TP) and 4 (FE) and will tighten to 0.22 mg/l TP at the end of AMP6. The expected growth in the catchment is 14% by the design horizon of 2028.

The capital investment project is being delivered by CiM6, a partnership between Costain and Stantec UK who are one of Severn Trent’s design and build partners. The scheme is part of the ASP Batch; a programme of work to refurbish and upgrade ASP works being delivered for Severn Trent by MMB, nmcn PLC and CiM6.

The solution

To meet the project outcomes the existing primary sludge extraction and thickening, and ASP are to be upgraded and a new tertiary treatment process added. In addition to the upgrade, capital maintenance improvements are required. The project scope comprises:

- Refurbishing the existing de-sludging system by providing new ram pumps and additional screening to the existing north and south PSTs.

- Provision of additional thickening capacity for the site co-settled sludge and imports.

- Replacement and upgrade of the existing ASP including diffusers, air blowers, air bus-main and control software.

- Installation of IFAS media in the existing ASP to provide additional treatment capacity.

- Provision of new tertiary treatment process based on ballasted coagulation (CoMag).

- A ferrous chloride storage and dosing facility for iron dosing in the ASP, replacing the existing life-expired Copperas based equipment.

- Provision of iron and polymer dosing systems associated with the tertiary treatment plant.

- Modification of an existing pumping station to feed the new tertiary treatment process.

- Upgrade of the site HV and SCADA networks.

- Improvements to site hydraulics.

- Improvements to the existing storm tanks.

At the time of writing this paper (May 2019), the project was under construction and installation with handover scheduled for Autumn 2019.

IFAS cage installation – Courtesy of Costain

Delivering solutions maximising use of existing assets

The ethos of the combined CiM6 and Severn Trent team in delivering the project was to engineer solutions that maximised reuse of existing assets and delivered cost effective solutions demonstrating lowest TOTEX.

This principle was applied from the start of the project, where the single solution identified was based on maximising reuse of existing assets within the existing plant footprint. At the start of outline design, working in close collaboration with Severn Trent, CiM6 process engineers obtained historical information from Severn Trent to inform decisions on selection of the optimum process technology for secondary and tertiary treatment. The decision-making process was supported by a collaborative review of available process technologies. This was augmented by the sharing of worldwide technical expertise by Stantec and case studies from supply chain partners.

Performance data from existing sites using technologies being considered were reviewed with stakeholders including Severn Trent expert panels such as the Secondary Treatment Community of Practice (CoP) and Tertiary CoP. This demonstrated robustness of the processes, assured process performance and obtained process approval.

After extensive consultation with Severn Trent stakeholders, the technology partners selected were Eliquo Hydrok Ltd for IFAS, and Evoqua Water Technologies (EWT) for tertiary treatment; EWT supplied the CoMag process.

Tertiary treatment process (CoMag) – Courtesy of Costain

The combined Severn Trent, CiM6, Eliquo Hydrok Ltd and EWT team were faced with integrating the processes within the existing assets accommodating many site constraints. These included maintaining process performance throughout each phase of the project from design through to installation and commissioning and ensuring existing structures could be modified to suit the required process constraints.

CiM6 worked closely with the technology partners and Severn Trent to engineer a solution that maximised the use of the existing assets whilst delivering the project outcomes. The Eliquo Hydrok Ltd IFAS at Finham has been retrofitted within the existing ASP reactors with minimal changes to the existing tanks and practically no additional head losses that could potentially affect the process hydraulics. This feature enabled the solution to be integrated within the existing reactors with no structural changes.

New aeration grids – Courtesy of Costain

The upgrade of the existing ASP aeration system included the blowers being replaced on their existing footprint, additional air infrastructure capacity, the existing FBDA diffusers being replaced by high efficiency tubular units and an upgrade of the control software. This required extensive integration with existing assets and careful planning to maintain the ASP operational throughout installation. This challenge was resolved by adopting a phased approach which included development of detailed transitional plans to move from the existing configuration to new.

The approach of maximising use of existing assets continued into the ASP where the diffusers were replaced, but the existing air bus-main was retained and supplemented by an additional ‘piggy-back’ main. In addition, two of the newer existing blowers were retained to provide a robust process with increased redundancy.

CoMag clarifiers – Courtesy of Costain

The ethos of adopting existing assets was continued and maximised in the new tertiary treatment plant. The new CoMag process by EWT has been accommodated within existing sand filters and adjacent redundant humus tanks. The team engineered a solution that enabled conversion of the existing sand filter structures to flocculation tanks and use the humus tanks as a back-shutter for the new clarifiers. By reusing these existing assets, significant savings in terms construction programme and capital expenditure were achieved.

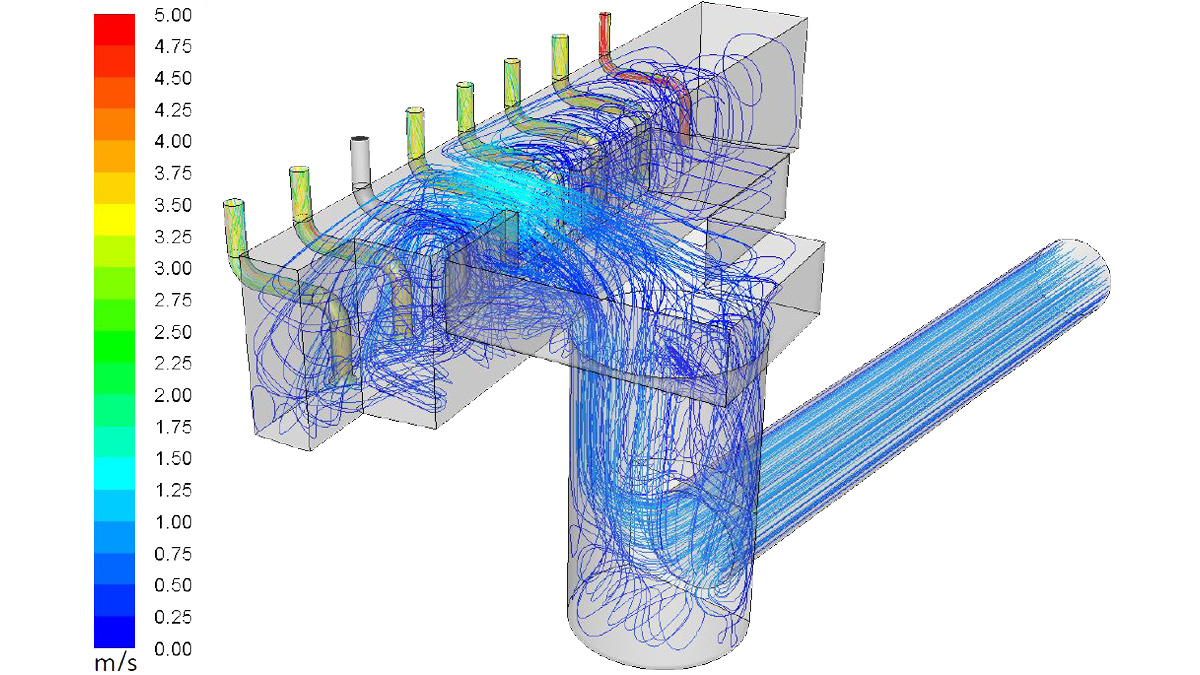

Another example of reuse of existing structures in the tertiary treatment area is the existing sand filter feed pumping station wet-well which was remodelled and converted to the feed pumping station for the CoMag process. To enable reuse of the existing pumping station, two-stage modelling was undertaken by Hydrotec on behalf of CiM6. An initial computational fluid dynamics (CFD) model to identify high level issues was followed by a validation physical model to identify improvements required. The physical model was particularly beneficial because it identified vortexing at certain pump inlets and at the wet-well inlet. This was resolved by baffling and flow presentation improvements.

CoMag clarifier – Courtesy of Costain

CiM6’s understanding of the engineering challenges associated with large pumping stations combined with Hydrotec’s expertise in CFD and physical modelling enabled pin-pointing of potential problems and resulted in delivery of an optimised solution to Severn Trent.

The existing dry-well has also been reused in the scheme. Redundant plant has been stripped out to provide room for the 8 (No.) new 65kW feed pumps and the twin 1000mm rising main to the flocculation reactors. The new motor control centre (MCC) for the feed pumps and ancillary plant has been located in the position of an existing part-redundant MCC, again requiring significant planning and phasing.

Another area where reuse of existing assets was promoted to deliver the project outcomes was the sludge stream improvements. In this area CiM6 working closely with Severn Trent developed a solution that meets the project outcome whilst using the existing thickening building which maximises the existing space/site footprint and the capacity of the existing assets. Here, space for a new drum thickener was provided by stripping out existing redundant plant. This enabled the drum thickener to be supported locally through a minor upgrade of the existing polymer dosing system.

Finham STW: Supply chain – key psrticipants

- Project delivery: CiM6

- CFP & physical modelling: Hydrotec

- IFAS & diffusers: Eliquo Hydrok Ltd

- CoMag: Evoqua Water Technologies

- Chemical Dosing: Colloide Engineering Systems

- Safety showers & eyebaths: Aqua Safety Showers International Ltd

- Pipelines: FSD Ltd

- TSR civils: STAM Construction Ltd

- Blowers: Sulzer

- Sludge cake silos: Stortec Engineering Ltd

Sand filters converted to CoMag reaction tanks – Courtesy of Costain

Other areas of work

The CiM6 scope included upgrading the site HV network and transformers to increase the site resilience and meet Severn Trent updated specifications. This work involved extensive site excavation to install the new HV cables and liaison with STW Operations to ensure the site could operate normally during the new HV cable installation and termination.

Electrical and control detailed design included identifying the optimum solution of the site MCCs to serve the refurbished ASP and new tertiary process. This included development of system architecture, SCADA and communication interfaces. The new systems had to integrate with the existing systems to maintain continuity during transition and to ensure interfaces were compatible. This work has been completed with no impact to the site’s process capacity.

TSR Feed PS CFD modelling – Courtesy of Hydrotec

A full hydraulic assessment to identify root causes of on-going flow restriction issues was undertaken to identify solutions that could be integrated within existing constraints, but also remain buildable. CiM6 engineers developed alterations and methodologies that enabled the hydraulic restrictions to be overcome with minimal impact to process capacity during the construction phase.

Another significant area requiring integration with existing Severn Trent assets was development of 3D models and 3D visualisation. These were used to assist CiM6 to facilitate access, lifting and maintenance (ALM) studies for the new plant showing the context and interaction of the existing with new to support mitigation of hazards during operation and maintenance. The models were also used to demonstrate the interface/scale between new and existing facilities during consultations with external stakeholders including local residents.

Summary

Severn Trent, CiM6 and key suppliers of innovative treatment processes have delivered a project from outline through to detail design, procurement, construction and commissioning. This has enabled delivery of an affordable solution that maximises reuse of existing assets and adopts the use of new technologies to meet stringent quality standards.