PBJ Engineering Services Ltd

Strongford STW

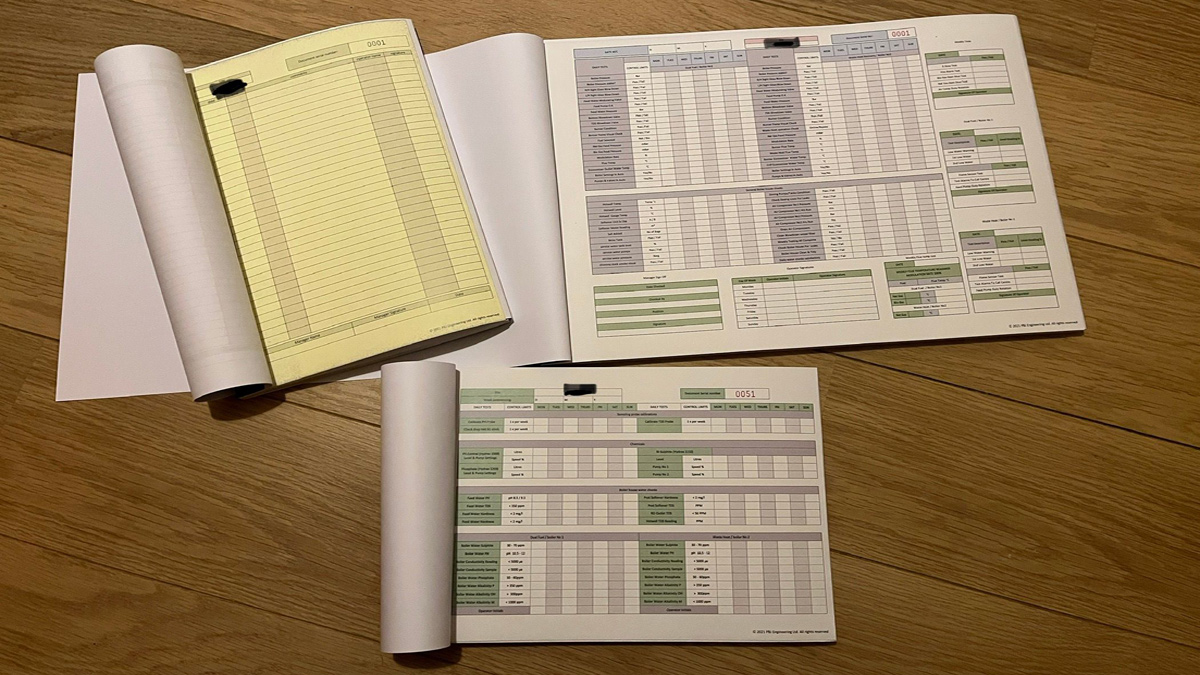

(left) PBJ Engineering's testing kit and (right) boiler training - Courtesy of PBJ Engineering

Severn Trent’s Strongford Sewage Treatment Works recently completed a major upgrade to improve wastewater processing for a population of around 350,000 people across Newcastle-under-Lyme and Stoke-on-Trent. A key part of the upgrade project was introducing Thermal Hydrolysis Process (THP) technology, a method that treats sludge (the solid byproduct of wastewater) so it is safer and more efficient to process. THP helps break down the sludge, making it easier to produce biogas — a renewable energy source — and improving the plant’s overall efficiency.

PBJ Engineering’s role

PBJ Engineering’s team was on the ground at Strongford every day for around 18 months, running the steam boilers and training Severn Trent’s staff until they were ready to earn their Boiler Operations Accreditation Scheme (BOAS) certification.

Our job didn’t stop there, though. During this period and beyond, we supplied boiler testing kits, managed stock resupplies, maintained detailed logbooks, and offered ongoing support, including coverage during management leave. We also provided and installed a hired reverse osmosis (RO) unit, currently still in operation on site. This unit improves boiler performance by reducing total dissolved solids (TDS), which lowers the frequency of boiler blowdowns and minimises operational issues. It was a proactive measure to help ensure smoother day-to-day operations while the client develops a permanent solution.

Challenges and solutions

Keeping everything running smoothly meant being prepared for any unplanned downtime. The PBJ team provided round-the-clock support and quick-response services whenever needed. We supplied specialised testing equipment and designed a comprehensive logbook to track and simplify daily maintenance — making sure nothing slipped through the cracks.

The reverse osmosis unit was also key to maintaining efficiency, preventing disruptions by improving boiler reliability and performance. This combination of technical expertise and ongoing support ensured that Strongford’s upgrades moved forward without a hitch.

Boiler area – Courtesy of PBJ Engineering

Value & impact

With our support, Strongford’s upgrades ran safely and efficiently, helping Severn Trent meet their environmental goals. By reducing downtime and boosting reliability, we contributed to a more sustainable treatment system that benefits the entire community.

In the bigger picture, the THP technology has transformed Strongford into a central sludge treatment hub, now capable of handling up to 94 tons of sludge per day and supporting nearby sites by taking on additional processing.

The upgrades also boost Severn Trent’s sustainability efforts: the plant now produces an extra 16.34 GWh of biogas per year, which improves energy self-sufficiency and reduces carbon emissions by 3,000 tons annually, alongside producing cleaner Class A sludge that’s safer for reuse or disposal.

One thing to note: while our THP Operator services were not required on this project, it is an option we can offer in the future. If that’s something you’re considering for your next project, get in touch to discuss your requirements.