Aarsleff Ground Engineering Ltd

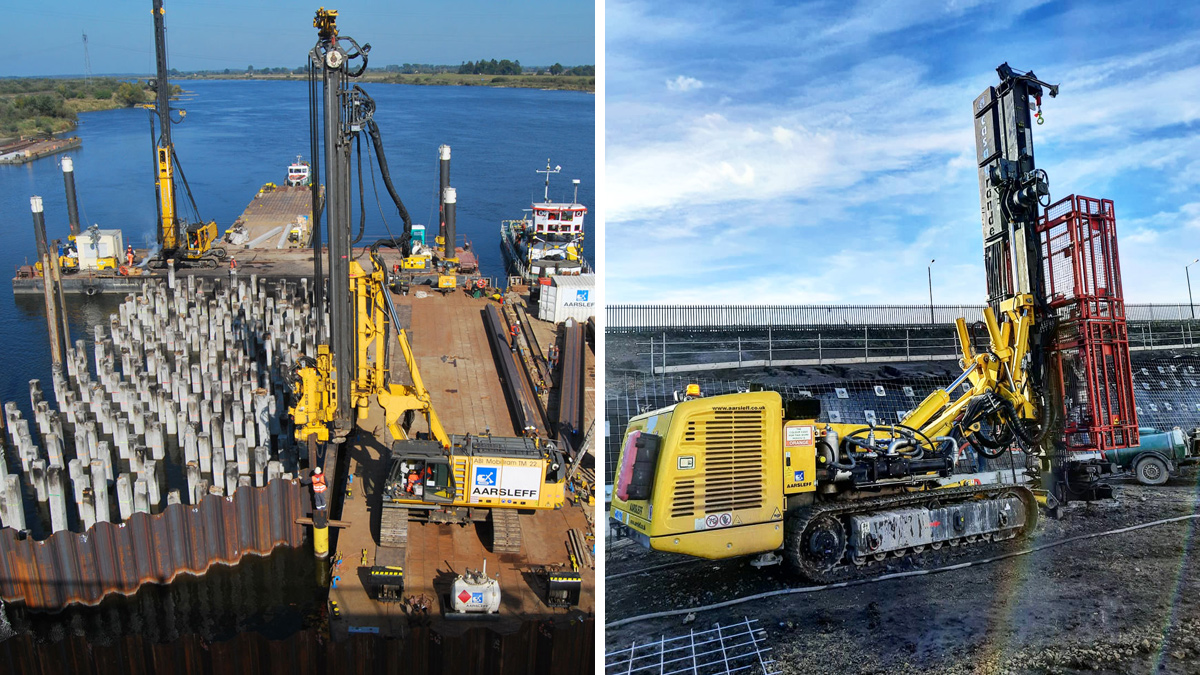

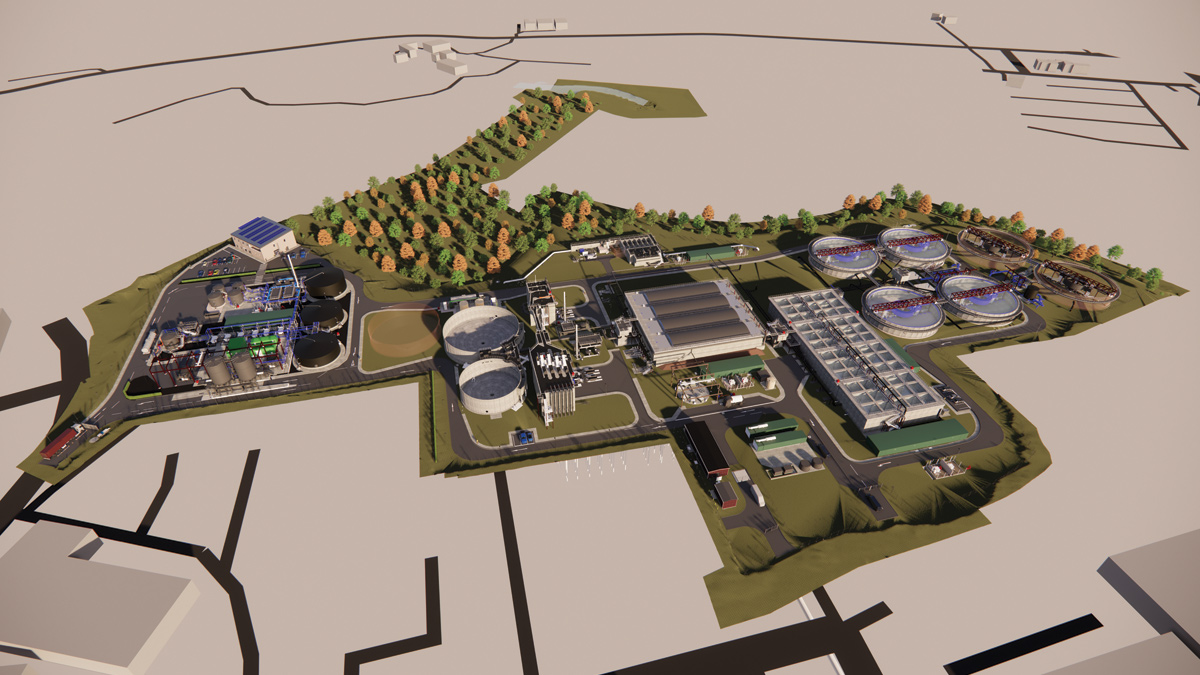

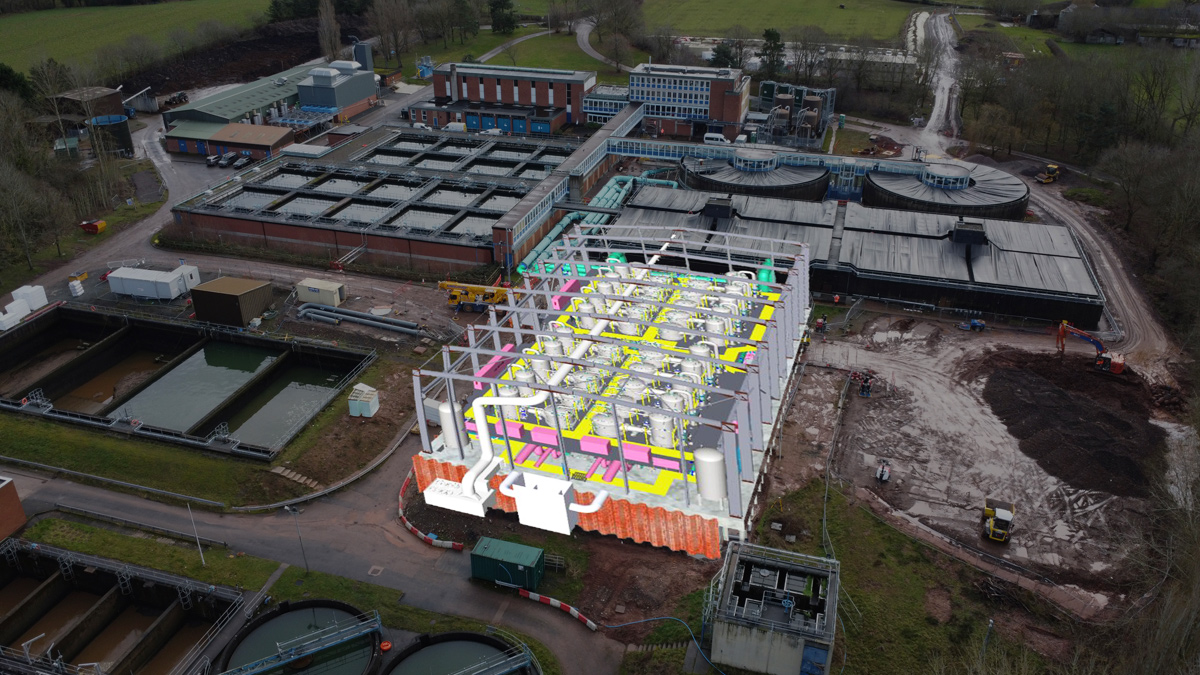

In addition to driven and drilled pile foundations, they design and install specialist retaining walls such as sheet pile walls, contiguous pile walls and secant pile walls, as well as driven and drilled king post walls. Their expertise also comprises soil nail, anchoring, drilling and grouting work, augured piles, and restricted access piling – all adapted and value-engineered to the needs of the individual client and sector. Operating across the Energy, Marine, Residential, Infrastructure and Commercial construction markets, Aarsleff’s diverse portfolio has enabled their customers to enjoy several benefits, combined with cost-saving programmes.

Together with sister company Centrum Pile Ltd, their onsite manufacturing facilities are state-of-the-art, utilising the most advanced robot technology to build strong, and robust reinforced precast concrete piles.

Aarsleff’s in-house Design teams work at a high, international level enabling the company to develop new and alternative solutions in connection with the design of foundation and ground engineering projects.